A complete set of highway construction standardization examples, including site construction, pavement engineering, bridge engineering, tunnel engineering, safety production, test detection! This is the first part, sorting out the site construction, pavement engineering, bridge engineering! There are all kinds of signboards and safety signs in the construction site

.

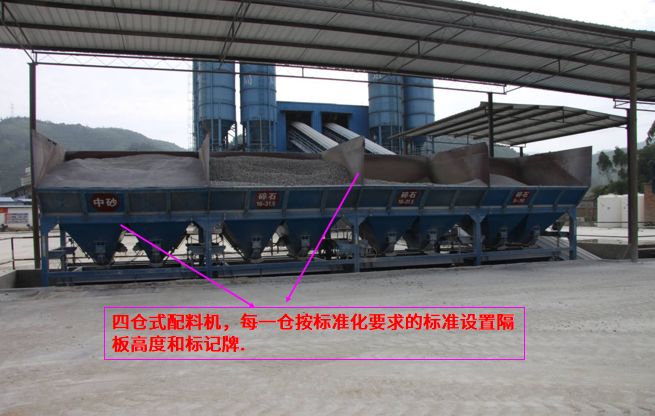

The four bin batching machine ensures that the aggregate does not mix during mixing

.

The storage and processing of reinforcement are transferred from outdoor operation to on-site operation, and closed management is adopted

.

Raw materials, semi-finished products and finished products are stacked in different areas, and the steel is stored in a standardized way

.

The indication is clear, and the anchorage is stored in a standardized way

.

The steel should be hung with the detailed design drawing, and the reinforcement is processed in a centralized way, The finished and semi-finished products of steel bars are stacked in different zones and categories, and all kinds of operation procedures are complete

.

The aggregate shall be strictly graded and stacked separately, and rainproof measures shall be set

.

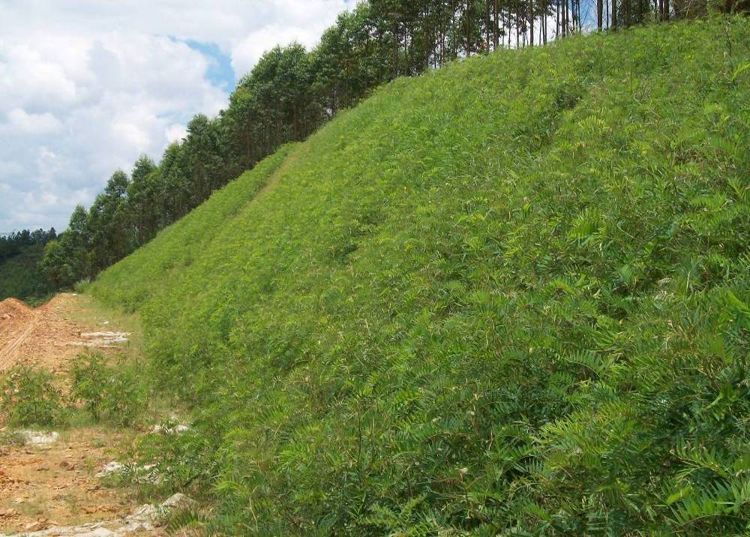

The surface and soft of subgrade engineering shall be cleaned thoroughly

.

