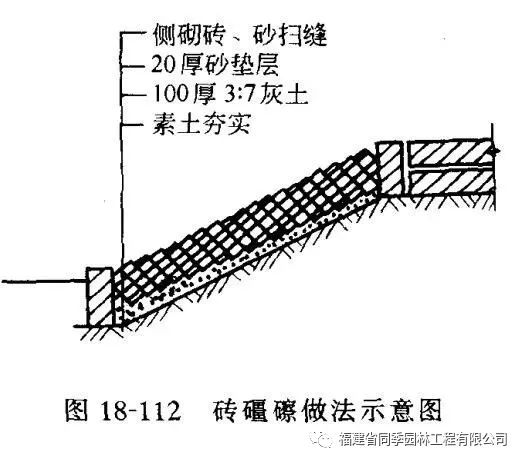

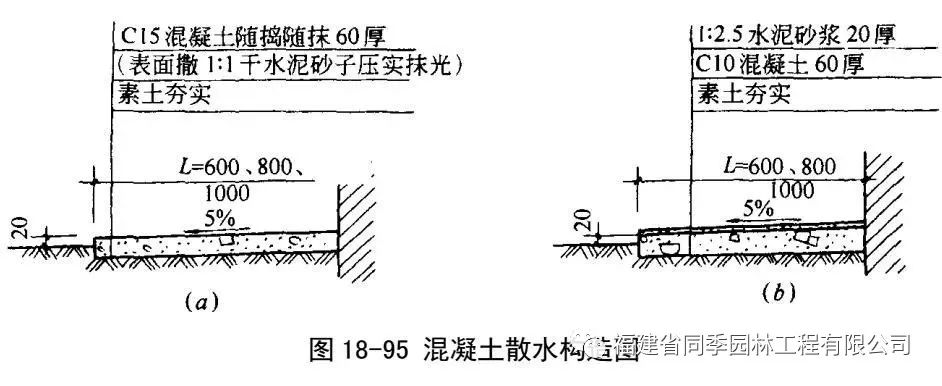

Content source: landscape micro review If there is any infringement in Baidu Library, please contact to delete the apron, which is made of brick, concrete and other materials

.

The construction method is shown in Fig

.

18-93, FIG

.

18-94 and Fig

.

18-95 (a) and (b)

.

The cross slope of apron is 5%

.

Before the construction of apron, the elevation line of the upper edge of apron shall be drawn on the outer wall, and the formwork shall be erected outward according to the transverse slope and width of apron

.

The top surface of the formwork shall be the elevation of the lower edge of apron (for brick apron, the trench shall be excavated), and the top surface of the formwork shall be 50 mm higher than the outdoor floor

.

When building a brick apron, a line of vertical bricks should be built in the soil trough by pulling wires, and the top surface of the brick should be 50 mm higher than the outdoor floor

.

The loose water foundation soil shall be excavated into 5% slope and tamped for three times (if the soil quality is poor, it shall be excavated to a depth of 10cm and backfilled with 3:7 lime soil and tamped for three times)

.

Sand shall be laid on the foundation soil surface, bricks shall be laid flat and joints shall be filled with sand

.

The construction of Sanhe soil and concrete apron is the same as the corresponding ground surface course

.

Deformation joint shall be reserved at the corner of concrete apron and every 12m long

.

The deformation joint at the corner is 45 ° to the outer wall ° Other parts are perpendicular to the exterior wall

.

The position of deformation joint should be avoided at the outlet of downcomer

.

The joint shall be filled with asphalt mortar

.

