Many friends mentioned about the broadband construction will use those equipment, today we come to see

.

1

.

Specifications of optical junction box common specifications of front view of optical switch: 72, 144, 288, 432, 576 core (2) base: 288-144 core optical junction box, (15 (+ – 2) cm, with external slope) 2

.

Installation process of optical junction box step 1: site selection step 2: layout of optical fiber tube and embedded bottom frame step 3: installation of concrete base step 4: installation of junction box step 5: layout of tray step 3 Step 6: storage management preset pigtail step 7: external cable introduction step 8: external cable and pigtail fusion step 9: route opening

.

3

.

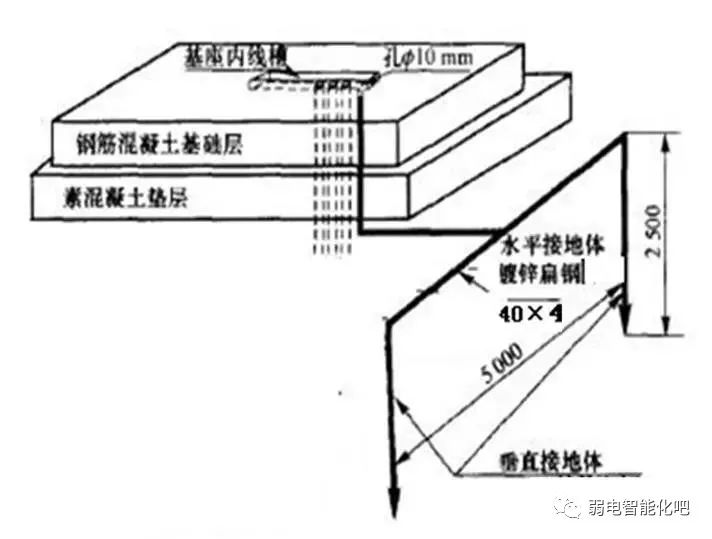

The installation and fixation of the base pouring and grounding outdoor floor type jump free optical cable junction box mainly consists of the laying of the upper pipe and the grounding rod, the pouring of the cement pier, the laying of the inner conduit, and the installation of the box

.

The copper wire above 16mm2 is used for grounding, and the grounding body shall be welded with two pieces (different sides); and the grounding body shall be welded with 40 × 4 grounding flat steel and driven into the underground

.

4

.

Points for attention inside the optical junction box

.

5

.

Construction points of the optical junction box (1)

.

The optical junction box must be placed flat and fixed firmly; (2) the grounding shall be reliable, and the anti-corrosion, anti rust and anti acid treatment shall be carried out; the ground wire of the optical junction box shall be of 16mm * 2 The copper nose should be fixed with screws

.