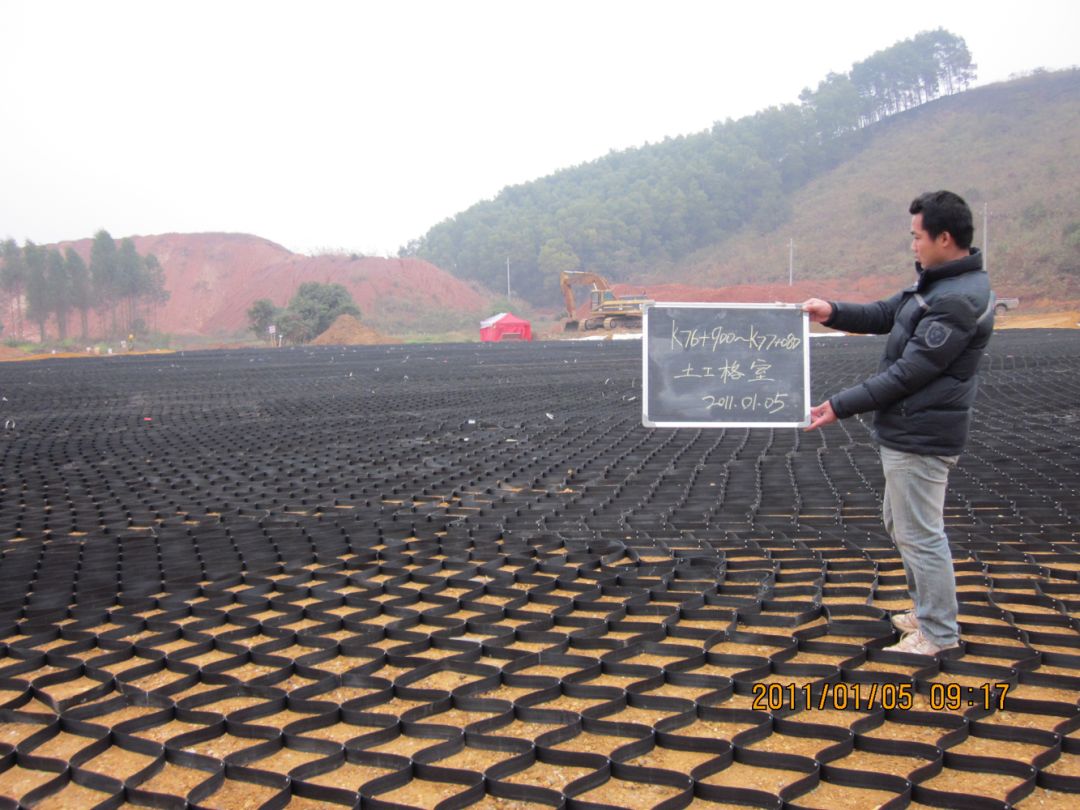

The geogrid for soft foundation replacement and filling shall be installed firmly

.

The construction site shall be neat and orderly

.

The subgrade filling must be constructed horizontally and in layers, and the square grid shall be made

.

The loose paving thickness shall be controlled

.

The high filling subgrade shall be reinforced by impact rolling to effectively eliminate the post construction settlement of subgrade

.

The use of line filling effectively ensures the layer thickness and compactness of subgrade filling, with high filling quality and standard construction site

.

Strictly control the width and depth of the step treatment at the filling and excavation junction, and excavate the step to the solid soil, so as to ensure the beautiful alignment and effectively ensure the filling quality at the filling and excavation junction

.

The filling thickness is reasonable and uniform, the mechanical configuration is reasonable, the rolling is in place, and the flatness of subgrade and the cross slope of road arch are well controlled

.

