[recommended] pay attention to more than half a year, improve 30-50% performance! Introduction to ceramic marketing, new employee training and understanding of ceramic industry knowledge, you need to pay attention to the video number — [Hu Jun says about ceramics], one ceramic marketing practice every day to share! Construction technology and process of rockslab rockslab rockslab is a new type of multi-functional building materials

.

At present, it has a place in the field of home overall decoration and tooling overall decoration

.

It can freely cut a variety of specifications to meet the needs of personalized space design

.

Today, we will share with you the construction technology and process of the wall on the rock slab

.

After the slabs are packed and installed in the warehouse, they are transported to the installation destination by the freight car arranged by the installation team

.

When findyworkay is installed in a high-rise building, it is necessary to use a crane to transport the bound wooden pallet of the rock slab

.

Only a good quality wooden pallet can support the heavy weight of the rock slab and ensure the safety during transportation

.

After arriving at the corresponding floor safely, the installation personnel will move it to the specific location and wait for the construction and installation

.

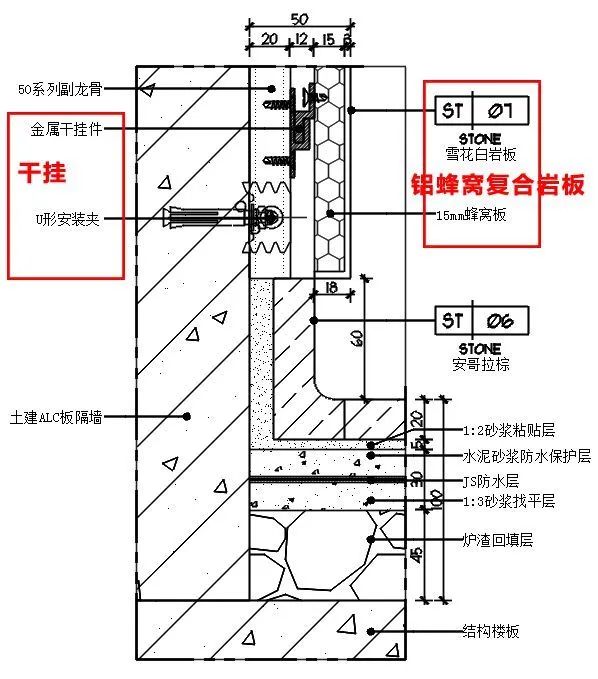

Construction method / rock slab installation construction method / for walls below 2.4m, it is suitable to use metal corner screw fixation + adhesive method; for rock slabs with large height and thickness, dry hanging method is recommended for safety consideration

.

At present, the most commonly used technology in the construction of rock slab is adhesive technology

.

The use of special instruments and tools can solve the problems of large plate width, difficult handling and instable installation

.

1

.

Base treatment 2

.

Snapping line and dividing 3

.

Mixing rock plate glue 4

.

Applying rock plate glue 5

.

Handling and paving 6

.

Flattening and pressing 7

.

Leveling 8

.

Hollowing inspection 9

.

