The new cantilever beam side fully embedded installation and erection device of this project is an efficient construction technology system in the prefabricated construction technology under the key technology field of housing and urban construction technology development

.

The amount of I-steel used in the new cantilever beam of this project is less than that of traditional products, which can cross the wall and extend into the indoor anchorage The length of the floor beam and the floor panel is reduced by more than 56% and a lot of steel is saved

.

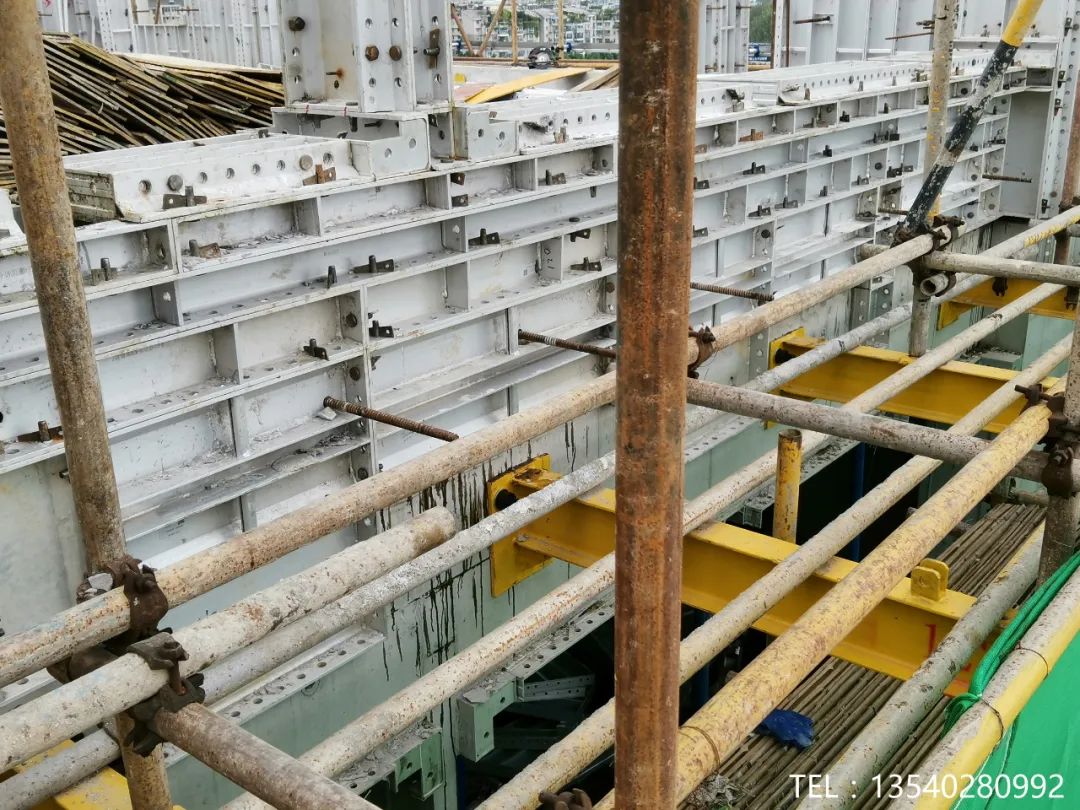

Therefore, when installing the new cantilever frame, the construction is simple and lightweight, and does not affect the construction of other processes

.

A variety of construction processes can be crossed, which effectively improves the construction efficiency and optimizes the construction process

.

No longer need to implement welding, cutting and other processes on site, effectively eliminating the fire hazards

.

This new installation method can effectively ensure the construction quality, eliminate the hidden danger of water leakage, and the reuse rate of components is 95%

.

For the construction site using aluminum formwork, because the beam of the new cantilever frame does not need to extend into the room, it is unnecessary to use wood formwork to effectively eliminate the phenomenon of formwork explosion

.

For the construction site using “prefabricated building”, the new cantilever frame can provide an effective solution to the pain points on the cantilever layer

.

This project is an industry university research cooperation project between Hunan Zhengwei Construction Technology Co., Ltd

.

and Central South University, which is supported by Hunan high-tech enterprises and Changsha key enterprises

.

The relevant technology has passed the intellectual property management system certification, and obtained 1 invention patent and 12 utility model patents

.

In recent years, with the increasing height of the building, the structure is becoming more and more complex

.

In order to meet the needs of the construction of the main structure and external wall decoration, the external wall scaffold needs to be set up

.

Among them, the fastener type steel pipe scaffold is widely used in the field of construction because of its better performance

.

In order to ensure the safety of steel pipe scaffold, table 3.2.1 of article 3.2.1 in gb51210-2016 stipulates that under the general condition of safety level II, the erection height of floor type steel pipe scaffold shall not exceed 40m, and the erection height of steel pipe scaffold with cantilever steel beam bearing frame at the bottom shall not exceed 20m, About every 18 meters, a cantilever steel beam bearing frame needs to be set up again

.

