The maximum mass of each steel pipe shall not be more than 25.8kg

.

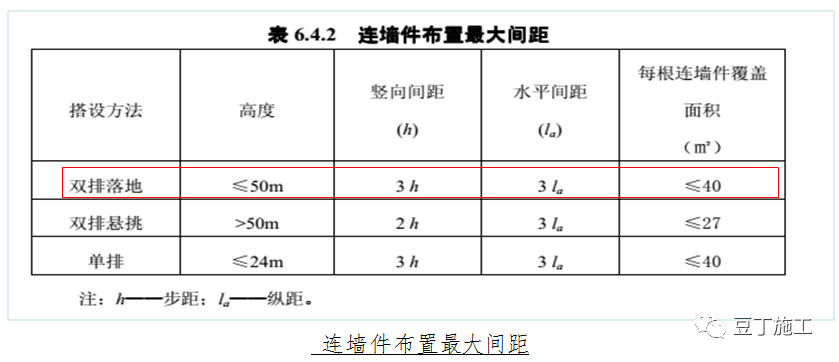

Technical code for safety of steel tubular scaffold with couplers in building construction (jgj130-2011)

.

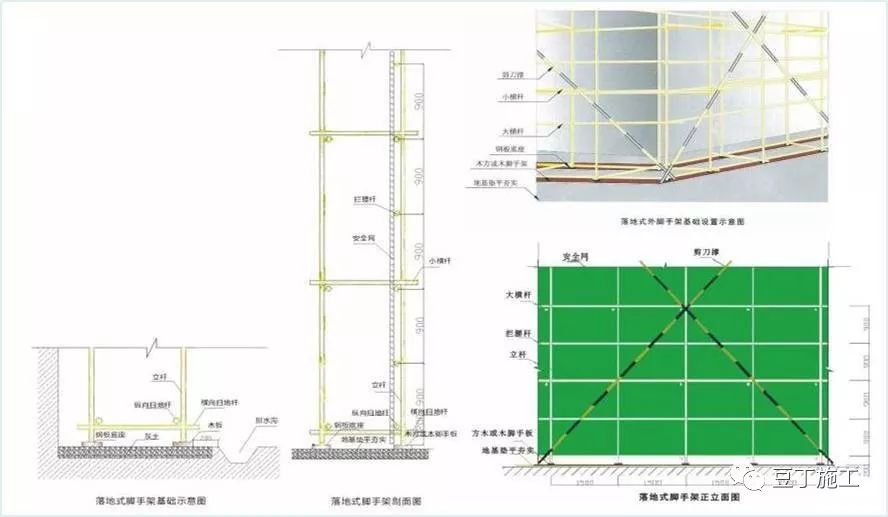

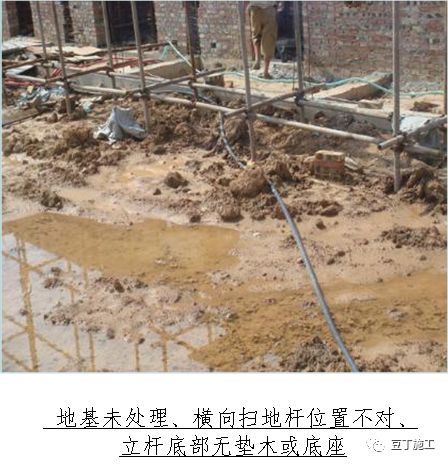

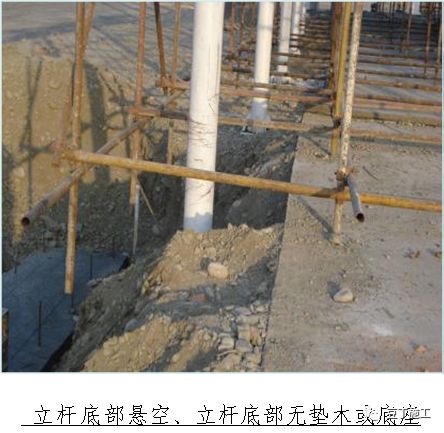

Pole (1) quality requirements: ① the pole foundation shall be leveled and compacted according to the scheme requirements, and drainage facilities shall be adopted

.

