The content is from Zhulong forum

.

The copyright belongs to the original author

.

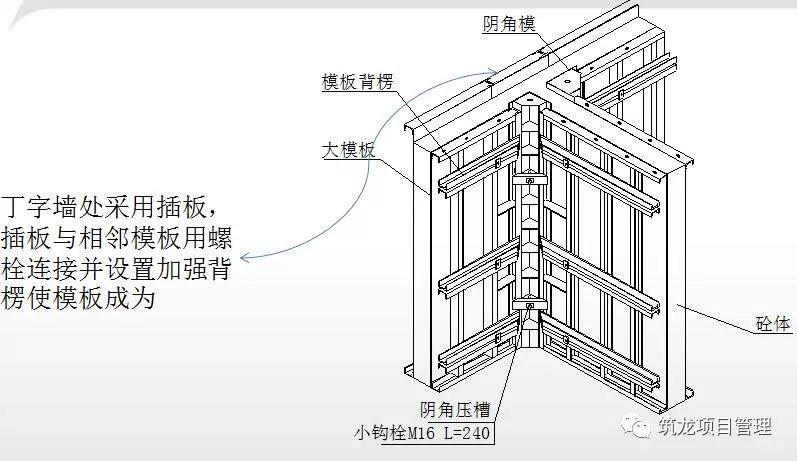

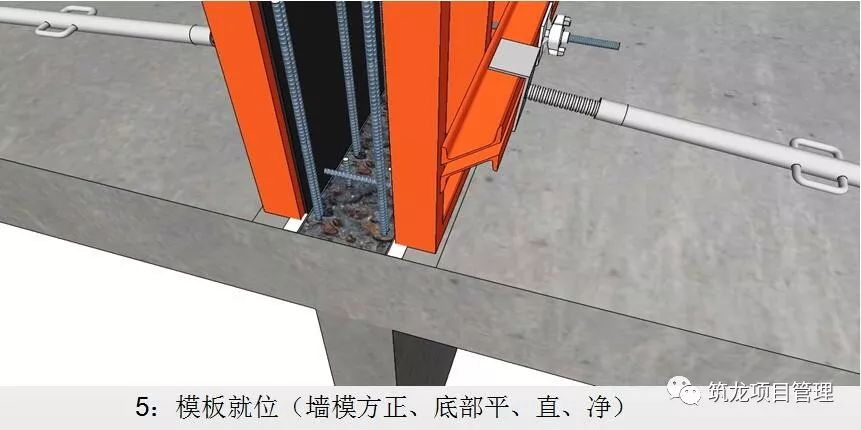

The selection of formwork should be reasonable

.

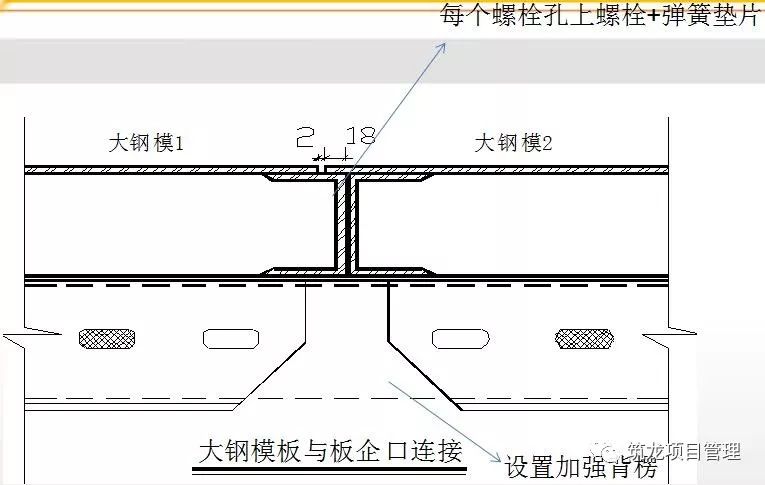

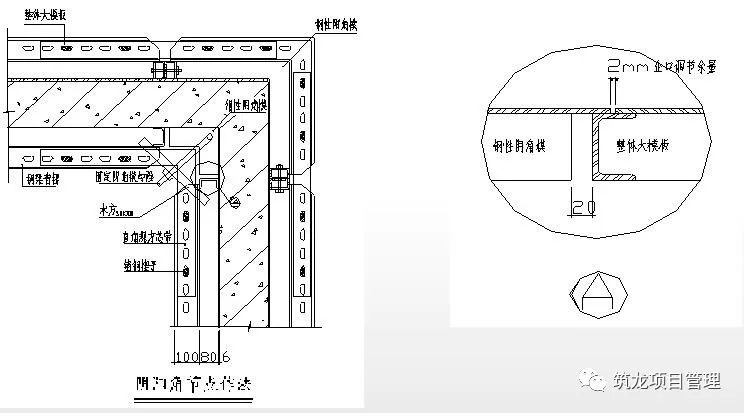

Large formwork should be spliced with internal corner formwork

.

