5

.

A construction method of air pressure balanced shield machine, which is characterized in that it includes the following steps: water spraying step: water spraying in front of cutter head to reduce dust and temperature; starting step: motor and reducer rotate to drive main bearing big gear ring in main drive to rotate, and finally cutter head rotates; slag discharging step: cutter head upper hob extrudes and breaks undisturbed soil in front of cutter head and falls to the lower part in front of cutter head When the scraping plate rotates through the lower part, the slag will be scraped into the slag chute

.

The purpose of the invention is to overcome the shortcomings of the prior art, to provide an air pressure balanced shield machine and a shield construction method, to set an air pressure chamber and a slag discharge channel, to balance the air pressure with the water and soil pressure of the undisturbed soil on the shield excavation surface, and to be suitable for tunnel construction

.

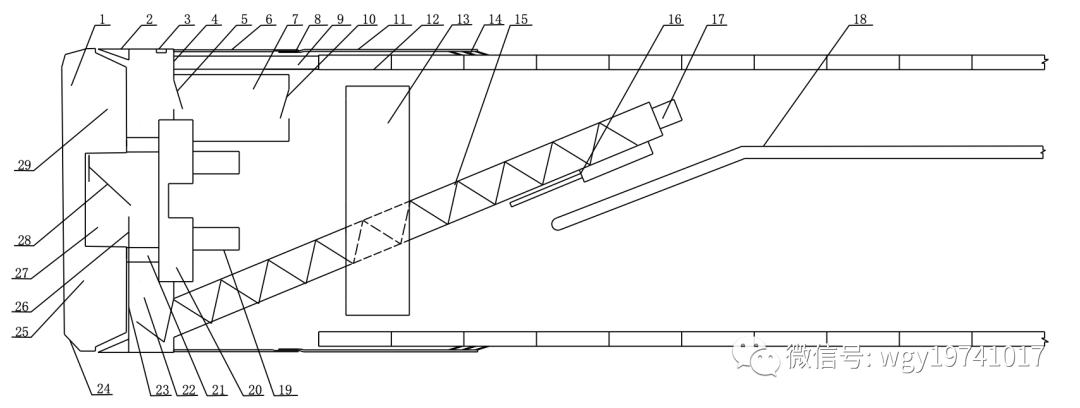

The air pressure balanced shield machine according to claim 1, which is characterized in that the shield machine comprises a front shield, a middle shield and a shield tail

.

It pushes the shield machine in the ground, supports surrounding rock through shield shell and segment to prevent collapse in the tunnel, and excavates the soil in front of the excavation face with cutting device

.

8

.

The advantages of using hard rock tunnel boring machine are fast construction progress, hob is only broken rock wear, no secondary wear, only need to add water to improve, the slag is dry, the disadvantage is that the excavated rock must be hard rock, can not be applied to soft rock stratum; the advantages of using earth pressure balance shield construction are small area of working shaft, low equipment cost and construction cost, fast construction progress, etc.; the disadvantages are soil chamber pressure control Sometimes the surface settlement is large after construction, and the second wear of cutting tools is serious due to the full cabin pressure retaining slag

.

The invention relates to the technical field of an air pressure balance shield machine and a construction method, and relates to a shield machine design, in particular to an air pressure balance shield machine and a shield construction method

.

The air pressure balance shield machine according to claim 1, which is characterized in that: a water jet is arranged on the cutter head, the water jet is connected with a water pump through a pipe, and the water pump is connected with the water storage device

.

Nowadays, hard rock tunnel boring machine (TBM), earth pressure balance shield (EPB) and slurry balance shield (SPB) are mainly used in tunnel mechanical construction

.

3

.

Shield method is a fully mechanized construction method in the construction of underground excavation

.

The invention also discloses a construction method of an air pressure balance shield machine

.

