Professional bidding document making, engineering budget, engineering cost 16 years old brand, for your bidding escort, winning the bid is to give you the best service! Source: the copyright of the network belongs to the original author

.

With the rapid development of the city, urban drainage engineering plays an important role in daily life

.

As the basic drainage pipe network system of the city, it is widely distributed in every corner of the city

.

The construction of drainage pipeline is a systematic project, which is the basis and guarantee for the normal operation of the whole municipal road

.

Due to the increasing demand for urban service system, the quality of municipal drainage pipeline project has become the focus of attention

.

The quality of this project is related to the survival problems of urban waterlogging prevention and prevention of groundwater or soil pollution

.

Therefore, it is of great significance to take effective measures to ensure the construction quality of drainage pipeline engineering

.

1、 The basic composition and construction characteristics of the drainage system of municipal road engineering 1

.

The basic composition of the drainage system of municipal road engineering in the construction of municipal road engineering, in order to fully guarantee the traffic capacity of the road, and further improve the overall performance and service life of the road, it is generally necessary to carry out the design and construction of drainage engineering

.

At present, in the domestic municipal road engineering, the drainage system mainly includes: (1) rainwater well rainwater well is an important part of the municipal road drainage system, which is usually called “water intake”

.

In the construction of municipal road drainage engineering at the present stage in China, the common rainwater wells mainly include eight six rainwater wells, double grate, four grate and eight grate rainwater wells with silt wells, etc

.

their main purpose is to discharge a large amount of water on the road

.

The construction of rainwater wells is generally suitable between lime gravel and black road construction

.

(2) In the municipal road drainage system, the settling well is often constructed at the same time as the rainwater well, which is also an important part of the prefabricated rainwater well

.

Different from the function of the rain well, the main function of the mud well is to deposit or store a large amount of silt and garbage on the road due to the rain erosion, so that the road cleaners can clean up in time, and effectively prevent the drawbacks and problems of road drainage system blockage

.

Generally, the construction of the settling well should be carried out after the installation of the edge stone and the basic leveling of the sidewalk earthwork

.

(3) Cross street drainage pipe is an important connecting pipe in the rainwater well or silt well

.

Its main function is to lead the road water into the drainage inspection well

.

At present, in the domestic municipal road drainage engineering, the selected cross street drainage pipe is mostly concrete pipe, its general specifications are: outer diameter 400-450cm, wall thickness 3-3.5cm, single section length 1-2m

.

Generally, the construction of drainage pipe across the street should be carried out between lime soil construction and lime gravel laying, which is conducive to excavation and trench forming

.

2

.

At present, the construction of municipal drainage pipeline has two characteristics: (1) the construction content of drainage pipeline is complex

.

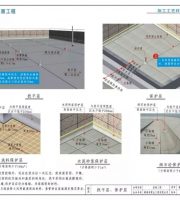

Urban drainage pipeline engineering includes demolition of pavement above the drainage pipeline, excavation of trench, trench support construction, drainage, dewatering, pouring foundation, masonry inspection well and receiving well, pipeline installation, earthwork backfilling, road restoration, etc., with large quantities, and some sub projects are mutually exclusive Therefore, it is necessary to make overall arrangement and coordination in the construction

.

(2) Drainage pipeline construction has a relatively wide range of impacts

.

Drainage pipeline construction has a great impact on urban traffic, original pipelines, normal operation of roads and living environment of residents

.

Therefore, great impacts on traffic and pedestrians should be avoided as far as possible during construction

.

Comprehensive consideration must be given during construction, so as not to affect the normal function of existing pipelines

.

In order to minimize the impact on traffic and improve the surrounding environment, the construction period is generally very short, but the quality requirements are very high

.

It can be said that the construction period is tight, the people are heavy, and there are many units involved in the construction, so the construction management personnel need to do a lot of coordination and organization work, and effectively deal with the relationship between the construction unit and other relevant units

.

2、 A municipal road project is a part of the construction of the urban industrial area project

.

The road is designed as a two-way six lane road with an overall width of 60m

.

The main project content of the municipal road engineering focuses on the construction of roads and various pipeline projects, especially the drainage pipeline construction project technology is more strict

.

In various pipeline projects of the project, the drainage pipe is reinforced concrete drainage pipe

.

2

.

Road drainage pipeline construction technology the first and very core step of road drainage pipeline construction technology is to carry out the measurement and setting out of pre installed pipeline Road, so as to locate the pipeline axis to be installed, and determine the elevation, starting and ending points, the location of drainage outlet and inspection well

.

The accuracy of Surveying and setting out is of great significance to the operation of all process of pipeline engineering construction, which is related to the success or failure of the whole project, and no mistakes are allowed

.

The project uses the rectangular building setting out technology which combines the conventional design drawings with the site, and also applies a large number of theodolite setting out technology, which ensures the accurate setting out measurement by positioning the lead wire with theodolite

.

The backhoe excavator is used to complete the measurement of the installation pipeline line in the excavation of the foundation pit, and the form of temporary stacking is adopted

.

This method is conducive to the good soil excavation construction of the pipeline project and is easy for the later backfill construction

.

When using soil piling measures, it must ensure that the soil is more than 3 meters away from the edge of the foundation pit of the pipeline, and the stacking height is less than 3 meters, which can more effectively ensure the stability of the foundation pit slope of the pipeline

.

When excavating the pipeline foundation pit, the end excavation method is mainly used in the project, and the manual bottom soil foundation operation technology is used to assist with proper manual trimming and cross excavation, and to tamp and level

.

Good foundation pit treatment ensures the smooth progress of pipeline foundation construction

.

The concrete used in this project is mixed by the on-site mixing station and transported by the motor tipper

.

The concrete foundation is 1800 and 1200 respectively, and the label is mainly 10MPa

.

After the concrete is transported to the pouring section, the chute is used to transport the concrete to the pouring site of the foundation pit, and the plug-in vibrator is used to vibrate and compact

.

Then further check the quality of the pipeline materials used

.

The drainage pipeline installation project uses a 12t truck crane to complete the hoisting of the drainage pipeline

.

This hoisting technology realizes the lifting and lowering with care to avoid the damage of the pipeline

.

After the installation, the pipeline cushion should be made in time

.

The pipeline installation engineering must ensure that the pipeline is smooth and straight, and the gradient shall be in strict accordance with the design requirements

.

45 drainage inspection wells are set up in the drainage pipeline project, and all the well walls are 7.5Mpa cement mortar masonry machine-made brick structure

.

Firstly, the location of the inspection well is measured and lofted, and then the concrete well foundation of 10MPa is poured

.

When the strength reaches 2.5MPa, the wall of the inspection well is built

.

The main technical points are the plumpness of mortar, the straightness of shaft wall and the smoothness of mortar joint

.

After the completion of the inspection shaft masonry, use 1:2.5 cement mortar to plaster the internal and external walls of the inspection shaft with a thickness of 20 mm

.

The plaster shall be smooth and polished to avoid cracks or hollowing

.

It is one of the key points of the technology that the steps inside the inspection well are firmly embedded to ensure the accurate position

.

The 20 MPa flat and smooth precast reinforced concrete cover plate is used, and honeycomb and pockmarked surface are not allowed

.

The accurate and stable installation should be based on mortar, and triangular plaster is required at the corners

.

The last step in the construction of drainage pipeline is the construction of drainage outlet

.

Similarly, first measure the positioning and setting out, then use the concrete with the strength of 10MPa to pour the foundation with the thickness of 10cm, manually hang the line technology to build the well wall, and then use the 1:2.5 cement mortar to plaster the inner wall.

.