The composition of the heating system is that when the indoor temperature is lower than the outdoor air temperature, in order to maintain the required indoor temperature, the corresponding heat must be supplied to the indoor, This kind of engineering equipment system supplies heat to the room

.

In short, the composition of heating system is: heat source + heat pipe + cooling equipment

.

Central heating system: the heat source and heat dissipation equipment are set separately, and the heat source transmits the heat to each room and building through the heat medium pipe, which is called central heating system

.

Floor heating belongs to central heating system

.

Central heating system is the most common heating system in South China

.

Generally, a heat source point is set up for an owner, a building or a group of buildings, and each user uses the heat source of this heat source point

.

Common forms of floor heating: floor heating can be divided into water heating and electric heating according to different heat media

.

Water heating system: water heating is through the ground coil, there is circulating hot water in the pipe, through the heat medium in the floor radiation layer, heating the whole ground evenly, using the ground’s own heat storage and upward radiation of heat to conduct from bottom to top, so as to achieve the purpose of heating

.

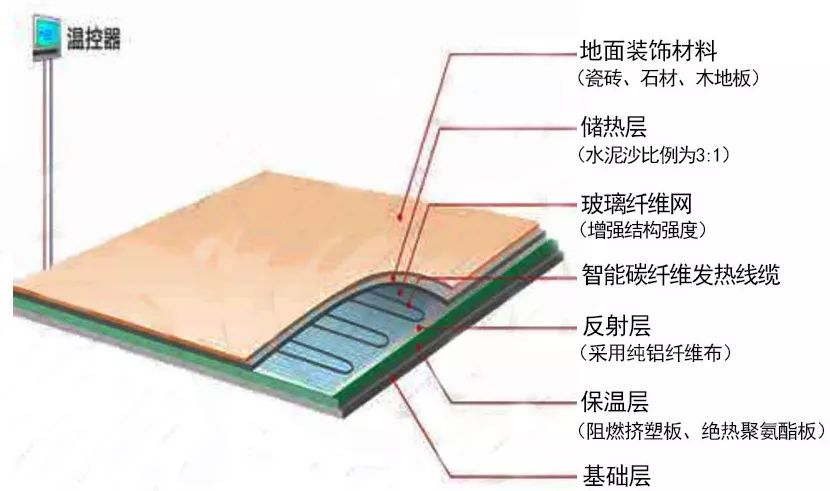

Water heating △ electric heating system: the heating cable is used as the heating body, which is laid under various floor, tile, marble and other ground materials, and then equipped with intelligent temperature controller system, so as to finally achieve the purpose of heating

.

The principle as like as two peas is different from the principle of water heating

.

The principle of electric heating is simpler than that of plumbing

.

Besides the principles, other structural methods, design requirements, process and precautions are exactly the same

.

02

.

Floor heating construction process 1

.

