Pay attention to the WeChat official account of builder, add by two-dimensional code

.

The reinforcement process is an important process to ensure the safety of the main structure

.

The construction process ensures that the raw materials are qualified and the re inspection is qualified

.

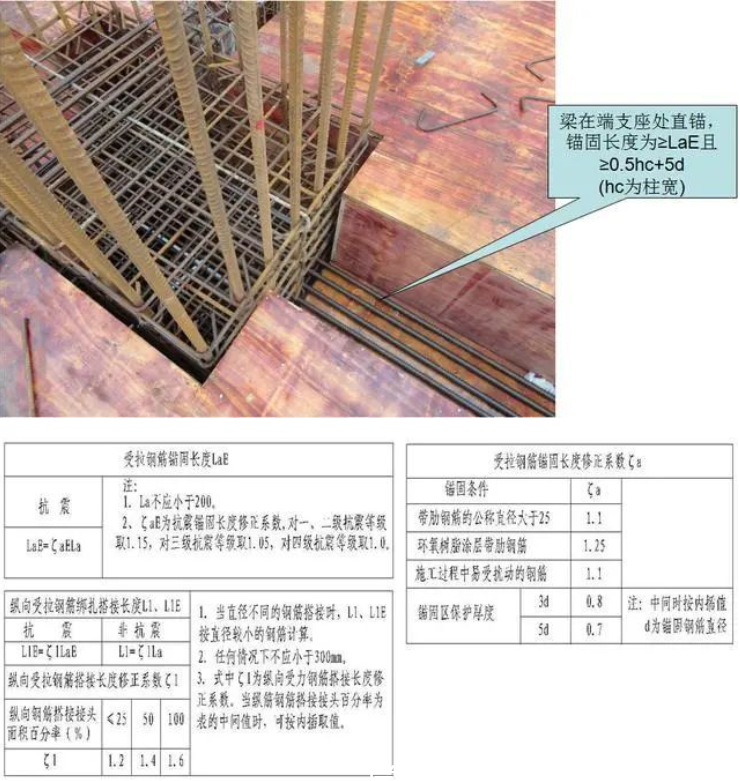

The anti-seismic requirements, connection and anchorage of the reinforcement meet the specification requirements

.

The specification, model, spacing, quantity, thickness of protective layer, manufacturing and installation sequence and position of the reinforcement are consistent with the design requirements

.

The binding is firm, in place and horizontal Vertical

.

Material selection, inspection and re inspection 1

.

When steel bars enter the site, information shall be provided: metal tag (brand, model, specification, weight, ex factory date, etc.), certificate, heat number, inspection certificate, etc

.

2

.

All incoming steel bars must pass the re inspection before they can be used in the project

.

Each inspection lot shall be composed of steel bars of the same brand, furnace and tank number and of the same specification with a weight of no more than 60 tons

.

3

.

Appearance quality: mainly refers to the reinforcement surface shall not have cracks, scars and folds; surface bump shall not exceed the height of transverse rib; other defects shall not exceed the allowable deviation range

.

Reinforcement construction technology (1) technical preparation 1

.

Be familiar with construction drawings, relevant specifications and atlas

.

(1) Before making the material list, discuss with the technical director, the construction director, the quality director and the construction manager on the principle of material list making; (2) ask in writing about all the unclear parts on the drawings

.

2

.

The material list must be clear and accurate, and a complete set of material list shall be submitted to the project department for review and filing according to the construction progress and filing requirements

.

3

.

Cooperate with project department to put forward material plan

.