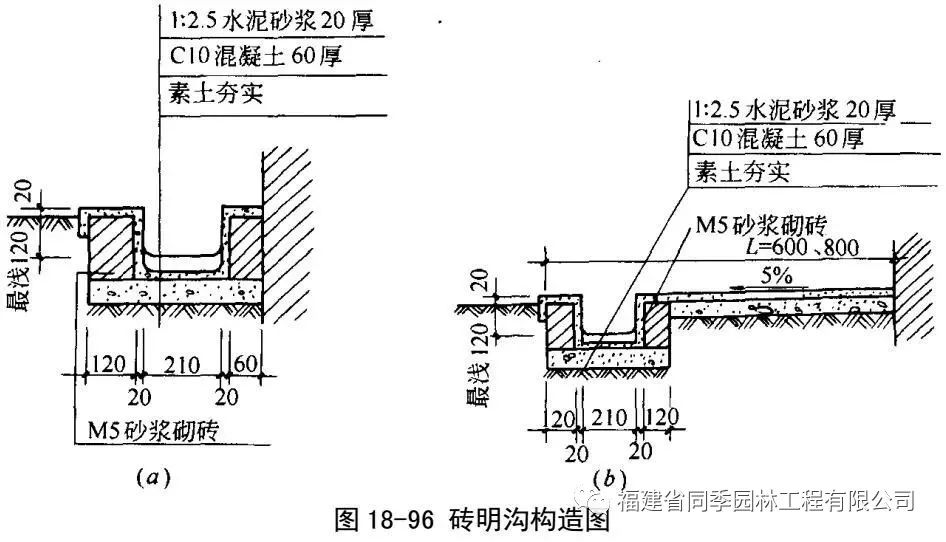

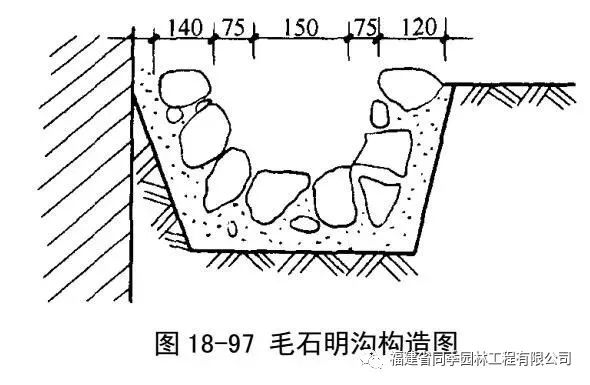

The open ditch is made of brick, rubble, concrete and other materials

.

The construction method is shown in Fig

.

18-96 (a), (b), FIG

.

18-97, FIG

.

18-98 (a), (b), (c)

.

Each structure layer of outdoor open ditch should be: plain soil compaction, cushion and surface layer

.

The material, mix proportion, strength grade and thickness of each layer shall meet the design requirements

.

The construction shall be carried out according to the construction points and precautions in relevant chapters of foundation soil, similar cushion and surface course

.

The expansion joint should be set in the open ditch of cement concrete, and the distance between them should be determined according to the local climate conditions and traditional practices, but the distance should not be greater than 10m

.

The expansion joint should be set at the corner of the house, and the joint should be 45 degrees away from the outer wall ° Angle

.

The joint between open ditch and building should be set for technical treatment

.

The width of the joint is 20 mm, and the joint is filled with asphalt binder or asphalt mortar

.

The longitudinal slope of outdoor open ditch bottom drainage should be equal to or greater than 0.5%, and the slope should be made by foundation soil (or base)

.