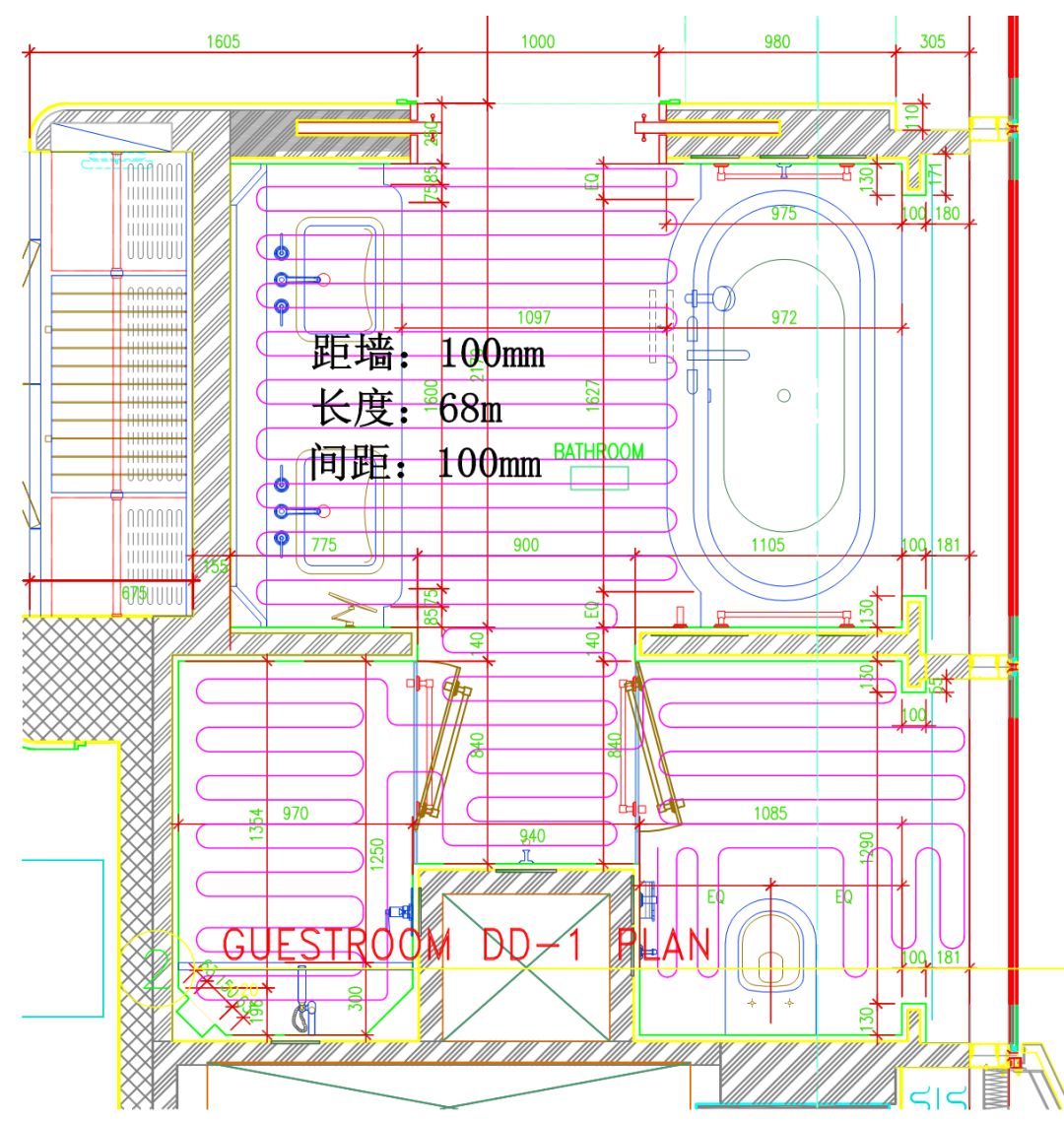

Construction preparation (1) construction drawing design document preparation (1) design description; ② Layout plan of heating system and heating components in the building; ③ Layout of temperature control device and relevant pipelines

.

When centralized control system is adopted, wiring diagram of relevant control system shall be provided; ④ Power supply system diagram and related pipeline plan( 2) Technical preparation: 1

.

Calculate the total heat load of the room and the total power supply of the heating cable; ② Determine the brand, specification (line power), total length, working voltage, working temperature and other technical data of heating cable; ③ Determine the layout of heating cable; ④ Determine the type, thermal conductivity, density, specification and thickness of the insulation material; ⑤ Determine the temperature control measures and the type of temperature controller, as well as the working voltage, working current and other technical data and conditions of the electronic control system

.