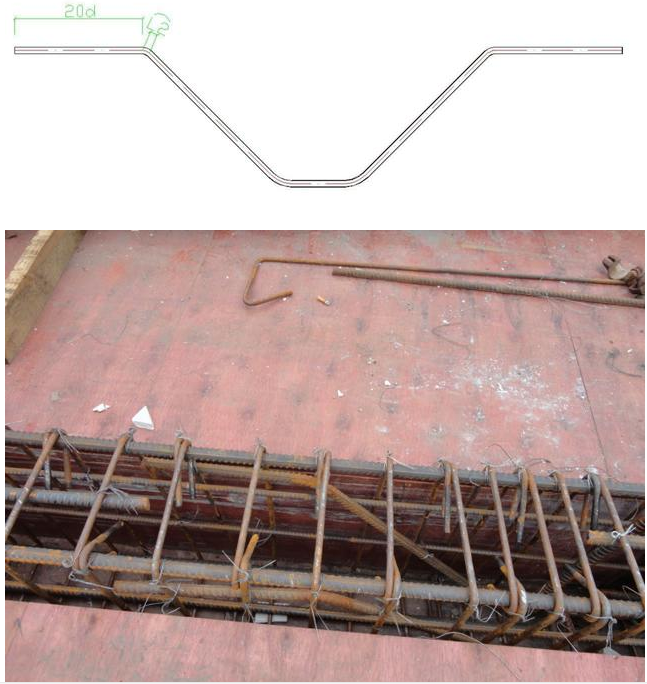

Common data (1) 20d (straight length of suspension bar) the external length of suspension bar hook is 20d, and the diameter and number of suspension bars are marked by the design

.

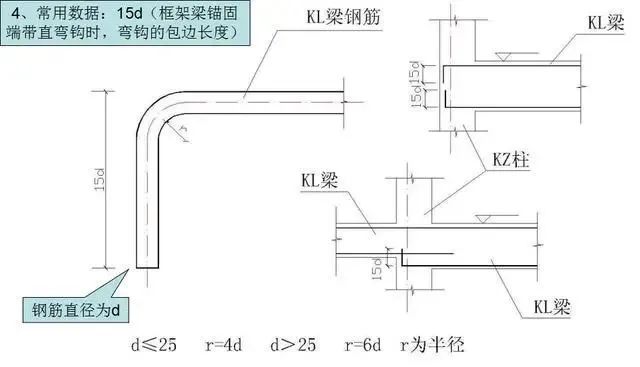

(2) 15d: 1) when the anchorage end of the frame beam is equipped with a straight hook, the wrapping length of the hook

.

2) When the anchor end of ll beam is equipped with straight hook, the length of the edge wrapping of the hook

.

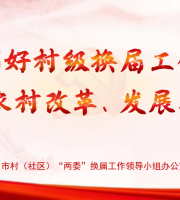

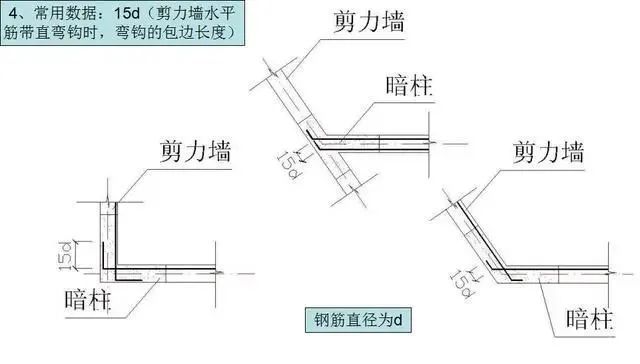

3) When the horizontal reinforcement of shear wall is provided with straight hook, the length of the edge of the hook

.

4) The length of the waist bar of the beam structure and the lower bar of the cantilever beam entering the support

.

5) When the anchorage end of the slab (including the negative reinforcement of the terrace) is equipped with a straight hook, the wrapping length of the hook

.

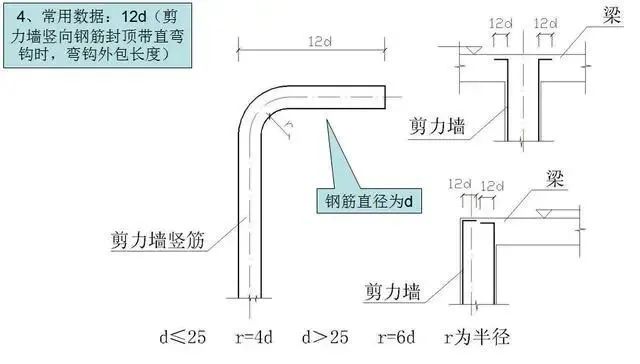

6) The thickness of protective layer of wall foundation joint bar is less than 5D or the anchorage length is less than Lae (LA), and the binding length of joint bar hook

.