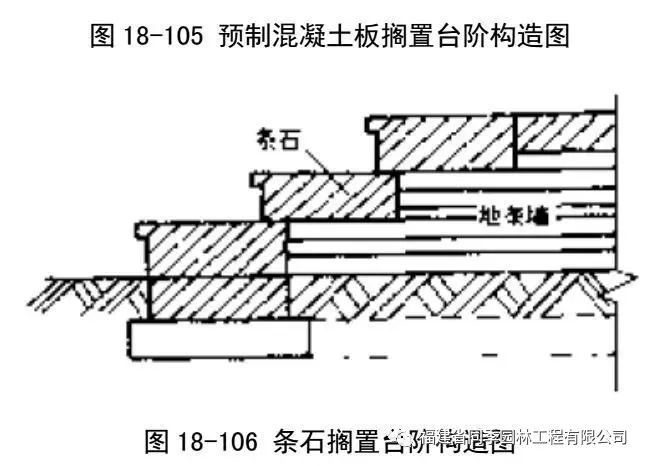

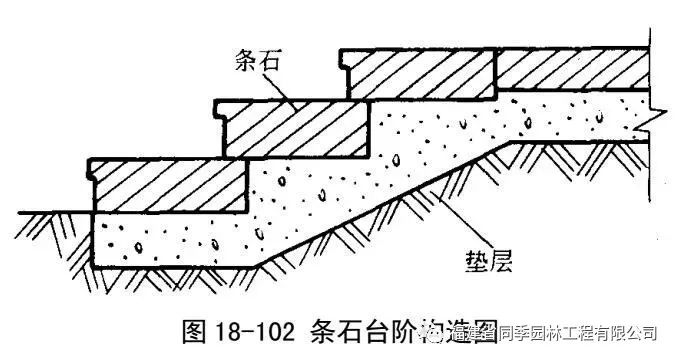

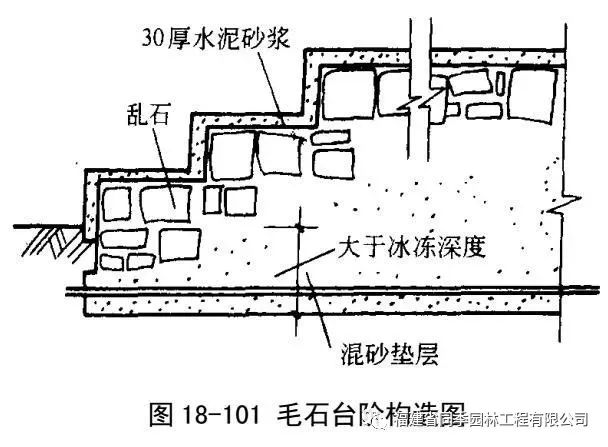

Step 1

.

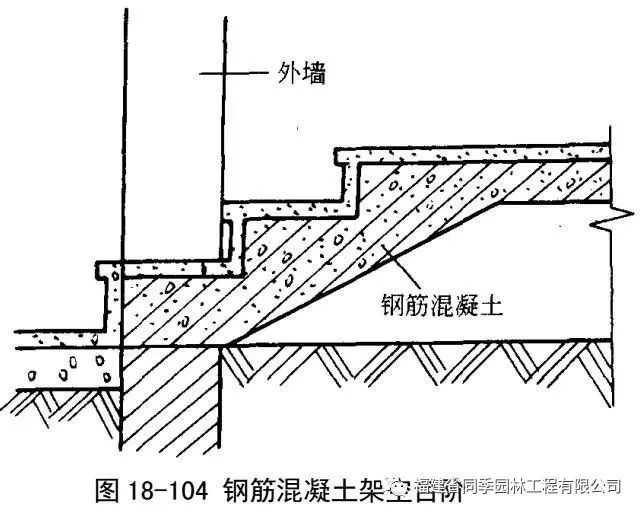

Outdoor entrance step (step) The step is the outdoor entrance step

.

Common steps are made of cement mortar, terrazzo, brick and other materials

.

There are also the use of rubble, rubble, monolithic concrete and reinforced concrete overhead, precast concrete slab shelving, rubble shelving and other steps

.

The construction method is shown in figure 18-99, figure 18-100, figure 18-101, figure 18-102, figure 18-103, figure 18-104, figure 18-105 and figure 18-106

.

During the construction of cement mortar steps and terrazzo steps, the foundation soil shall be rammed into an inclined plane according to the gradient of the steps, and the lime soil above shall also be rammed into an inclined plane, then the formwork shall be erected, and the cast-in-place concrete shall be made into steps, and the surface layer of each step shall be constructed according to the corresponding step surface layer

.

