1

.

Construction preparation (1) the position and size of the technical preparation gate shall be consistent with the construction drawing, and the technical disclosure shall be done according to the construction requirements

.

( 2) Quality requirements There shall be no degumming blisters on the door panel

.

The warpage of the plate with nominal thickness over 6 mm shall not exceed 1%( 3) Working condition 1) after the door frame is closed and leaves enter the site, organize the oil workers to brush the side of the frame against the wall and the ground with anti-corrosion paint in time

.

The bottom layer should be placed on the skids

.

In the warehouse, the height of the skids from the ground should not be less than 200 mm

.

The height of the temporary open shed skids from the ground should not be less than 400 mm

.

The skids should be padded between each layer to make it natural ventilation

.

It is strictly forbidden to stack wooden doors in the open air

.

2) Before installation, check whether there is warping and twisting, bending, angle shifting, splitting, loose joint between mortise and groove, and repair if any

.

3) The pre installed door frame shall be installed at the elevation of the floor and ground base or when the wall is built to the elevation of the window sill

.

The post installed door frame shall be installed after the acceptance of the main works and the embedding of anti-corrosion wood bricks at the door opening

.

4) The door leaf shall be installed after finishing

.

For the door leaf without wooden door frame, the embedded parts shall be installed at the wall side

.

2

.

Key points of materials and quality (1) key requirements of materials 1) the specification and model, wood category, material selection grade, moisture content and production quality of wood door or frame leaf shall meet the design requirements

.

2) Preservative, paint, wood screw, hinge, bolt, stile hook, door lock and other hardware must meet the design requirements( 2) Key technical requirements: when installing hinges, the hinge groove should be flat inside and lying outside

.

Wood screws are strictly prohibited to be nailed in at one time

.

The depth of nailing should not exceed 1 / 3 of the length of the screw, and the depth of screwing should not be less than 2 / 3

.

When screwing, it should not be tilted

.

In case of knots, drill holes on the knots, re insert the plugs and then tighten the wood screws

.

Only in this way can the hinge be flat and the wood screw be tightened horizontally

.

In case of hard wood, it can be drilled in advance, and the diameter is less than 1.5mm of wood thread diameter( 3) Key quality requirements: 1) grasp the thickness of plastering layer when erecting the frame to ensure that the door frame with face is flush with the plastering surface after installation

.

2) When installing the door frame, you must measure the size of the opening in advance, calculate and adjust the gap width

.

Avoid too large or too small gap between door and window frame and door and window hole

.

3) The embedment of wood bricks must meet the requirements of quantity and spacing, that is, each side of the door within 2m high should not be less than 3 wood bricks, and the spacing of wood bricks should be 0.8-0.9m; For the door frame more than 2m high, the spacing between wooden bricks on each side shall not be more than 1m, so as to ensure that the door frame is firmly installed( 4) Key requirements of occupational safety and health: 1) when cutting the board, it should adapt to control the harm of sawdust to the construction personnel, and wear protective masks when necessary

.

2) When using shelves and miter ladders, pay attention to check whether they are firm before operation

.

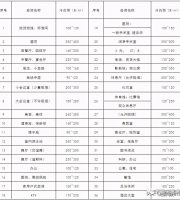

3) Strictly regulate the safe construction electricity, and check whether the wire and leakage protection are in good condition in the construction on time( 5) Key environmental requirements: the following factors affect the environment during the manufacturing and installation of wooden doors, as shown in the table Wooden door production and installation engineering environmental factors 3

.

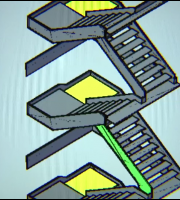

Construction technology (1) process (2) operation technology 1) Batching and cutting Batching is carried out on the basis of discharging

.

Therefore, it is necessary to calculate the size and quantity of each component, list the batching list, and carry out batching according to the batching list

.

The raw materials should be selected when mixing, and the rotten and inclined cracked wood should be avoided as far as possible; Wood that is not dry cannot be used

.

Careful calculation, length matching, first with long material, then with short material; First frame material, then fan material

.

When the door frame material has a straight bending, the bending is generally not more than 4mm

.