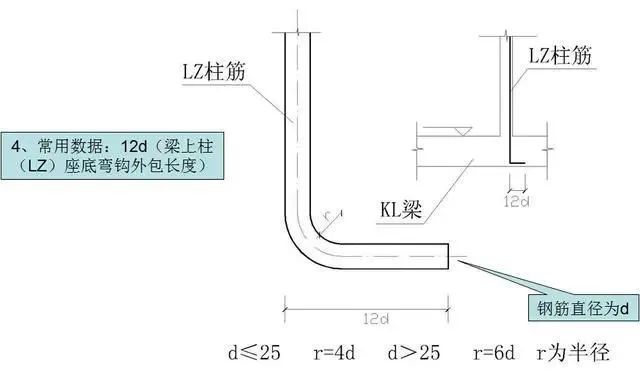

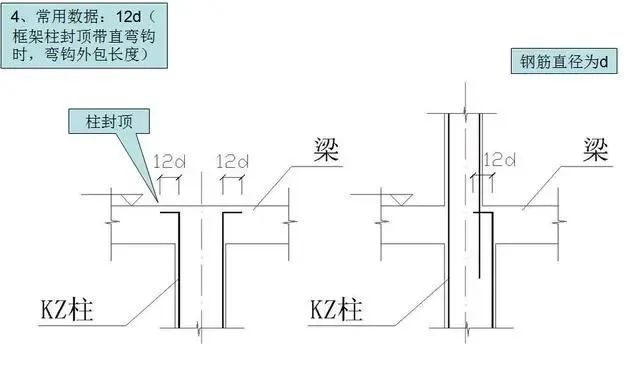

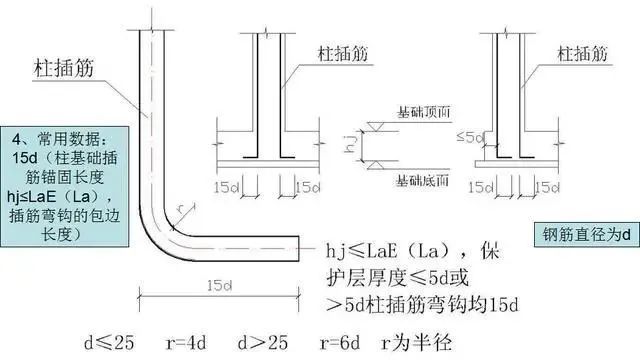

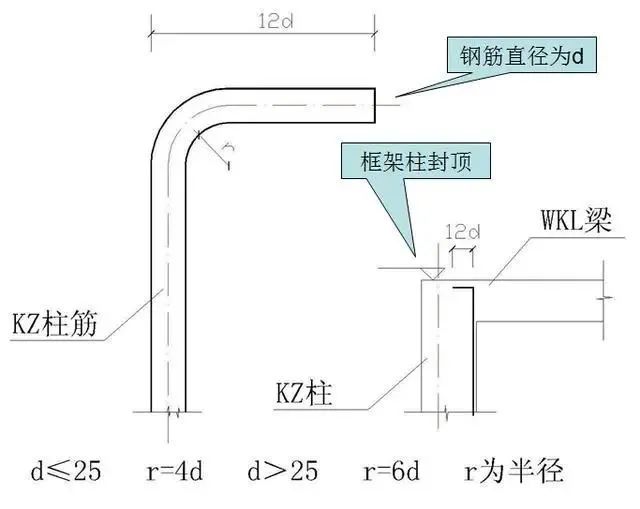

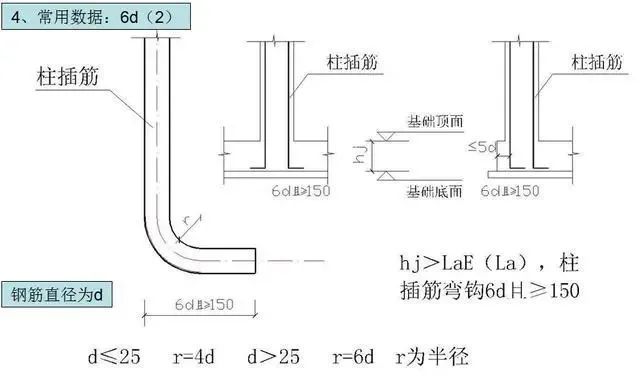

7) When the anchorage length of column foundation joint bar HJ ≤ Lae (LA), the binding length of joint bar hook (3) 12D: 1) when the frame column is capped with straight hook, the outer length of hook

.

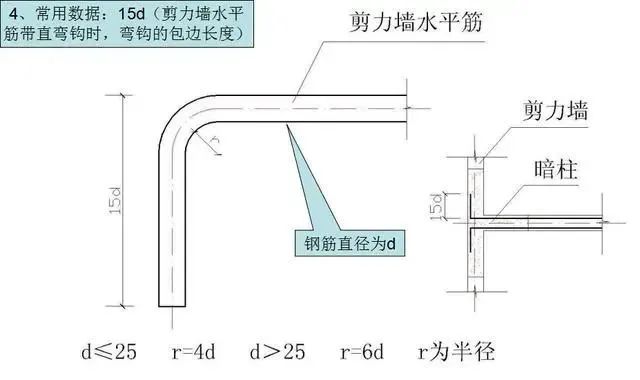

2) When the vertical reinforcement of shear wall is capped with straight hook, the outer length of the hook is longer

.

