Safety operation procedures are also known as “safety technical instructions” and “safety technical rules”

.

According to the nature of production and the characteristics of technical equipment, combined with the actual situation, the enterprise designates safety operation rules for workers of various types of work

.

It is a basic document for the enterprise to implement safety production, and also the main basis for safety education for workers

.

It generally includes four parts: General principles, safety rules before work (i.e

.

preparation before work), safety rules at work, safety rules before work, safety rules before work, safety rules before work Safety rules at the end of work (including handover work)

.

The text of the regulations should be concise, not only indicating the specific operation requirements and methods, but also pointing out the matters that should be paid attention to or prohibited

.

In terms of safety, it is to follow this operation procedure, so as to reduce the risk factor as much as possible

.

In simple terms, only when you comply with the relevant safety operation terms in the operation of equipment or operation, can you ensure your safety and avoid accidents; These terms are summed up to form an operation procedure, which is called safety technical operation procedure

.

It is the summary of people’s long-term practical experience

.

It not only reflects the safety relationship between people and things (equipment), guides people’s safety behavior, but also reflects the relationship between people

.

Moreover, it is an important rule to guide the safety production of employees; It is the most powerful weapon to prevent production safety accidents《 According to the production safety law of the people’s Republic of China, the construction law of the people’s Republic of China, the regulations on the administration of production safety of construction projects, and the relevant technical standards and specifications for construction project safety, the technical operation procedures for construction safety of construction projects are compiled by domestic experts《 The main technical contents of “construction safety technical operation regulations” are as follows: first, the general requirements of construction safety organization management and safety technology; The second is the standard of safety technical facilities; The third is the safety standard of equipment; Fourth, safety technical operation standards

.

