As an electrician, lighting wiring is one of the most common jobs

.

There are many kinds of materials used in wiring

.

Today, I have learned a lot from a Chinese electrician who works in Japan

.

Now I will introduce to you a kind of material “wire binding adhesive” used by Japanese electricians when they are laying wires indoors

.

It is suitable for concealed works

.

In Japan, when using sheathed wires on the ceiling, there is no need to wear wire tubes for protection

.

“Wire binding adhesive” needs special quick drying adhesive to achieve the desired effect

.

It can be used in concrete surface, metal surface, wood surface, etc

.

Usage: after the quick drying adhesive is applied on the “wire binding adhesive”, please stick it on the concrete wall in two minutes

.

It takes 30-60 minutes to harden under the environment of 23 ℃ and 50% humidity

.

The data is only for reference, after all, it is related to the construction environment and the adhesive contact surface

.

Please keep it out of the reach of children, away from direct sunlight as far as possible, at room temperature of 5-35 ℃ and in a ventilated place

.

As long as it is opened for use, in principle, it should be completely used up at one time

.

If it is not used, please wrap it with tape at the sealing place and keep it

.

“Wire binding adhesive” is composed of two parts

.

The gray square panel is 30mm in length and width

.

There is a thin concave convex layer on the surface

.

The Yellow binding tape is about 100 mm long

.

There should be wire inside and insulating material outside

.

The amount of quick drying glue applied should be just right

.

If there is more waste, it will fall down if there is less

.

At the same time, it depends on whether the binding wire is weak or strong, and whether one or more wires are connected

.

“Wire binding adhesive” is the Chinese name given by this electrician friend

.

After consulting some electrician friends, they said that they have never seen this material in China, and there is a similar method of using it inside the distribution cabinet, but they have not seen the one to bind and fix wires during wiring

.

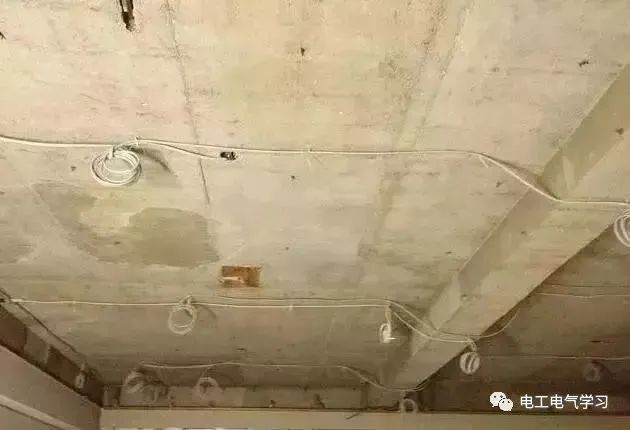

Have you ever used it for indoor wiring? The following is a specific introduction to you with examples! Usually, the electrician will go ahead and tie the wires to the top of the concrete ceiling when wiring, so that the later will not interfere with the construction of other workers and will not rework

.

The distance between strong and weak current wiring should be at least 150 mm

.

In the figure above, all the wires are weak wires, which are used for fire alarm (milky white), two kinds of network wires (blue, gray and yellow), telephone wire (gray) and TV signal wire (black)

.

Under normal circumstances, the weak wire outside the fire alarm sensor (installed on the ceiling) should be the ground wiring

.

However, many of the electrical modification projects are added, and the location has changed, so the wire goes above the ceiling

.

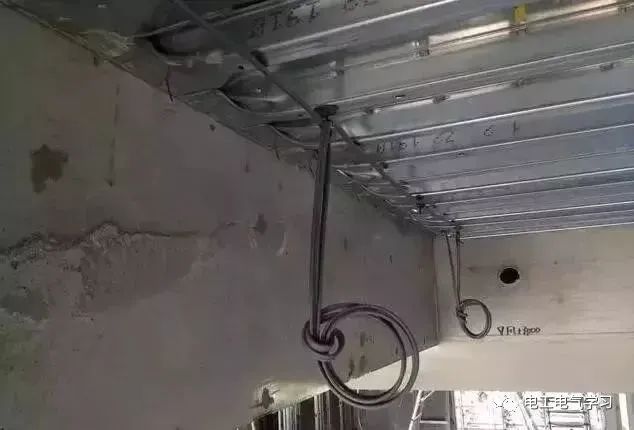

In the picture above, the lower right corner is the cable tray installed by electricians this time

.

The Yellow hook hanging on the screw rod and the small gray clip are also the materials often used in wiring

.

The binding distance of wires is one meter

.

According to the number and total weight of wires, the distance can be reduced appropriately, such as about 800 mm

.

This does not need a ruler to measure, more wires have a sense of falling, you can add a binding adhesive in the middle

.

When wiring, if you encounter the corner of the beam, please leave more wires and bend them by hand to make a shape

.

Do not let the wire directly contact the concrete corner of the beam, it is easy to break the wire when shaking violently

.

“Wire binding adhesive” can also be used on concrete walls

.

The above picture shows a metal ceiling, and its upper layer is a poured concrete floor

.

This structure has gradually become popular in Japan in recent years

.

The angle of this shot is not very good

.

Xiaobian wanted to show you that the wire didn’t touch the concrete corner

.

In this case, if it is possible to contact, a black special adhesive tape will be pasted at the corner

.

It is thick and smooth, which can reduce friction and protect the wire

.

This is also one of the inspection items during acceptance

.

Three bathrooms will be built in this corner

.

After the formwork is removed, the electrician is the first type of work to enter the construction site

.

Before other workers come in, the wires have been pulled almost

.

The advantage of electrician wiring first is that there is no obstacle and the work can be completed quickly

.

However, as shown in the scene above, the light steel keel should be plastered to the top and be soundproofed

.

Before plastering the plasterboard, the electrician can’t pull the wire, because it will be cut because of the obstruction

.

This kind of situation should be grasped in advance in the embedded stage

.

If there are wires between the two rooms separated by the light steel keel that need to pass through, according to the number and position of wires, the wire tube should be reserved in the ground, so that the wiring in the later stage is much more convenient

.

When wiring, generally draw the position of lighting and other appliances on the ground, and then paste wire binding adhesive above the corresponding position

.

After half a day or so, you can pull wire binding, and then add several adhesive stickers at the position with long distance

.

When wiring, the length of the wire should be determined according to the height of the ceiling, which is usually about one meter longer than the ceiling

.

I don’t know how long do you reserve for domestic peers? Wire should be tied up and put up about 300 mm, too low will affect the work of the ceiling

.

Meet someone and cut your wires

.

After wiring, the outline of the light steel keel came out, waiting for the plumber to finish, and then plasterboard and ceiling can be pasted

.

In Japan, electricians only do electrician’s work, and the plumber does the water pipe

.

Water and electricity are completely separated

.

The pink coating is styrofoam

.

When the other side of the wall is outdoor, the wall needs to be sprayed with Styrofoam

.

The thickness in the figure above is 25 mm

.

The foreman should master this situation well in advance, and make sure that the binding glue used for electrical wiring is well pasted before the foaming glue is erupted

.

If he forgets, it will increase a lot of work, and the surface of the foaming glue can not be pasted

.

“Wire binding adhesive” in normal room temperature environment, with special quick drying adhesive, a adhesive can bear 2kg

.

For 2.0 mm * 3-core sheathed wires, the maximum binding amount of one adhesive is no more than four

.

Japan has been using it all these years

.

It will not fall down if it is done according to the requirements

.

Excerpt from the network, please delete the infringement

.

Scan QR code, pay attention to our shared technology world ~ ~.

.