Chu Yusong’s reservation and embedment is not only a difficult point but also a key point in the construction of mechanical and electrical installation

.

It complements and restricts each other with other processes

.

It can not only shorten the construction period and save the cost, but also lay a good foundation for the next installation

.

The author shows the control method of water and electricity reservation and embedment of the project, which is used to guide the construction of the project, and has achieved the expected effect, so I would like to share with you

.

Casing cutting production and processing, pipe less than or equal to DN 100 are used cutting machine cutting, gas welding cutting is strictly prohibited

.

In the current industrial and civil engineering construction site, automatic cutting is rarely used

.

In order to ensure the accuracy of hole diameter, the fixed fixture is made and the water stop ring is cut by hand

.

The round hole is smooth without burr

.

Casing production finished product: standard water stop ring, smooth pipe, full welding, no slag and air hole

.

Three steps of floor embedded casing: oil painting, fixation and draft· The first step: oil painting

.

The second step: marking, positioning and fixing

.

The third step: drawing through wall casing embedding

.

Installation of waterproof steel casing and civil air defense sealed casing; The casing pipe shall be fixed firmly with correct coordinate and position; The reinforcement densification area of the hole is densified in place· The outer wall casing grounding flat iron is reserved

.

The civil air defense area is three closed ribs

.

The civil air defense ventilation pipe is reserved 10cm out of the wall

.

The hole densification area must be densified with reinforcement

.

After removing the formwork, check the relationship between the embedded casing and the wall

.

The appearance quality is good and meets the installation requirements

.

The process control of mechanical and electrical installation engineering quality is based on the current national quality acceptance standards and enterprise construction technology standards

.

But for the operation team, the construction technical disclosure is the basis for the professional quality inspector to check and control the operation quality

.

Therefore, in order to effectively control the quality of mechanical and electrical installation engineering during team operation, the first thing is to improve the preparation and disclosure of technical disclosure

.

In the preparation of technical disclosure, reliable measures, operation technology and quality standards for preventing and controlling common quality problems are formulated according to the current national quality acceptance specifications and enterprise construction technology standards; It is to strengthen the process inspection of the quality inspector, focusing on whether the process meets the requirements of the corresponding standards, whether the process quality meets the requirements of the technical disclosure, and timely discover the illegal operation, so as to eliminate the common quality problems in the bud

.

Ensure that the later installation can be carried out smoothly! Lightning protection grounding welding: lightning protection grounding welding requirements: double sided welding, welding length greater than 6D; The welding point shall be smooth and flat without undercut, slag inclusion and welding leakage, and the welding slag shall be removed

.

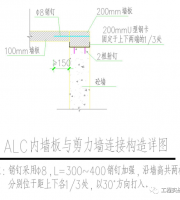

Positioning and installation of steel wire box of shear wall: the spacing and elevation of embedded wire box in the same place are consistent; The location and spacing of the reserved wire box should be reserved and embedded according to the standard line

.

Positioning and installation of embedded shear wall threading box: pop up the wall control line on the board, and take this control as the benchmark; According to the location map of hydropower station, the dimension of wire box is located; The steel wire box shall be bound firmly

.

After the formwork is installed, the box mouth is close to the formwork

.

After the formwork is removed, the box mouth is flush with the wall, which is beautiful and does not need to be repaired

.

Electric box bottom box prefabrication and processing: in the water and electricity processing room angle steel production, electric box hole in place; The back of the box body shall be provided with grid to meet the tight connection of concrete pouring

.

Positioning and installation of the bottom box of the primary structure electric box: the four corners of the electric box shall be made of 30 * 3 angle steel equal to the thickness of the wall, clamped with steel bars, fixed firmly, the four corners shall be flush, and the level ruler shall be used to level the box

.

The embedding method of primary structure box: the electric box is sealed and firmly supported, and the wood is used to support the box, so as to avoid the deformation of the box during the pouring

.

After removing the formwork, check that the bottom box of the box is flat with the wall, without deformation and good appearance

.

The pipelines are dense, so the distance between pipelines must be ensured when arranging pipelines to meet the requirements of later concrete pouring

.

Strengthen the cooperation between installation engineering and civil engineering

.

1

.

Be familiar with the drawings and do a good job in the joint review of drawings

.

After receiving the construction drawings, the mechanical and electrical installation personnel should be familiar with the drawings, understand the functions, civil structure, construction schedule and construction methods of the mechanical and electrical installation engineering, so as to achieve the ability of reading and speaking drawings, and do a good job in the joint review of drawings with the civil construction personnel

.

The incomplete design on the drawings and the parts in conflict with the civil construction shall be put forward to the designers during the joint review, and the parts requiring civil cooperation shall also be discussed, so as to prepare for the reservation and embedding work

.

2、 Grasp the time, do a good job with civil engineering, civil engineering cooperation is multi type of work, multi process, multi personnel cross construction operation

.

In order to do a good job of embedding, it is also the key to improve the construction period to grasp and control the construction time of each type of work, that is, to understand the content of electromechanical embedding, the situation of building structure and the location of embedding according to the requirements of electromyography and civil engineering drawings, closely cooperate with civil engineering, and reasonably arrange and cross work

.

Each type of work should do a good job in the next process handover, only timely and accurately do the embedded work, can the project be carried out orderly

.

Select a few architectural micro signals and recommend them to you by pressing the identification QR code.

.