Multiple internal corner grooves should be used to ensure that the internal corner is tight and straight

.

When the T-shaped wall node exceeds 4m, it should be arched according to 1 ‰ ~ 3 ‰ and hard arched, and the arched should be straight, Do not fold line arch or inverted arch

.

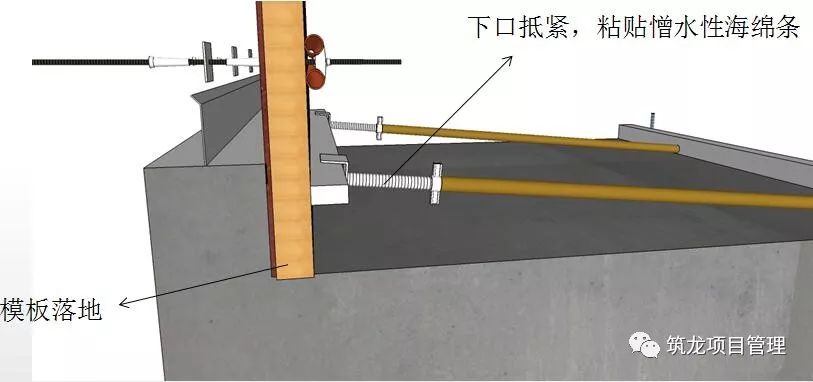

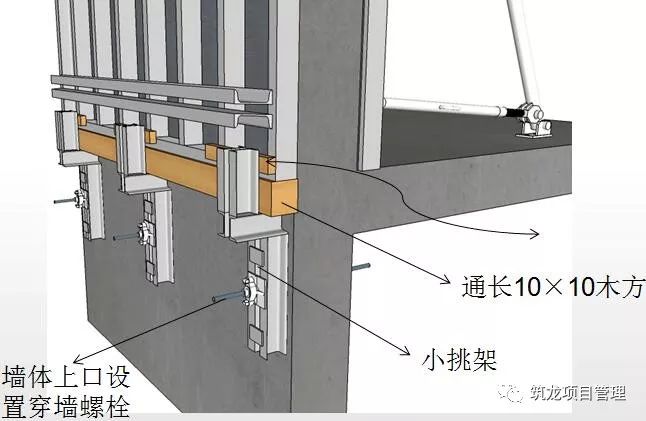

The basement guide wall formwork shall be connected with large steel formwork

.

The exterior wall shall be connected with the exterior wall slab

.

The roof internal corner joint shall be connected

.

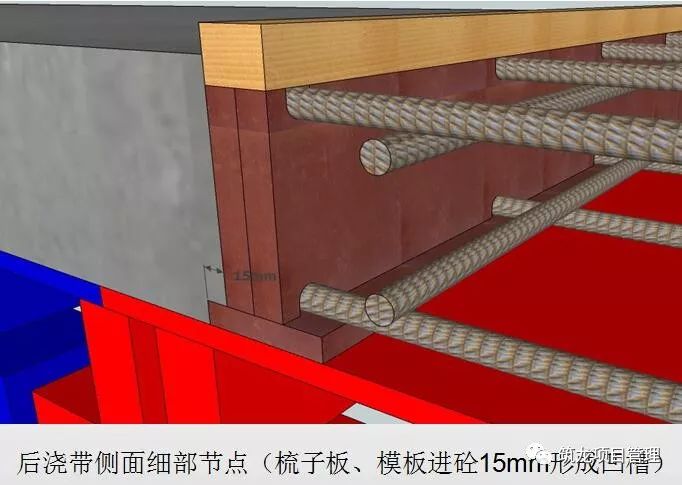

The roof post cast strip formwork shall be used to support the beam column joint joint

.

The door and window opening formwork shall be used for the door and window opening formwork

.

