Pay attention to the WeChat official account of builder, add by two-dimensional code

.

Please read down the text The kitchen and bathroom floor area is the key and difficult point of concrete structure construction

.

If the hanging formwork construction is not in place, it will cause more difficult to rectify the concrete quality problems

.

In this paper, we share the scheme of lifting formwork with height difference of falling slab adopted by China Construction Fourth Engineering Bureau in a case project, which has achieved good quality effect, and we can refer to it for reference

.

Falling slab area is the key and difficult point in the construction of concrete structure

.

In the process of falling slab construction, it is easy to have quality defects such as falling slab forming is not square, falling slab height is not standard, finishing is not smooth, finished product protection is not in place, resulting in missing edges and corners and so on

.

The height difference hanging formwork height is not enough, the internal and external corners are not square, the concrete is lack of edges and few corners, and the internal and external corners are not smooth, It is very important to lift the formwork with the height difference of the falling slab

.

The system consists of three parts: the material of the hanging formwork of the falling plate; the material of the hanging formwork of the falling plate; the material of the hanging formwork of the falling plate; Support of falling plate hanging formwork; Reinforcement of the hanging formwork of the falling plate

.

There are three options for the selection of the materials for the four sides of the falling plate, namely, wood square, angle steel and square tube

.

Comprehensive comparison of wood square angle steel square pipe, this project selects square pipe: 2

.

Support of falling plate hanging formwork, support method of falling plate four sides hanging formwork material, there are three options, using cement cushion block support, using steel support, using angle steel support

.

According to the comprehensive comparison of the right angle shaped channel steel support, the right angle shaped angle steel support is selected for the project: 3

.

The reinforcement of the hanging formwork of the falling plate, and the reinforcement method of the hanging formwork of the four sides of the falling plate

.

There are three options: fixing with positioning bars, binding with iron wires, and fixing with wooden wedges

.

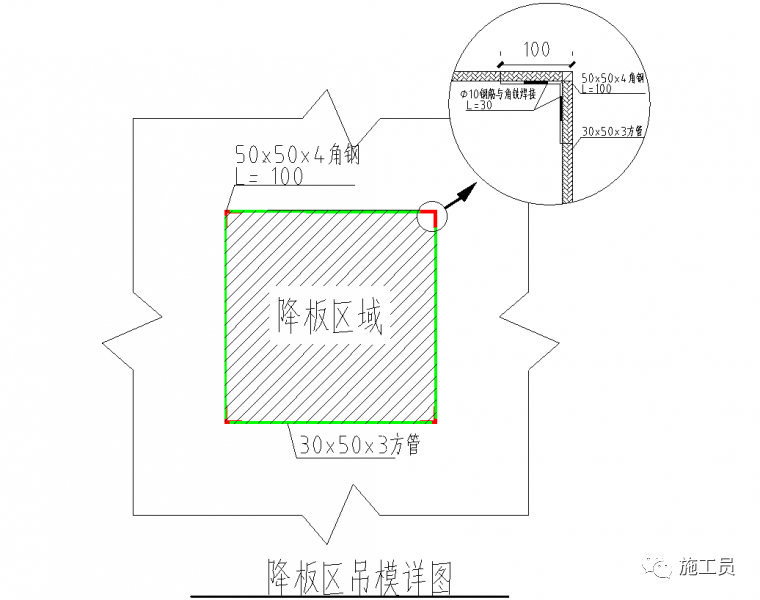

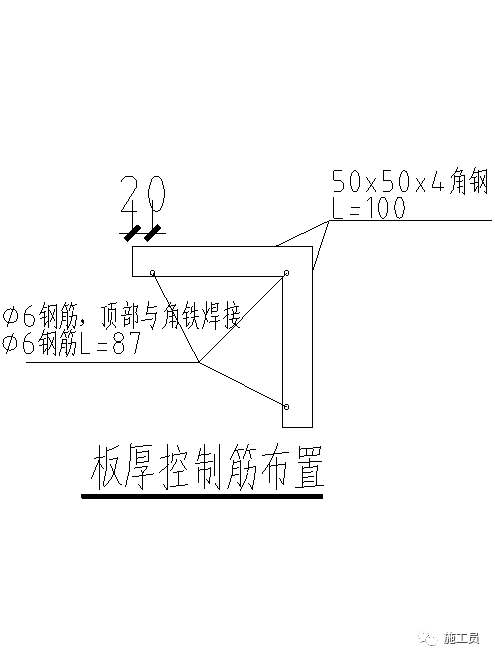

Through comprehensive comparison, the project adopts wood wedge fixation Scheme of lifting formwork with height difference of falling plate : The four right angles of the descending plate are provided with shaped angle steel supports

