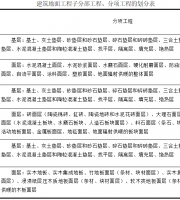

1

.

Bored pile I

.

construction preparation Before the commencement of construction, the “three supplies and one leveling”, design document review, raw materials and their tests, equipment selection, labor organization, commencement report, etc

.

shall be completed

.

The total station or GPSRTK with 2 “accuracy is used for construction lofting, and the S3 level is used for elevation measurement

.

After lofting, the protective pile is inserted and driven, and the protective pile shall be firm, stable and protected

.

Drilling equipment shall be selected reasonably according to the geological conditions and progress of the construction site, and rotary drilling rig and circulating drilling rig shall be preferred

.

Click me to read: sharing the latest practical series of excellent materials of the project

.

2、 Casing burying The top surface of the casing shall be 2m higher than the construction water level or underground water level, and 0.5m higher than the construction ground

.

For permeable stratum such as sandy soil and silt, clay shall be used to replace and fill to the bottom of the pile casing edge not less than 0.5m, the diameter of the pile casing shall be 20-30cm larger than the designed pile diameter, the length shall not be less than 2m, the wall thickness shall not be less than 10mm, the pile casing shall be buried vertically, the cohesive soil filled at the bottom and around shall be compacted layer by layer, and the top shall not bear load

.

3、 Mud system remarks: the figure above shows the setting standard of rotary drilling rig mud pool

.

The rotary drilling rig mud pool is set at every two piers, and the size of the mud pool is the same as above

.

· Mud consists of water, clay (or bentonite) and additives

.

The specific gravity of mud in clay layer is 1.05 ~ 1.20, and the viscosity is 16S ~ 22s; The specific gravity of mud in sandy soil layer is 1.20 ~ 1.45, and the viscosity is 19S ~ 28s

.

Mud pit protection: around the mud pit, custom-made protective railings are used for protection, the protective railings are assembled, the height of vertical pole is 1.5m, and the size of mesh is 1.2m × The width is 2.0m, and the surface is painted with red and white paint

.

The protective fence is installed on the top of the retaining dam

.

The distance between the protective fence and the edge of the foundation pit is not less than 0.5m

.

Plastic cloth is used inside the mud pit to protect the slope

.

After the mud pit fence is installed, night warning lights are installed at the four corners, and the warning lights are powered by LED dry battery

.

4、 Drilling · Rig in place: check the site and the installation of the main machines and tools of the rig, and prepare to start drilling only after the perpendicularity and center position of the drill bit and drill pipe meet the requirements Alignment: after the drilling rig is in place, the center of the pile position shall be restored by using the retaining pile, and the center of the pile shall be aligned manually with the mechanical drill, and the deviation shall not be greater than 5cm

.

Drilling: after the prepared mud is injected into the hole, the bit starts to run slowly During drilling, mud specific gravity shall be detected at any time, and drilling slag samples shall be taken according to the design requirements

.

The slag sample box is divided into five parts: 10 * 10 * 10cm square, hole finishing, hole cleaning and inspection

.

After the hole reaches the design elevation, the hole depth, hole diameter, hole position, hole shape and geological condition at the bottom of the hole are inspected

.

The slurry exchange method is used for hole cleaning to maintain the water head in the hole and prevent hole collapse and necking

.

After hole cleaning and before grouting, the mud indexes are tested respectively, and the requirements are as follows: 6

.

Fabrication and installation of reinforcement cage

.

The reinforcement cage is manufactured by automatic roll welding machine in the reinforcement processing plant

.

When the reinforcement cage is processed, the steel bar extending into the bearing platform is covered with a 1cm thick foam tube slightly larger than the main reinforcement diameter of the reinforcing cage and secured by wire binding

.

The foam tube can insulate the bond between steel bar and concrete, facilitate the peeling of concrete and steel bar, reduce the mechanical damage to the steel bar when breaking the pile head, but the position should be strictly controlled in the construction process

.

After the finished reinforcement cage passes the inspection, fill in the finished product label of pile foundation reinforcement cage, which adopts 40cm wide and 30cm high vehicle sticker + iron sheet

.

Click me to read: share the latest practical series of excellent materials of the project After the completion of hole inspection, the reinforcement cage shall be lowered

.

The reinforcement cage shall be hoisted by crane with double lifting points

.

The reinforcement cage shall not be dragged to the ground

.

Single side lap welding shall be adopted for the reinforcement cage orifice extension, the weld length shall not be less than 10d, and the joint reinforcement must be pre bent

.

The comprehensive grounding reinforcement must be identified and accurately butted

.

After the reinforcement cage is lowered, the cross arm is placed on the sleeper (220 * 160 * 2600mm) outside the orifice to ensure that the reinforcement cage is firmly installed

.

