The bending radius in concrete shall not be less than 10d, in brick wall shall not be less than 6D, the bending flatness shall not be greater than 1 / 10 of the outer diameter of the pipe, and there shall be no fold at the bending place; the junction box shall be fixed flat and firm, the mortar shall be full, and the vertical and horizontal coordinates shall be accurate

.

In case of special design requirements, anti-corrosion treatment shall be carried out according to the design regulations

.

When the steel pipe is concealed in the cast-in-place concrete, a 15mm thick concrete cushion block shall be placed under the steel pipe as the support

.

The distance between concealed conduit and building surface shall not be less than 15mm

.

Polystyrene board and other materials can be used to fill the iron box for protection to prevent mortar from penetrating into the box

.

When the pipe length exceeds 30m, there is no bending; when the pipe length exceeds 20m, there is one bending; when the pipe length does not exceed 15m, there are two bending; when the pipe length exceeds 8m, there are three bending, and a junction box shall be added in the middle

.

When the insulating conduit is embedded in the masonry, the cement mortar with strength grade not less than m10shall be used for plastering protection, and the thickness of the protective layer shall be greater than 15mm

.

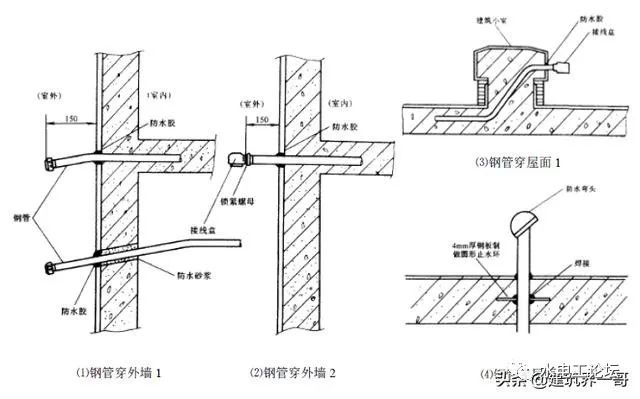

When the steel pipe passes through the roof slab, the steel pipe is made into a wing stop ring in the concrete

.

When the steel pipe passes through the roof slab and external wall, it needs to be waterproof

.

The buried depth outside should not be less than 0.7m from the ground, and there should be an appropriate waterproof slope

.

Basic requirements for steel pipe surface: galvanized steel conduit shall not be welded with jumper grounding wire, and the connecting wire between the two cards bridged by special grounding card shall be copper core flexible wire with sectional area not less than 4mm2

.

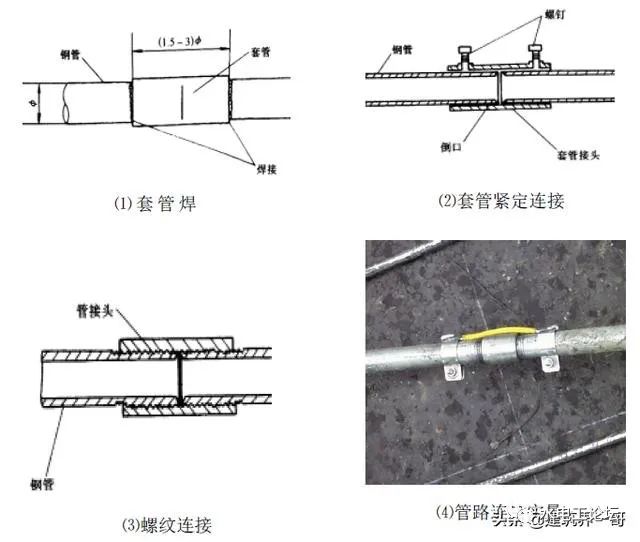

During casing welding, the pipe to pipe joint should be located in the center of casing and welded tightly; when the set screw is connected, the screw should be tightened, and anti loosening measures should be taken for the set screw in vibration place

.

After the completion of concrete, the embedded objects can be removed for piping and installation of junction box

.

When the equipment breaks down or is overhauled, press the button to stop the equipment

.