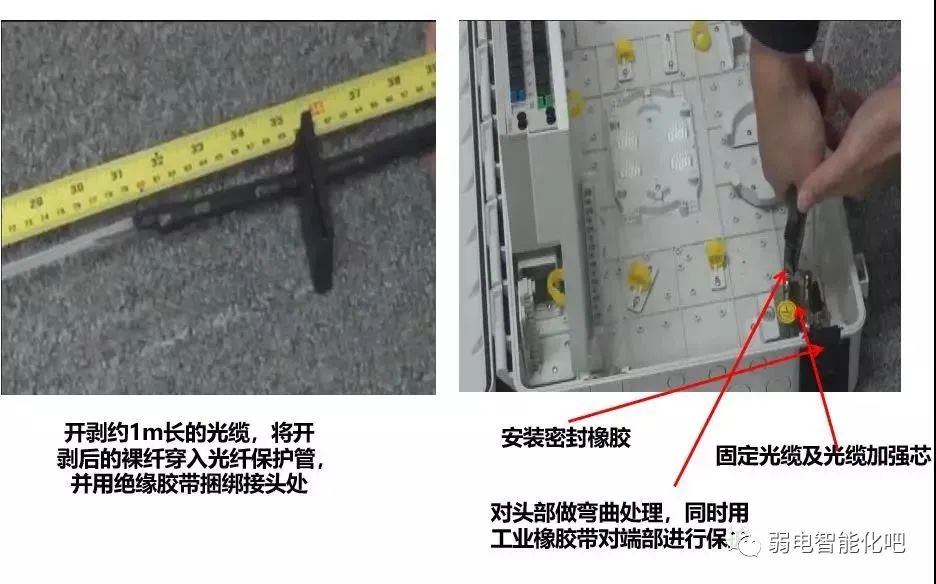

(3) (4) the optical cable must be fixed from left to right in order; the reinforcing core shall be 10-15mm from the center of screw, and the tape shall be uniformly black with the same length; if it is not fixed enough, the black binding tape shall be uniformly used to bind the uniform horizontal plane, which shall be neat and consistent, and the shear opening shall be inward and flat; (5) the distribution optical cable shall be in the fusion fiber distribution In the line integration module, the fiber fusion construction shall be carried out from bottom to top and from left to right; (6) the transition bundle tube shall not be coiled more than half a circle in the integrated module; the transition bundle tube shall have the same radian, and all the fiber transition bundle tubes shall be bound neatly together; (7) the cable inlet hole of the optical cable junction box must be sealed with fireproof clay, and the sealing must be smooth; the optical fiber connection box shall be well sealed The cable junction box shall be waterproof and dustproof, and the optical cable shall be hung in the base; (8) in the integrated module of fused fiber distribution (fused fiber tray), the optical fiber transition bundle pipe in the integrated module of fused fiber distribution must be fixed with small plastic ties; (9) after the completion of the construction, the construction site shall be cleaned, and the inside of the optical fiber shall be clean; the dust cap shall be covered completely, and the color shall be the same; (10) after the completion of the construction, the optical fiber shall be cleaned The panel label must be pasted within three days, and the additional end position must be indicated on the panel label after the completion of the construction; (11) the attenuation of the fiber core in the optical cable test must meet the standard, and those that do not meet the standard must be rectified and repaired on the spot, and the fiber must be aligned to ensure the correctness of the end of the optical cable; (12) the optical cable inlet hole in the optical junction box must be sealed with fireproof mud (13) the remaining optical cables shall not be coiled under the optical junction box, Second, optical fiber separation box and channel 1, optical fiber separation box location n indoor installation requires that the bottom of the box / frame should be 1.2m ~ 2.5m above the ground; n outdoor installation requires that the bottom of the box / frame should be 2.8m ~ 3.2m above the ground; n vertical shaft installation requires that the bottom of the box / frame should be 1.0m ~ 1.5m above the ground

.

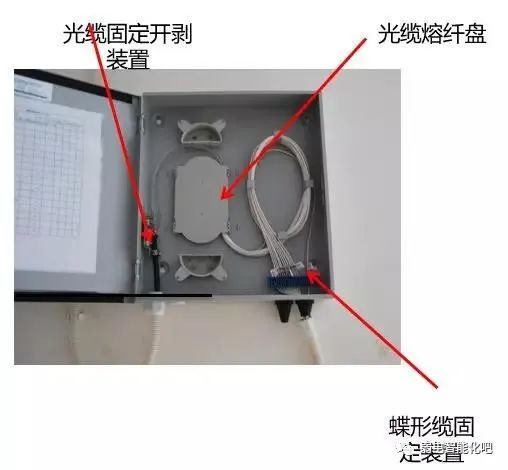

The wall and position of the optical fiber distribution box are direct fusion type

.

The optical fiber distribution box is used in the corridor, weak current well and other places under the primary distribution mode

.

It is mainly used for the fusion of optical cable and home butterfly optical cable

.

The box is equipped with optical cable, butterfly optical cable fixing device and optical fiber disc position, and can stack the fusion discs

.

The box body capacity is 24, 48 cores

.

The installation site shall be constructed according to the design documents

.

Generally, the suitable installation sites such as property equipment room, garage, corridor, shaft and corridor shall be selected as far as possible

.

2

.