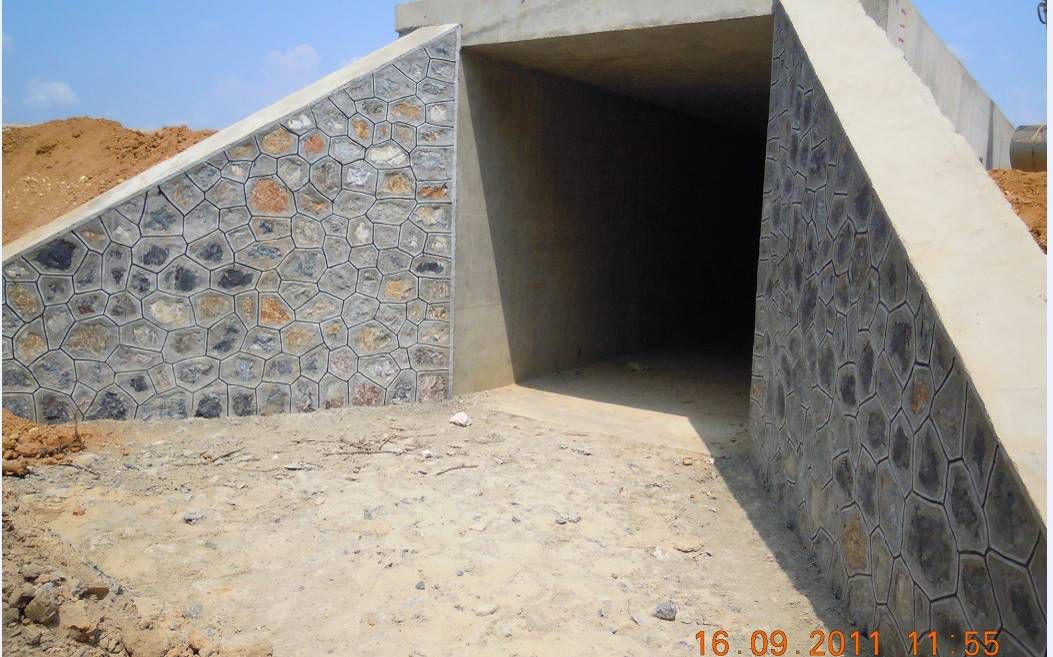

The hydraulic reinforcing and tamping machine is used to reinforce the culvert back backfill

.

The reserved steps are convenient for inspection

.

The layer thickness is controlled by marking

.

The construction site of culvert back and abutment back backfill is well controlled in layer thickness and compactness, and the scene is standard

.

After filling, fine materials shall be used to fill the joints, and the rolling shall be in place

.

The large surface shall be smooth

.

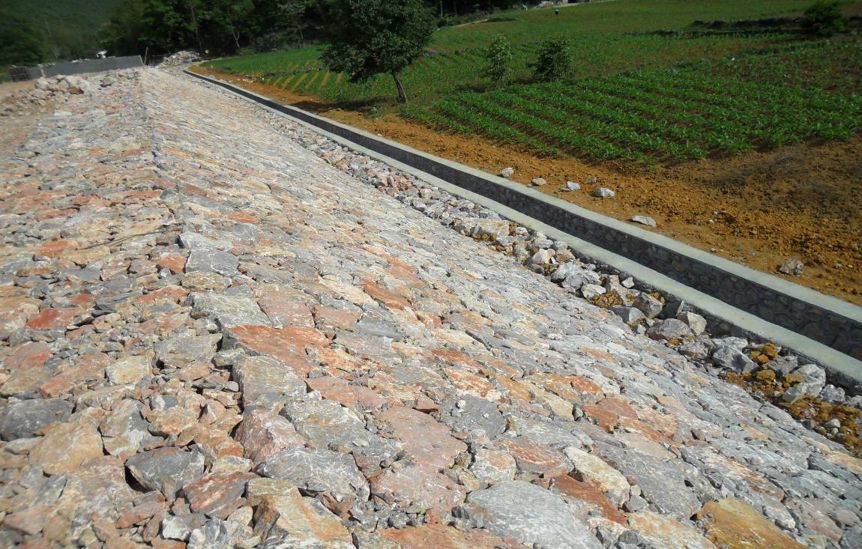

The working face of rock filling shall be clean, flat and dense, and the construction site shall be standard

.

Using dynamic compaction to reinforce high rock fill subgrade can effectively eliminate subgrade settlement and ensure construction quality

.

The side slope is laid in a big way, the surface is smooth, the caulking is dense, and the thickness is guaranteed

.

The masonry mortar of anchor lattice beam and arch skeleton is full and dense, the wall surface is smooth, the joint is dense, and the effect is beautiful

.

