1、 Site construction operation (1) site mechanical equipment of project 1 work area: 1 cement mixing vertical tank, 1 generator, 2 excavators; Site construction content: steel sheet pile support for sewage pipe trench in mileage K0 + 703 ~ K0 + 698 section; Intercepting ditch is built at the top of the trench of mileage K0 + 570 ~ K0 + 590, and reinforcement mesh is hung at the side of the trench of sewage pipe of mileage K0 + 700 ~ K0 + 730; The wall body and roof formwork shall be installed on the bottom plate of communication cable pipe gallery in mileage K0 + 095 ~ K0 + 125, and the bottom plate formwork shall be installed in mileage K0 + 155 ~ K0 + 185

.

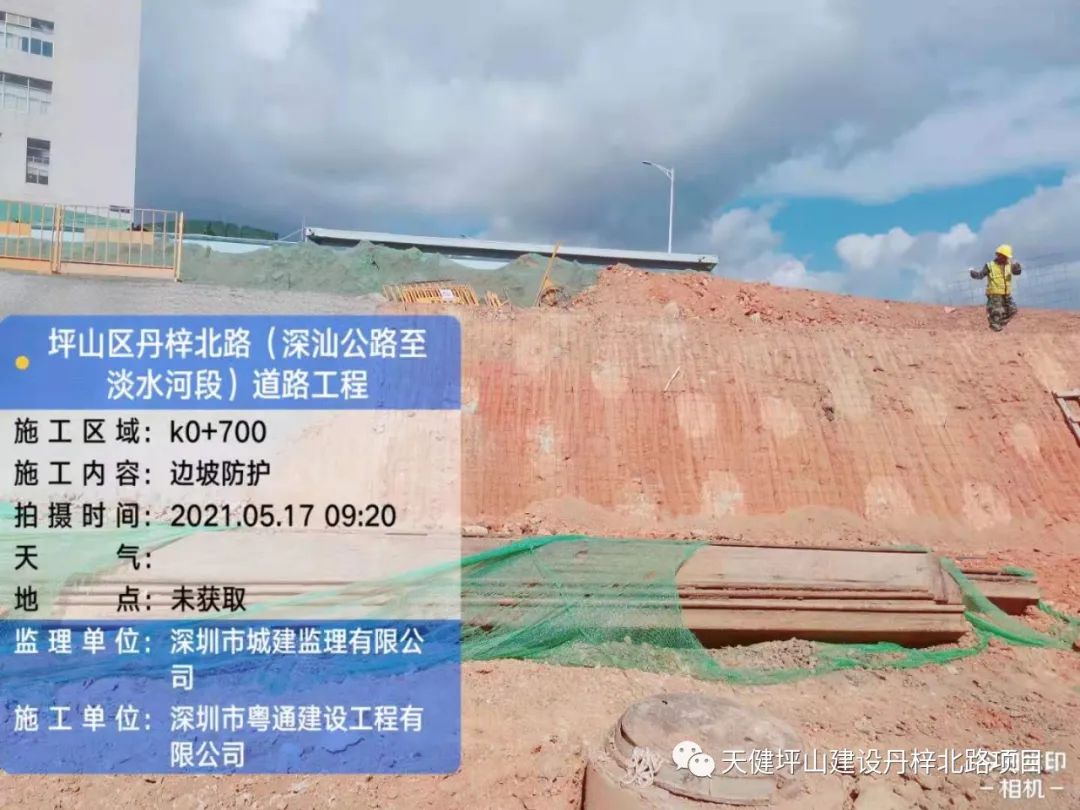

K0 + 700 slope protection (2) site mechanical equipment in the second work area of the project: 1 cement mixing pile machine, 7 excavators, 15 new energy dump trucks, 1 roller and 1 local curing equipment; Site construction content: Earthwork excavation of rainwater tank culvert in mileage K2 + 010 ~ K2 + 020 section turns to 490 m inside ³; Installation of bottom slab reinforcement formwork for 7 × box culvert in section K1 + 835 ~ K1 + 844; 80m graded crushed stone cushion is backfilled at the base of box culvert in section K1 + 910 ~ K1 + 950 ³; Installation of bottom plate reinforcement for communication cable pipe gallery of mileage K2 + 310 ~ K2 + 280 section; Y156, y157, y158, y159, y81 rainwater shaft installation; The excavation earthwork of y72-y74 rainwater pipe foundation trench is turned inward, and the formwork of y78 rainwater well is installed; The sewage pipe trench of w109-w110 section is backfilled layer by layer and compacted with stone powder; Excavation of sewage pipe trench in w110-w111 section, earth transfer 250m ³; 65 cement mixing piles have been completed in K1 + 220 ~ K1 + 260 section; In situ curing construction of mileage K1 + 520 ~ K1 + 570 section has completed an area of 1100 m2

.

