Operation points: first, after comprehensive layout planning for all kinds of pipes, determine the pipeline coordinates, elevation position and direction, draw the layout drawing, and construct according to the drawing after confirmation by the owner, supervisor or design

.

2

. ![]()

Quality requirements: steel pipe below sc25 shall be bended by matching pipe bender, and pipe bender or hot simmer method shall be adopted for pipe above sc32

.

1

.

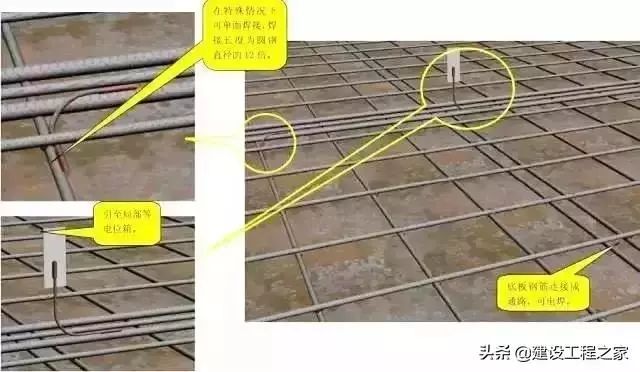

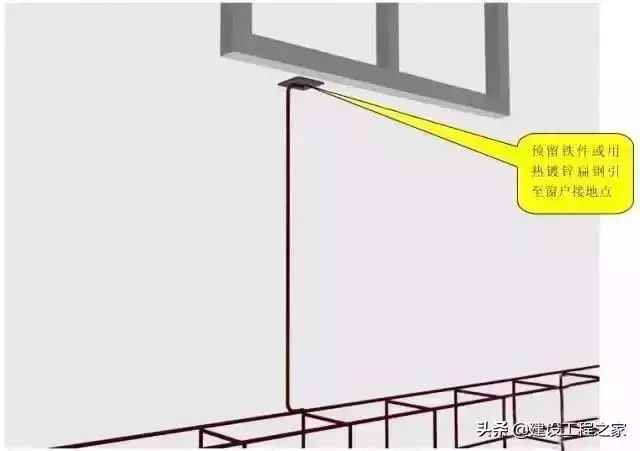

4) The practice of metal steel window equipotential bonding reserved point (the bridging with the window is completed by a professional company)

.

4

.

Timely put on the belt line, and effectively block the pipe orifice, box orifice and box orifice

.

Concealed inspection records shall be made for concealed equipotential bonding lines and their joints, and the actual direction and position shall be indicated on the as built drawing

.

6) Note: 1

.

3

.

3) Note: 1

.

See the effect picture: 1) conduit into the box method note: JDG steel pipe is connected with the iron box, using the fixed claw nut

.

5) Note: 1

.

There is no PE line in the bathroom

.

The grounding resistance of the grounding device must meet the design requirements

.

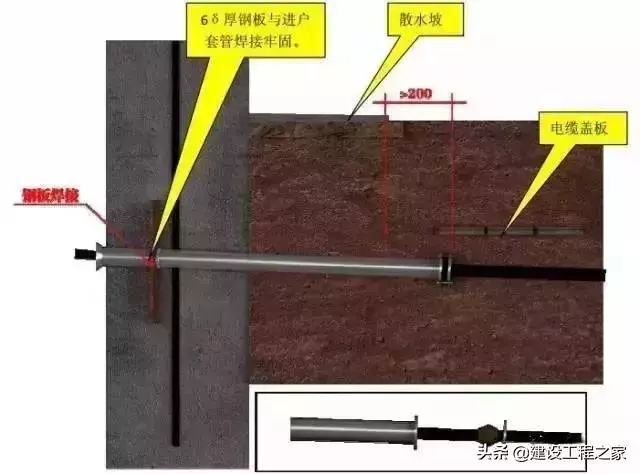

The buried depth shall be no less than 700mm away from the outdoor surface, and the waterproof slope (5p0p ~ 10p0p) shall be provided

.

Construction points: according to the construction drawing, measure and set out positioning, coordinate and elevation, direction, determine the location of junction box, which meets the design requirements after review Please

.

Quality requirements: according to the size and location requirements of the design drawing, the grounding device shall weld the two main structural reinforcement in the bottom plate and connect them with relevant reinforcement (such as pile foundation reinforcement)

.

Construction technology: snap line positioning → processing elbow pipe → concealed pipeline → grounding jumper → protective measures 2

.