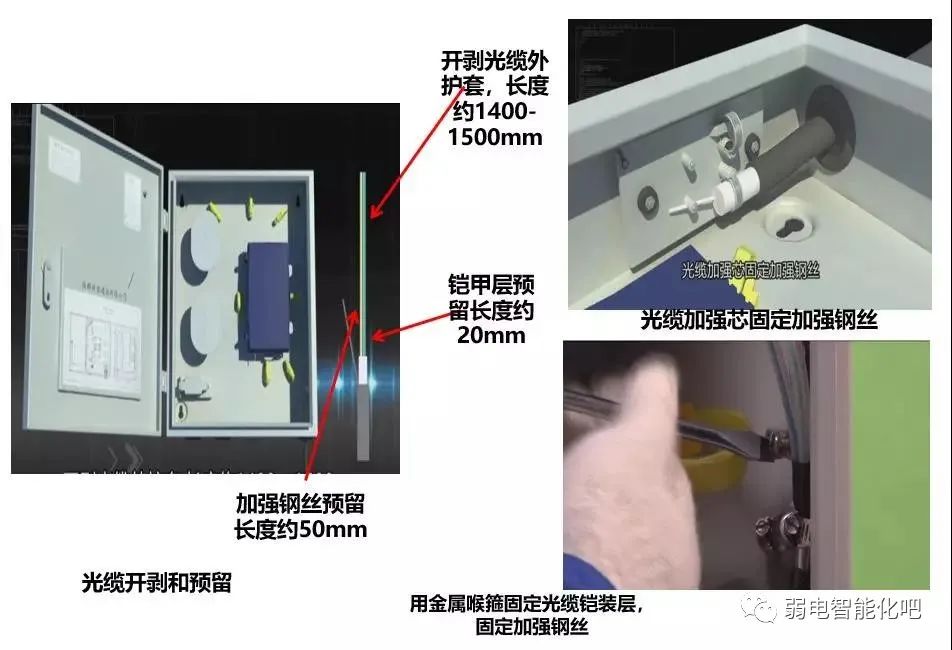

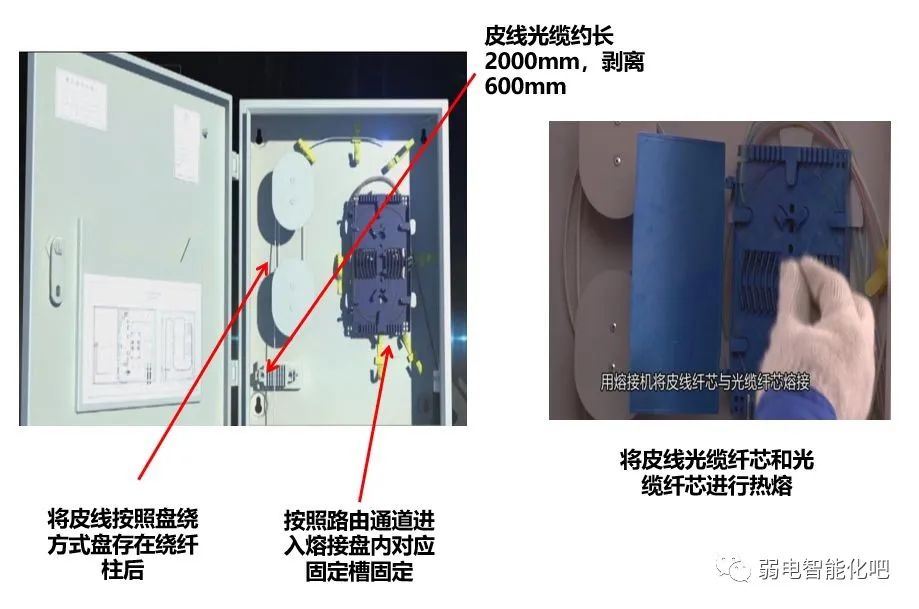

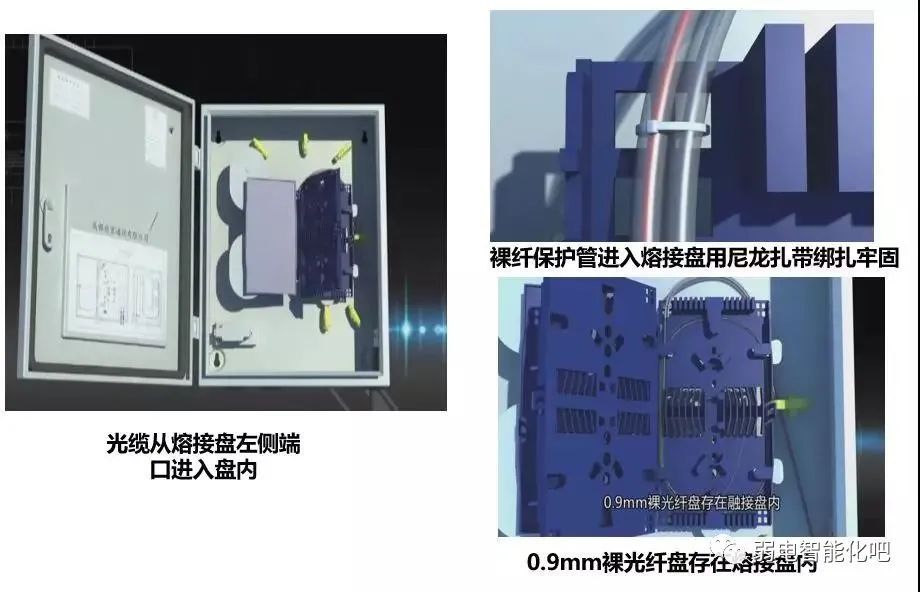

Optical branch box incoming optical cable 3

.

Optical branch box incoming optical cable coil protection 4

.