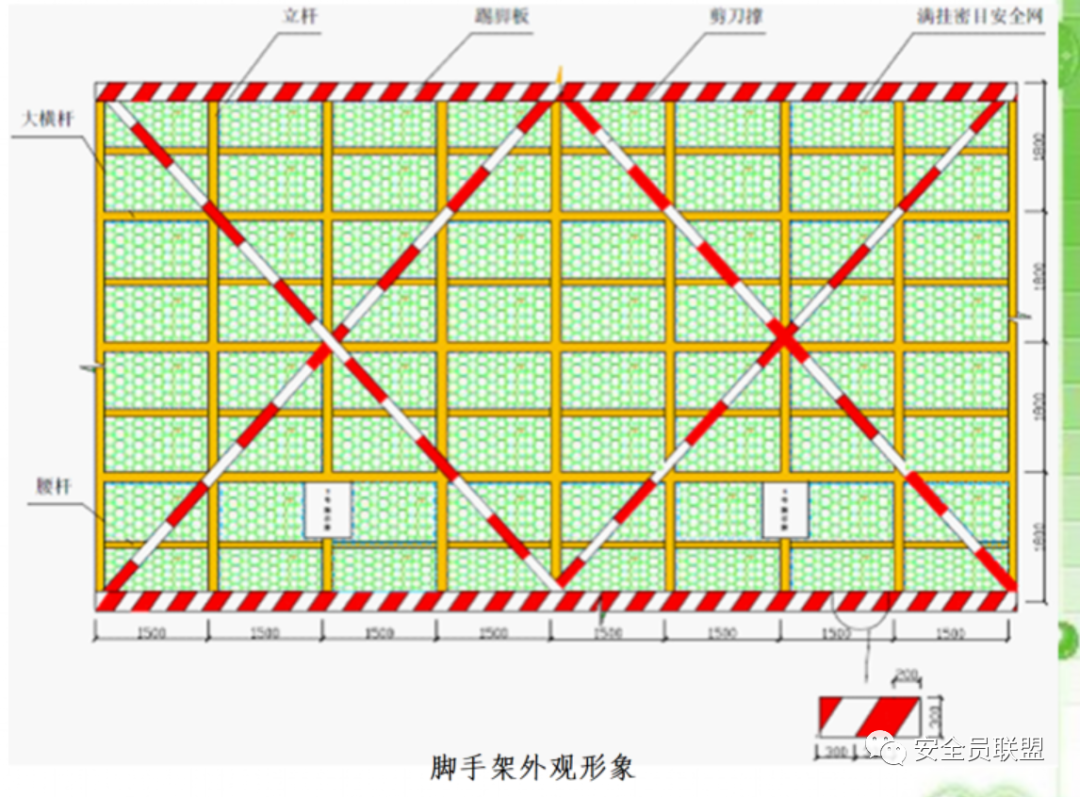

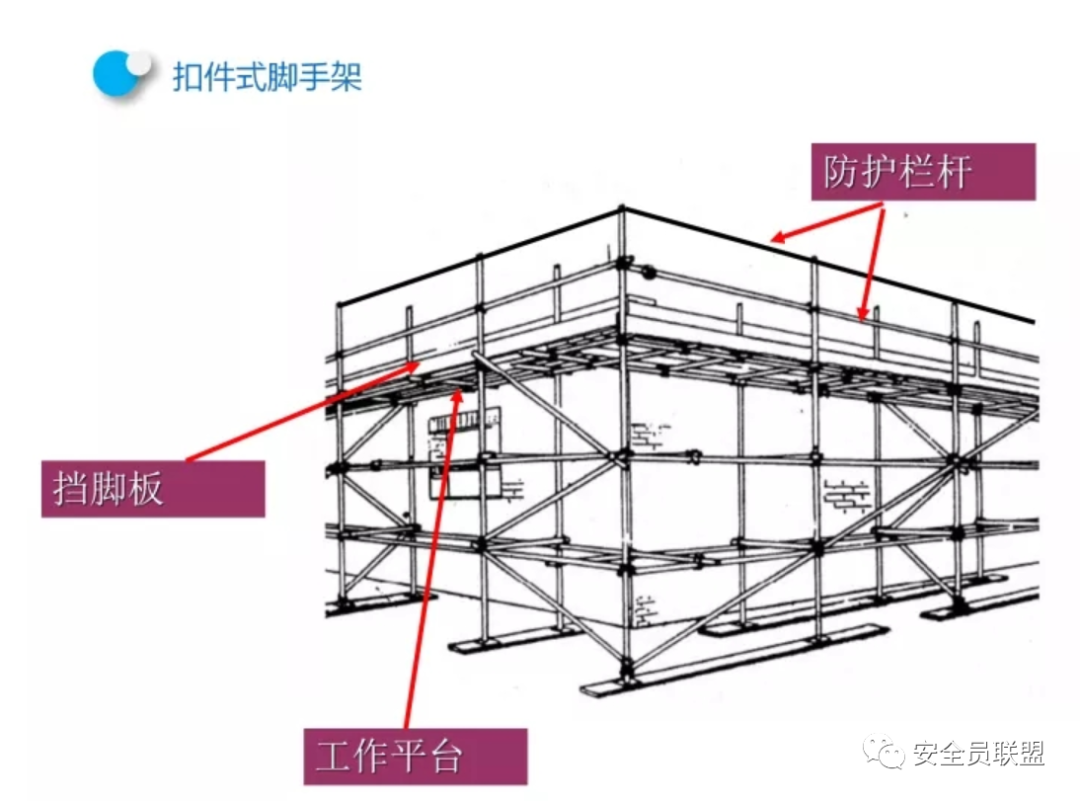

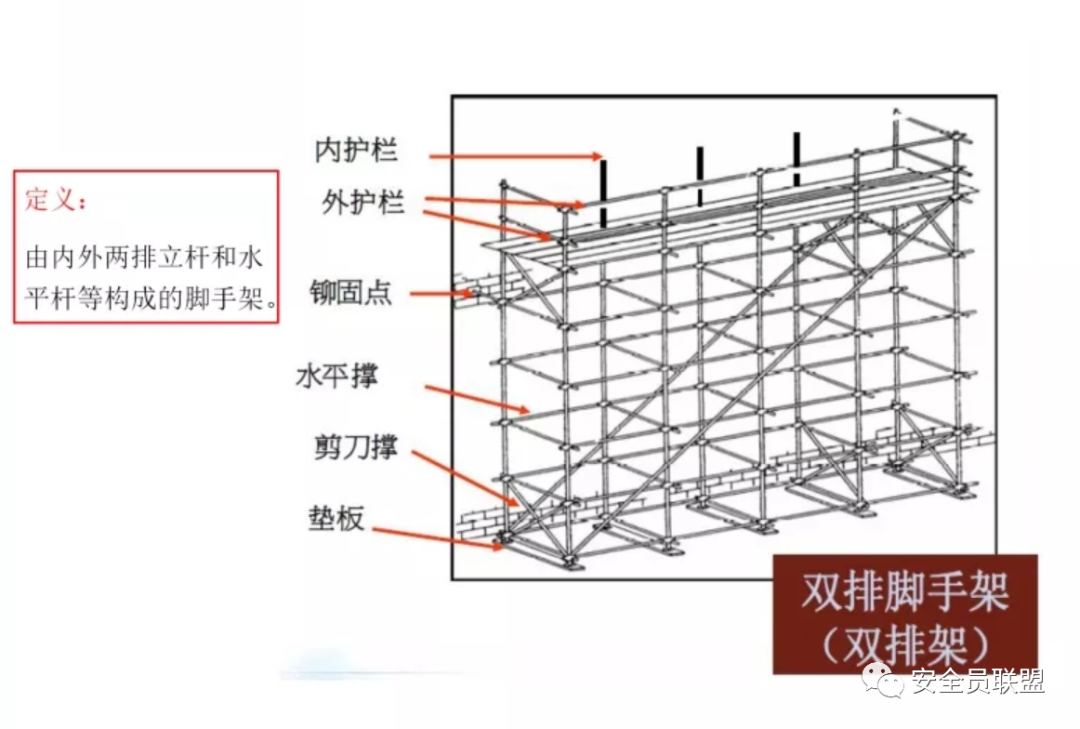

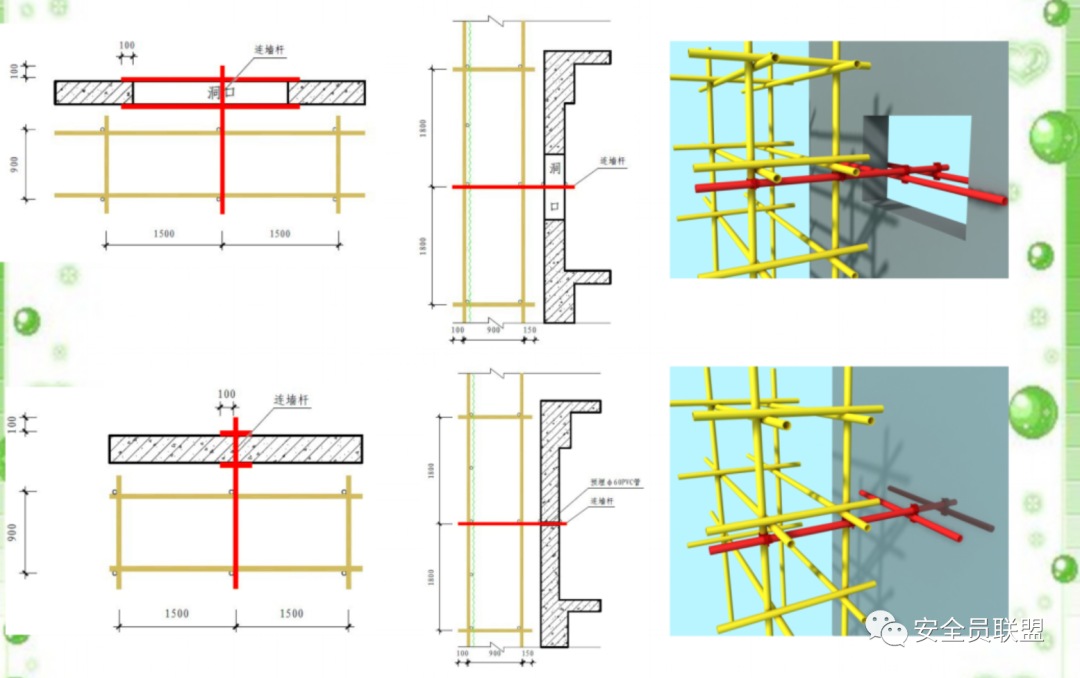

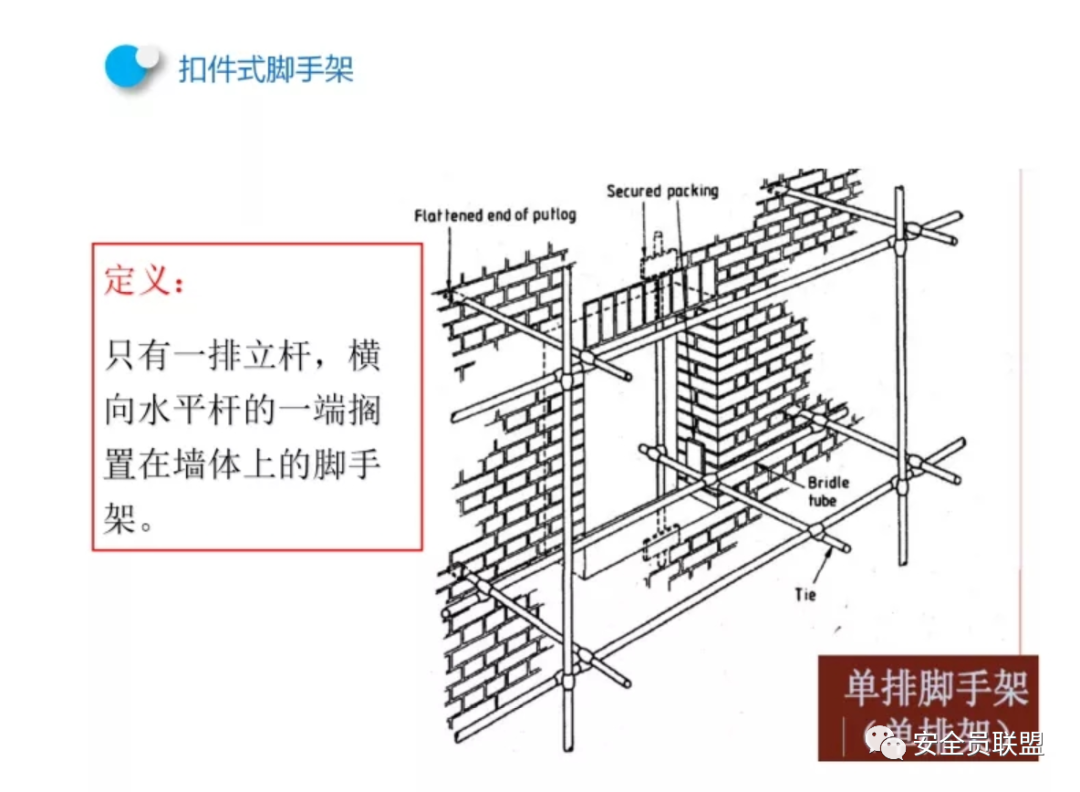

Fastener type steel pipe scaffold 1

.

The distance between vertical poles is generally not more than 2.0m, the horizontal distance between vertical poles is not more than 1.5m, the connecting wall parts are not less than three steps and three spans, the bottom layer of scaffold is fully paved with a fixed scaffold board, the operation layer is fully paved with scaffold board, and from the operation layer down, every 12m must be fully paved with scaffold board

.

The specific size shall comply with the provisions of table 6.1.1-1 and table 6.1.1-2 of technical code for safety of steel tubular scaffold with couplers in building construction (jgj130), or special design shall be carried out

.

2

.

Except the top step of the top layer, the joints of other layers must be connected by butt fasteners

.

The joints of two adjacent vertical poles shall not be set in the same step distance, and the height direction staggering distance of two separated joints separated from one vertical pole shall not be less than 500mm; The distance between the center of each joint and the main node should not be greater than 1 / 3 of the step distance

.