K2 + 260 cable trench reinforcement installation K1 + 350 local solidification construction K1 + 200 cement mixing pile construction (3) site machinery and equipment in the third work area of the project: 1 cement mixing vertical tank, 1 cement mixing pile machine; Site construction content: none

.

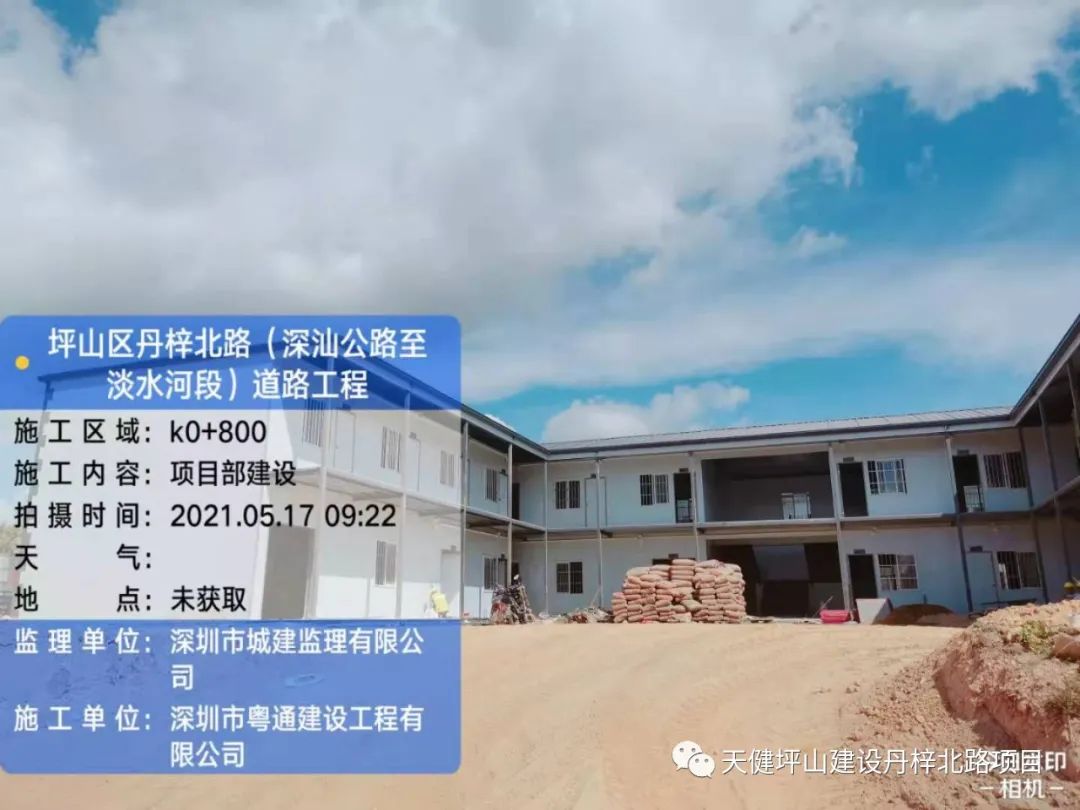

(4) mechanical equipment of temporary construction site of project department: 1 excavator, 1 forklift, 1 sprinkler; Site construction content: the temporary construction site of the project department is clean and sanitary

.

K0 + 800 temporary construction materials mobilization II

.