Optical branch box incoming optical cable box layout 5

.

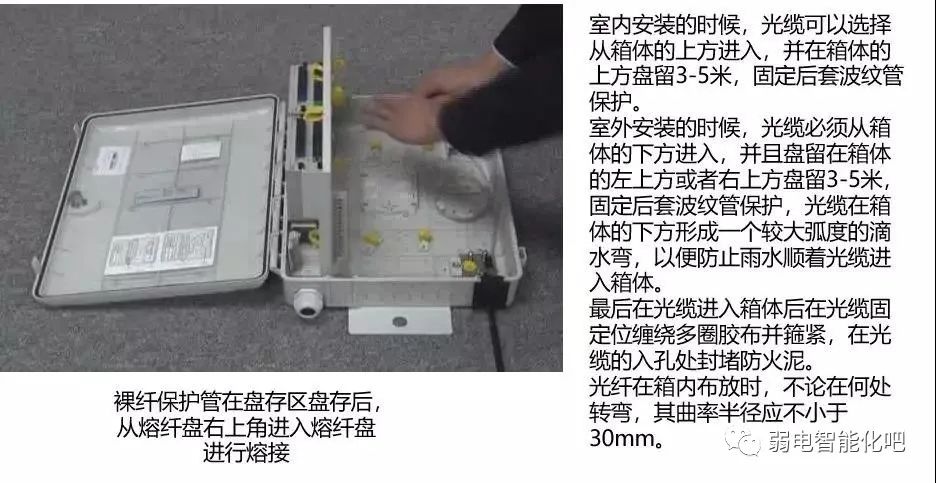

Optical branch box Park optical cable incoming 6

.

Optical branch box Park optical cable incoming 7

.

Optical branch box tail fiber routing process 8

.

