Pay attention to the WeChat official account of builder, add by two-dimensional code

.

In order to further promote high-quality management, low-cost operation, and promote the overall improvement of the company’s quality development, the fourth company of China Construction Eighth Bureau has formulated the “company’s new technology promotion management measures” in combination with the requirements of the company’s “2 + 5” plan implementation plan, a wave of new technologies, new processes, and new materials with high efficiency, high cost, good quality, safety and reliability , new equipment and other hard core “four new technologies” applications are coming! Pain points of aluminum alloy formwork: traditional wood formwork is light in weight, low in price, but not durable, with low reuse rate; steel formwork has high strength, high reuse rate, but heavy in quality and high in cost; plastic formwork is not afraid of water, low in cost and durable, but with insufficient strength, easy to expand

.

Advantages: aluminum alloy formwork has obvious comprehensive performance advantages over the above types of formwork: first, aluminum alloy formwork has good concrete appearance and high product quality; second, aluminum alloy formwork has short construction period; third, aluminum alloy formwork is light and flexible, and does not need any mechanical equipment; fourth, aluminum alloy formwork technology is energy saving and environmental protection, and will not cause on-site pollution; fifth, aluminum alloy formwork The comprehensive use cost is low

.

Scope of application: in principle, aluminum alloy formwork must be used in residential projects with shear wall structure of more than 20 floors of standard floor, and other projects with height or structural form can be selected according to the actual situation

.

Application demonstration projects: Qingdao Ligezhuang, Qingdao Lantian apartment, Qingdao Jinsha Yuefu, Hefei Hexiang garden, Jinan Binhe Xinyuan, etc

.

Advantages of coiled scaffold: coiled scaffold is a new type of scaffold

.

The vertical pole is connected by sleeve socket, the horizontal pole and inclined pole are connected by end buckle joint and locked by wedge bolt, forming a flexible support structure system combined by multiple modules, which can not only ensure the overall stability of formwork support, but also realize the flexibility and stability of external frame and bent structure Safety, compared with the traditional fastener steel pipe scaffold, the socket type plate buckle scaffold is not only quick to set up and disassemble, but also has a significant lead in safety, bearing capacity, stability, economy, environmental protection and beauty

.

The application of socket type turnbuckle scaffold not only improves the work efficiency, the working face is orderly, reasonable, easy to plan, and the site appearance is beautiful, but also as the surrounding auxiliary materials, its actual utilization rate and management efficiency are high

.

At the same time, it improves the site safety and civilized construction level, which can not only meet the requirements of safety structure, but also ensure the progress demand

.

Scope of application: it is necessary to popularize the application of coil type scaffold in the high formwork support area of public construction projects and the external scaffold of public construction projects below 50m, and the external scaffold over 24m shall be demonstrated by experts in advance to ensure it can be used

.

Application demonstration projects: Central Academy of fine arts Qingdao Campus, Zhenjiang tal, Weihai Wanda, Jiaozhou Haier plant project, etc

.

Plastering gypsum pain point: at present, the plastering materials used in the plastering process of concrete interior wall and ceiling in China are generally mixed mortar and lime mortar

.

The main disadvantages of this process are large drying shrinkage, poor adhesion, complex process and low labor productivity

.

Moreover, the concrete mortar has strict requirements on the base treatment and the mortar strength of each layer

.

Once one of the links is not strictly controlled, it will lead to the common quality problems such as hollowing, cracking, wall bubbles, flowering, whitening and so on

.

When the putty powder is directly used for leveling construction, the secondary construction technology is easy to be aged, and the super thick parts are easy to crack and fall off

.