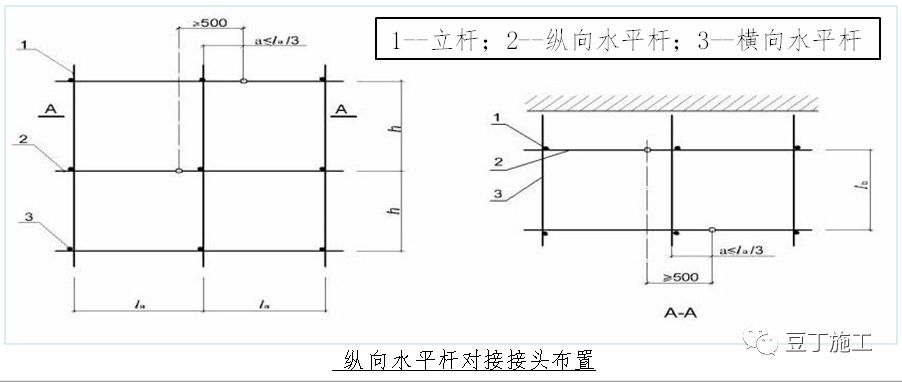

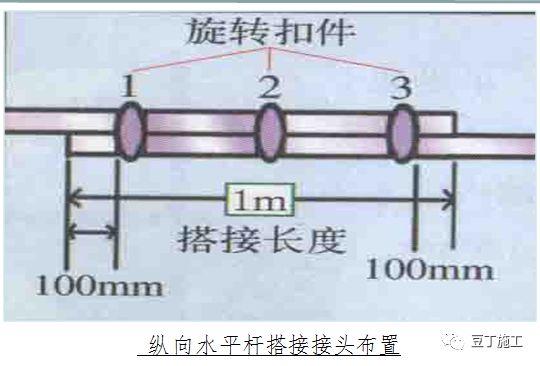

(2) The extension of longitudinal horizontal bar shall be connected or lapped by butt fastener, and shall meet the following requirements: ① the joint of two adjacent longitudinal horizontal bars shall not be set in the same span or in the same synchronization; the distance between two adjacent joints of different spans or in the horizontal direction shall not be less than 500mm; the distance between the center of each joint and the nearest main node shall not be greater than 1 / 3 of the longitudinal distance.

.

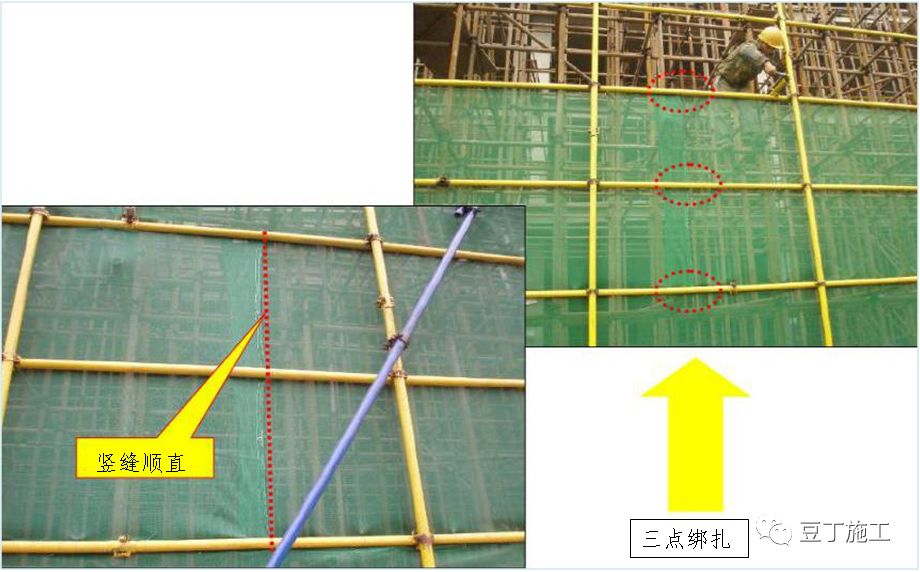

Safety sign number and product certificate shall be marked on the right side of each dense mesh

.

The length shall be specified by the terms agreed by both parties, but the minimum length shall not be less than 2m

.

Two galvanized steel wire hoops with a diameter of not less than 4 mm shall be set at both ends of the wooden scaffold board, and the distorted, split and decayed scaffold board shall not be used

.

(2) The surface of the steel pipe shall be straight and smooth without cracks, scabs, delamination, dislocation, hard bending, burr, indentation, serious corrosion and other defects

.

(2) Special construction scheme for safety of scaffold Engineering 1

.

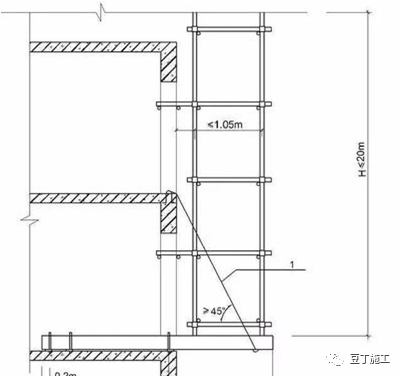

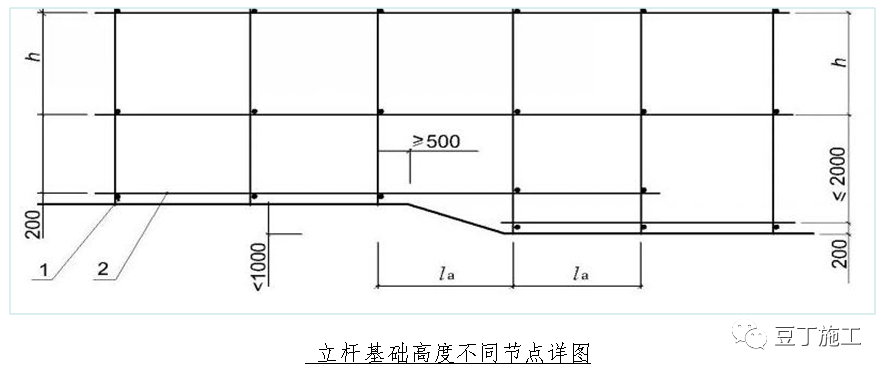

(2) when the scaffold vertical pole foundation is not at the same height, the vertical sweeping pole at the high place must be extended to the low place for two spans and fixed with the vertical pole, and the height difference shall not be greater than 1m

.

