The copyright of Zhuolong supervision is owned by the original author from Baidu Library

.

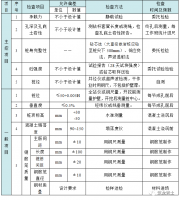

The main points of scaffold engineering supervision are as follows: 1

.

2

.

The supervision personnel shall focus on the inspection of the height of the scaffold, the connecting wall of the scaffold, the connection of each member, and the fixation of the cantilever member; the foundation and slope treatment of the floor type scaffold; and the anti falling and anti tilting devices

.

3

.

It is necessary to organize experts to demonstrate whether the installation and erection of scaffold is a special safety plan, and whether it is a divisional and subdivisional project with greater risk

.

4

.

Check whether the professional sub contractor of scaffold erection has the corresponding qualification and safety production license

.

5

.

Whether the special operation personnel who set up scaffolds work with certificates and should be person to person

.

6

.

Whether acceptance is organized after scaffold installation

.

Plan preparation and Review Article 57 of the regulations on the administration of production safety of construction projects

.

In violation of the provisions of these regulations, if the project supervision unit has one of the following behaviors, it shall be ordered to make corrections within a time limit; if it fails to make corrections within the time limit, it shall be ordered to suspend business for rectification and be fined not less than 100000 yuan but not more than 300000 yuan; if the circumstances are serious, its qualification level shall be reduced or even its qualification certificate shall be revoked; major safety hazards shall be caused If the accident constitutes a crime, the person who is directly responsible shall be investigated for criminal responsibility in accordance with the relevant provisions of the criminal law; if losses are caused, he shall be liable for compensation according to law: (1) failing to review the safety technical measures or special construction scheme in the construction organization design; (2) failing to require the construction unit to rectify or temporarily stop the construction in time when potential safety accidents are found; (3) the construction unit refuses to carry out the construction Failing to rectify or stop the construction, failing to report to the relevant competent department in time; (4) failing to carry out supervision in accordance with laws, regulations and compulsory standards for engineering construction

.

Through comparison, it can be seen that steel pipe scaffolds with different structural forms require special construction scheme to be prepared before scaffold construction

.

Plan first, then work

.

If the scheme compilers implement the general construction contract, the special construction scheme shall be organized and prepared by the general construction contractor

.

Among them, for the subcontracting of mechanical installation and disassembly engineering, deep foundation pit engineering, attached scaffold and other professional engineering, the special scheme can be organized and prepared by the professional contractor

.

Program audit points 1

.

Procedural audit (1) whether the approval procedures of the preparation unit are complete

.

① The general special construction scheme shall be prepared by the technical director of the project, reviewed by the project manager, approved by the person in charge of the technical department of the enterprise and stamped with the official seal of the technical department; ② the approval procedure shall meet the specification requirements

.

Whether it has been proved by experts

.

(2) the director shall organize professional supervision engineers to audit

.

2

.

According to the main contents of mandatory safety standards for engineering construction, check the conformity of (1) construction environment, construction characteristics, construction technology and management level, engineering characteristics, difficulty analysis, objective situation of engineering project, etc

.

with the actual engineering; (2) review of compilation basis and objectives: ① whether there are major differences in principle with the organization design of technical bid promised in the bid, including (quality, progress, quality, quality, quality, quality, quality, quality, quality, quality, quality, quality, quality, quality, quality, quality, quality, quality, quality, quality, quality, quality Economic and safety objectives, management system, personnel and organization guarantee system, etc.); ② the construction organization design objectives, including progress, quality, investment and safety objectives, must comply with the provisions of the contract; ③ whether the adopted specifications, procedures and relevant documents are effective; whether they meet the requirements of the design documents; whether the adopted geological reports are effective; and whether they are related to the safety of the project construction Whether the main contents of the full mandatory standards meet the requirements or not

.

4

.

The main contents of the construction organization design should be complete

.

3

.

Targeted audit of the goal setting (whether the personnel, machinery, materials, methods and environment can meet the project objectives)

.

1

.