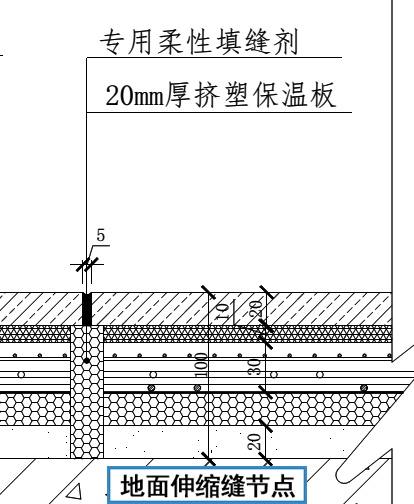

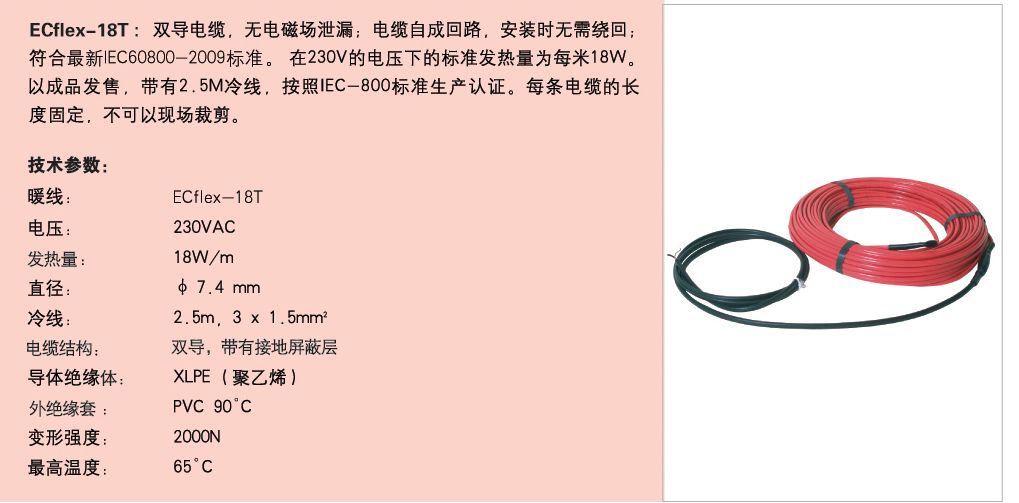

When the centralized control system is adopted, the control requirements and principles shall be explained; ⑥ Determine the node diagram of floor heating construction; ⑦ Determine the expansion joint setting of large area floor heating construction space, determine the cable model: ① heating cable: ecflex-18t Danfoss double conductor cable, and the factory certificate, inspection report, attached instructions and other technical documents shall be complete

.