The basement outdoor wall shall adopt three section head water stop bolt foundation formwork

.

The two sides of the cup core formwork shall be nailed with car bars so as to be placed on the upper step formwork, The bottom formwork is not set for the cup core formwork to facilitate the concrete vibration at the bottom of the cup mouth

.

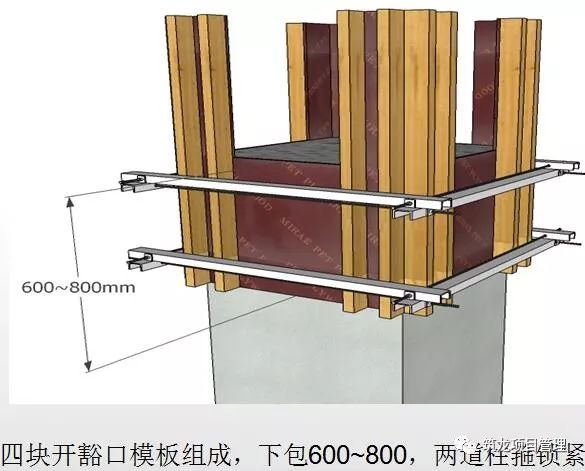

Fixture and fixture: commonly used tool type column hoop and combined beam fixture

.

Column hoop, also known as positioning clamp hoop, is made of angle steel, channel steel, flat steel or wood

.

It is a supporting part for directly supporting or clamping all kinds of column formwork

.

The operation quality of column hoop formwork installation of column hoop adjustable column formwork is the key process to ensure the quality of formwork engineering and concrete structure

.

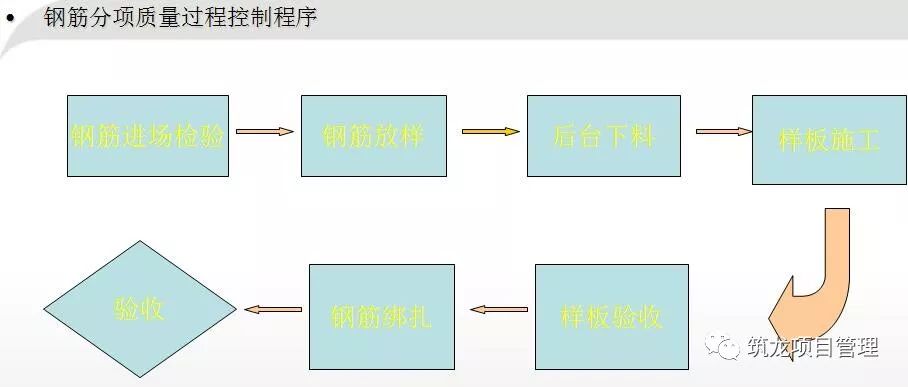

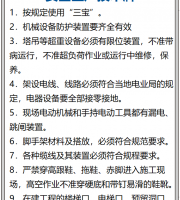

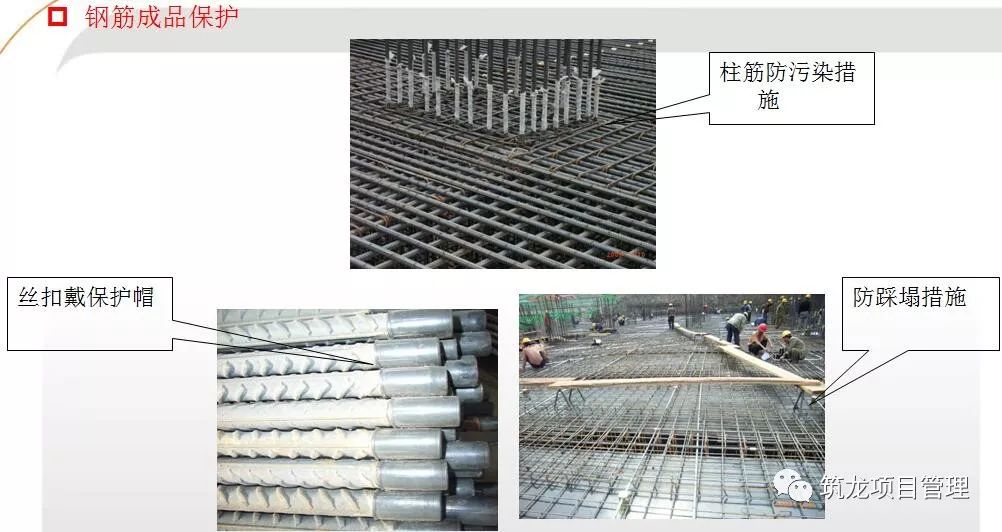

Reinforcement yard classified stacking, ridge wall and signboard reinforcement engineering are key sub projects to ensure earthquake resistance and structural safety

.