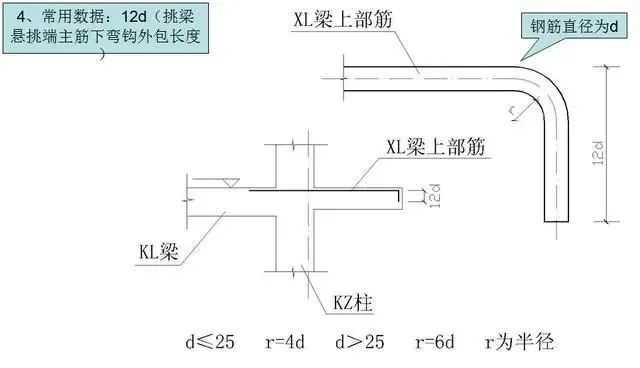

3) The outer length of the lower hook of the main reinforcement at the cantilever end of the cantilever beam

.

4) The total length of the lower reinforcement of the non frame beam (excluding the arc beam) entering the support

.

5) The outer length of the bottom hook of LZ seat

.

(4) 10d1) 10d; ≥ 75mm: the straight length of all stirrups and hooks when seismic requirements are met

.

2) 10d; ≥ 100mm: the requirements to be met at the same time of the center line of the slab bottom reinforcement lintel

.

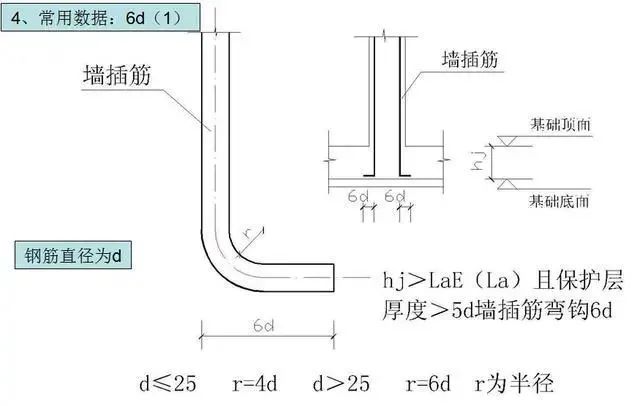

(5) 6D: 1) the anchorage length of the wall foundation joint bar HJ > Lae (LA) and the thickness of the protective layer > 5D, the binding length of the joint bar hook

.

2) The anchorage length of dowel bar in column foundation is HJ > Lae (LA), and the binding length of dowel bar hook

.

(6) 3D: the straight length of 180 degree hook at the end when the smooth reinforcement is in tension

.

1) the straight length of the hook of the main reinforcement of the constructional column of the infilled wall

.

2) Straight length of main reinforcement hook of ring beam and lintel

.

3) Straight length of hook of stair slab reinforcement

.

(7) 150: lap length of structural reinforcement (erection reinforcement) and main reinforcement

.

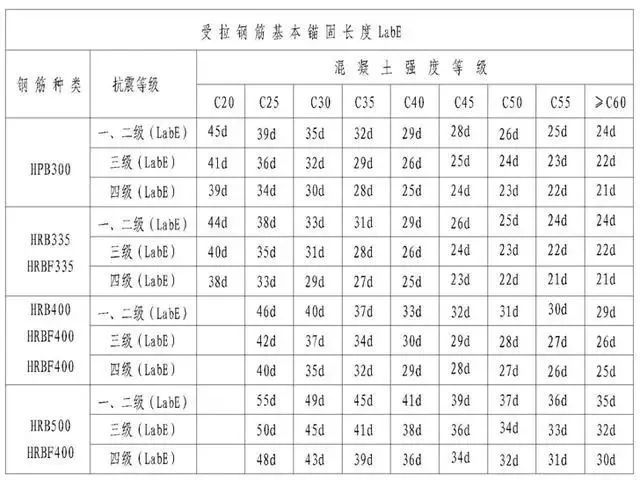

(8) La: shall not be less than 200 for all members of non seismic structure; the cardinal number of minimum anchorage length and minimum lap length (LL) of L beam (secondary beam), XL beam (cantilever beam), JZL (grillage beam) and tensile reinforcement in slab of seismic structure (lap 100%: 1.6la; lap 50%: 1.4la; lap 25%: 1.2la)

.