If the top step upright pole is lengthened by overlapping, the starting overlapping length shall not be less than 1000mm, and it shall be fixed with not less than 2 rotating fasteners, and the distance from the edge of the end fastener cover plate to the pole end shall not be less than 10mm

.

3

.

A transverse horizontal bar must be set at the main node, which shall be connected with right angle fastener and shall not be removed

.

The center distance of two right angle fasteners at the main node shall not be greater than 150 mm

.

In the double row scaffold, the extension length of the horizontal bar at the end of the wall shall not be greater than 500mm

.

4

.

Scaffolds must be equipped with vertical and horizontal sweeping poles

.

The vertical and horizontal sweeping poles shall be fixed with right angle fasteners at the place not more than 200 mm away from the base On the pole

.

When the vertical pole foundation is not on the same horizontal plane, the vertical sweeping pole at the high place must be extended to the low place for two spans and fixed with the vertical pole, and the height difference shall not be greater than 1m

.

The distance between the axis of the vertical pole above the slope and the slope shall not be less than 500mm

.

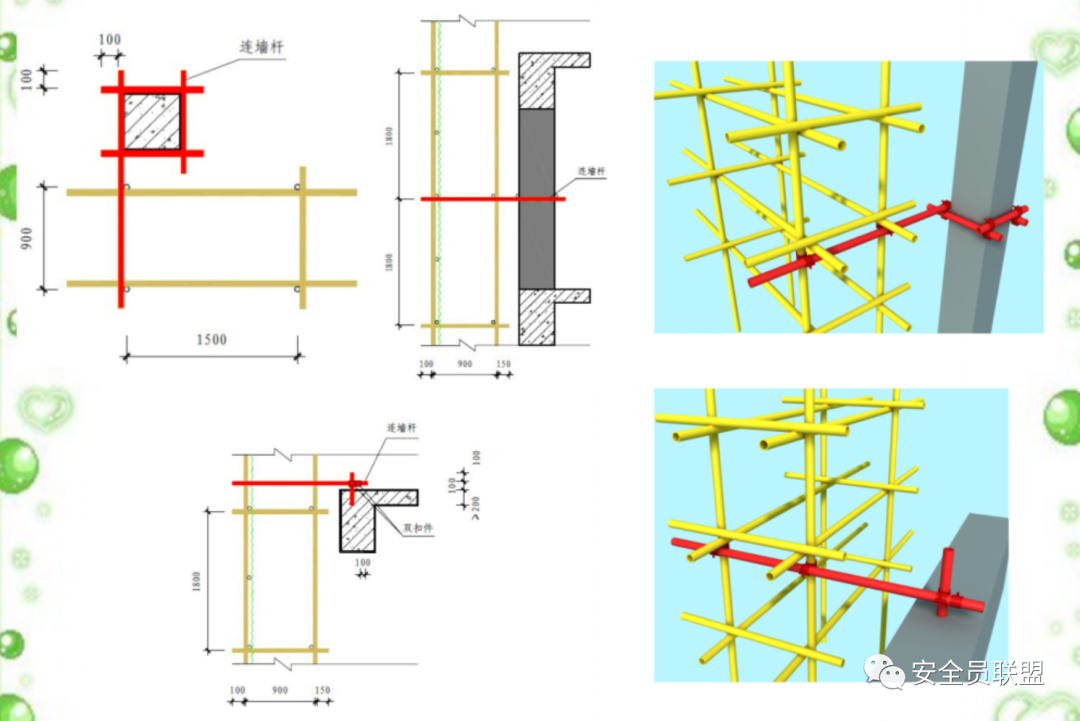

5

.

The double row fastener type steel pipe scaffold with a height of more than 24m must be reliably connected with the building by rigid wall connecting pieces

.

For the single and double row scaffolds with the height less than 24m, the rigid wall connecting parts should be used for reliable connection with the building, and the wall attached connection method with the combination of tie bar and top support can also be used

.

It is strictly forbidden to use flexible wall connecting parts only with tie bars

.