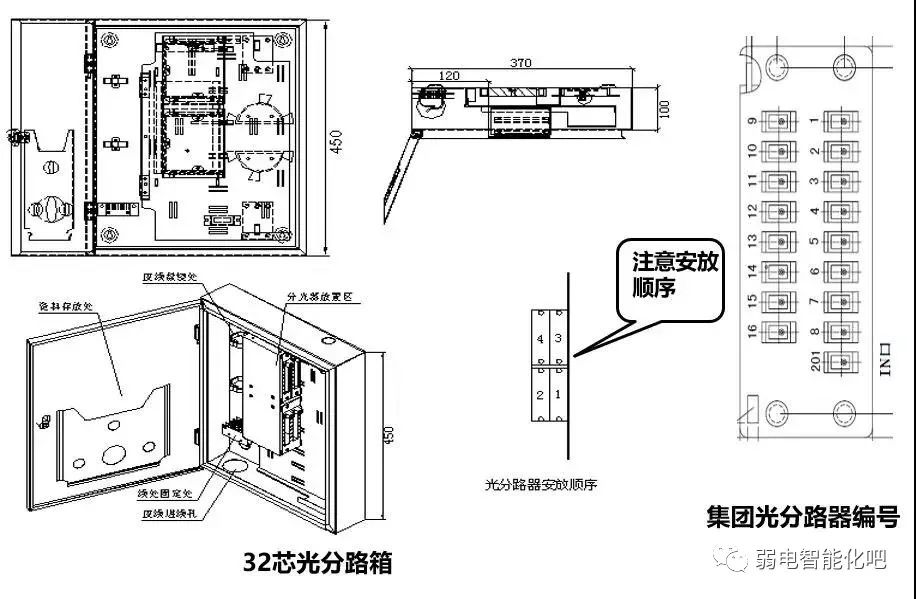

Optical branch box internal coding and placement sequence 3

.

Optical cable layout 1

.

Pipeline optical cable requires optical cable laying in the manhole

.

Pipeline optical cable shall be designed according to the access requirements The middle manhole is required to be reserved

.

The optical cable label shall be hung in the manhole to indicate the specification, program, use and other specific requirements of the optical cable, and the red hose shall be used for protection

.

2

.

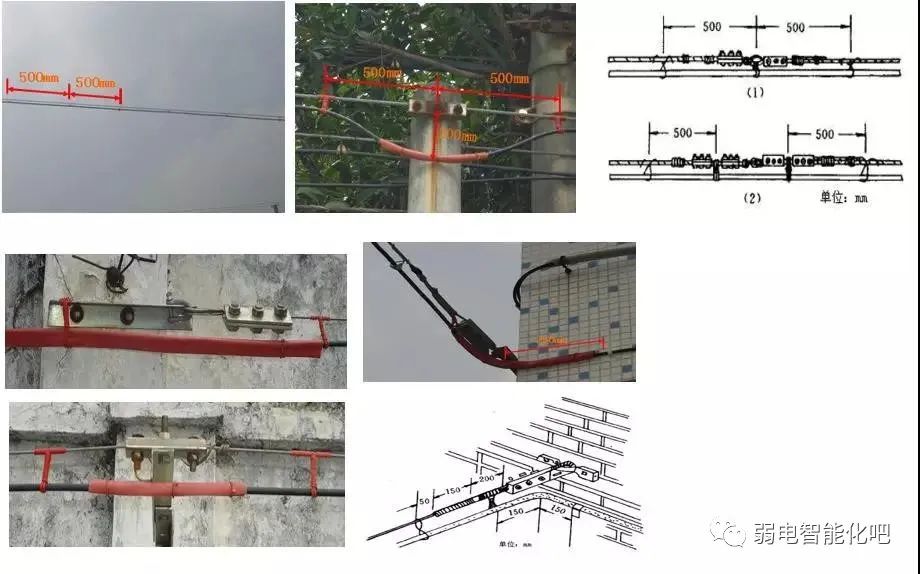

Requirements for overhead and wall optical cables 3

.

The v-optical branching box for corridor wiring should be installed close to the vertical pipeline and convenient for maintenance

.

V in order to facilitate the subsequent wiring, the optical splitter box should be installed in the middle floor

.

V the first choice of vertical pipeline location is the platform close to the user’s door, and the second choice is the rest platform

.

After the vertical pipeline is laid, the floor holes shall be repaired and the polluted wall shall be painted

.

V

.

PVC pipe is preferred for vertical pipe, and a crossing box is added for each layer; plastic trunking is selected for secondary

.

Corrugated pipe is the first choice for horizontal pipe, single hole PVC pipe and plastic trunking are the second choice, and the nailing method of corridor open line should be cautious

.

4

.

Laying of vertical pipeline in corridor 5

.