The following management links and quality control shall be strengthened during construction

.

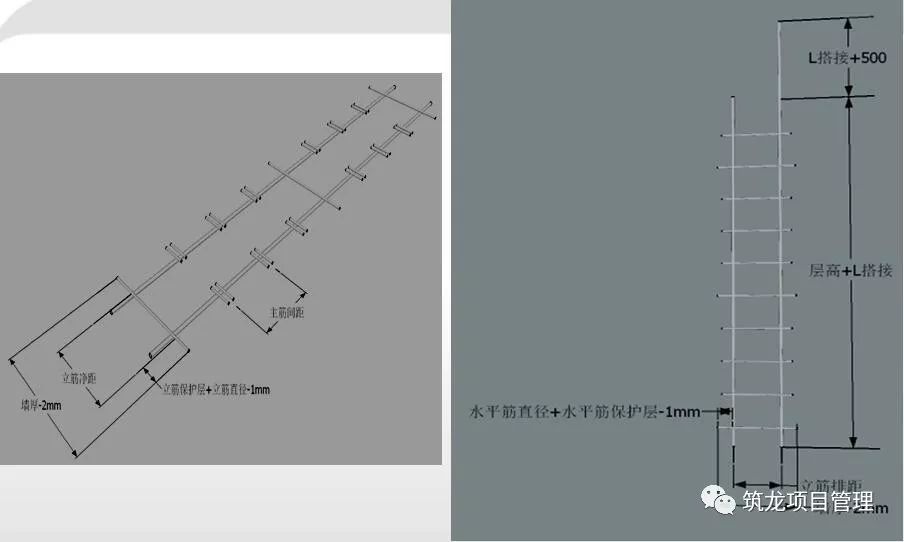

The locating bar shall have a detailed drawing, and the locating bar shall have a starting bar in the detailed drawing

.

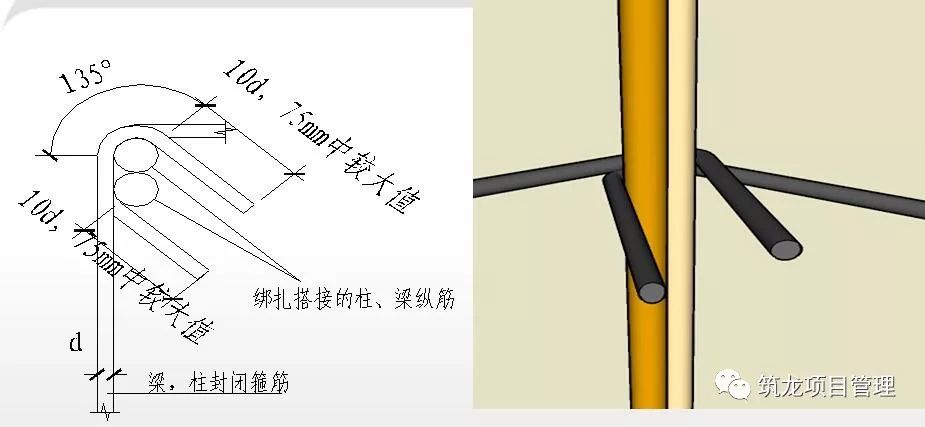

1) one stirrup of coupling beam is located at the edge of the hidden column and is 50 mm away from the edge of the hidden column; 2) The floor reinforcement is 50mm away from the wall (beam side); 3) The distance between beam stirrup and column edge; 4) The stirrups at both ends of the secondary beam are 50mm away from the main beam; 5) The distance between the wall horizontal reinforcement or hidden column stirrup and the floor (ground) surface is 30 ~ 50mm; 6) The vertical reinforcement of the wall is away from the concealed column and the special stirrup at the overlap of the main reinforcement of the column (concealed column) 50 mm near the door

.

The stirrup on the sleeve of the column (concealed column) is adjusted

.

The concealed column is bound

.

