Duct production: 1.1 duct material: metal (galvanized steel, stainless steel…) Nonmetal (PVC, FRP, Mg, etc.) Composite material (non combustible material surface composite insulation material board: phenolic, aluminum foil centrifugal cotton…) Building air duct

.

1.2 smoke exhaust duct: the body, frame, fixing material and gasket material must be non combustible material

.

The thickness of steel plate air duct shall be selected according to high pressure system, and the inspection and detection shall be conducted according to medium pressure system

.

1.3 composite materials: the cladding materials must be non combustible materials, and the internal insulation materials shall be non combustible or flame retardant B1 grade materials, which are harmless to human body

.

1.4 type of air duct system: low pressure: P ≤ 500pa; medium pressure: 500pa < P ≤ 1500pa; high pressure: P > 1500pa dust removal system: (thickness selection of steel plate air duct) 1.5 composite material: the covering material must be non combustible material, and the internal insulation material shall be non combustible or flame retardant B1 grade material, which is harmless to human body

.

Duct components: 2.1 the flexible short pipe of smoke control system must be made of non combustible materials

.

2.2 the flexible short pipe shall be made of anticorrosive, moisture-proof, airtight and non moldy flexible materials, and the measures to prevent condensation shall be taken for the air conditioning system

.

2.3 generally, the length of flexible short pipe should be 150 ~ 300 mm

.

2.4 flexible short pipe should not be used as reducing connecting pipe for alignment and leveling

.

2.5 the length of the flexible short pipe set in the structural deformation joint should be the width of the deformation joint plus 100 mm or more

.

2.6 for the connection of air outlets, the external decorative surface shall be flat, the distribution of blades or diffusion rings shall be uniform, the color shall be consistent, and there shall be no obvious scratch and indentation

.

Installation of air duct system: 3.1 when the air duct passes through the fireproof and explosion-proof wall or floor that needs to be closed, the pipe or protective sleeve shall be embedded, and the thickness of the steel plate shall not be less than 1.6 mm

.

The air duct and protective sleeve shall be sealed with non combustible and harmless flexible material

.

3.2 air duct support: the distance between supports and hangers shall be less than or equal to 400mm, not more than 4m, greater than 400mm, not more than 3m; the distance between supports and hangers of thin steel plate flange air duct shall be not more than 3m

. ![]()

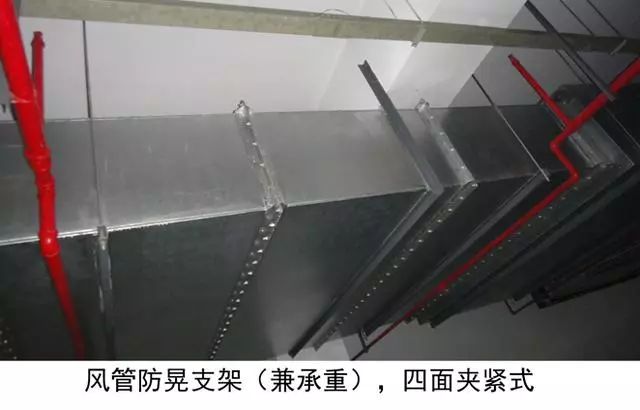

3.3 anti sway support of air duct: when the length of main and main pipes is not more than 20m, fixed points shall be set to prevent swinging, and each system shall not be less than 1

.

3.4 when the diameter or big side of fire damper is larger than 630mm, independent supports and hangers should be set

.

3.5 the connecting flange nuts of air duct should be on the same side (with the same orientation), the flange gasket should meet the system function requirements, the thickness should not be less than 3mm, and the gasket should not protrude into the air duct or protrude out of the flange

.

3.6 the length of flexible metal or non-metal air duct should not exceed 2m, and there should be no dead bend or collapse

.

Installation of ventilation and air conditioning equipment: 4.1 foundation screws of floor equipment; anti corrosion of screws

.

4.2 shock absorption of fan (smoke exhaust and air exhaust) 4.3 protective cover (net) or other safety facilities must be installed at the exposed parts of fan transmission device and the inlet and outlet directly to the atmosphere

.

Air conditioning water system pipeline and equipment installation: 5.1 groove type connection pipe support, hanger setting (spacing, principle) p65

.

5.2 maximum spacing of steel pipe supports and hangers p665.3 gas and pressure test: (time and pressure) valve strength and tightness test; fan coil unit; pipeline system (zoning and layering; system) 5.4 pressure gauge assembly 5.5 the connecting pipe between pipeline and water pump and water chiller must be flexible interface, flexible short pipe shall not be forced to be connected, and the connected pipeline shall be provided with independent support

.

5.6 the steel casing of the pipeline shall be flush with the decorative surface of the wall, and the casing through the floor shall be 20 ~ 50mm higher than the finished surface

.

5.7 equipment shock absorption and anti displacement

.

Anti corrosion and heat insulation: 6.1 the construction of air duct and air conditioning equipment heat insulation engineering shall be carried out after the system tightness inspection is qualified

.

6.2 the pipeline insulation construction of air conditioning project shall be carried out after the system strength and tightness test is qualified and the anti-corrosion treatment is completed

.

6.3 the anti-corrosion treatment of supports and hangers shall be consistent with that of air pipes or pipes, and the surface mounted parts must be coated with finish paint

.

6.4 thermal insulation material: non combustible or refractory, and its material, density, specification and thickness shall meet the design requirements

.

6.5 non combustible materials must be used in the following situations: air duct and insulation layer 800mm in front of and behind the electric heater; air duct, pipeline and insulation layer 2m on both sides of the fire partition wall

.

6.6 construction method of adhesive fixation

.

6.7 construction requirements for fixing insulation nails

.

6.8 construction of metal protective shell

.

Statement:

.