.

The steel bar is welded at the bottom of the angle steel

.

The height of the column is the same as the thickness of the plate

.

The column is supported on the platform plate template, and an iron nail is welded beside the column

.

The iron nail is nailed into the template to fix the support

.

The square tube is placed on the support

.

The short steel bar for fixing the square tube is welded at the side of the support, and the wood wedge is used to plug between the square tube and the fixed steel bar

.

The first is to weld the square pipe of the hanging formwork into an integral control: during the use of the hanging formwork system, the square pipe of the hanging formwork is deviated due to the construction load

.

Measures: weld a single square pipe into a quadrilateral, and then weld and fix the square pipes on the two adjacent sides with steel bars for diagonal bracing

.

Objective: to make the square pipe of falling slab formwork form a whole, and the square pipe will not move during the construction

.

2

.

Check the height control of the fixed support column: the height of the falling plate hanging formwork support column is consistent with the plate thickness

.

Once the column height deviates, the plate thickness and falling plate elevation will deviate

.

Measures: check the column height of the completed falling plate hanging formwork support, and list the support with deviation greater than 2mm as unqualified products

.

Objective: the height deviation of standardized support column is not more than 2mm

.

3

.

Nail the iron nail of the angle steel of the fixed hanging formwork into the platform plate template control: during the use of the hanging formwork support of the descending plate, the iron nail of the fixed support is not completely nailed into the template, resulting in the stereotyped support not falling on the platform plate, and the elevation of the square tube of the hanging formwork is not accurate

.

Measures: check whether the iron nails are completely nailed into the formwork before concrete pouring

.

Objective: to make the iron nails for fixing the angle steel of the hanging formwork completely nailed into the platform plate, so that the angle steel column has the same thickness as the plate

.

4 check and control the embedded height of angle steel support column: due to the different quality of construction personnel, it is easy to cause the elevation error of formwork support

.

Measures: measure the embedded height of angle steel column, and the deviation is less than 2mm

.

Objective: the elevation of the bottom formwork of the hanging formwork square tube is accurate

.

5 control the elevation control of the falling slab: after the falling slab and the initial leveling of the slab surface concrete, pull the wire to accurately control the elevation of the floor and the falling slab

.

Measures: take line to receive light and check the elevation of the board surface

.

Objective: the height deviation of the falling plate is not more than 5mm

.

6 control the time control of removing the square tube of hanging formwork: the removal of the square tube of hanging formwork is too early, the concrete does not reach the strength of loading, the personnel of removing formwork and construction materials damage the edges and corners of the falling plate, and the late removal of formwork causes the square tube to be pressed by the materials, and the square tube is difficult to take out

.

Measures: arrange a special person to remove the formwork after the wall column reinforcement binding and before the formwork installation

.

Objective: to reduce the concrete corner damage caused by formwork removal, so that the damage rate is less than 10%

.

In 2021, the first and second registration examinations: the official account platform of the constructors provided the most complete and professional guidance materials for one or two construction projects annually: 1, 2021, one and two examinations, teaching materials, exercises and real questions

.

2

.

In 2021, the first and second construction of video courses in various subjects, including intensive lecture, sprint, quiz class, pre exam simulation paper, quiz paper, blue book, the last three pages and other materials

.

3

.

Charging system: 100 yuan / section for the first and second construction materials! Welcome to consult, please add wechat: hailun6818 Or scan the QR code to pull you into the test group

.

Note: test category, such as No.1 building / No.2 building / fire protection..

.