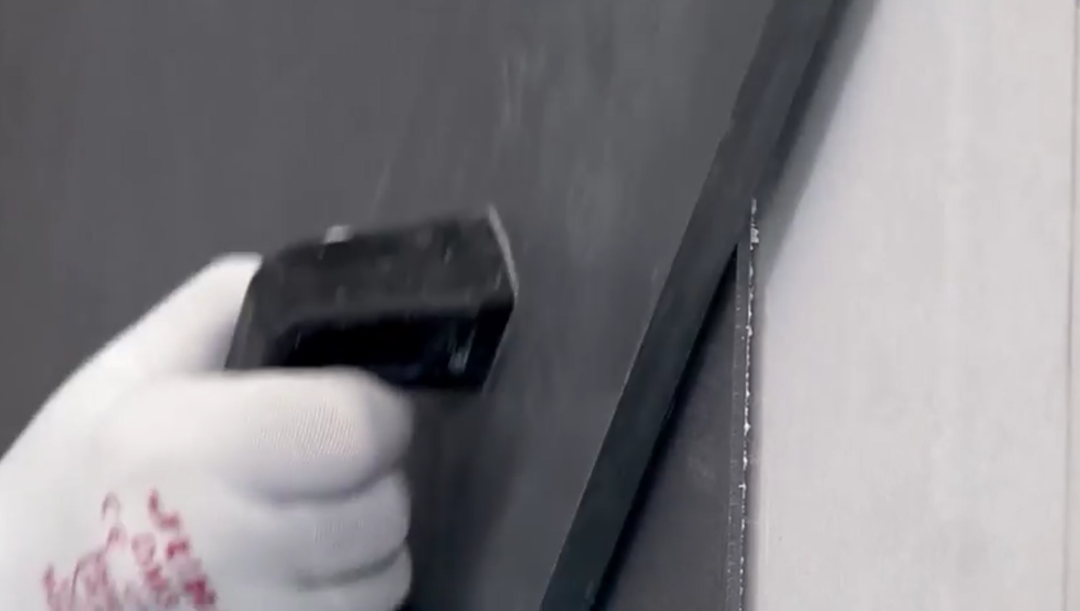

Cleaning and caulking 2

.

Dry hanging construction method of rock plate 1

.

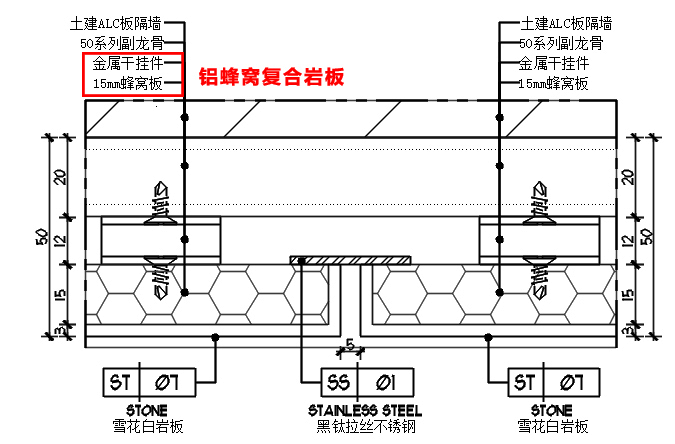

Dry hanging transverse section of aluminum honeycomb composite rock plate} dry hanging vertical section of rock plate} 2

.

Gluing method + stainless steel corner piece fixation is the same as the ground installation method, and stainless steel corner piece can be added to ensure the safety The distance between two corner pieces should not exceed 600mm

.

Protection and acceptance / protection and acceptance / after the completion of the construction, the Construction Party of the rock slab is responsible for completing the surface, corner, edge and other protection measures, and the customer carries out the acceptance according to the drawings and the actual completed surface on site

.

After passing the site acceptance, the Construction Party of the rock slab will immediately withdraw from the site to complete the project

.

Findyourway protection measures show [2nd live broadcast notice] how to find new growth point of ceramic marketing in 2021? Next Monday (February 22) from 20:00 to 21:00, we will make a live broadcast on wechat video number [spectator Hu Jun] to share “how to find a new growth point of ceramic marketing in 2021?”? 》Main contents: 1

.

Analysis of the growth mode of ceramic dealers in 2021

.

2

.

How to improve the sales of stores? 3

.

How to improve channel sales? 4

.

How to improve profit margin and total profit? 5

.

How to improve the efficiency of stores, channels and teams? No permission is set for this live broadcast

.

Please forward to the team group to watch the live broadcast, take notes and hold a meeting the next day to discuss the team and individual planning for 2021! Next, we plan to launch 9 live shows

.

Please pay attention to wechat video number [bystander Hu Jun], and make an appointment for live broadcast

.

There will be live broadcast tips when you see wechat!.

.