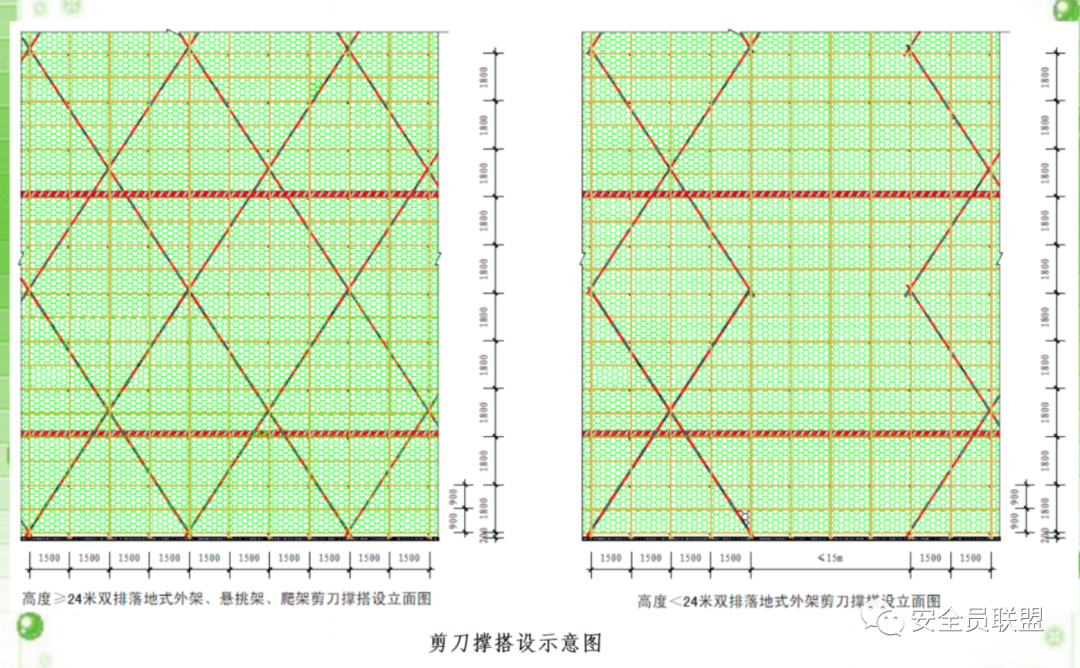

6

.