3

.

2

.

Standard for construction safety inspection (jgj59-2011)

.

(5) when the vertical pole is lengthened by overlapping, the overlapping length shall not be less than 1m, and shall be fixed by not less than 2 rotating fasteners; the distance between the edge of the end fastener cover plate and the pole end shall not be less than 100 mm

.

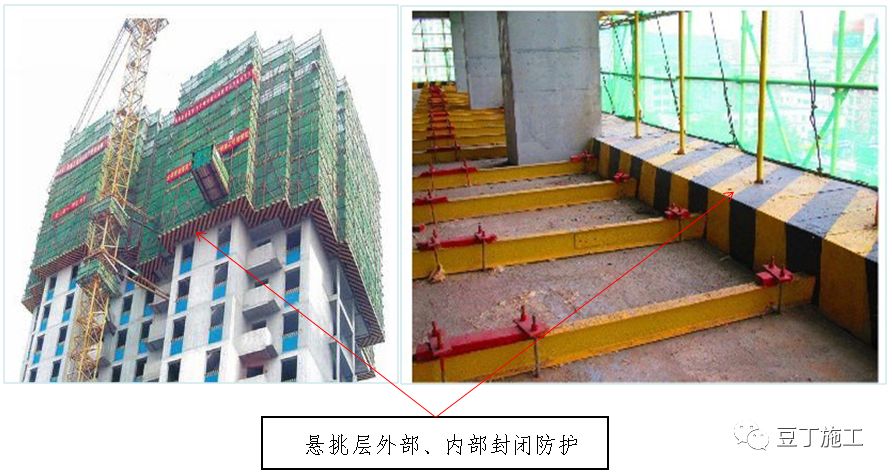

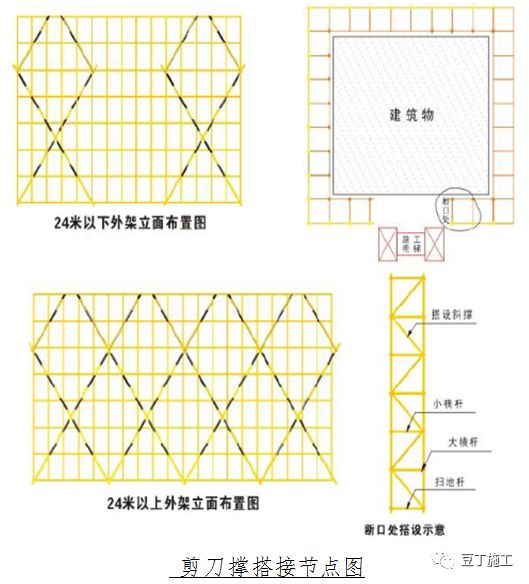

