Professional bidding document making, engineering budget, engineering cost 16 years old brand, for your bidding escort, winning the bid is to give you the best service! Source: the copyright of the Internet belongs to the original author

.

The traditional construction method of windowsill capping can not be carried out simultaneously with the masonry of the wall, resulting in intermittent construction and prone to quality defects such as leakage of concrete forming expansion mold

.

The project Department of Zhengzhou No.1 Construction Group innovates the technology in the case project, and applies a low-cost, easy to operate, high-efficiency and non intermittent construction technology: U-shaped shell type windowsill capping

.

This technology simplifies the windowsill capping construction process, saves the construction period and cost, and improves the construction quality of windowsill capping, which is worthy of your reference

.

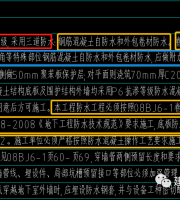

Process introduction: (1) according to the drawing requirements, using BIM Technology to design the windowsill coping U-shaped mold shell, customized processing U-shaped mold shell; (2) according to the BIM layout, masonry the wall to the windowsill coping bottom elevation, then masonry the U-shaped mold shell, and finally masonry the walls on both sides of the window; (3) binding the windowsill coping reinforcement, pouring concrete

.

BIM layout of detail drawing of U-shaped formwork shell this technology is free of formwork, low cost, fast progress, guaranteed construction quality and wide application range

.

Process planning and design of 300 mm U-shaped mold shell, using BIM Technology to design 300 mm U-shaped mold shell, select qualified manufacturers to produce in batch according to the design size, randomly select and check the size of prefabricated block, carry out strength test, meet the requirements, and the quality is qualified

.

Check the size deviation of components, carry out strength detection, masonry installation, masonry wall installation, U-shaped formwork pouring, BIM layout, and on-site disclosure

.

After the completion of masonry, the acceptance shall be carried out, and the elevation of the windowsill of the wall shall be controlled within ± 3mm, and the masonry quality shall meet the requirements; then the vibration and surface closing effect of the windowsill coping shall be inspected, and the sectional dimension deviation of the windowsill coping shall be within ± 2mm, and the vibration shall be dense without cracks, with good appearance

.

Typesetting, masonry wall, installation of U-shaped formwork, binding of steel mesh in components, concrete vibration and compaction, closing of windowsill coping and covering of membrane, confirmation of effect, combined with the existing code acceptance standard, combined with the existing code GB 50203 “code for acceptance of construction quality of masonry structure”, 12yj series Atlas GB 50204 “code for acceptance of construction quality of concrete structure”, according to the site construction technology The acceptance standard was established to check the forming effect of windowsill coping

.

The quality meets the relevant regulations and the established acceptance standards

.

Through the innovation of windowsill coping construction technology, it simplifies the construction process, improves the construction efficiency, shortens the construction period, saves the construction cost, improves the construction quality, and achieves good social benefits

.

Make project budget on behalf of others

.

Settle project budget, settlement, quota, quantity and price, tender preparation (Engineering, procurement and service), construction organization design, completion data preparation, drawing design, house decoration budget and project cost consultation

.

Professional direction: Civil Engineering, installation, municipal, garden, hardcover, steel structure, water conservancy, highway, bridge, electric power, oil

.

Budget of agent project www.yusuanw.com List quota, drawing quantity group price.

.