Prestressed concrete engineering is to pre tension the steel bar or steel strand along the bending direction, so as to apply the pre compression stress to the concrete along the bending direction of the structure, so as to offset the tensile stress in the bending area of the concrete, delay the occurrence of concrete cracks, and greatly improve the bearing capacity of the beam and slab

.

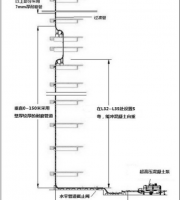

According to the way of prestressing, prestressing engineering can be divided into: post tensioned prestressing (according to the bonding state of prestressing tendons, it can be divided into ① post tensioned bonded prestressing and ② post tensioned unbonded prestressing) and ③ pre tensioned prestressing

.

Animation demonstration based on engineering examples, easy to understand the three forms of Prestressed Engineering! Construction demonstration of post tensioned bonded prestressing project ↓ ↓ construction demonstration of post tensioned unbonded prestressing project ↓ ↓ construction demonstration of pre tensioned prestressing project ↓ through the above example demonstration, it can be seen that post tensioned construction is to cast concrete first, and tension prestressing tendons after reaching a certain strength, in which the bonding method is to embed pipes first, and cast concrete through tendons, and then grouting without reinforcement The bonding method is to use the steel bar which has no bond with the concrete after the surface treatment

.

After pouring the concrete, it can be directly tensioned without reserving holes and grouting

.

The pre tensioning method is to tension the prestressed steel bar first and then pour the concrete

.

The post tensioning method does not need to be fixed

.

The equipment is not limited by the location

.

However, the process is complex and the anchorage can not be reused

.

The pre tensioning method is simple and suitable for repeated use of anchorage It is widely used in the industrial production of small and medium-sized components, but the reinforcement arrangement of the fixed pedestal equipment is mostly straight rather than curved

.

The prestressed technology makes full use of the characteristics of high compressive strength of concrete and high tensile strength of steel bars, and the use of materials “develops strengths and avoids weaknesses”, greatly broadening the application scope of this kind of composite engineering materials

.

At present, the ability to build large-span reinforced concrete bridges, floors, high-rise buildings, etc., all rely on prestressed concrete technology

.

If you think it looks good, please click here.

.