Professional bidding document making, engineering budget, engineering cost 16 years old brand, for your bidding escort, winning the bid is to give you the best service! Source: the copyright belongs to the original author

.

Introduction of plastering gypsum 1

.

Product description plastering gypsum is a kind of finished plastering gypsum made by factory premixing with high-purity semi hydrated desulfurization gypsum as the main cementing material, adding appropriate amount of additives and inorganic light aggregate

.

It can widely replace the traditional cement mortar for plastering and leveling of internal walls and floors in indoor dry areas

.

The gypsum content in plastering gypsum products shall not be less than 75% by weight

.

After leveling, full batch of putty shall be used before finishing

.

2

.

Scope of application plastering gypsum is suitable for general plastering works of indoor wall and ceiling, except for indoor wet areas such as kitchen and toilet

.

Lightweight plastering gypsum is suitable for plastering and leveling of most base materials (aerated concrete, lightweight partition board, brick, concrete, etc.)

.

The conventional plastering thickness of light plastering gypsum is 6 mm ~ 25 mm, the minimum thickness of plastering finished surface is 6 mm, and the total thickness of ceiling plastering should be less than 10 mm

.

3

.

Product features: 1) high tensile bond strength, suitable for a variety of base, good matching with lightweight wall materials, not easy to empty and crack after construction

.

2) In normal construction environment, there is no need to water the wall in advance before plastering, and the construction environment is obviously improved

.

3) The construction saves materials and labor, and its weight is only half of that of traditional cement mortar

.

4) Fast construction, short final setting time and maintenance time

.

5) The finished surface has high perpendicularity and flatness, and local trimming is convenient

.

6) It can adjust the indoor air humidity, auxiliary insulation and improve the indoor comfort

.

7) It has stable physical properties, good fireproof performance and moisture absorption and drainage function

.

8) Green environmental protection building materials products

.

4

.

Technical index construction technology 1

.

Main appliances: hand held electric mixing gun, ash bucket, batching knife, ash supporting plate, 1.5m aluminum alloy wedge scraper, 2m aluminum alloy square ruler, 50mm aluminum alloy square ruler (for closing at window edge and external corner), trolley, ladder, discharging platform, etc

.

2

.

Working conditions 1) all the structural works have been completed and passed the acceptance

.

2) Working conditions: the site temperature is 5 ℃~ 35 ℃, and the site must be dry and clean

.

3) The construction site should have faucet interface

.

The water pressure is more than 2kg, and continuous water supply can be ensured

.

4) There shall be power interface at the construction site, and each floor shall have at least one dedicated power interface

.

5) Remove the dust, dirt and oil stains on the base surface of brick wall, concrete wall and aerated concrete wall, and repair the missing edges and corners on the aerated concrete surface layer by layer

.

6) All kinds of main pipelines in the floor should be installed

.

The buried depth of electrical junction box shall be suitable for the thickness of leveling layer

.

The grooved pipeline surface shall be repaired and leveled with light plaster

.

7) The pipes shall be installed in advance

.

During the structural construction, the reserved holes on the wall shall be blocked in advance

.

The structural surfaces of the columns, lintels, etc

.

protruding from the wall shall be leveled and the concave parts shall be cleaned in advance

.

8) Prepare the plastering disclosure drawing, determine the Bay / depth and each detail size

.

9) The data of horizontal line, datum line, cross line and room net size are given

.

3

.

Process flow: base wall treatment → paste grid cloth → snap line → make ash cake → punching steel bar → manually put on the wall → trowel → repair → door and window openings and external corners closing → cleaning

.

4

.

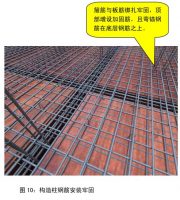

Key points of Construction: 1) base wall treatment; 1) split bolt holes in shear wall should be plugged in time

.

(2) The protruding parts such as expansion formwork concrete shall be chiseled

.

(3) Switch trunking shall be installed in place and repaired with light plaster

.

(4) The dust on the base wall must be cleaned

.

You can clean it with a broom

.

2) Paste mesh cloth (1) 160g / m2 alkali resistant mesh cloth should be pasted at the junction of different base materials to prevent cracking

.