During the construction of brick steps, the foundation soil is rammed into an inclined plane, and the lime soil is rammed into a step shape

.

Then the bricks are laid on the lime soil layer, and each step is first laid with a layer of flat bricks, and then with a layer of side bricks

.

The outer corner of the steps is laid with a brick

.

The gap between bricks shall be filled with mortar

.

The steps of fair faced brick shall be pointed with 1:1.5 cement mortar

.

2、 Indoor floor step (step) Indoor floor step, common step surface layer is made of cement mortar, terrazzo (integral terrazzo or prefabricated terrazzo plate) materials

.

Also has uses the marble, the granite and the brick (the stone tile, the ceramic floor tile, the cement tile) and so on the plate material paving becomes

.

1

.

Composition materials The materials used are the same as those of the same kind of surface course in “18-4 overall surface course laying” and “18-5 plate surface course laying” in this chapter

.

2

.

Key points of construction ① The height of stair steps shall be divided according to the elevation of the structural layer of the stairwell, combined with the practice of the upper and lower stair steps and the surface layer at the joint of the platform and the walkway, so that the height difference between the height of each step after laying and that of the upper step and the next step shall not be greater than 10 mm

.

② Before the construction of stair step surface, the height, width and shape of each step after finishing shall be drawn on the wall of one side of the stair, or a diagonal line shall be drawn at the upper and lower ends of each step as the step-by-step standard, as shown in figure 18-107

.

③ The construction of stair step surface is basically the same as that of corresponding surface, and each step should be plastered with facade (riser) first and then with plane (tread)

.

The surface course of stair step shall be constructed from top to bottom

.

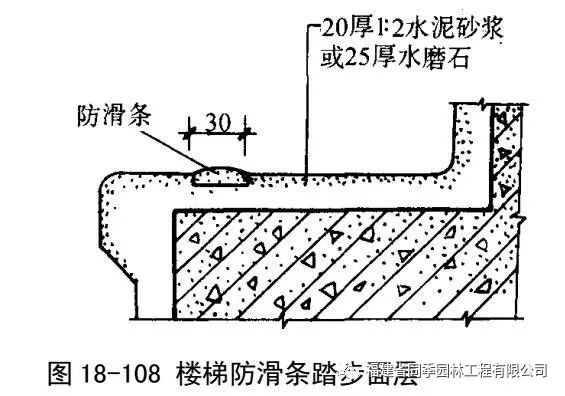

④ Cement steel chip anti-skid strip is often made on terrazzo surface, as shown in figure 18-108

.

For the step with anti-skid strip, after the bottom layer mortar is plastered, paste the millstone soaked in water with plain cement slurry, and then plaster the surface layer mortar to be level with the millstone

.

After the surface layer mortar is solidified, take out the millstone, fill the groove with 1:1.5 cement steel slurry, which is 4 ~ 5mm higher than the tread, and smooth it with round external angle trowel

.

Prefabricated anti-skid strips of cement and steel chips can also be used, which are bonded and embedded in the groove with plain cement slurry

.

⑤ Cement mortar stair step construction: 1) Clean the base course, spray water to wet it, apply a layer of plain cement slurry, and then apply 1:3 cement mortar (volume ratio) base ash with a thickness of about 15mm; 2) When plastering the facade (riser), first press it on with a guiding rule, and leave a plaster hole according to the size, and then rub it with a wooden plaster according to the guiding rule, as shown in figure 18-109 (a); Then, put the guiding rule on the facade and wipe the plane

.

According to the guiding rule, rub the plane with wooden plaster, as shown in figure 18-109 (b), and make the edges and corners, and mark the bottom ash and cover the next day; 3) 1:2 ~ 2.5 cement mortar (volume ratio) with thickness of 8mm should be used for the covering ash

.

According to the dry and wet condition of the mortar, it should be troweled a few steps first, and then returned to the surface for calendering, and the internal and external corners should be troweled with the internal and external corner trowel

.

