Source: the copyright of Baidu Library belongs to the original author

.

The main contents are as follows: 1

.

Main diseases of tunnel; 2

.

Quality inspection of tunnel initial support construction; 3

.

Quality inspection of tunnel lining concrete; 4

.

Ground penetrating radar nondestructive inspection; 5

.

Quality inspection of shield tunnel segment; 6

.

Tunnel construction monitoring; 7

.

Inspection and evaluation of tunnel condition; 8

.

Electric penetration waterproof technology for underground structure; 9 Tunnel disease maintenance and reinforcement technology 1

.

Main tunnel diseases (water damage, lining crack damage) 1

.

Tunnel water damage tunnel water damage refers to the interference and harm of water in the process of tunnel construction and operation, which is the most common tunnel disease

.

It mainly refers to the water disaster of operating tunnel, that is, the damage caused by the groundwater and surface water of surrounding rock entering the tunnel directly or indirectly in the form of leakage or gushing out

.

Tunnel water disaster can be divided into: seepage (gushing), water around the lining, undercurrent erosion, etc

.

Tunnel water disaster: tunnel water seepage and gushing tunnel leakage, according to its location and flow can be divided into: arch water seepage, dripping, water leakage into a line and jet into four kinds, the side wall has two kinds of water seepage, dripping, a few tunnels have tunnel gushing disease

.

The harm of tunnel leakage: the leakage promotes the weathering and erosion of concrete lining, resulting in the damage of lining structure; The seepage water will soften the surrounding rock and cause the deformation of surrounding rock; Some tunnel seepage water contains corrosive medium, which causes corrosion damage of lining concrete and masonry mortar and reduces the bearing capacity of lining

.

Water leakage accelerates the corrosion of internal equipment (communication, lighting, etc.), affects the normal use of equipment, shortens the service life of equipment, and increases maintenance costs

.

Water disasters cause subgrade subsidence, basement cracking, mud boiling and other diseases

.

Serious water leakage causes uneven settlement and damage of ground buildings

.

Serious water leakage causes a large amount of surface water and aquifer water loss, damages the surrounding water environment and causes environmental disasters

.

Tunnel water disaster: the accumulated water around the lining refers to the seepage of surface water or groundwater to the surrounding of the operating tunnel

.

If it can not be drained away quickly, the following diseases will be caused: the lining will be broken when the water pressure is high; The surrounding rock is softened by water immersion, the bearing capacity is reduced, the lining pressure is increased, and the lining is broken; The volume expansion of expansive surrounding rock leads to lining rupture; Frost heaving is caused in cold area

.

Tunnel water hazard: Undercurrent erosion refers to the erosion and dissolution caused by groundwater seepage and flow, and its hazards include: lining foundation sinking, side wall cracking or invert and monolithic track bed sinking and cracking; The slip and dislocation of surrounding rock lead to the deformation and cracking of lining; If the surrounding rock is not fully backfilled or backfilled, the surrounding rock will collapse and the lining will be damaged

.

The main reason of tunnel water disaster is that the construction of the tunnel destroys the original balance of the groundwater system, and the tunnel becomes the channel for the accumulation of groundwater nearby

.

When the surrounding rock of the tunnel is connected with the aquifer, and the waterproof and drainage facilities and methods of the lining are not perfect, the tunnel water disaster will inevitably occur

.

Lining is the last layer of tunnel waterproof protection, so the key point in the detection of water disaster is the detection of tunnel lining quality

.

2

.

The lining cracks are caused by deformation pressure, loosening pressure, uneven distribution of strata along the longitudinal direction of the tunnel and mechanical properties, temperature and shrinkage stress, swelling or frost heaving pressure of surrounding rock, corrosive medium, human factors in construction, cyclic load of operating vehicles, etc, It affects the normal use of the tunnel, which is called the tunnel lining crack disease

.

Lining cracks are divided into: cracking, excessive deformation, corrosion damage, spalling and so on

.

The lining crack damages the stability of the tunnel structure, reduces the safety and reliability of the lining structure, affects the normal use of the tunnel, and even endangers the traffic safety

.

The main hazards of lining crack deformation are: reducing the bearing capacity of lining structure to surrounding rock; It makes the tunnel clearance smaller, invades the building boundary, and affects the safe passage of vehicles; The arch lining falls, which affects the safety of driving and people; Cracks and water leakage cause corrosion of facilities in the tunnel, frost heaving of pavement and Frost Heaving in severe cold and cold areas; The pavement and invert are damaged, the subgrade bed is boiling, the line is deformed, the driving safety is endangered, the vehicle running speed is forced to reduce, and the maintenance workload is greatly increased; Under the operation condition, the repair of the cracked lining will interfere with the construction and transportation, and the cost will increase

.