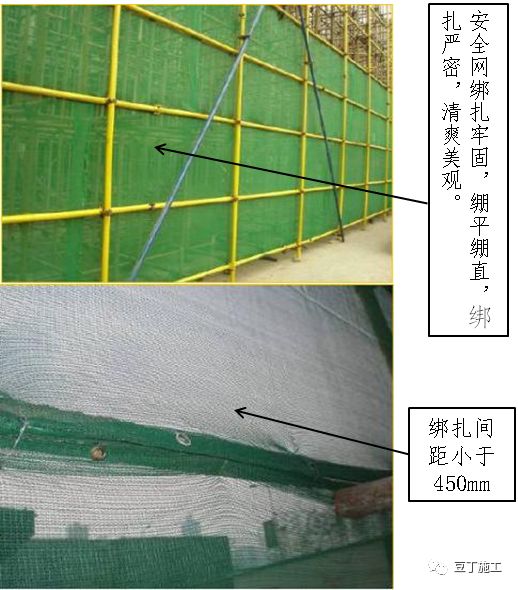

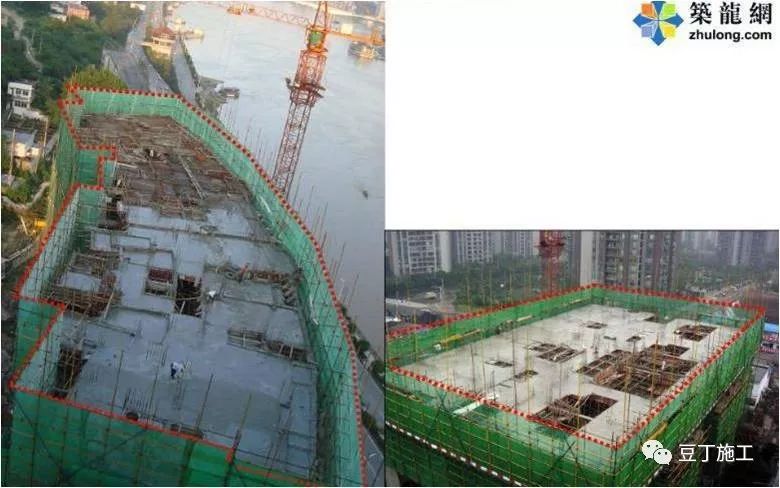

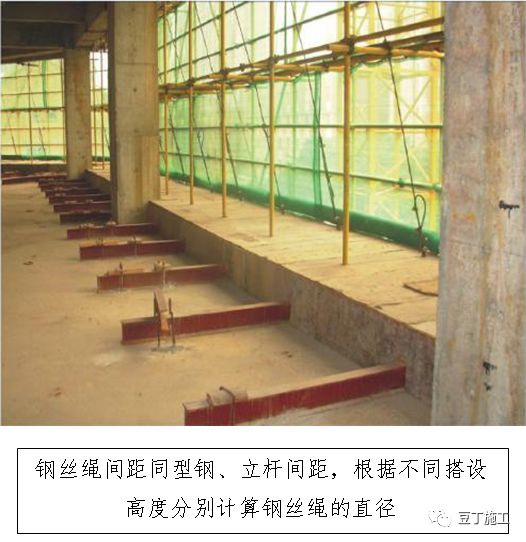

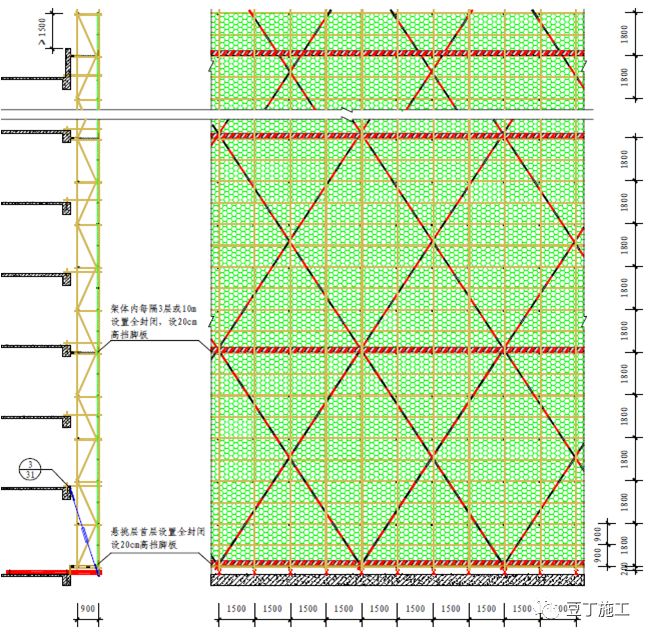

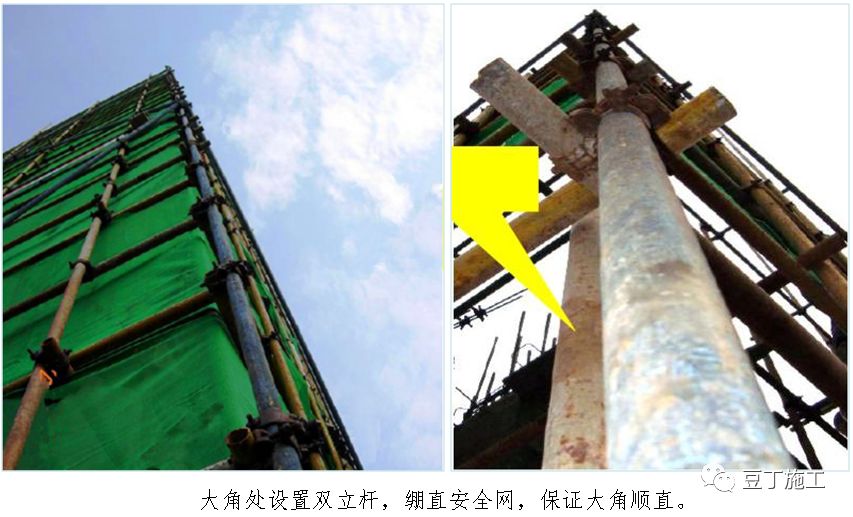

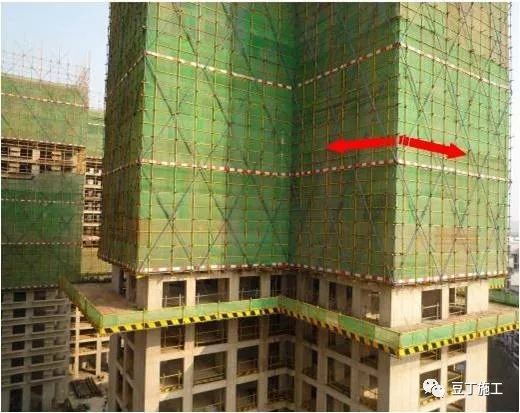

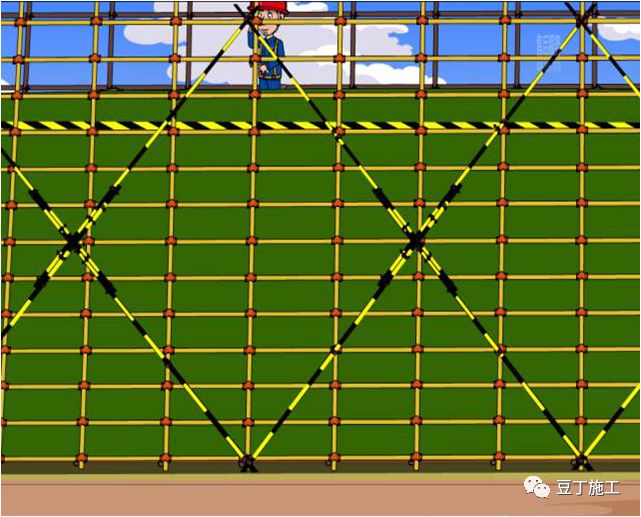

The cross bracing of external scaffold is set up continuously, and the setting of skirting line and waist line is standard

.

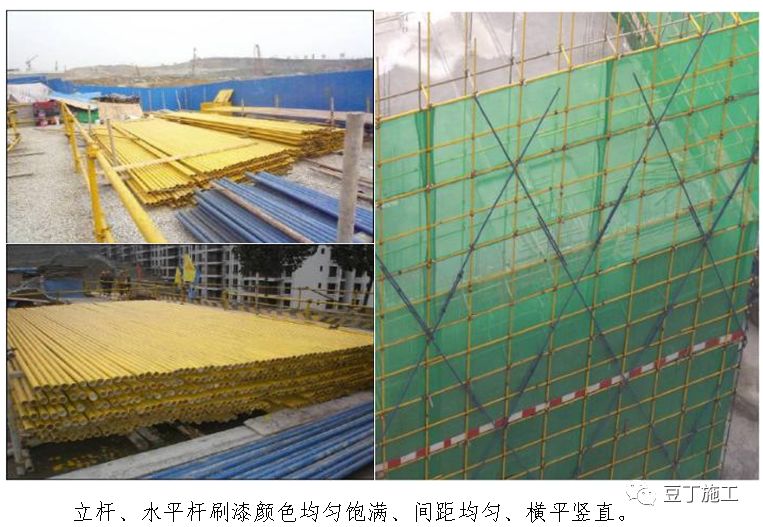