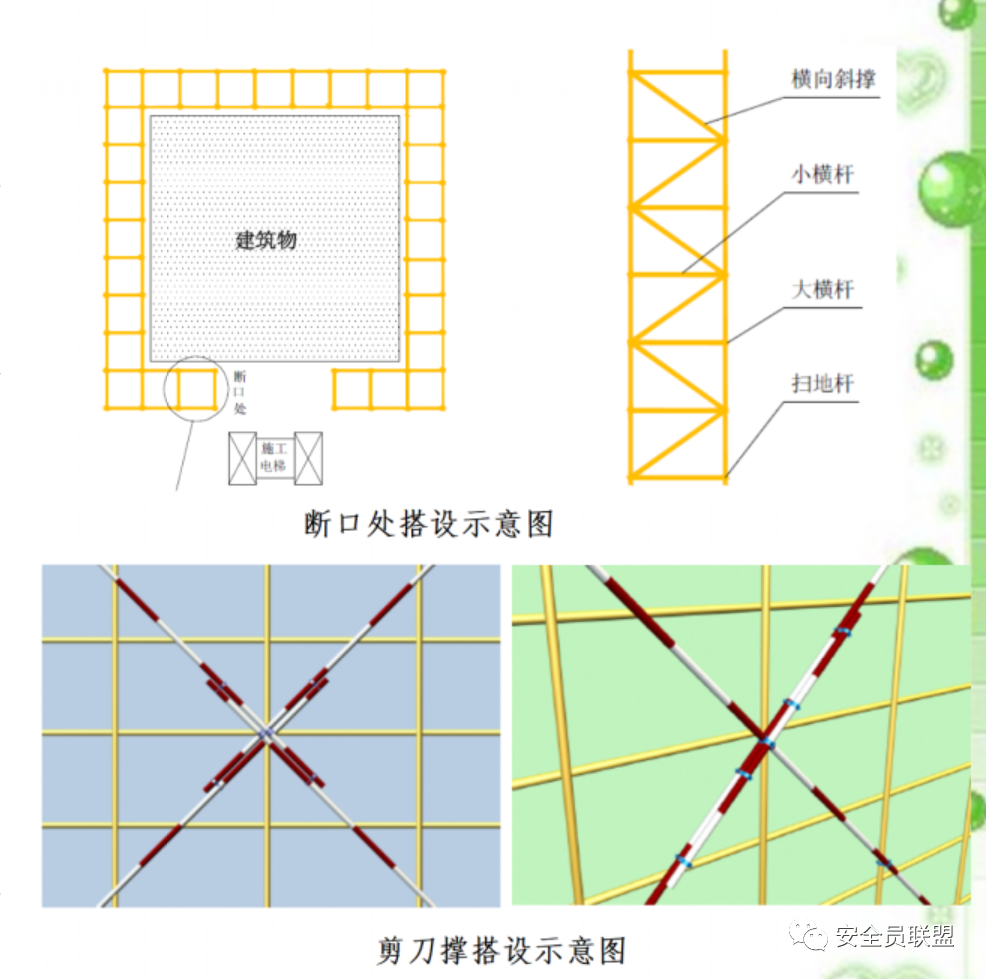

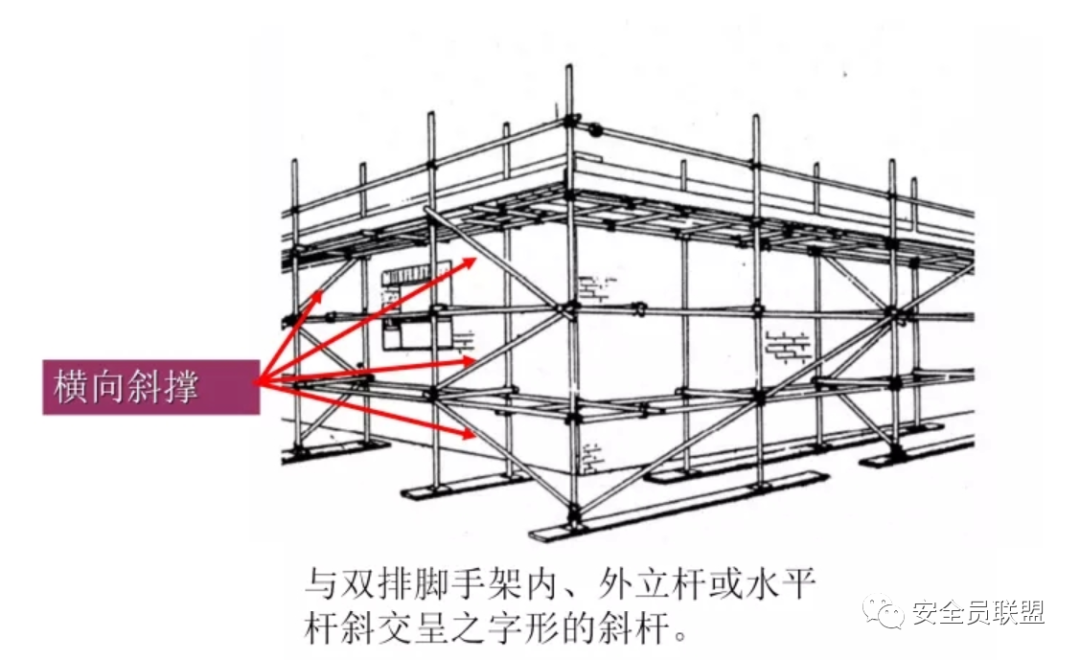

Horizontal diagonal braces must be set at both ends of the I-shaped and open double row steel pipe fastener scaffold

.

For closed scaffolds with a height of more than 24m, transverse diagonal braces shall be set at the corners, and one scaffold shall be set at every 6 spans in the middle

.

The transverse diagonal braces should be arranged in zigzag form from bottom to top in the same section

.

Your forwarding is our biggest support for the official account: the Security Union Union is concerned by the two-dimensional code

.

We welcome you to fight for the security cause

.

Just for your daily improvement.

.