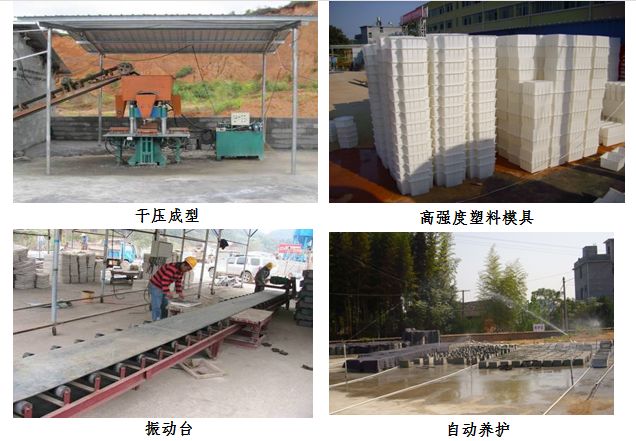

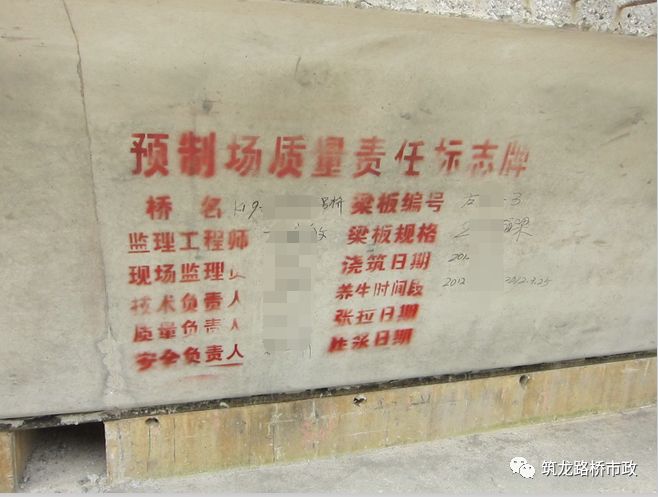

Centralized prefabrication of cover plates in the standardized construction site of small structures is conducive to quality control

.

The measured reinforcement spacing and concrete appearance quality are good, solid inside and smooth outside

.

The centralized processing of bridge engineering adopts numerical control steel bar bending machine and automatic roll welding machine, which improves the quality and efficiency of steel bar processing, and changes the traditional manual small workshop processing mode

.

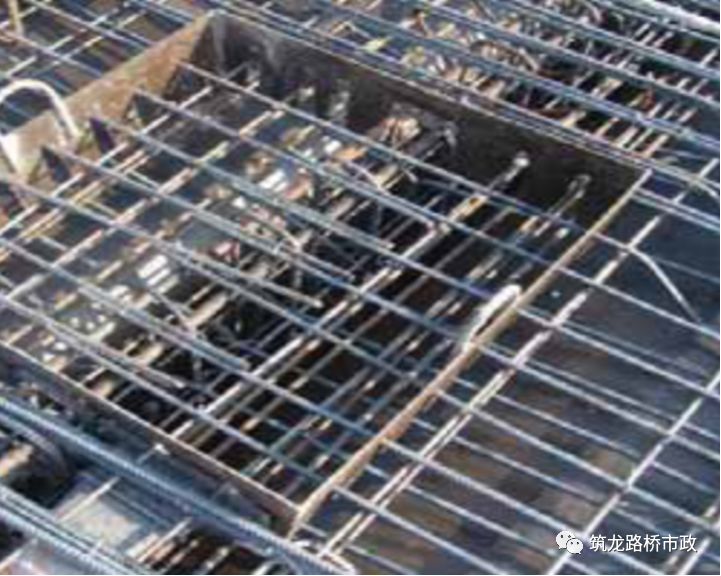

After processing, the reinforcement cage of pile foundation has the advantages of high working medium saving, firm binding, good welding quality and even reinforcement spacing

.

Equipped with numerical control steel bar bending machine and numerical control steel bar bending hoop machine, centralized processing of all types of steel bars can improve the quality of steel bar processing

.