The steel pipe must be painted with antirust paint before use

.

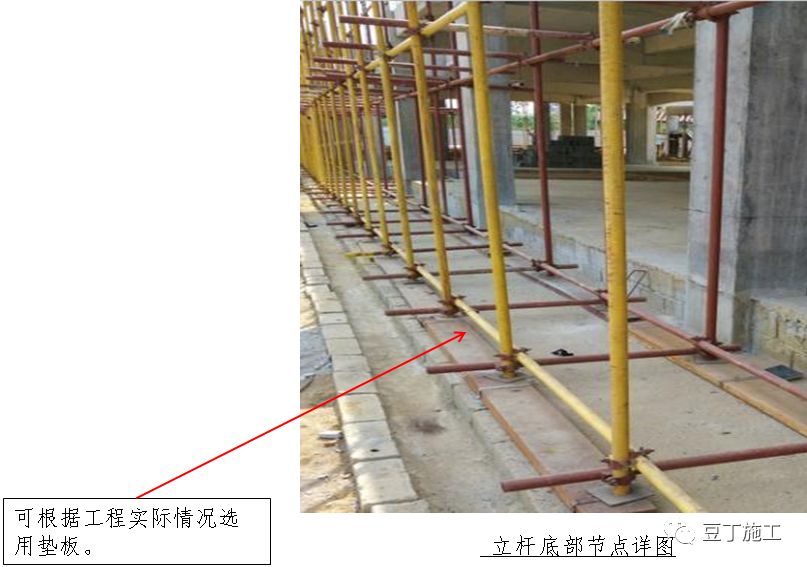

② The base or base plate should be set at the bottom of each vertical pole; the base and base plate should be accurately placed on the positioning line; the base plate should be a wood base plate with a length of not less than 2 spans, a thickness of not less than 50 mm and a width of not less than 200 mm

.