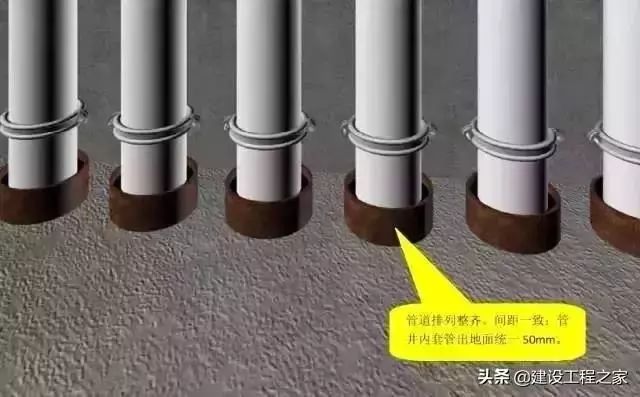

Construction technology: production of casing → positioning and fixation → technical review → installation and molding 2

.

The common steel conduit grounding wire adopts the cross welding method; 2

.

There shall be no slag inclusion, undercut, crack, false welding, air hole and other defects at the welding joint

.

See effect picture 1) method of plate reinforcement and pile foundation grounding device 2) conventional method of using vertical structure main reinforcement as lightning protection down lead (according to design or local regulations) Note: using building main reinforcement as concealed down lead: when the diameter of reinforcement is 16mm and above, two reinforcement (binding or welding) shall be used as a group of down lead; when the diameter of reinforcement is 10mm and above, four reinforcement shall be used Two bars are used as a group of down conductors

.

Operation points: according to the design, flexible waterproof casing or rigid waterproof casing shall be used, and the material, specification and size of casing shall be processed and manufactured or purchased in the market according to the requirements of standard drawings of waterproof casing; according to the coordinate size of layout plan confirmed Binding or welding on structural reinforcement

.

There is PE line in the bathroom, and the local equipotential bonding in the bathroom must be connected with the PE line

.

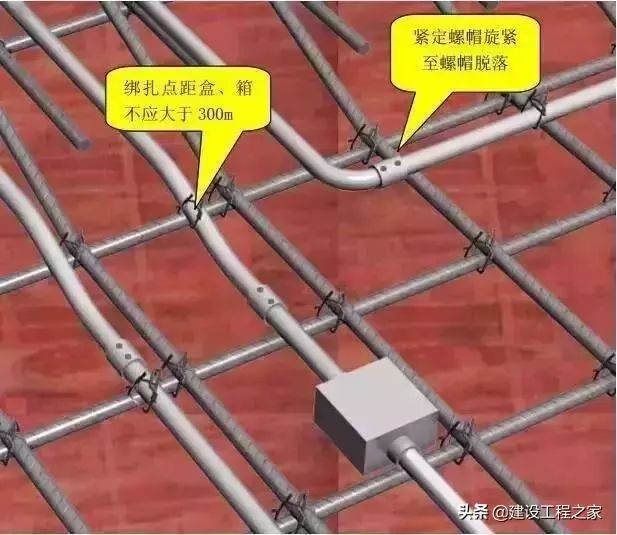

After inserting and positioning, use the tightening wrench to continuously tighten the tightening screw until the “neck” is broken, so that it becomes a whole, and there is no need to make a jumper wire

.

Note: the metal frame of curtain wall and the metal doors and windows of buildings that are required to be grounded in the design shall be reliably connected with the grounding main line nearby, and the anti electrochemical corrosion measures shall be taken between different metals at the connection

.

The conductor is reserved at 0.8m ~ 1m below the outdoor floor, and the external artificial grounding body is attached

.

When there is no design requirement, it is 500mm away from the ground

.

3) Note: it is forbidden to connect metal conduit by butt fusion welding; galvanized and steel conduit with wall thickness less than or equal to 2mm shall not be connected by sleeve fusion welding

.

The bending flatness of the pipeline shall not be greater than 10% of the outer diameter of the pipe, and there shall be no wrinkles, pits and cracks at the bending place

.

When the plastic pipe is laid horizontally in the large formwork wall, the distance between fixed points shall not be greater than 0.5m

.

4

.

Specification table of jumper wire 7) protection method of plastic pipe out of the ground note: when laying plastic pipe, the bending shall be reduced

.

3

.

3

.

Construction technology: drawing hole drawing → hole positioning → technical review → hole forming → casing installation 2

.