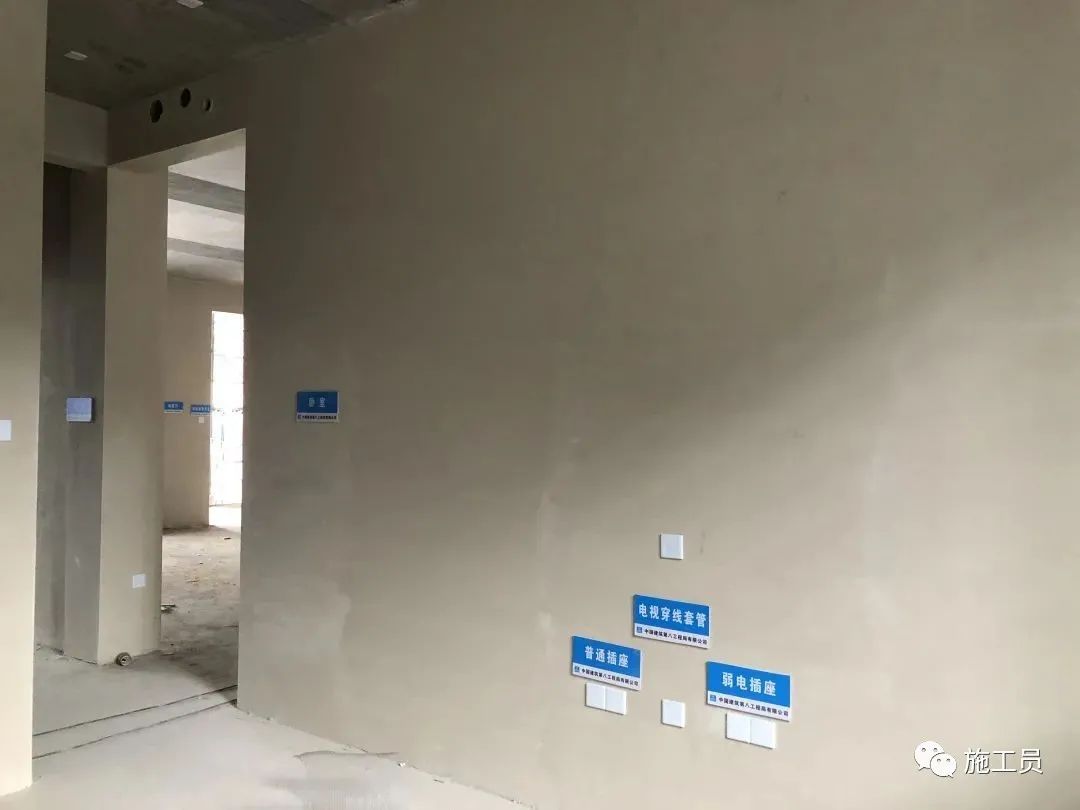

Advantages: now the company popularizes the application of plaster plastering

.

Compared with the traditional plastering process, the construction process has the advantages of fast condensation, fire prevention, heat preservation, sound insulation, adjusting indoor humidity, no hollowing, no cracking, firm bonding with the base, smooth and delicate surface, convenient construction operation, short construction period, high efficiency (10 times of the traditional plastering process benefit), etc

.

Scope of application: plastering gypsum should be used for indoor plastering walls of residential projects (except for no plastering, thin plastering and water room in kitchen and bathroom)

.

If the design is ordinary plastering, the project department must actively communicate with the designer and the owner to change the design practice

.

Advantages of steel bar NC processing: NC steel bar processing equipment adopts intelligent NC system with high man-machine affinity, which processes the required steel bar according to the preset program

.

NC steel bar processing technology has high precision, which fully ensures the precision of steel bar’s sizing, straightening, cutting and bending hoop

.

It has the characteristics of high one-time bending qualification rate, and the energy consumption will be greatly reduced, so the corresponding advantages are achieved The equipment process layout is reasonable, which can save time, labor, materials and land, and has great application value

.

Scope of application: full automatic CNC steel bending hoop machine instead of traditional manual and semi mechanized production mode

.

Advantages of JS composite insulation board for basement waterproof wall: JS composite insulation board is used for basement exterior wall facade waterproof protective layer

.

JS composite insulation board is made of cement pressure board and benzene board through adhesive molding to form a whole, which becomes an integrated external wall insulation board, with the advantages of saving work efficiency, energy saving and environmental protection

.

Application scope: JS composite insulation board must be used for the waterproof protective layer of basement exterior wall facade

.

Through the new technology, the promotion and application of the engineering quality, the improvement of the engineering efficiency, the reduction of the construction period and the construction safety will help the eight bureau to implement the brand strategy and enhance the core competitiveness of the enterprises in the four Bureau of the four Bureau, and promote the transformation and upgrading of enterprises

.

The first and second registration examinations in 2021: the official account platform provides the most complete and professional guidance materials for the first and second construction projects: 1, 2021, Second, the construction of various subjects examination materials, exercises, real papers

.

2

.

In 2021, the first and second construction of video courses in various subjects, including intensive lecture, sprint, quiz class, pre exam simulation paper, quiz paper, blue book, the last three pages and other materials

.

3

.

Charging system: 100 yuan / section for the first and second construction materials! Welcome to consult, please add Xiaobian wechat: hailun6818 “or scan QR code Xiaobian to pull you into the examination group

.

Note: test category, such as No.1 building / No.2 building / fire protection..

.