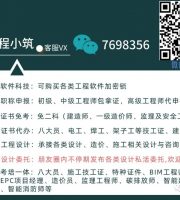

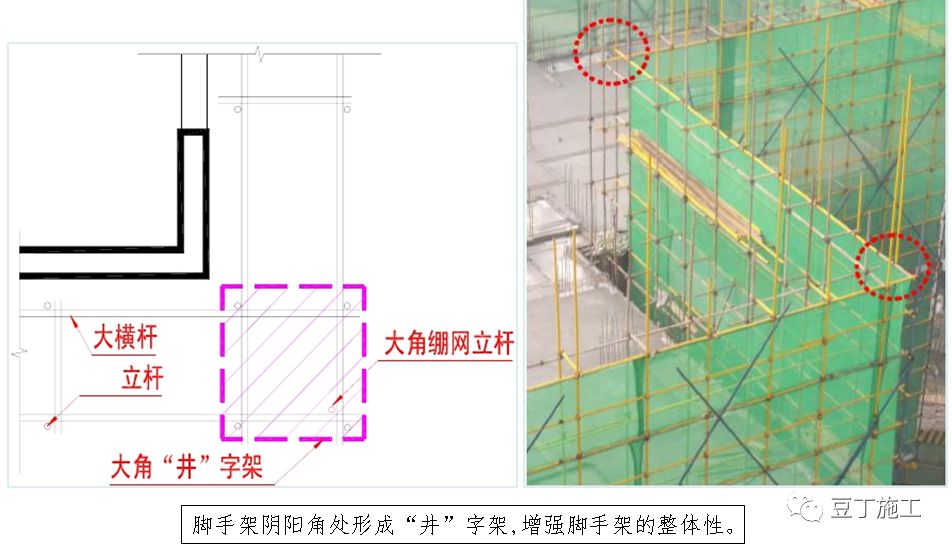

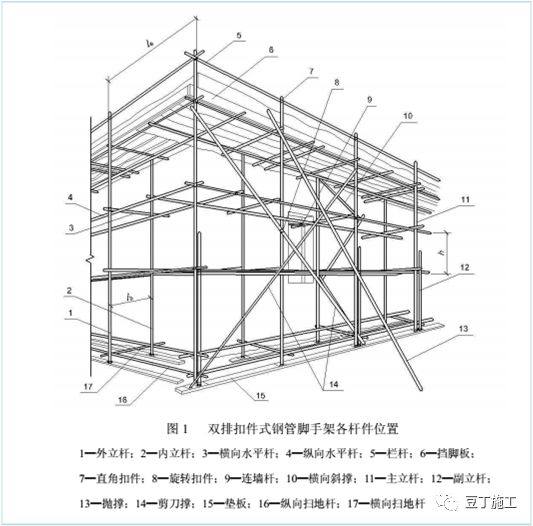

(2) Common problems: (3) structural requirements: ① the scaffold must be equipped with vertical and horizontal sweeping poles

.

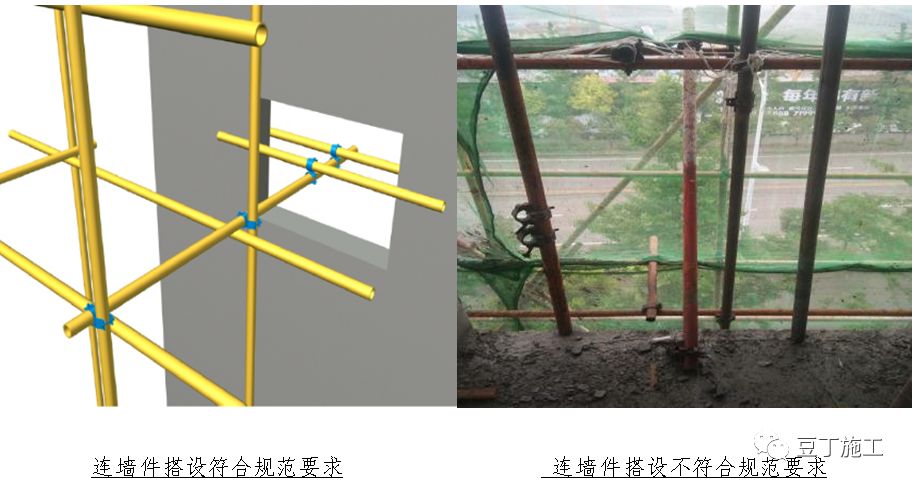

The large angle of the external scaffold is straight, the safety net is bound firmly, and the net is tight

.

Fastener: according to the structural form, it can be divided into butt joint, right angle and rotary fastener

.

Key control painting process (derusting, primer, finish), painting effect, steel pipe cleaning, derusting steel pipe painting (2) fastener 1

.

In the construction of the main structure, the protection shall be carried out first, and the outer frame shall be 1.5m higher than the operation floor

.

Except for the top step of the top layer, the joints of each step of the other layers must be connected by butt fasteners

.

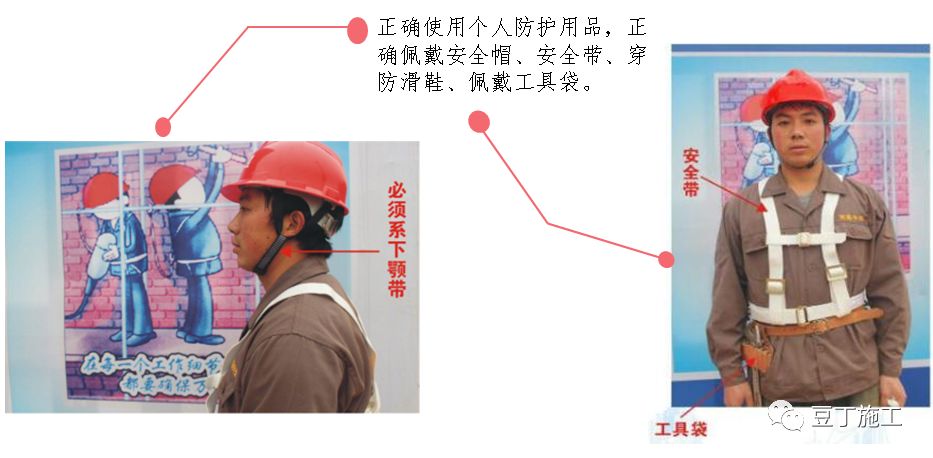

Safety technical disclosure of fastener scaffold erection (4) wearing of safety helmet and safety belt

.

