Click the blue font above to subscribe for free! Source: Internet, Civil Engineering Forum, if there is any infringement, please contact to delete 1

.

Constructional column (1) procedure: operation preparation – concrete pouring – vibration – concrete maintenance( 2) Construction methods: 1

.

The construction joint at the root of structural column should be paved with 5cm thick cement mortar with the same mix proportion with concrete before pouring

.

2

.

Pouring method: unloading concrete onto iron sheet and unloading concrete into the mold with shovel

.

3

.

When pouring concrete structural column, first insert the vibrator into the bottom of the column to make it vibrate, and then pour into the concrete

.

The concrete shall be poured and vibrated in layers, each layer shall not exceed 60cm, and the pouring height shall not exceed 1.5m

.

4

.

Concrete vibration: when pouring concrete, it is required to strike the formwork with a rubber hammer while pouring, and pay attention to whether the formwork is deformed, and the deformation shall be corrected at any time

.

5

.

When pouring concrete, attention should be paid to protect the position of reinforcement and the waterproof structure of external brick wall and external wall panel from damage, and special personnel should be assigned to check whether the formwork and reinforcement are deformed and displaced; Whether the bolt and pull rod are loose or fall off; In case of slurry leakage, special personnel shall be assigned for maintenance

.

6

.

Surface troweling: every time the concrete of lintel and slab joint is vibrated, it shall be immediately compacted and troweled with wooden trowel, and the surface shall be free of loose concrete

.

7

.

Concrete curing: concrete shall be covered and watered for curing within 12h after concrete pouring

.

Water at least twice a day under normal temperature, and the curing time shall not be less than 7 days

.

The setting requirements of constructional column: the length of masonry wall is more than 5 meters or more than 2 times of storey height, the wall junction and corner, the external corner of external wall, the end of independent wall with length more than 2.5 meters, the end of infilled wall (more than 3 meters) without wall column, and the two sides of opening width more than 2.0 meters shall be set with constructional column

.

The formwork of special structural column needs to be drilled on the masonry

.

Attention should be paid to the drilling of external wall

.

The holes should be low on the outside and high on the inside, which has the effect of structural water resistance

.

2

.

Treatment of door and window openings

.

1

.

The openings of compartment door and fire door should be reserved according to the drawing size

.

The width and height of entrance door should be reduced by 20 mm according to the drawing size (one centimeter on one side)

.

2

.

All window openings are constructed according to the design drawings

.

The height of the window should be calculated from the bottom of the sill

.

3

.

Precast concrete blocks shall be set at the openings of doors and windows, cement blocks shall be set within 200 mm above and below the door edge, and the spacing between cement blocks in the middle shall not exceed 600 mm; 4

.

Cement blocks shall be set up within 200 mm above and below both sides of the window

.

The spacing between the middle cement blocks shall not exceed 300 MM5

.

The masonry length of each side shall not be less than 240 mm

.

At the corner, junction and adjacent infill wall at the same time

.

3、 Windowsill coping 1

.

The openings of doors and windows shall be provided with reinforced blocks or precast concrete blocks

.

The bottom of lintel at the window top shall be made into external internal high slope to provide a structural waterproof layer for the leakage of water at the window edge

.

2

.

When the window opening is left on the external wall, the window sill shall be poured with 120mm high reinforced concrete to press the top, and the two ends shall extend 250mm into the wall; 3

.

If the side wall of the window is shorter than 1000mm, a full-length sill beam shall be set on the windowsill

.

The top of the windowsill shall be sloped from the inside to the outside, and the slope shall be greater than or equal to 10%

.

4

.

In order to reduce the cracking of the peripheral wall, the full-length reinforcement can be set in the middle of the wall, through the setting, with 2 Φ 6 steel bars

.

4、 Lintel 1

.