According to the direction of cracks and the relationship between cracks and tunnel length, tunnel lining cracks can be divided into three types: longitudinal cracks, circumferential cracks and oblique cracks

.

Generally, the circumferential working crack has little influence on the normal bearing capacity of lining structure

.

The longitudinal and oblique cracks of arch and side wall destroy the integrity of structure and do great harm

.

The longitudinal crack is parallel to the tunnel axis, which is the most harmful

.

The development of the longitudinal crack can cause the tunnel arch falling, the side wall fracture and even the whole tunnel collapse

.

The longitudinal crack distribution has the rule that the arch waist part is more than the arch crown, the double track tunnel mainly occurs in the arch waist, and the single track tunnel mainly occurs in the side wall

.

The circumferential fracture is mainly caused by the longitudinal uneven load, the geological change of surrounding rock and the improper treatment of settlement joint

.

It mostly occurs at the junction of the entrance or the bad geological zone and the complete rock stratum

.

Inclined cracks are generally 45 ° to the longitudinal axis of the tunnel ° It is also often caused by the tensile stress formed by the combination of circumferential stress and longitudinal stress of concrete lining

.

Its harmfulness is second only to longitudinal cracks, and it also needs to be seriously strengthened

.

Due to the deformation of the lining, the concrete lining converges and deforms, resulting in insufficient tunnel clearance or occupying the space reserved for reinforcement, and the concrete lining of individual tunnels invades 30 ~ 40mm

.

Therefore, the operating tunnels need to carry out boundary measurement regularly as the basis for reinforcement

.

Segment staggered lining corrosion damage lining spalling II

.

Tunnel initial support construction quality inspection 1

.

Anchor bolt pull-out force inspection 2

.

Anchor bolt anchoring quality non-destructive inspection (applicable to full-length adhesive anchor bolt) (length and mortar compactness) anchor bolt is a kind of support measure to connect broken or unstable rock mass (block) with stable rock mass to improve the overall stability

.

There is no perfect calculation method to detect the bearing capacity of anchor

.

It is mainly determined by experience or test

.

The test items include ultimate uplift test, performance test and acceptance test

.

Test requirements: 1

.

At least one group (3 bolts) shall be randomly sampled for each 300 bolts installed, and another group of pull-out force test shall be conducted when the design or material changes

.

2

.

The average value of anchoring force or pulling force of the same group of bolts should be greater than or equal to the design value

.

3

.

The anchoring force or pulling force of a single bolt in the same group shall not be less than 90% of the design value

.

Nondestructive testing of bolt quality when the bolt works, the functions of different parts of the bolt are different

.

The inner end of the bolt is located in the section of firm and stable rock mass, and its anchoring force mainly plays the role of fixing the bolt; The outer end of the bolt is in the section of broken or unstable rock mass, and its anchoring force mainly plays the role of connecting this section of rock mass (block) with the bolt

.

In order to make the bolt play the role of design, in addition to ensuring that the length of the bolt meets the design requirements, each section can be anchored with the rock evenly and effectively (ensuring the grouting saturation)

.

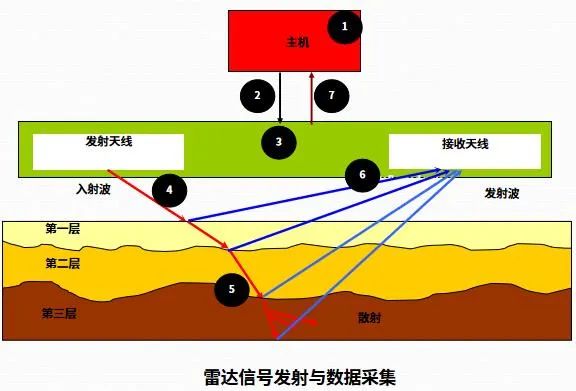

The length of anchor rod and grouting saturation are detected by stress reflection wave method or acoustic reflection wave method

.

The detection instrument is the anchor quality detector, as shown in the figure below

.

Basic principle: the content of non-destructive testing of bolt quality is bolt length and grouting density

.

In the anchorage system composed of bolt, binder and surrounding rock, when the stress wave propagates in the anchorage system of bolt, the wave length of the stress wave will decrease λ> 10d (D is the diameter of anchorage system) and λ<< L (L is the length of anchorage system), the anchorage system can be simplified as one-dimensional homogeneous variable cross-section member embedded in surrounding rock

.

The change of grouting compactness is the change of cross-sectional area of rod, and the change of bolt length is the change of material.

.