The mesh density of dense mesh safety net shall be 10cm × 10cm, and the area shall be greater than or equal to 2000 mesh, and the buildings shall be fully closed to prevent dust; it is stipulated that the weight (quality) of single (dense mesh) net of 1.8 × 6m shall be more than 3.0kg

.

④ When the vertical pole is butt lengthened, the butt fasteners of the vertical pole shall be staggered, the joints of two adjacent vertical poles shall not be set in the synchronous range, the staggered distance of the two separated joints separated from a vertical pole in the height direction shall not be less than 500mm; the distance between the joint center and the main node shall not be greater than 1 / 3 of the step distance

.

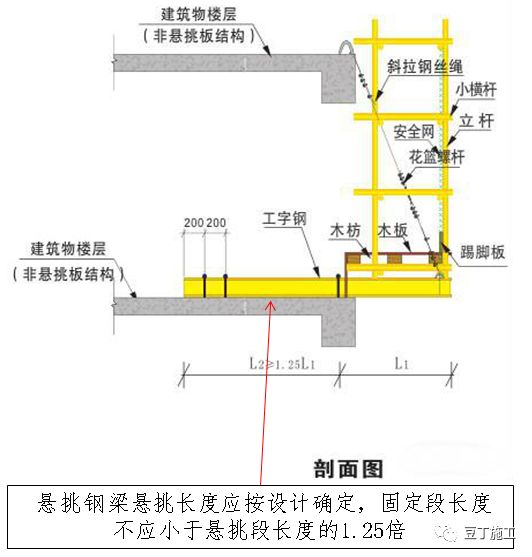

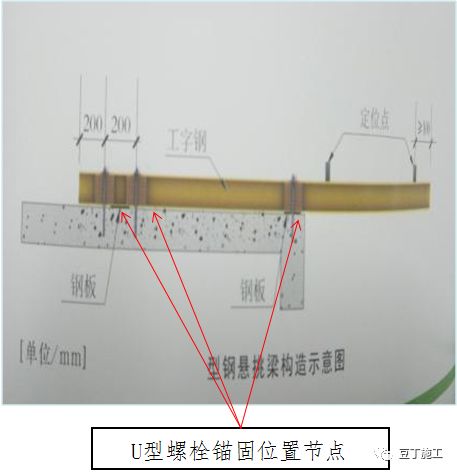

1、 In excellent cases, the profile steel is set reasonably, the distance between poles is uniform and straight, the color is consistent, and the safety net is smooth

.

The facade of scaffold is fresh and beautiful, and the setting of advertisement and safety slogan is standard

.

2

.

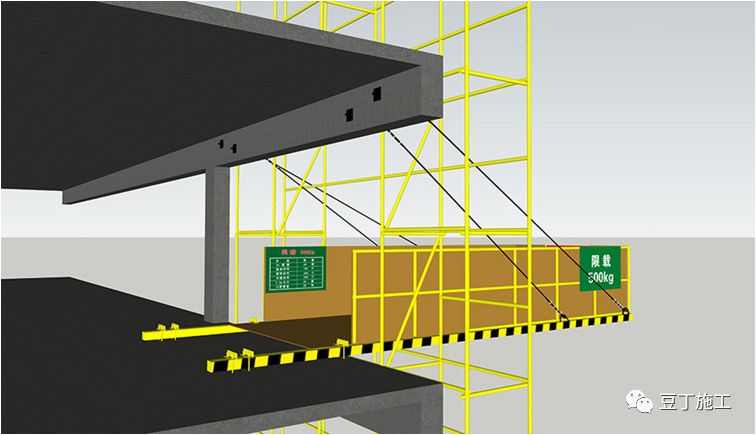

Strengthening measures must be taken for the fastener type steel pipe scaffold with the erection height exceeding 50m and the cantilever type scaffold with the erection height exceeding the specification requirements (≥ 20m), and the special construction scheme must be verified by experts

.

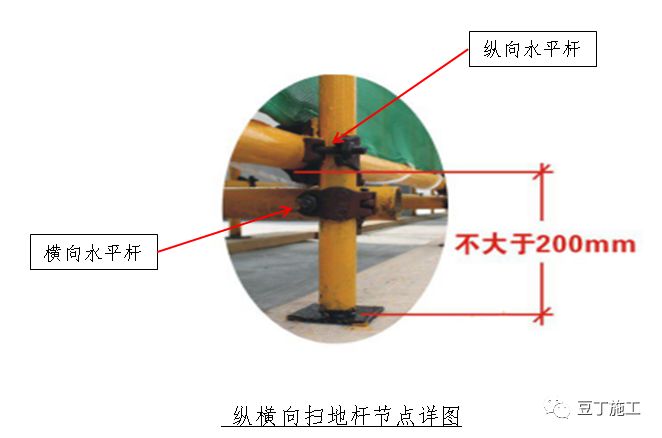

The longitudinal sweeping pole shall be fixed on the vertical pole not more than 200 mm away from the bottom of the steel pipe with right angle fasteners

.