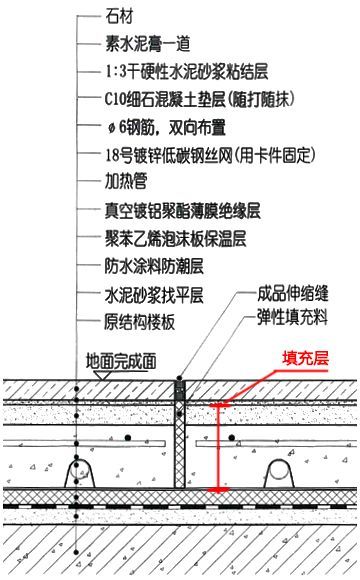

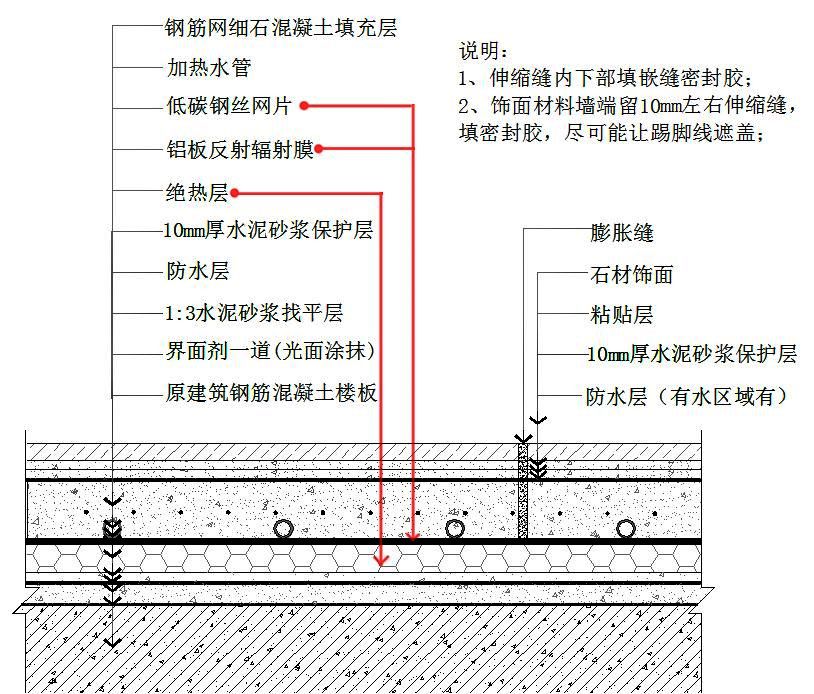

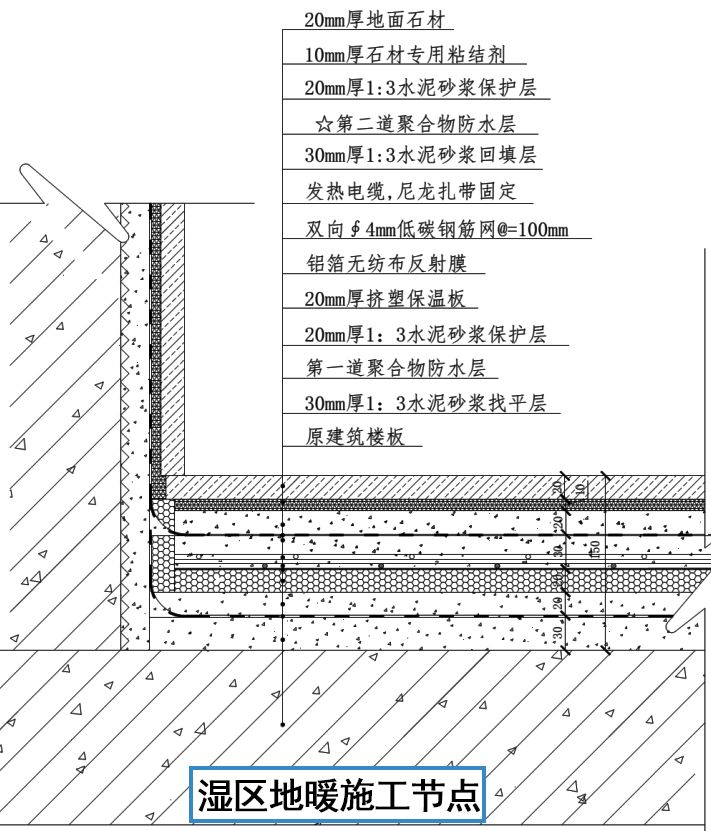

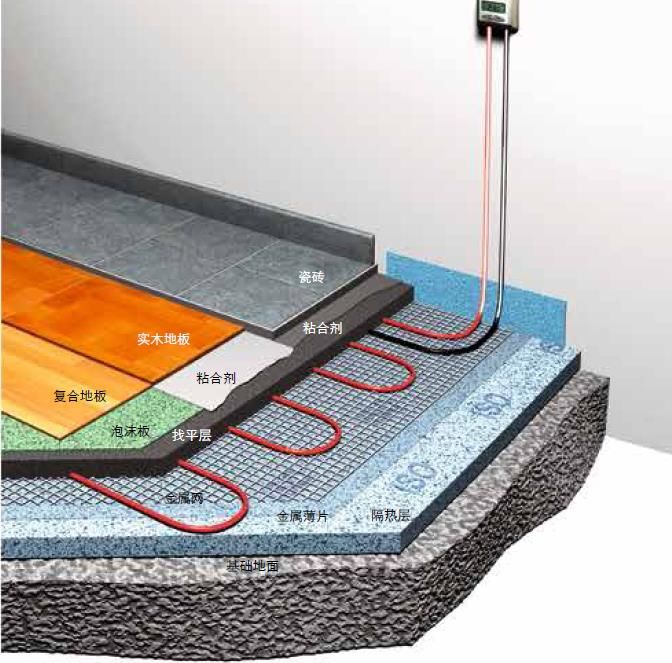

② Insulation layer: 20 mm thick, B2 grade extruded board ③ reflective layer: aluminum foil non-woven reflective film ④ Fixation: Φ 4mm@100 *100 steel wire mesh, nylon tie, ⑤ temperature controller: devlregtouch intelligent electronic temperature controller (3) draw the layout of different areas, indicating the laying distance of cables and the laying length of heating cable circuit( 4) Drawing the node diagram of floor heating construction, the general electric floor heating includes: insulation layer, cable layer, filling layer and surface layer

.

There will also be two waterproof layers for floor heating in wet areas

.

When setting the ground expansion joint, we should put the floor heating cable layout, furniture layout and floor finish together

.

We should not only consider the function of the expansion joint, but also consider the beauty of the surface decoration

.

2

.

Insulation layer construction (1) the original working face of laying insulation layer should be flat, dry and free of debris, and the root of corner interface should be straight and free of ash deposition( 2) the insulation material should be made of high foamed polyethylene foam, and the thickness should not be less than 10mm (specification)

.

The 20mm Extrusion board is used in Tianjin four seasons

.

The lap joint shall be adopted, and the lap width shall not be less than 10 mm; ( 3) The side insulation layer should be from the upper edge of the radiation surface insulation layer to the upper edge of the filling layer; Reliable fixing measures shall be taken at the junction, and the side insulation layer and radiation insulation layer shall be tightly connected

.

3

.

When the reflective film is laid on the insulation layer, a layer of aluminum foil reflective film is usually laid

.

The overlapping mode shall be adopted between the reflective films, and the insulation layer shall not be exposed

.

4

.