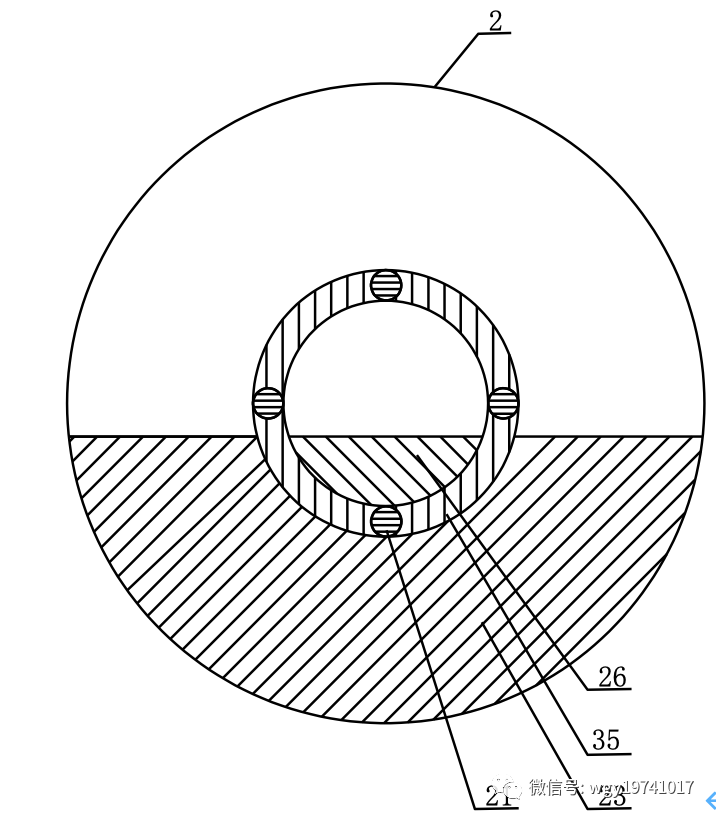

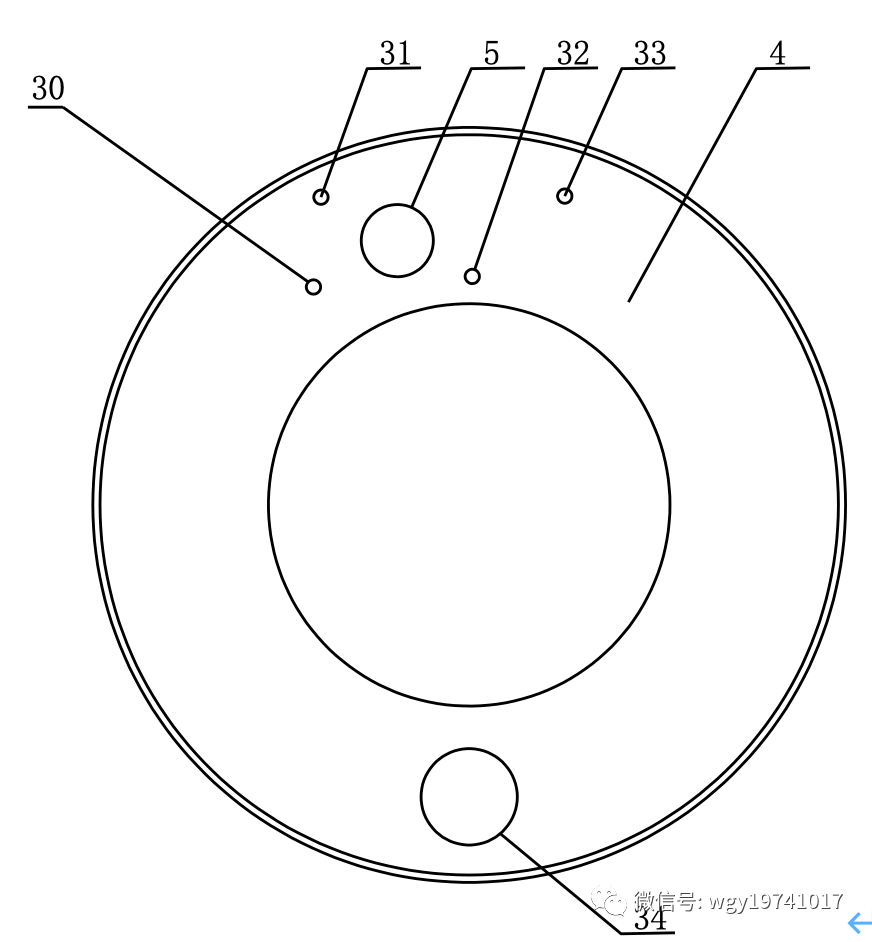

The invention discloses an air pressure balance shield machine, which is provided with an air pressure chamber and a slag storage chamber, a cutter head is provided with a hob and a slag inlet, the slag inlet is connected with the slag chute in the cutter head, the cutter head support arm is connected with the main drive, and the cutter head support arm rotates under the drive of the main drive; a slag scraper is installed on the cutter head, and the slag scraper is used to scrape the slag into the slag chute in the cutter head; a slag retaining ring is installed on the front shield, The slag chute is set in the slag retaining ring, the inlet of the slag chute is set on the slag retaining ring, and the slag chute is connected to the slag storage tank; the slag chute, the slag retaining ring and the slag chute together form a slag outlet channel; the slag in the slag chute is transported to the slag storage tank through the slag chute

.

The air pressure balance shield machine according to claim 1, which is characterized in that: the soil compartment partition comprises an outer soil compartment partition and a middle soil compartment partition, the outer soil compartment partition and the middle soil compartment partition are respectively fixed with the front shield, the soil compartment partition ring is between the outer soil compartment partition and the middle soil compartment partition, and the soil compartment partition ring is fixed with the cutter head support arm

.