When the top elevation of the door and window openings of the wall is different from the bottom elevation of the ring beam and the frame beam, if the difference between the top elevation of the lintel of the door opening and the bottom elevation of the structural beam plate is less than the height of the lintel, the lintel shall be cast in situ together with the ring beam and the frame beam, and the two ends of the lintel shall extend into the wall not less than 250mm, or be connected with the structural column and the frame column, and the concrete strength grade shall not be lower than C20, The lintel is the same thickness as the wall

.

2

.

When the elevation of the top of the door and window opening of the wall is the same as the elevation of the ring beam and the bottom of the frame beam, the precast lintel can be used, and the two ends of the lintel extend into the wall no less than 250mm

.

5、 Ring beam elevator shaft starts from the starting elevation, every 2.5m, ring beam height: 250mm

.

It is impossible to share a ring beam for the ring beam of fire elevator and public elevator shaft wall of Building 1 and 2

.

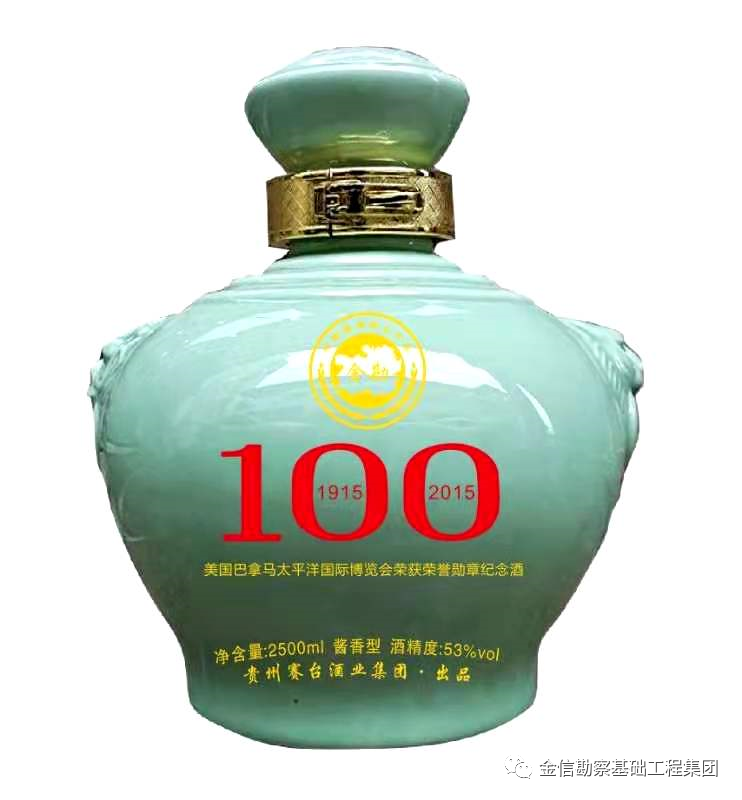

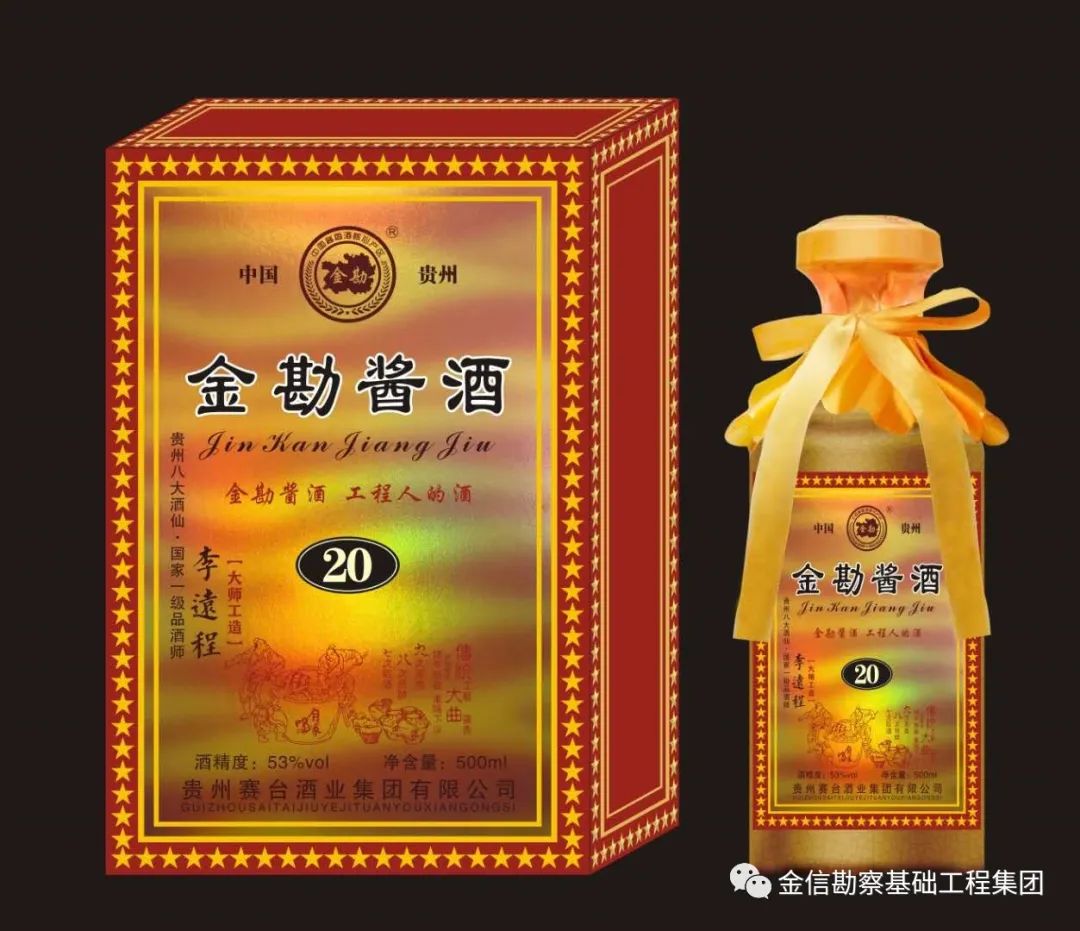

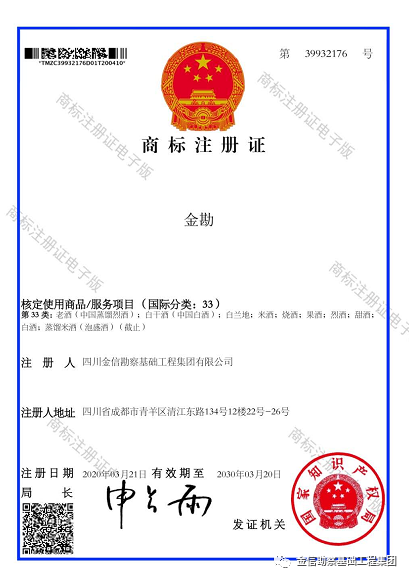

The setting of ring beam is calculated from top to bottom( Jinkan sauce wine, engineer’s wine, wholesale one Sichuan Jinxin group company has the following qualifications: 1

.

Engineering Investigation Major: {Geotechnical Engineering (geotechnical engineering investigation, geotechnical engineering design, geotechnical engineering geophysical testing and monitoring) engineering survey} class B 2

.

Geotechnical water quality test, in-situ test (wave survey) 3

.

Detection of radon in soil, indoor air, sanitation in public places, drinking water and secondary water supply, lightning protection detection 4

.

Agency of sanitation license 5

.

Grade I of professional contracting of foundation engineering 6

.

Grade III of general contracting of municipal public engineering 7

.

Grade III of general contracting of construction engineering 8

.

Grade III of professional contracting of steel structure engineering 9

.

Special engineering (structural reinforcement) 10

.

Grade II of professional contracting of Building Decoration Engineering 11

.

Surveying and mapping qualification (Geographic Information System Engineering, engineering survey Building demolition engineering company address: no.22-26, 12th floor, No.134, Zhongkai building, East Qingjiang Road, Qingyang District, Chengdu contact number: 13808217768 028-66320799 。

.