4

.

Quality inspection (1) there should be product quality certificate and quality inspection report

.

2、 Scaffold engineering safety management requirements (1) requirements of operators scaffold installation and removal personnel must be qualified professional scaffolders, scaffolders should work with certificates

.

The basic specification of dense mesh net is 1.8m wide and 6m long, which is recorded as ml-1.8×6.0 (gb5275-2009); the width of dense mesh net should be between (1.2-2) M

.

Technical code for safety of construction work at heights (jgj80-2016)

.

Quality control points: 2

.

(3) the bottom step distance of single and double row scaffolds shall not be greater than 2m

.

It is strictly forbidden to drill holes in the steel pipe

.

Longitudinal horizontal bar (1) the longitudinal horizontal bar should be set inside the vertical bar, and the length of a single bar should not be less than 3 spans

.

2

.

⑥ The top rail of scaffold pole should be 1m higher than the upper end of parapet and 1.5m higher than the upper end of cornice

.

Special construction scheme shall be prepared for scaffold erection, and structural design shall be calculated, reviewed and approved according to regulations

.

The distance between the axis of the vertical pole above the slope and the slope shall not be less than 500mm

.

Technical code for safety of wooden scaffold in building construction (jgj164-2008)

.

Safety net gb5725-2009

.

③ The spacing between poles shall be consistent, and the construction shall be carried out in strict accordance with the approved scheme

.

3、 Steel pipe: the steel pipe of scaffold should be Φ 48.3 × 3.6

.

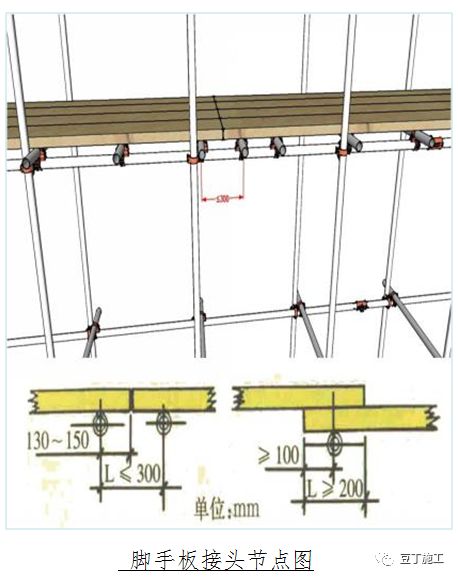

(2) The width and thickness of the wooden scaffold board shall not be less than 200 mm and 50 mm respectively

.

Unified standard for safety technology of construction scaffolds (gb51210-2016)

.

The horizontal sweeping pole shall be fixed on the vertical pole close to the bottom of the longitudinal sweeping pole with right angle fastener

.

Quality inspection: (1) fasteners shall have production license, quality inspection report, product quality certificate and retest report

.

(3) The fastening torque of the fastener should not be less than 40n · m, and should not be more than 65N · m; in the fastener test, the torque of the fastening bolt is 40n · M

.

4

.

(3) Scaffold operators must accept safety education and safety technical disclosure

.

When the bolt tightening torque reaches 65N · m, the fastener shall not be broken, and the fastener specification must be the same as the outer diameter of steel pipe

.

2

.

Scaffold engineering is a divisional and sub divisional project with high risk

.

(3) Bamboo scaffold board should be made of Moso bamboo or Phyllostachys pubescens

.

3

.

Key points for quality control of other materials to be prepared: during the construction of dense mesh safety net, each eye opening ring shall be threaded with a tether, which shall be bound on the support frame, and the spacing shall not be greater than 450mm

.

Key points of quality control: the safety net shall be firmly bound and tightly connected with each other, and the adjacent dense mesh nets shall be closely combined or overlapped

.

Relevant requirements: (1) the surface deflection of stamping steel scaffold board shall not exceed the allowable range of the specification, and the new scaffold board shall have product quality certificate, and the scaffold board shall not have cracks, open welding and hard bending, and the new and old scaffold boards shall be painted with antirust paint

.

(3) Scaffold board: it can be made of steel, wood and bamboo, and the single scaffold board should not be more than 30kg

.

(5) Structural drawing of floor scaffold main structural drawing of floor scaffold detailed drawing of floor scaffold 1

.

The main reference materials are as follows: 1

.

6

.

(3) Vernier caliper is used for measurement and inspection

.

Dense mesh safety net must be flame retardant

.

2

.

The allowable deviation of outer diameter (48.3mm) is ± 0.5mm, the allowable deviation of wall thickness (3.6mm) is ± 0.36mm, and the minimum allowable wall thickness is 3.24mm

.

(2) The fasteners shall be selected one by one before use, and no cracks, deformation and bolt sliding wire are allowed; the contact part between the fastener and the steel pipe shall not have oxide skin; the surface of the fastener shall be treated with anti rust treatment, the paint shall be uniform and beautiful, and there shall be no paint stacking or iron exposure

.

5

.

2

.

(4) Safety net 1

.