Audit the project organization: the qualification of the unit and the qualification of the project management personnel (project manager, deputy manager, chief engineer and full-time quality inspector, etc.) Whether the qualification meets the requirements of the project category; whether the construction personnel engaged in special types of work have the corresponding work experience; 2

.

Whether the construction personnel engaged in special types of work have the certificate; 3

.

Whether the entry acceptance and inspection system of materials is perfect; 4

.

Whether the management measures for safe and civilized construction are complete; whether the installation and disassembly, operation, use and management meet the requirements of relevant specifications

.

Whether there are major hazard detection, assessment, monitoring measures and emergency plans for the safety evaluation and prevention measures of major hazard installations

.

The following points should also be paid attention to when reviewing the more dangerous engineering special scheme beyond a certain scale: 1

.

Whether the reviewer of the construction unit in the special safety scheme approval form is the technical director specified in the enterprise qualification certificate; 2

.

Whether the expert demonstration report, demonstration opinions, demonstration meeting minutes and meeting attendance form are signed by 5 or more experts meeting the relevant professional requirements; 3 Whether the construction unit modifies and improves the special scheme according to the demonstration report; whether the project leader of the construction unit signs; 4

.

Evaluation and prevention of major hazard installations; 5

.

Whether the safety management organization is responsible to the person; 6

.

Whether the quality assurance system and management system are responsible to the person; 7

.

Whether the emergency plan meets the requirements; 8

.

Whether the scaffold erection and demolition procedures have been demonstrated by experts Before erection, the construction unit should be urged to carry out safety technical disclosure to the scaffolders according to the special construction scheme of scaffold; 2

.

Material preparation

.

Check and accept the steel pipe, fastener, scaffold board, adjustable brace and safety net; 3

.

Prepare the erection site

.

Supervise and urge the construction unit to do a good job in the construction acceptance of the scaffold foundation and foundation according to the scaffold erection height, the soil condition of the erection site and the current “code for acceptance of construction quality of building foundation engineering”, so as to ensure that the foundation is solid and flat without ponding; 4

.

The scaffolder should hold an effective operation certificate for special operation personnel

.

Attention should be paid to (1) the construction scheme should be determined in advance, and the construction can only be carried out after examination and approval

.

The erection shall be carried out in strict accordance with the specified scheme

.

(2) The members shall be erected in strict accordance with the lapping sequence and process requirements

.

(3) In the process of erection, attention should be paid to the measures of temporary roof support or tie with buildings

.

(4) In the process of erection, measures should be taken to prevent non operators from entering the erection area

.

(5) fasteners should be fastened and the tightening degree should be appropriate

.

(6) During the erection, the deformed bars and unqualified fasteners shall be eliminated in time

.

(7) Erection workers should wear safety belts to ensure safety

.

(8) Correct the vertical and horizontal deviation of the bar at any time to control the deviation within the specified range

.

(9) In the process of erection, in case of temporary shutdown, temporary measures shall be taken to ensure the safety and stability of the shelf and prevent collapse

.

(10) If there are external overhead lines in the erection site, the safe distance between the scaffold and the external overhead lines shall meet the following requirements: 1

.

Before the demolition, the construction unit shall be urged to comprehensively check whether the fastener connection, wall connecting parts and support system of the scaffold are complete; 2

.

The construction unit shall be urged to supplement and improve the demolition sequence and measures in the special scheme of scaffold, which shall be implemented after approval; 3 The construction unit should be urged to disclose to the scaffolders; 4

.

The removal of single and double row scaffolds must be carried out layer by layer from top to bottom, and simultaneous operation is strictly prohibited; the wall connecting parts must be removed layer by layer along with the scaffold, and it is strictly forbidden to remove the whole or several layers of wall connecting parts before removing the scaffold; when the height difference is greater than two steps, the wall connecting parts should be added for reinforcement

.

It is strictly forbidden to throw the components to the ground during discharging

.

5

.

The installation and removal personnel of fastener type steel pipe scaffold must be qualified professional scaffolders

.

Scaffolders should work with certificates

.

6

.

When there is strong wind of force 6 or above, dense fog, rain or snow, the scaffold erection and demolition operation shall be stopped

.

Anti skid measures shall be taken for the operation on shelves after rain and snow, and snow shall be removed.

.