The bearing frame at the bottom of the cantilever double row steel pipe scaffold is the most popular indoor and outdoor anchorage of the traditional cantilever steel beam bearing frame, and the embedding of the upper fixed point of the cable is shown in the following figure: the traditional cantilever steel beam must pass through the external wall of the building, extend into the indoor and lay on the main structure floor, and then anchor on the floor panel and floor beam with three U-shaped embedded parts

.

If you are interested in the new technology, you can add the following two-dimensional code to obtain relevant information and data

.

The special wechat of Zhengwei technology business has the following disadvantages: (1) the layout of steel beams stretching into the room is complex, which hinders the cleaning of indoor construction waste and the walking of construction workers; (2) the steel beams passing through the wall are easy to damage the concrete beams and slab components, which is easy to cause building damage (3) before removing the steel beam, it may be necessary to cut the U-shaped anchor ring on site, and after the removal, it is also necessary to mend the hole and subsidize the brick, which increases the construction time

.

The fixed length extending into the room should not be less than 1.25 times of the outdoor cantilever section

.

Therefore, under normal circumstances, it is necessary to use steel beams of ≥ 3M and 4-5m at the corner

.

Disadvantages: (1) a large amount of steel is put in at one time, and the weight is large; (2) a 3-5M I-beam needs to rely on tower crane in the whole process of installation and removal, and there are many blind areas in the lifting process, which has a great potential safety hazard

.

When the steel beam runs through the stairwell, I don’t know how many workers have experienced a “slap in the head” accident here

.

When the fixing ring at the upper end of the cable is removed, it needs to be cut on site and cannot be recycled

.

The traditional cantilever steel beam demolition process has many disadvantages, sometimes it needs to be cut on site, which not only wastes materials, but also time and labor

.

After the traditional overhanging steel beam is removed, the wall holes need to be repaired, the wall bricks need to be repainted, and the external wall bricks need to be subsidized

.