Quality requirements: all casings shall be flush with the wall, and the one out of the floor shall be 20 mm higher than the floor finish, (toilet and pipe well 50mm) more information, please pay attention to WeChat official account: construction house 4, see effect 3., pipe support and hanger manufacture and installation 1, construction technology: Iron embedded pre positioning, bracket manufacturing, to determine the horizontal height and spacing of supports and hangers, bracket installation and fixing 2, operation points: 1) iron embedded prefabricated hangers: follow the structure construction, and arrange the iron according to the plan

.

4) Note: 1

.

2

.

The outer wall of welded pipe in masonry shall be painted with anticorrosive paint

.

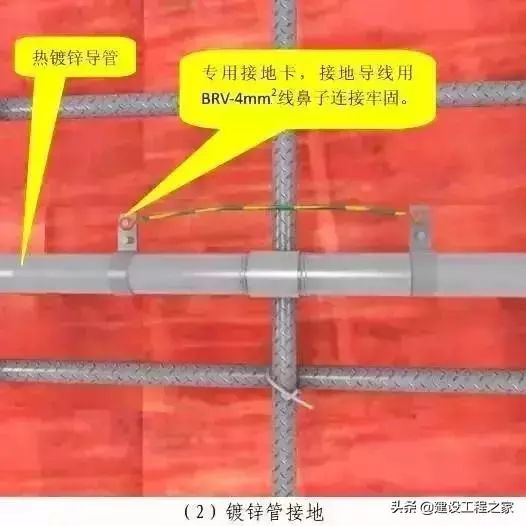

The jumper wire of galvanized steel pipe or flexible metal wire protection tube shall be connected by grounding wire clamp instead of fusion welding

.

When the length of straight section exceeds 15m or the number of right angle bending exceeds 3, the junction box shall be added

.

Lightning protection and grounding 1

.

3) Form of supports and hangers: the structural form of supports and hangers shall be determined according to the pipeline laying form in the design and layout drawing, and shall be processed and manufactured on site or in factory according to the requirements of indoor pipeline supports and hangers atlas

.

Quality requirements: ensure that the hole position and size are correct

.

Waterproof casing embedded 1

.

Welding steel pipe method 1

.

3

.

After the production, the rust shall be removed and two layers of antirust paint shall be applied

.

For more information, please pay attention to WeChat official account: construction house 2, embedded steel conduit for grounding

.

The pipes laid in the reinforced concrete wall and floor should be tightly bound with the reinforcement inside, and the distance between fixed points should not be more than 1m when laid in a straight line

.

The conduit is straight into the box and fixed with special lock nut

.

It is suggested to use common support for centralized pipeline layout, strengthen design optimization and construction planning, see the effect picture: 4

.

Quality requirements: the material, specification, model and structural form of the support and hanger must meet the requirements, the production and welding must be firm, the welding seam must be full and beautiful, the installation and fixation must be firm, and the spacing must meet the requirements

.

Construction technology: construction preparation → installation of grounding device → downlead → equipotential connection 2

.

3

.

The water-proof treatment must be done for the directly buried cable through the wall

.

Construction points: the materials used for lightning protection and grounding must be hot-dip galvanized products

.

5

.

The local equipotential connection in the bathroom shall not be connected with the outdoor PE line

.

The tightening type thin-walled steel conduit grounding wire adopts the matching claw lock nut at the box, and the pipe connection is broken by screwing the set screw

.

For the supports and hangers of special forms or those beyond the atlas, they shall be checked by calculation and made of section steel meeting the requirements to ensure the firmness, safety and reliability of the supports and hangers

.

3

.

6) Seal with temporary cover plate to prevent pollution (other boxes should also be protected in this way).

.

Method of reserving pipe hole and pipe casing 1

.

2

.

5) Note: 1

.

2

.

The coordinates, elevation and spacing of the layout shall be used for positioning and embedding; the horizontal elevation of the support and hanger shall be determined on the embedded iron parts, and the fabricated support and hanger shall be welded on the embedded iron parts

.

The manual grounding device or the grounding device using building foundation reinforcement must set the test point above the ground according to the design requirements

.

2) Note: 1

.

The galvanized steel pipe grounding wire adopts the grounding wire clamp cross connection method; 3

.

The distance between the buried depth of concealed conduit and the surface of buildings and structures shall not be less than 15mm, and the clear distance of conduit used for fire-fighting facilities shall not be less than 30mm

.

4

.

4

.

2) Field expansion bolt fixed support and hanger: the strength and tension of the selected expansion bolt must ensure that the provisions of the pipeline are firm, safe and reliable; the spacing, elevation and coordinate of the support and hanger shall be determined according to the planning layout

.

See the effect picture: 2

.