After 24 hours, it should be watered for curing, generally about a week

.

It is strictly forbidden to go on before reaching the strength

.

⑥ In situ terrazzo stair step construction: 1) Generally, 1:1.5 cement stone slurry (volume ratio) is used for the overlay, and the common stone particle size is 4 ~ 6mm

.

For others, please refer to “cement mortar stair step” and similar surface construction; 2) After completion, it shall be laid on the step with wooden board or straw curtain for protection

.

⑦ Precast terrazzo, marble slab and other stair steps Construction: 1) First, pop up the skirting line and step line on the vertical wall

.

Refer to the construction requirements (2) for the method; 2) The installation sequence should be as follows: skirting board → step vertical board → step board, and gradually from top to bottom; 3) The hole position of the stair railings through the step board must be accurate, and the hole can be slightly larger

.

After the installation of the stair railings, the plain cement slurry with the same color as the step board shall be used to fill tightly; 4) For the construction (installation) method of skirting line, step vertical plate and step plate, please refer to “18-5-3 marble surface and granite surface” and “18-5-4 precast plate surface” in this chapter; 5) After construction (installation), wooden boards should be laid for protection

.

No people are allowed to get on within 7 days, and no materials and other heavy objects are allowed to be transported within 14 days

.

⑧ Before the acceptance of the stair step surface, it should be strictly protected to prevent the step edge from being damaged or knocked off

.

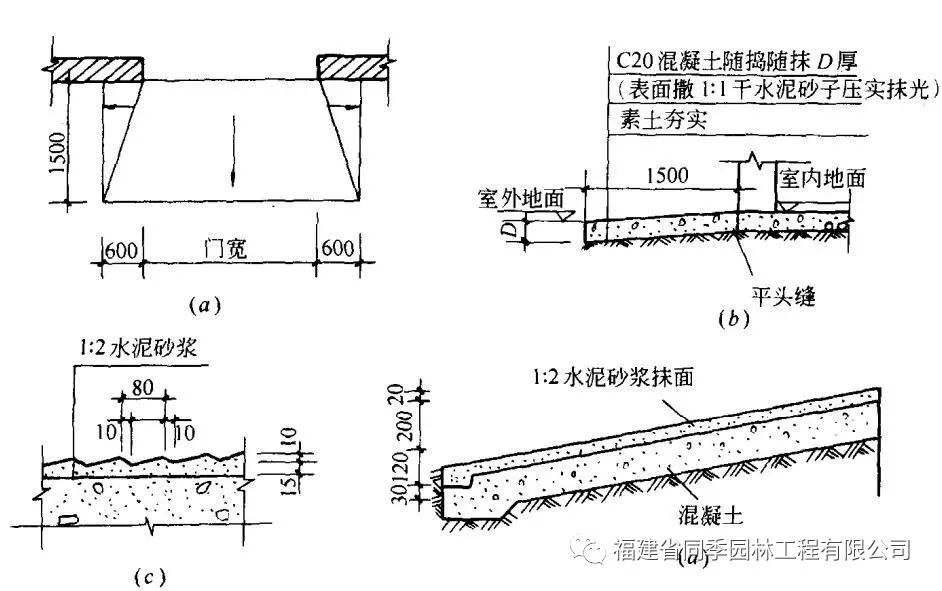

The ramp (gate ramp) is paved with cement mortar, terrazzo, concrete and other materials, and its construction method is shown in Fig

.

18-110 schematic diagram of gate ramp construction method( a) Plane sketch of gate ramp( b) Gate ramp structure( c) Detail drawing of gate ramp slot; ( d) Concrete surface ramp( e) Cement floor ramp( f) Terrazzo ramp The construction method of the ramp is basically the same as the corresponding ground engineering construction, except that the foundation soil and cushion are made into slope according to the gradient, and the thickness of the foundation soil and cushion should meet the design requirements.

.