When binding the wire, the wire head should be bent towards the structure and welded to ensure that the pre bending angle is sufficient, the weld seam is full, and the weld seam length is qualified

.

Appropriate research, development and application of new technology should be carried out

.

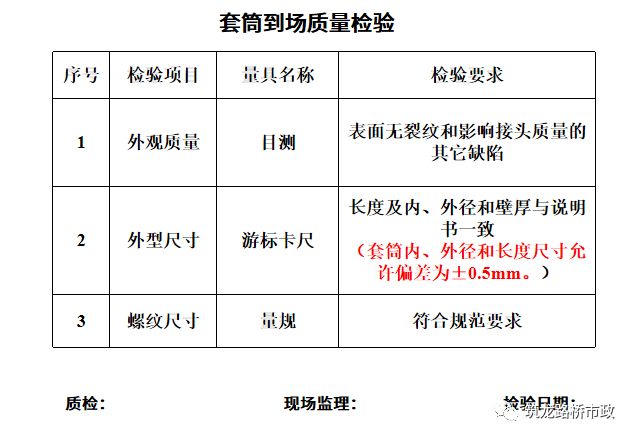

The sleeve connecting screw rod should be cut flat, cut teeth and ground flat in strict accordance with the requirements Processing

.

The screw rod should be stored properly after processing and used within the specified time

.

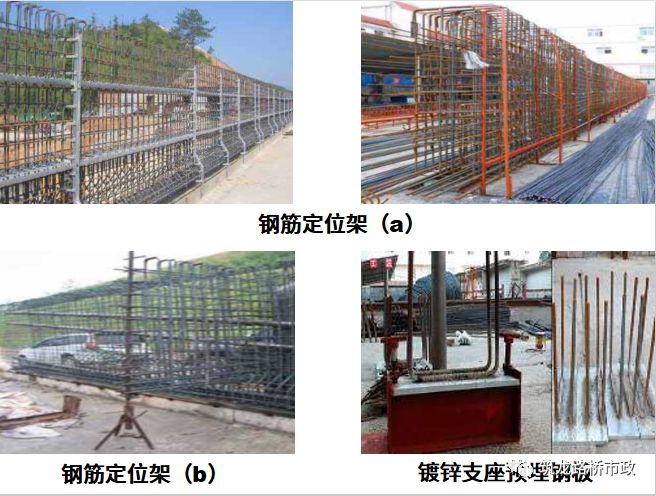

It is a good way to improve the qualified rate of steel bar spacing to use high-quality cushion blocks and reasonable layout and installation

.

It is a good way to improve the qualified rate of reinforced concrete protective layer thickness

.

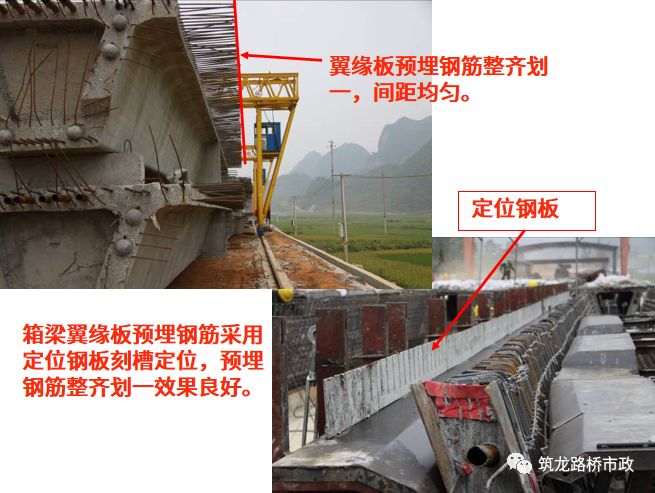

The number of embedded steel bars is sufficient, the number of embedded steel bars is neat, and the number of embedded steel bars is sufficient, which is conducive to the later welding process Effective grouting blocking measures can be taken for the holes, splicing joints and other parts prone to leakage

.