The distance between the steel pipe orifice connected with the equipment and the ground should be greater than 300 mm

.

The device can only be restarted if the button is turned clockwise to eject

.

Basic requirements for installation of steel pipe through external wall and roof panel: metal conduit and junction box must be grounded or grounded reliably

.

There shall be no iron filings and burrs in the pipe

.

It is not allowed to weld the jumper grounding wire for galvanized steel conduit, and the connecting wire between the two cards bridged by the special grounding card is the copper core flexible wire, with the sectional area of no less than 4mm2

.

The metal junction box shall be grounded

.

The jumper grounding wire shall be welded, and the connecting wire between the two cards bridged by a special grounding card shall be a copper core flexible wire with a cross-sectional area of not less than 4mm2.

.

After the connection, the thread is exposed by 2-3 threads, and the thread surface is smooth without damage

.

Basic requirements for motor piping installation: there shall be no joints for cables or wires in steel pipes

.

When the non galvanized steel conduit is connected by thread, the two ends of the connection are welded with jumper grounding wire; when the galvanized steel conduit is connected by thread, the two ends of the connection are fixed with special grounding card

.

Basic requirements for motor piping installation: when the steel pipe is indirectly connected with the equipment, for indoor dry places, the end of the steel pipe should be added with wire protection hose or flexible metal wire protection tube, which should be led into the junction box of the equipment, and the pipe orifice of the steel pipe should be tightly wrapped; for outdoor or indoor wet places, the end of the steel pipe should be added with waterproof elbow, and the wire should be covered with protective hose

.

Basic requirements for standard positioning and fixation of junction box in ceiling: according to the construction process standard, fixed suspenders are added at 150-300 mm at both ends of the pipe entering the box; the dimension of pipe box spacing conforming to the standard spacing is used as the processing dimension of the fixed strip, so as to position the pipe box spacing

.

The outer wall of the steel pipe directly buried in the soil layer shall be coated with two degrees of asphalt; when the galvanized steel pipe is used, the stripping part of the galvanized layer shall be coated with anti-corrosion paint

.

The exposed conduit shall be arranged in order, the distance between fixed points shall be uniform, and the installation shall be firm; the pipe clamp shall be set within 150-500mm from the middle point of terminal and elbow or the edge of cabinet, platform, box, plate, etc

.

Basic requirements for installation of directly buried cable through wall protection pipe: the pipe orifice shall be free of burr and sharp edges, and the pipe orifice shall be made into horn shape

.

The emergency stop button is usually installed next to the equipment

.

The connection between metal hose and rigid conduit or electrical equipment and appliances adopts special joint; the joint of composite metal hose is well sealed, and the anti liquid film coating is intact

.

The metal junction box shall be reliably grounded

.

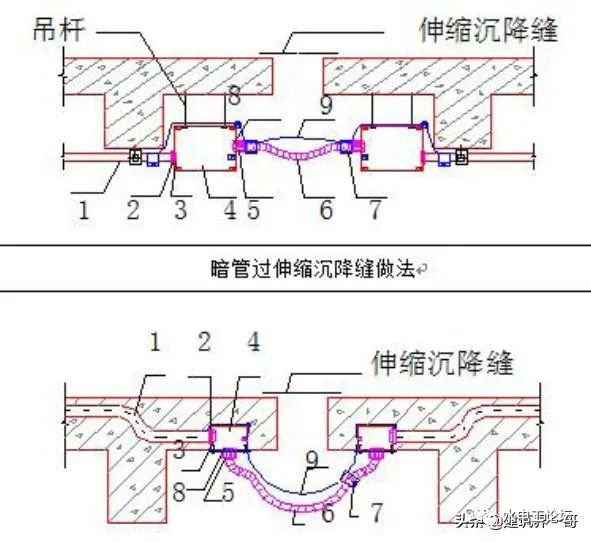

Basic requirements for installation of steel pipe passing through expansion joint and settlement joint: the pipeline passing through expansion joint shall be disconnected for flexible connection

.

When the non galvanized steel conduit is connected by thread, the two ends of the connection are welded with jumper grounding wire; when the galvanized steel conduit is connected by thread, the two ends of the connection are fixed with special grounding card

.