Each cast-in-place bored pile shall be provided with acoustic pipe according to the design requirements

.

The wall thickness and other indexes of acoustic pipe shall meet the design requirements, and measures shall be taken to fix firmly with the reinforcement cage during installation

.

The corresponding joints of adjacent sections shall be well marked

.

The bottom of the acoustic pipe shall be welded and sealed before leaving the factory

.

The joint connection shall be well sealed, and the top shall be sealed with rubber cover

.

When the reinforcement cage is lowered, clean water shall be injected into the pipe in time

.

After the installation, the measuring rope shall be lowered in time to check whether the acoustic measuring pipe is connected

.

If it cannot be connected, it shall be removed and placed again

.

Acoustic pipe installation (socket thread interface) reinforcement cage storage: the [14 channel steel welding diagram storage rack (the diagram is applicable to pile foundation with diameter of 1m) is adopted

.

The reinforcement cage is temporarily placed on the storage rack according to the specified area on site and covered with color strip cloth

.

It is strictly prohibited to put it directly on the ground

.

7、 After the concrete pouring and drilling reach the design elevation, the hole depth, hole diameter, hole position, hole shape and geological condition at the bottom of the hole shall be inspected

.

The slurry exchange method is used for hole cleaning to maintain the water head in the hole and prevent hole collapse and necking

.

After the reinforcement cage is lowered, the conduit shall be lowered one by one, and the distance from the lower opening of the conduit to the bottom of the hole shall be 25cm ~ 40cm

.

The first concrete pouring must ensure that the buried depth of the pipe is more than 1m, and the first concrete hopper must meet the requirements of bottom sealing

.

When pouring concrete, the filter screen should be used to filter the concrete, so as to prevent the large concrete from blocking the pipe

.

In the process of pouring, the elevation of concrete surface shall be measured in time by using the measuring rope and hammer that meet the requirements of the specification

.

Standard curing specimens: the concrete samples of the same part of the project mixed with 100 plates and not more than 100 cubic meters shall not be less than once, and at least one group of specimens shall be retained for each sampling

.

8、 The key points of management shall be implemented in strict accordance with the approved construction scheme and technical disclosure, and in accordance with the division of responsibilities Construction lofting: the survey group lofts the central pile position, hands over the pile to the on-site technical personnel, and does a good job in pile position protection Casing burying: the on-site technical personnel shall review the position and deviation of casing burying Mud preparation: on site testing personnel check mud index Pile foundation drilling: site technicians check the bit alignment and mechanical stability Pile foundation drilling: the technician of the first pile of each pile cap shall witness and take slag samples Final hole inspection: under the guidance of on-site technical or safety and quality personnel, the final hole inspection shall be conducted by using hole detector, and the inspection shall be reported to the supervisor after passing the inspection Reinforcement cage: the on-site technical or safety and quality personnel shall carry out factory inspection and on-site hole connection inspection, and report to the supervisor for inspection after passing the inspection Pile foundation grouting: the field test personnel test the concrete performance and make specimens, and the field technical personnel guide the whole process of grouting

.

2

.

Foundation pit excavation of bearing platform 1

.

The foundation pit of bearing platform shall be excavated manually with excavators, and the bottom shall be cleaned and the pile head shall be removed manually

.

When the foundation pit is excavated, a 20 cm high water retaining platform shall be set outside the excavation line to prevent surface water from flowing into the foundation pit

.

Collecting well and drainage ditch are set in the pit( This standard is applicable to ordinary foundation pit, and special foundation pit shall be constructed according to the corresponding special scheme after opening) · the enclosure of foundation pit of bearing platform shall be fully enclosed with fence, dense mesh, opening and step (including handrail)

.

The step ladder is assembled, customized, with armrest

.

The armrest is painted with red and white paint, which can be reused

.

2、 Reinforcement processing and installation: the reinforcement is processed and manufactured in the reinforcement processing workshop, transported to the site by flatbed truck, and after the inspection of the base is qualified, the accurate setting out and positioning, and the site binding are carried out

.

In order to ensure the overall stiffness of the bearing platform framework, it is necessary to set positioning support During the construction of mass concrete, the cooling pipe shall be buried according to the design requirements during the processing and installation of reinforcement The embedded reinforcement of pier body shall be installed with positioning fixture

.

3、 Concrete pouring and curing formwork shall meet the requirements of structural strength, rigidity and stability

.

Set shaped steel formwork is adopted to reinforce the structure

.

The ordinary bearing platform concrete pouring adopts the chute into the mold; When the concrete truck cannot reach the feeding port directly, the truck pump can be used to pour the concrete

.

The concrete is poured layer by layer, and the inserted vibrator is used to vibrate and compact.

.