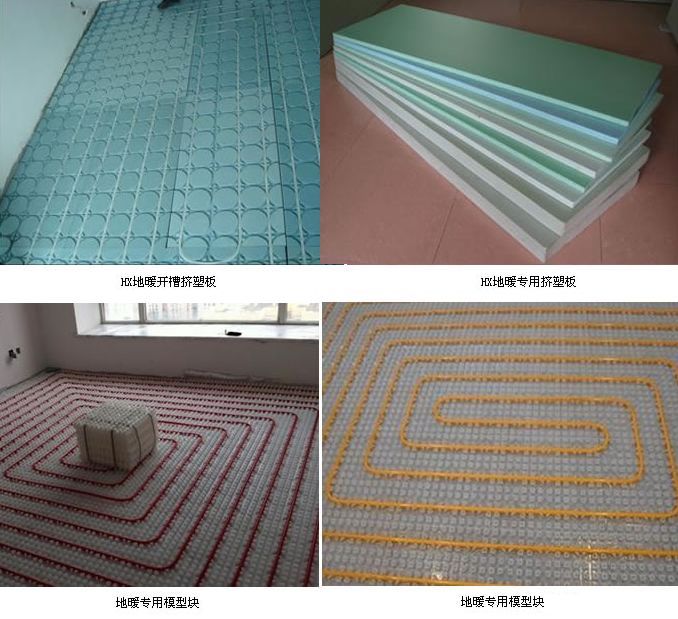

Cable laying: metal mesh shall be laid under the heating cable, and the following requirements shall be met: The mesh of metal mesh shall not be greater than 100 mm * 100 mm, and the metal diameter shall not be less than 1.0 mm

.

The heating cables shall be laid according to the cable spacing and direction specified in the construction drawings

.

The heating cable shall be kept straight, and the installation error of cable spacing shall not be greater than 10 mm

.

Before laying, check the model according to the construction drawings, and check the appearance quality

.

The maximum distance between heating cable hot wires should not exceed 300 mm and should not be less than 50 mm; The distance from the inner surface of the outer wall shall not be less than 100 mm, and the distance between the nearest cable and the wall shall be 200 mm-300 mm

.

In the process of construction, when there is overlap between heating cables, it is strictly forbidden to electrify the cables, and the heating cable circuit should be set independently in each room

.

When the heating power and total length of heating cable required by the room exceed the maximum total power or total length of single heating cable in the product specification, the cables shall be divided into two or more independent circuits

.

The maximum total power or total length of each loop heating cable should be determined by considering the following factors: it should not exceed the maximum rated working current of the selected temperature controller; It should not exceed the product specification limit

.

5

.

The following conditions should be met before the construction of filling layer: (1) the heating cable is qualified through resistance test and insulation performance test( 2) The expansion joints of side insulation layer and filling layer have been installed; ( 3) The installation box of the temperature controller and the cold wire of the heating cable have been arranged; ( 4) It has passed the acceptance of concealed works

.

6

.

Surface layer paving (1) considering that the stone will crack when heated, it is suggested that the stone should be treated with back glue and back net; ( 2) The expansion joint with a width of 10 mm shall be reserved at the junction of stone and ceramic tile with internal and external walls, columns and other vertical components

.

The expansion joint shall be 10 mm-20 mm higher than the upper surface of the surface layer from the upper edge of the filling layer

.

After the surface layer is laid, the excess part shall be cut off

.

7

.

Debugging of floor heating (1) considering the influence of heating rate on stone, indoor wood finish and latex paint, the heating rate should not be too fast, and 5 ℃ per day is recommended( 2) The heating temperature should not exceed 25 ℃, otherwise the emulsion paint and wood veneer are easy to crack

.

03

.

Floor cracking caused by floor heating and preventive measures 1

.

Cause analysis of cracking (1) in terms of materials, the quality of stone is unqualified, there are too many dark cracks, natural cracking due to external force, or the plate width of stone is too large (more than 800 * 800mm), and no strengthening treatment is carried out( 2) In terms of floor heating construction, the working principle of floor heating can be simply understood as raising the ground temperature to form a heat radiation surface, which is a way of heating indoor by radiation and convection heat transfer

.

Let’s take the concrete filled water and floor heating as an example: for example, the conventional: the thickness of the filling layer is insufficient, the expansion joint is not set, the steel mesh is not set reasonably, the compressive strength of the insulation layer (insulation board) is not enough, the bonding strength does not meet the requirements, and the maintenance is not in place, etc These factors will eventually lead to the cracking of the stone laid on the floor heating.

.