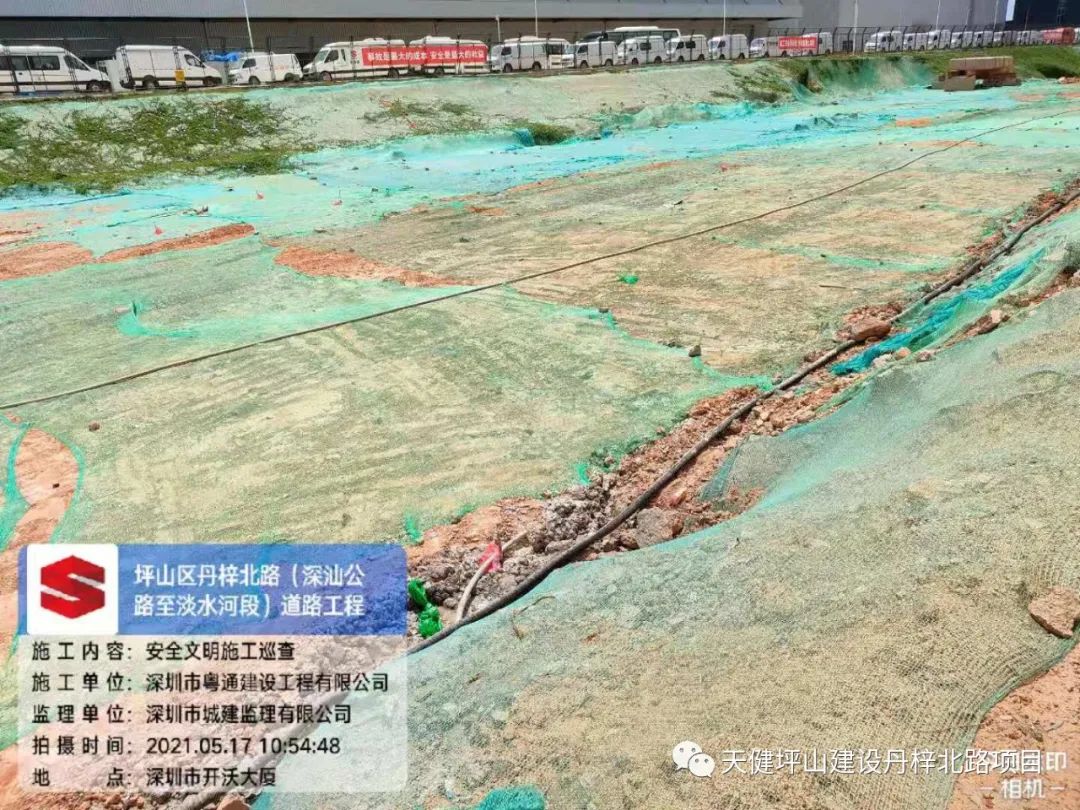

Safe and civilized construction (1) morning class meeting (2) evening class meeting (3) civilized construction new workers’ safety technical disclosure safe and civilized construction (1) safe and civilized construction (2) III

.

equipment and materials mobilization acceptance, inspection and submission for inspection No

.

4, No

.

5, No

.

4, No

.

5, No

.

1 work area of tomorrow’s construction schedule: driving supporting steel sheet piles in sewage pipe trench of mileage K0 + 650 ~ K0 + 700 section; The slope of sewage pipe trench at mileage K0 + 700 ~ K0 + 735 is hung with steel mesh and sprayed with concrete; The floor of communication cable pipe gallery at mileage K0 + 095 ~ K0 + 125 is installed with wall body, roof reinforcement and formwork

.

Two excavators were put into operation

.

Work area II: Earthwork excavation of rainwater tank culvert in mileage K2 + 010 ~ K2 + 030 section turns inward; 7 × box culvert installation of section K1 + 835 ~ K1 + 844, bottom slab reinforcement completed inspection and installation of formwork; For K2 + 310 ~ K2 + 280 section of communication cable pipe gallery, the installation of bottom plate reinforcement has been completed, and the application for inspection and installation of formwork has been completed; Y79, y80, y81, y158 shaft installation ladder; The trench excavation of y72-y74 rainwater pipe is carried out with earth turning in, and the bottom of y72-y74 rainwater pipe is laid with sand cushion and installed with pipes; Y69 and y70 rainwater wells are built with external wall brick formwork; Trench excavation and pipeline installation of sewage pipe trench in w110-w111 section; Construction of cement mixing pile in mileage K1 + 200 ~ K1 + 260 section; In situ solidification construction of mileage K1 + 300 ~ K1 + 900 section; One cement mixing pile machine, one set of on-site curing equipment, seven excavators, eight new energy dump trucks and one road roller are put into operation

.

Work area 3: no source: Tianjian Danzi North Road Project Department information release center editor: Danzi North Road Project Department office proofread by:.

.