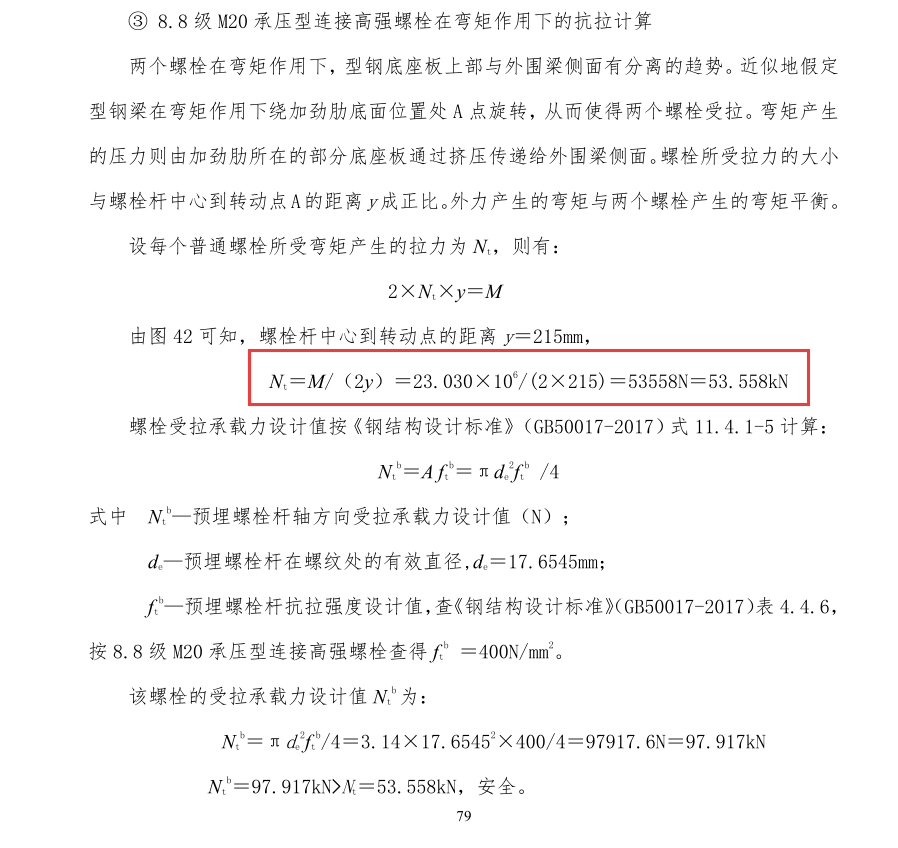

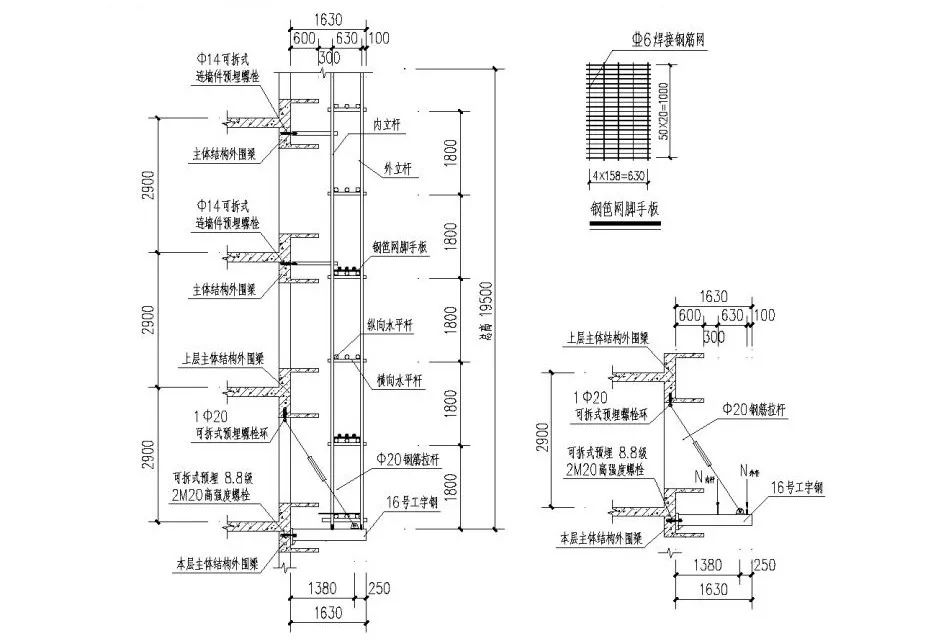

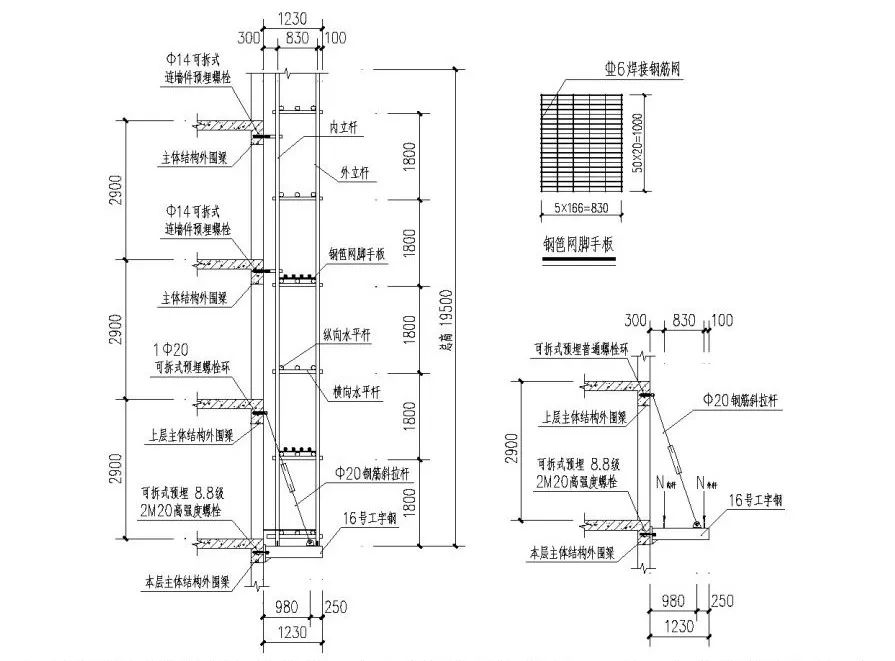

In view of the shortcomings of the traditional cantilever steel beam bearing frame, after five years of research and development, test and operation accumulation, the new cantilever beam side fully embedded installation and erection device with all technical indicators and safety performance up to the standard is shown in the figure below: there is no cantilever plate outside the beam, the distance between the inner and outer poles is 300 mm, and the distance between the inner and outer poles is 83 mm

.

The cantilever steel beam is 1.23m long (< 1.75m), and the "pull-up cantilever bearing frame" is adopted

.