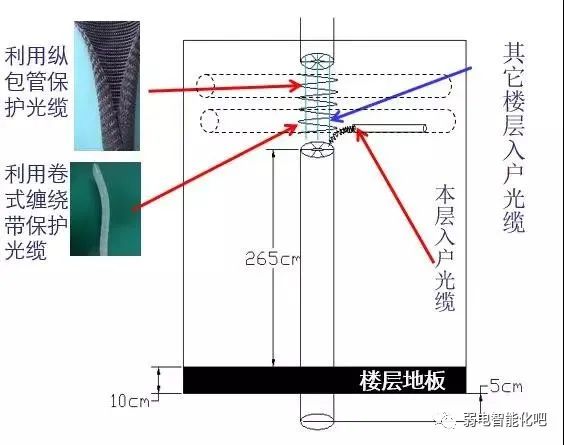

Method of crossing horizontal pipeline: crossing method of flexible protective pipe A

.

It is suitable for crossing horizontal pipeline when Ø 32 porous pipe is used

.

b

.

The perforated pipe is about 5 ~ 10cm above the floor, and the perforated pipe below is laid to the horizontal pipe position, about 2.65m; there is no crossing box between the upper and lower perforated pipes, and the butterfly optical cable on this floor directly diverges to the horizontal pipe, while the butterfly optical cable on other floors crosses the horizontal pipe, with appropriate excess length and protection pipe

.

6

.

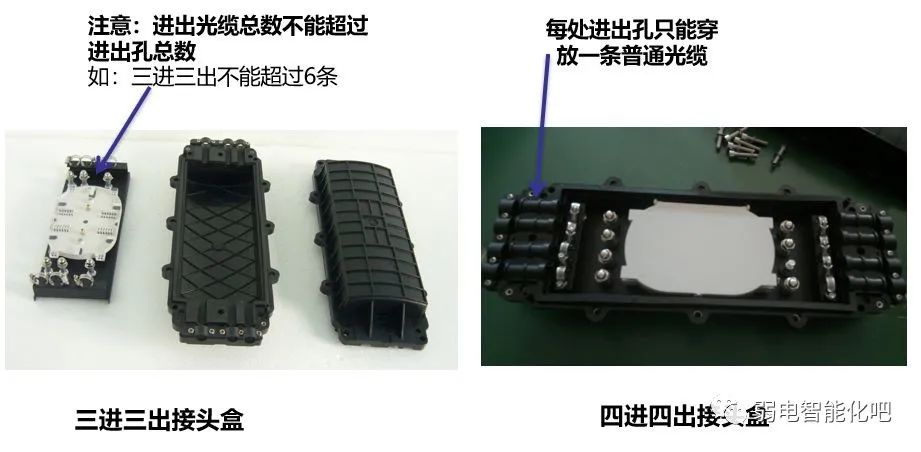

In addition to the common two in and two out, there are also three in and three out and four in and four out joint boxes

.

2

.

The use of joint box five, labels and tags, labels and tags production precautions: 1, for urban residential areas have house number, need to indicate the number section in the point naming

.

For example: residential area no.15-20, Haitang lane, Jingyang District, Deyang

.

2

.

In the equipment naming, only “Dong” can appear, but not buildings and others: do not appear special symbols, such as “” only house number, no district name, to XX district; if “dormitory”, “family area” equipment naming, no district is needed

.

3

.

The installation location of equipment can not be described as one and a half floors, but it needs to be standardized as the staircase from the first floor to the second floor

.

4

.

The label and tag contents include: project name, local end location, opposite end location and port occupation information

.

About the author, about the project cooperation and about the communication group, I am the author of weak current Lao Wang, a weak current migrant worker

.

The main occupation is the construction and maintenance of intelligent weak current, and the official account of the spare time operation

.

We have a professional weak current construction team to undertake the construction and maintenance of generic cabling, monitoring, access control, visual intercom, pedestrian and vehicle gate, video conference, public broadcasting [background music], five party intercom, smart home, computer room engineering in Hefei

.

The price is reasonable

.

If you need intelligent construction or maintenance, please add my WeChat friend 258770256, friends apply for “weak intelligent”, and attach “company + name scan”

.

Please pay attention to our official account: weak current intelligence.

.