The hole is reinforced and reinforced

.

Three horizontal bars are bound at the overlap of the vertical reinforcement of the wall The protective layer of steel bar at construction joint shall be controlled, the quality of steel bar background processing shall be checked, the steel bar binding measures shall be checked, and the concrete for the engineering structure of steel bar binding concrete shall be commercial concrete

.

The qualification data of commercial concrete manufacturer shall be complete, and the inspection shall be qualified

.

The opening appraisal, mix proportion list, alkali ion, alkali ion, etc

.

shall be provided for each batch of concrete arriving at the construction site During transportation, the time from concrete mixing plant to construction site shall be strictly controlled to ensure that the initial setting time of concrete meets the requirements

.

The transportation and pouring equipment shall be inspected to be qualified

.

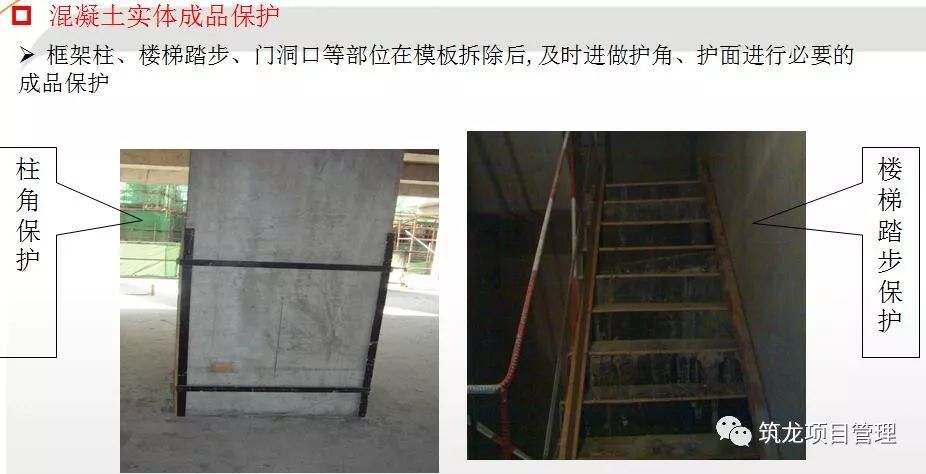

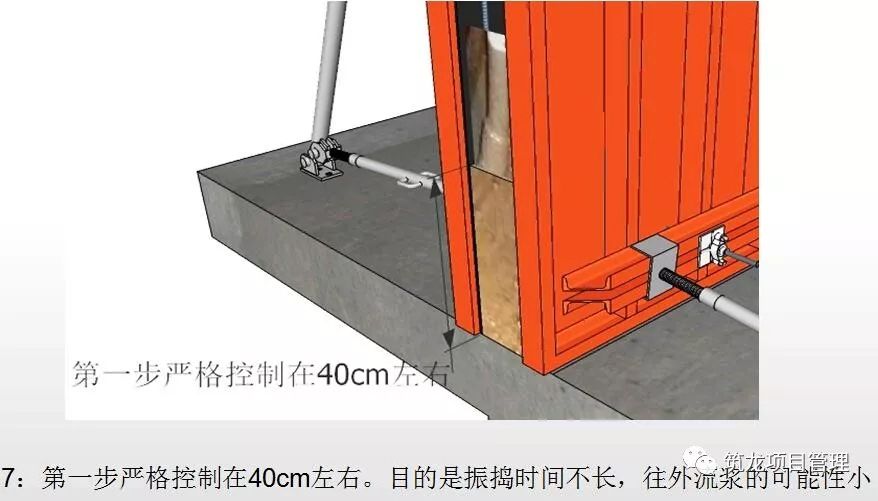

The scale rod shall control the layered blanking of concrete to prevent the wall and column from rotting, and the measures to prevent the wall and column from rotting, and the measures to prevent the wall and column from rotting, and the measures to prevent the wall and column from rotting Construction joint chiseling horizontal construction joint: remove weak layer and expose stones

.

Vertical construction joint: remove loose stones and expose dense concrete

.

The concrete foreman must do three things: 1) the first concrete of each shift should be identified; 2) The concrete pouring foreman must be there to see the layered vibration; 3) After removing the formwork, the foreman must come to remove the formwork and clean up the rotten roots (it must be plasterer or oiler, using the next truck of the same level of concrete slurry).

.