Basic requirements for connection of metal hose and junction box: rigid conduit is connected with electrical equipment and appliances through flexible conduit, and the length of flexible conduit is not more than 0.8m in power engineering and 1.2m in lighting engineering

.

Through the notch at both ends of the positioning strip, the suspenders at both ends are clamped, and the box body is fixed by the pull rivet (or machine screw), so that it can not rotate and shake

.

The vertical spacing of suspender is consistent; the junction box is fixed firmly and the orientation is consistent; the basic requirements of steel pipe concealed distribution: the pipeline connection mode and requirements are the same as the precautions of open distribution

.

When non galvanized steel conduit is connected by thread, the two ends of the connection shall be welded with jumper grounding wire; when galvanized steel conduit is connected by thread, the two ends of the connection shall be fixed with special grounding card

.

The steel pipe shall be free of flattening and cracks

.

It is forbidden to connect metal conduit by butt fusion welding; galvanized steel conduit and steel conduit with wall thickness less than or equal to 2mm shall not be connected by sleeve fusion welding

.

The installation of concealed metal trunking in the ground shall meet the basic requirements: the metal trunking must be grounded or grounded reliably, and the galvanized metal trunking shall not be welded

.

The insulated conduit laid along the surface of buildings and structures shall be equipped with temperature compensation device according to the design requirements

.

When it is buried in concrete, the outer wall of the steel pipe may not be treated with anti-corrosion treatment

.

Special column: table of contents: 1 pipe connection 2 pipe box connection 3 metal hose and junction box connection 4 standard positioning and fixation of junction box in ceiling 5 pipe fixation 6 steel pipe concealed distribution (1) 7 steel pipe concealed distribution (2) 8 steel pipe concealed distribution in wall and column 9 steel pipe through external wall, roof panel installation 10 steel pipe through expansion joint and settlement joint installation 11 directly buried cable through wall protection pipe installation 12 steel pipe exposed distribution (1) 13 steel pipe exposed distribution (2) 14 steel pipe along the wall and column (3) 15 steel pipe in the electric well (4) 16 motor pipe installation (5) 17 motor pipe installation (6) 18 cooling tower, fan, roof water tank pipe installation (7) 19 rigid plastic (PVC) pipe installation 20 rigid plastic (PVC) pipe installation in cast-in-situ concrete (2) 21 rigid plastic (PVC) pipe installation in the wall and column (3) )22 installation of concealed metal trunking in the ground 23 support method of concealed metal trunking in the ground 24 installation method of metal trunking in the ground of various structures text: basic requirements for piping connection: butt welding is strictly prohibited for metal conduit; sleeve welding is not allowed for galvanized and steel conduit with wall thickness less than or equal to 2mm

.

The distance between concealed conduit and building surface shall not be less than 15mm

.

The cut-off port shall be smooth and the pipe orifice shall be smooth

.

At this time, the equipment will not start

.

The tube mouth is smooth and smooth, and the insertion method is used for tube to tube, tube to box and other devices

.

Basic requirements for concealed steel pipe in wall and column: for parts whose size is difficult to determine, wood box or polystyrene board can be used for pre embedding

.

Basic requirements for pipe box connection: the connection between steel pipe and junction box shall be fixed with lock nut or retainer cap, and the thread of pipe section fixed with lock nut shall be exposed with 2 ~ 3 buckles of lock nut

.

The water-proof treatment must be done for the directly buried cable lead-in pipe passing through the wall

.

When the steel pipe is threaded, the length of the pipe end thread shall not be less than 1 / 2 of the pipe joint

.

Basic requirements for installation of rigid plastic (PVC) pipes: the exposed PVC pipes shall be arranged in order, and the spacing between fixed points shall be uniform

.

Metal hose can not be used as connecting conductor of grounding (PE) or neutral (pen)

.

The motor shell and metal base shall be grounded

.

For the rigid insulated conduit directly buried in the ground or floor, protective measures shall be taken when it passes through the ground or floor vulnerable to mechanical damage

.