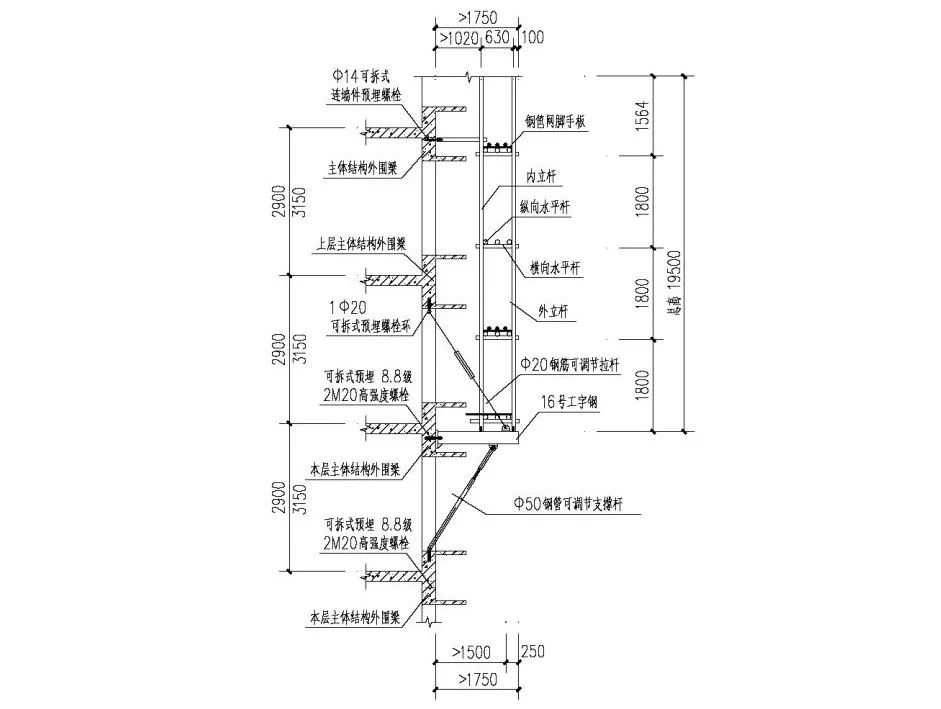

The outer side of the beam has 600mm convex window plate, the distance between the inner vertical pole and the outer wall is 900mm, and the distance between the inner and outer vertical poles is 630mm

.

The cantilever steel beam is 1.63M long (< 1.75m), and the "pull-up cantilever bearing frame" is adopted

.

The outer side of the beam has a convex window plate of > 600mm, the distance between the inner vertical pole and the outer wall is > 1020mm, and the distance between the inner and outer vertical poles is 630mm

.

When the cantilever steel beam is more than 1.75m, the “pull-up cantilever bearing frame + additional diagonal support rod” method is adopted

.

If you are interested in the new process, you can add the following two-dimensional code to obtain relevant information and data

.

Zhengwei science and Technology logo, wechat special for Zhengwei science and technology business, three new cantilever bearing frame component 1, cantilever beam 16 ᦇ ordinary I-beam as the main part, welding base plate, triangle reinforcing plate, U-shaped pull-up part and lower support part

.

The material is Q235

.

1) Straight line beam: it is installed on the cantilever beam with straight-line structure

.

The length is 1030, 1130, 1230, 1630 and other different models and specifications

.

For the model of straight beam used in each project, please refer to our company’s “cantilever beam layout plan” for each project

.

2) Diagonal beam and diagonal beam: the cantilever beam installed in the external corner of the building structure, the length code has “left 30, right 30”, “left 30, right 70” and other models and specifications

.

For the model of diagonal beam and diagonal beam used in each project, please refer to the “cantilever beam layout plan” of our company for each project

.

2、 The diagonal tie rod is composed of Φ 20, Q235 galvanized round steel tie rod (positive wire, reverse wire), closed adjustable blue and wire tooth protective sleeve

.

3、 The lower support rod is made of Ф 50 * 3.0 (Q235 material) seamless steel pipe as the main part and welded with Ф 34 * 5 (Q235 material) seamless pipe adjusting sleeve

.

Note: after the lower support rod is installed and adjusted to the stress state, the “adjusting sleeve” should be wrapped with adhesive tape in time to prevent the concrete from sticking on it

.

4、 Embedded system 1) embedded parts: there are two types: 180mm long ones are used for embedded in the connection between cantilever beam and building structure; 150mm short ones are used for embedded in the connection between upper tie rod and lower strut and building structure

.

Use 180mm long embedded parts (cantilever layer) and 150mm short embedded parts (upper layer of cantilever layer) and 150mm short embedded parts (lower layer of cantilever layer) to install screw: this process is equipped with special “temporary fixed screw”, which is used to ensure that the embedded parts will not deviate in the process of concrete pouring

.

After concrete pouring and before removing the side formwork, it is necessary to twist out the exiting turnover accessories

.

Note: (1) when installing the embedded parts, it is necessary to ensure that the contact surface between the embedded parts and the formwork is seamless and close, so as to prevent the concrete slurry from penetrating into the pipe of the embedded parts during the concrete pouring and tamping; (2) after the installation of the embedded parts, it is strictly forbidden for the vibrator to directly contact with the embedded parts during the concrete pouring and tamping, so as to ensure that the embedded parts are not damaged or offset

.

3) Components connected with embedded parts: double screw, double ear pull ring and single ear pull ring.

.