(2) First, light plastering gypsum is applied at the junction of different base materials, and then the pre cut 300 mm wide alkali resistant mesh cloth is pressed into the light plastering gypsum, compacted and smoothed

.

3) Snap the line and make the ash cake (1) first use the laser instrument for positioning, the laser line is overlapped or parallel with the positioning sideline of the wall, and then determine the most prominent point of the wall according to the laser vertical plane, and determine the thickness of the ash cake according to the actual situation of the inspection and the total average thickness of the plastering

.

(2) At the height of 0.8m and 2m from the ground of each wall, and about 30cm away from the internal or external corners on both sides of the wall, make a standard plaster cake with light plastering gypsum, with the thickness of plastering layer, about 3cm square

.

(3) After the standard ash cake is finished, nail the nail in the joint of the brick wall near the ash cake, tie the thin line and pull the horizontal line (the thin line should be about 1 mm away from the ash cake)

.

Then, a number of ash cakes are added according to the spacing of 1.2m ~ 1.5m

.

The horizontal spacing of ash cake should not be more than 1.5m

.

(4) All windows and corners must be made into grey cakes

.

(5) Before punching reinforcement, pull through line to check the construction quality of ash cake, whether it is in the same plane, whether it is vertical, etc

.

The defective ash cake must be repaired in time

.

4) According to the height of the upper and lower ash cakes in the same vertical plane, the blanking bar (1) shall continuously apply light plaster gypsum to the neutral part of the upper and lower ash cakes, and the thickness of application shall be about 3mm ~ 5mm higher than the ash cake surface

.

The light plastering gypsum used for punching reinforcement can not be stirred in a whole barrel at a time, but at most half a barrel

.

It can be stirred many times and used as soon as it is mixed

.

(2) Use a 2m aluminum alloy square scraping ruler (the surface is brushed clean and wetted) to cling to the upper and lower surfaces of the two ash cakes, flatten the light plaster plaster applied to the blank part of the ash cake, scrape off the excess plaster on one side of the aluminum alloy square scraping ruler with a batch knife, and gently push the aluminum alloy square scraping ruler to the other side along the horizontal direction, so that the aluminum alloy square scraping ruler can leave the wet surface of the punching reinforcement and can not be removed The surface of the punch is destroyed

.

(3) The upper and lower ends can be punched at one time, or the upper part can be punched after the lower part is hardened, so as to reduce the difficulty of punching

.

(4) The flatness and perpendicularity of the finished surface of the punching bar must be checked after the punching bar is hardened and before plastering, and the method of guiding rule, line hammer and drawing through line shall be used

.

The defective punching bars must be repaired in time

.

(5) There is a switch or socket in the middle to let out 10 cm

.

5) Do corner protection (1) according to the disclosure, use cement mortar to do door corner protection

.

(2) Before construction, the corner protection parts of doors and windows shall be inspected, and the relevant process personnel or on-site management personnel shall be timely informed of the interface size and other problems

.

(2) In the process of construction, the line hammer should be used to lift straight to ensure that the edges and corners are flat and vertical within the specified range

.

(4) Strictly control the size of door opening and window

.

6) Manual wall (1) the volume ratio of water and light plastering gypsum powder is 1:2, and the weight ratio is 7:10

.

(2) Add water first, then powder

.

(3) The hand-held electric stirring tool shall be used for continuous stirring for not less than 3 minutes, and the manual stirring shall be applied to the wall

.

(4) Manual wall painting must be divided into two times, under normal circumstances, two times of painting can be continuous

.

(5) For the first time, apply and press light plaster vertically from top to bottom

.

It is necessary to press the light plaster on the wall with a steel trowel to make the light plaster firmly stick on the base wall

.

For the second time, apply and press light plaster horizontally

.

The direction of two times of application and pressing must be vertical to ensure good bonding effect between light plaster and base wall

.

(6) When the light plastering gypsum is thick, it can be constructed in layers

.

The second construction can be carried out after the first layer of light plaster is hardened

.

It is suggested that the time interval between two times of construction should be at least 1.5h

.

(7) When the plastering gypsum can not be completed at one time, the construction joint must be plastered into an inclined opening.

.