In winter, when the temperature is low, some details should be paid attention to in the plastering construction of interior wall in many areas

.

The construction effect is better when the environment and base temperature are above 5 ℃ within 24 hours

.

Winter construction should pay attention to the following matters: 01 take thermal insulation graduationseason, deal with raw materials, mechanical equipment and workplace, take thermal insulation and antifreeze measures

.

If the light plastering gypsum is frozen at 0 ℃ or below, it cannot be used

.

02 storage requirements: plastering gypsum of graduationseason is easy to be moistened and caked

.

Antifreezing measures should be taken during storage, and the storage temperature should be higher than 5 ℃

.

The unloading and handling shall not be wet by rain and snow, and the storage shall be padded up with damp proof cloth; the transportation in rainy days shall be avoided as far as possible

.

Plastering, gypsum, ready mixed mortar and other materials shall be placed indoors in advance

.

03 it is forbidden to construct graduationseason on the frozen base

.

Before plastering, the doors and windows should be sealed and maintained, and the indoor environment temperature should be kept above 5 ℃

.

Construction on frozen base is not allowed

.

Heating measures can be adopted, but the wall should not be baked directly, and the indoor humidity should not be higher than 70%

.

04 do a good job in testing graduationseason

.

In the process of construction, a special person shall be assigned to test the weather, indoor and outdoor temperature and humidity, and the temperature of light plastering gypsum out of the machine every 4 hours, and make records

.

The construction time should be “start late and finish early” as far as possible

.

The construction should be concentrated in the relatively high temperature time of the day, and sufficient hardening time should be reserved, so as to avoid the quality hidden danger caused by the freezing of the dry plastered wall! 05 apply evenly

.

Graduationseason interface agent can be used only after fully mixing

.

Roll coating should be uniform without missing coating

.

During construction and drying, the temperature of continuous environment and wall base should not be lower than 5 ℃

.

It is recommended to select the time of high relative temperature in a day for centralized construction and reserve sufficient drying time

.

06 use water to clean graduationseason light plastering gypsum

.

When mixing, ensure that the water is clean

.

It is strictly forbidden to use water with ice

.

Ice water mixture is likely to cause serious consequences

.

According to the construction progress, a small amount of cement should be mixed, and the mixing time should be 1-2 minutes longer than the normal temperature, so that the plastering gypsum can be better dissolved and dispersed evenly

.

Due to the low temperature, the setting time of light plastering gypsum may be shortened, the mixed slurry must be used up as soon as possible, and it is forbidden to add water after thickening

.

07 avoid wind blowing during construction and maintenance of graduationseason

.

During the setting and hardening period, the plastering layer shall be protected from sun exposure, water flushing, impact, vibration and freezing, and the protection and maintenance measures shall be taken to ensure that the plastering layer has sufficient strength

.

08 timely clean up the residual pipeline

.

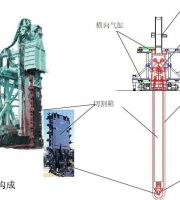

After using the graduationseason spraying equipment, open all drain valves to prevent frost damage, and timely remove the residual light plaster in tools, equipment, hopper, spray gun and pipeline..

.