When batching, reasonably determine the machining allowance, the specific reference is as follows: section size: single side planing increase 1-1.5mm, double side planing increase 2-3mm

.

When machining, single side planing increase 3mm, double side planing increase 5mm

.

See table for machining allowance of length allowance

.

Machining allowance of door member length The defects of wood should be paid attention to when batching

.

Knots should be avoided in the parts of holes and tenons to prevent chiseling or tenon breaking

.

Knots are also prohibited in the parts of thread starting

.

Cut off and split lines are drawn on the selected wood according to the size of the blank

.

Considering the loss of the broken wood, a loss of 2-3mm is generally reserved

.

When squatting, pay attention to the straight line and flat end face

.

3) Planing When planing, the lining with clear texture should be used as the front face, and a narrow face should be selected as the front face for the frame

.

For the stiles and risers of the door frame, only the face should be planed, not the side against the wall; The upper riser and stile on the door leaf can also be planed on three sides first, and the side near the stile can be planed according to the size of the joint when it is installed

.

4) scribing and scribing is based on the structural requirements of the door

.

When marking, we should first make clear the size and form of mortise and mortise, where to make mortise and where to chisel, make clear the drawing requirements and sample style, the size and specification must be consistent, and make samples first, and then formally mark after passing the examination

.

If there is no special requirement for door frame, it can be inserted with flat shoulder

.

When the width of stile exceeds 80mm, double solid tenons shall be drawn; When the thickness of stile exceeds 60mm, double tenon shall be drawn

.

Draw single tenon below 60mm

.

If the width of the riser is greater than 180mm, the upper and lower double tenons are usually painted

.

The tenon thickness is generally 1 / 4 ~ 1 / 3 of the material thickness

.

Generally, the depth of half mortise is not more than 1 / 4 of the cross section of the material, and the shoulder of the riser should match the tenon

.

Batch line drawing should be carried out on the easel

.

Stack the door material on the shelf, tighten and fix the screws, and then draw it with a T-square at a time, which is accurate and rapid, and mark the front or viewing side of the door material

.

All mortise and mortise shall be marked with full or half mortise and tenon or half mortise

.

After drawing the front liner, draw the eyeliner to the back and draw the chamfering and cutting line so that all of them are painted first

.

The line should be clear, accurate and complete

.

5) Before drilling, a chisel equal to the width of the hole should be selected

.

The holes should be straight along both sides of the wood grain, and no mistakes should be made

.

First full eye, then half eye

.

The whole eye should first hit the back, chisel to half, turn over and then hit the front until through

.

The front side of the eye should leave half of the inner line, and the back side should not leave the line, but it is slightly wider than the front side

.

When the tenon is installed in this way, the impact can be reduced, so as to avoid cracking around the hole

.

In batch production, check the position and size of the eye frequently to avoid errors

.

6) Tenon, pull shoulder tenon, also known as inverted egg, is according to the tenon line longitudinal crouch open

.

Shoulder pulling is to saw off the shoulder on both sides of the tenon, and the tenon is made by tenoning and shoulder pulling

.

Pull shoulder, tenon to leave half a ink line

.

The tenon should be square, straight, and the mortise should be intact without being damaged by the shoulder pulling operation surface

.

The length of half tenon should be 2-3mm less than the depth of half hole

.

The tenon should be square and straight, and the root of the tenon should not be damaged

.

The wedge head is chamfered to prevent the back of the eye from cracking when installing the wedge head

.

7) Cut and chamfered cut is to plane out a square corner of the frame for glazing

.

Use a cutting plane or a crooked mouth to plane

.

When quickly planing to the part to be planed, use a single line planer to remove the sawdust

.

Until planing, the cut mouth shall be square and straight, and there shall be no furring or uneven phenomenon of the berm

.

Chamfering is also called inverted eight character, that is, plane a triangle part along the frame

.

Chamfering should be straight and firm, and should not cross the line

.

The cutting edge can also be cut with electric socket, leaving 1mm, and then planed to the required position with a single line planer

.

8) Before assembly, the parts shall be inspected

.

The parts shall be square and straight, the thread feet shall be neat and clear, the surface shall be smooth, and the size, specification and style shall meet the design requirements

.

And use a fine plane to polish the remaining ink lines.

.