The air pressure balanced shield machine according to claim 1, which is characterized in that the shield machine also includes an assembler, which is used to assemble multiple segments of a ring segment into a ring in sequence

.

Background technology tunnels are generally constructed by underground excavation method, and the quality of tunnel construction generally depends on the process quality, that is to say, in the process of tunnel construction, we must master the quality of excavation, initial support and waterproof and drainage, because only after mastering the quality of these processes can we ensure the quality of tunnel construction

.

When the inward angle of the slag chute exceeds 0 degrees, the slag in the slag chute will slide downward due to the action of gravity, and fall into the slag storage tank through the slag chute; propulsion steps: start the propulsion oil cylinder, and the propulsion oil cylinder will support and push forward on the front surface of the segment; slag transportation steps: open the rear gate of the screw conveyor, and start the screw conveyor The screw conveyor drives the screw shaft in the screw conveyor to rotate, and the slag falls into the lower belt through the slag inlet, screw conveyor and screw conveyor rear gate, and is transported to the slag truck through the belt

.

6

.

9

.

The invention adopts the air pressure to balance with the undisturbed soil and water pressure of the shield excavation face, which can effectively reduce the settlement of the surface and nearby buildings (structures), greatly reduce the secondary wear of the hob, and has a great promotion prospect

.

The air pressure balanced shield machine according to claim 6, which is characterized in that the hinged seal is adopted between the middle shield and the shield tail

.

The advantages of slurry balance shield construction are that the pressure of soil tank is controlled by air pressure, the pressure is controlled accurately, the surface settlement is small during construction, and the connection between soil tank and slurry pipe will not cause gushing; the disadvantages are that the slurry separation system on the working shaft covers a large area, the cost of shield equipment is high, the construction power consumption is large, and the construction progress is affected by the capacity of slurry separation system

.

The air pressure balance shield machine according to claim 1, which is characterized in that the sliding slag groove is an inclined structure, and the inclined angle of the inclined structure is 30-45 degrees

.

The air pressure balanced shield machine according to claim 1, which is characterized in that the main drive is connected with the motor and the reducer, and the main drive is driven by the motor and the reducer

.

The air pressure balanced shield machine according to claim 6, which is characterized in that the shield tail is sealed

.

2

.

The object of the invention is realized by the following technical scheme: an air pressure balanced shield machine, the front of the front shield diaphragm of the air pressure balanced shield machine includes two parts: an air pressure chamber and a slag storage chamber, wherein the air pressure chamber is the upper space between the front shield diaphragm and the soil tank diaphragm and the front space of the soil tank diaphragm, and the slag storage chamber is the lower space between the front shield diaphragm and the soil tank diaphragm The cutter head is provided with a hob and a slag inlet, the slag inlet is connected with the slag chute in the cutter head, the cutter head support arm is connected with the main drive, and the cutter head support arm rotates under the drive of the main drive; the cutter head is provided with a slag scraper, which is used to scrape the slag into the slag chute in the cutter head; the front shield is provided with a slag retaining ring, and the slag chute is set in the slag retaining ring, and the inlet of the slag chute is set on the slag retaining ring The slag chute is connected to the slag storage tank; the slag chute, the slag retaining ring and the sliding slag chute form a slag discharge channel; the slag in the slag chute is transported to the slag storage tank through the sliding slag chute.

.

In view of the current situation of tunnel mechanical construction, it is urgent to design a shield machine to adapt to the increasingly demanding urban tunnel construction

.

1

.

4

.

An air pressure balance shield machine, which is characterized in that: the front of the front shield diaphragm of the air pressure balance shield machine includes two parts: an air pressure chamber and a slag storage chamber, wherein the air pressure chamber is the upper space between the front shield diaphragm and the soil tank diaphragm and the front space of the soil tank diaphragm, and the slag storage chamber is the lower space between the front shield diaphragm and the soil tank diaphragm; a hob and a slag inlet are arranged on the cutter head, and the slag inlet is connected with the bottom space A slag chute is arranged in the cutter head, the cutter head support arm is connected with the main drive, and the cutter head support arm rotates under the drive of the main drive; a slag scraper is installed on the cutter head, and the slag scraper is used to scrape the slag into the slag chute in the cutter head; a slag retaining ring is installed on the front shield, and a sliding slag groove is set in the slag retaining ring, and the inlet of the sliding slag groove is set on the slag retaining ring, and the sliding slag groove is connected to the slag storage chamber; a slag chute, a slag retaining ring and a sliding slag chute are installed on the front shield The slag chute forms the slag channel together, and the slag soil in the chute is transported to the slag storage tank through the sliding slag chute

.

10

.

The soil is transported out of the tunnel by the excavation machine, and is jacked by the pushing oil cylinder at the rear, and prefabricated concrete pipes are assembled It is a mechanized construction method to form tunnel structure

.

7

.