Strong rubber or rubber rod joint sealer can be used to stop grouting

.

Inverted trapezoidal integral comb shaped slab beam top concrete is densely covered and wrapped, which is also a major measure to ensure concrete maintenance

.

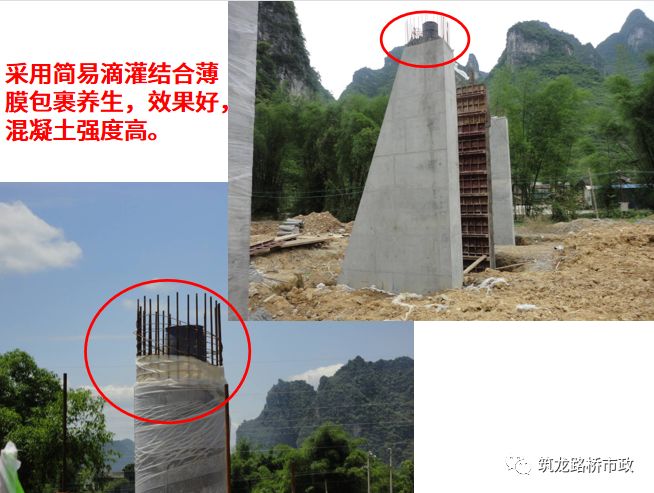

Simple drip irrigation combined with film wrapping is adopted for curing, with good effect and high concrete strength

.

The pad stone adopts the formwork prestressed intelligent tension with adjustable elevation to effectively ensure the tension quality

.

In December 2013, our station issued the notice on relevant requirements of prestressed intelligent tensioning technology in Bridge Engineering (gjjlf [2013] No

.

166), intelligent circulating grouting can effectively ensure the grouting compactness of prestressed pipeline

.

In February 2014, our station issued the notice on the requirements of intelligent circulating grouting technology for prestressed duct of Bridge Engineering (gjjlf [2014] No

.

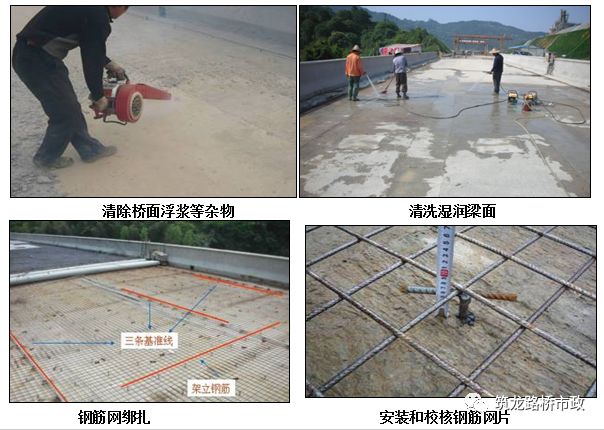

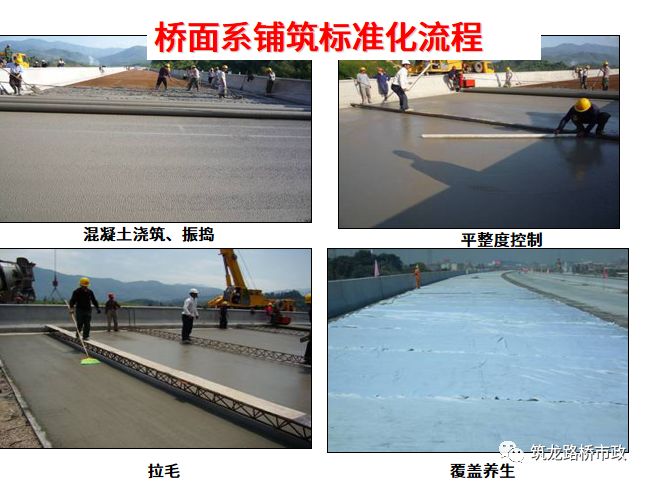

5) and installed the expansion device in the standardized process of bridge deck paving.

.