(9) Lae: the base number of the minimum anchorage length and the minimum lap length LLE of tensile reinforcement in seismic components such as KZ (frame column), kzz (frame pillar), KL (frame beam), KZL (frame supported beam), q (shear wall), LL (coupling beam) of seismic structure

.

(10) 1.7labe (LA): the lap length of the side joint of the column anchor beam, the outer column reinforcement and the main reinforcement of the roof frame beam surface

.

(11) 1.5 labe (LA): the lap length of the outer column reinforcement and the main reinforcement of the roof frame beam surface layer when the column is anchored into the inner joint of the beam

.

(12) 1.2lae (LA): 1) lap length of horizontal reinforcement in shear wall

.

2) The lap length of vertical reinforcement in shear wall

.

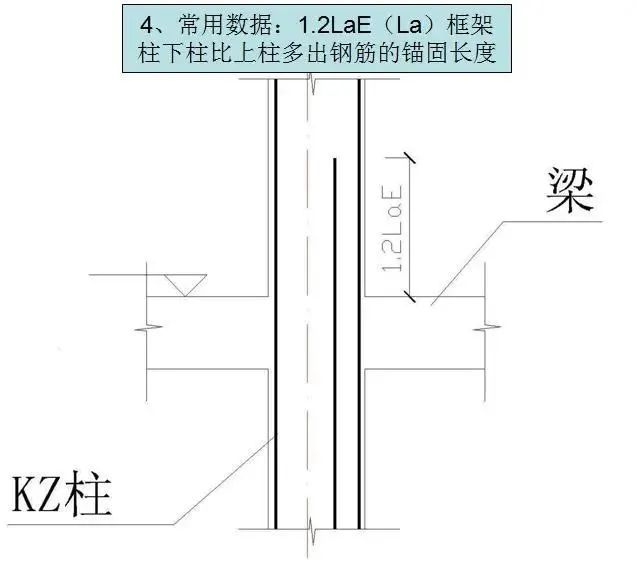

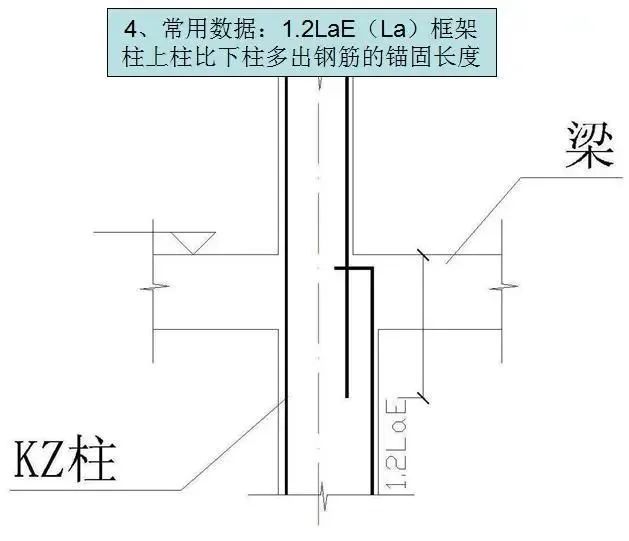

3) The length of the anchorage column is longer than that of the upper column

.

4) The anchorage length of the lower column is longer than that of the upper column

.

(13) Joint center staggered spacing: 1) binding lap: 1.3lle (LL)

.

2) Mechanical connection ≥ 35d

.

3) Welding time ≥ 35d and ≥ 500

.

4) The vertical reinforcement of shear wall is special: the binding lap length is 1.2lae (LA), the staggering distance between the ends of grade I and II seismic joints is 500; the staggering distance between the centers of mechanical connection and welded joints is 35d

.

In 2021, the first and second registration examinations: the official account platform of the constructors provided the most complete and professional guidance materials for one or two construction projects annually: 1, 2021, one and two examinations, teaching materials, exercises and real questions

.

2

.

In 2021, the first and second construction of video courses in various subjects, including intensive lecture, sprint, quiz class, pre exam simulation paper, quiz paper, blue book, the last three pages and other materials

.

3

.

Charging system: 100 yuan / section for the first and second construction materials! Welcome to consult, please add Xiaobian wechat: hailun6818 “or scan QR code Xiaobian to pull you into the examination group

.

Note: test category, such as No.1 building / No.2 building / fire protection..

.