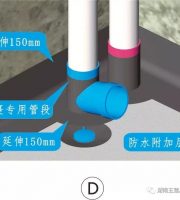

Fig

.

The reinforcement of the arch structure at the 1-2 floors is straight-line reinforcement, which can be bound according to the conventional reinforcement, and the reinforcement connection adopts the form of binding and overlapping

.

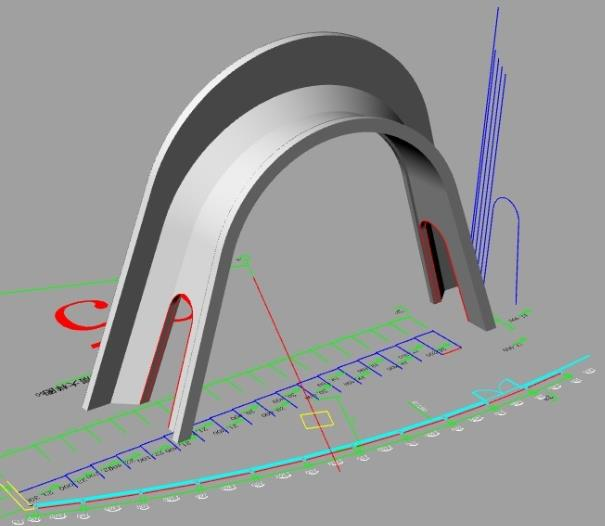

Figure 1 Overall effect of the project 1.2 overview of tall arch structure arch concrete structures vary in size, with a longitudinal width of 10 ~ 20m, a transverse width of about 3M and a height of 8 ~ 15m

.

Figure 16 Site drawing of arch side small door formwork 3.6 Reinforcement binding, arch crown formwork erection and reinforcement, concrete pouring on floors 1-2, the height of arch structure is large, and there are many spanning floors, so we pour concrete in sections according to floors

.

The lower part of the arch structure is a straight section and the upper part is an arc section, with an inner diameter of about 5m and an outer diameter of about 6m

.

The foundation positioning must be accurate

.

3 section schematic diagram of arch structure arch structure is reinforced concrete structure, main reinforcement is C20 and C16, stirrup is C10@100 The concrete strength grade is C40

.

5 reinforcement diagram of arch crown structure 2

.

2.2 the biggest construction difficulty in selecting arch structure by labor force is positioning and setting out and formwork support

.

Arch structure bottom formwork and line bottom formwork shall be installed in place at one time (see FIG

.

5

.

The conventional split screw method shall be adopted for reinforcement.

.

Lintel reinforcement at the top of side small arch shall not be omitted

.

12), and the fasteners shall be temporarily fixed first, After the large formwork on both sides are hoisted, recheck the overall size and elevation, and tighten the fasteners after confirmation

.

Spot work shall be adopted for reinforcement binding and concrete pouring

.

3.4 bent erection the vertical and horizontal spacing, step distance and other parameters of bent erection shall be calculated, the cross bridging shall be followed up synchronously with the erection progress (as shown in Figure 10), and the arch bottom support shall be in the form of double fasteners

.

Fig

.

The project is mainly divided into East and West blocks, which are connected by steel structure corridors

.

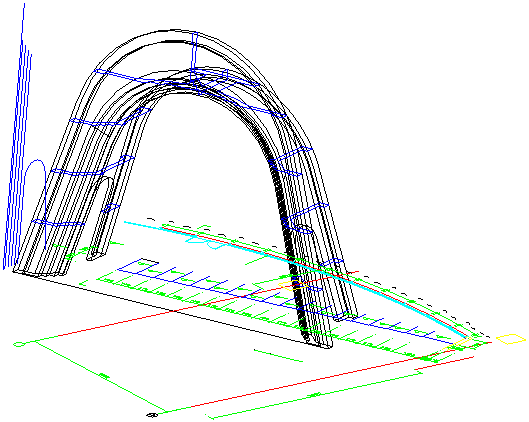

2 elevation schematic diagram of arch structure Fig

.

See the detail drawing of arch and foundation on site

.

The specific construction process of arch structure is shown in Figure 8

.

Project overview 1.1 overall overview of the project Nanjing Science and technology entrepreneurship business center (sandboat outlets) project (see Figure 1) is located at the junction of Shuanglong Avenue and mozhou Road, Jiangning District, Nanjing

.

The formwork rib support is set every 200mm on the reverse side of the line (see Fig

.

The reinforcement on the second floor must be painted with a position of overlapping length, and the joints shall be staggered

.

After the reinforcement binding is completed (as shown in Figure 17), the formwork can be sealed only after passing the acceptance

.

Figure 14 Figure 15 rib support of line formwork Site drawing of arch bottom formwork erection small arch on the side of arch shall first process the wooden box in the floor according to the setting out size, then snap the positioning line on the arch bottom formwork, and finally install it directly according to the line (see FIG

.

Two elevations and sections of the arch structure are selected as the schematic diagram, as shown in Figure 2 and figure 3

.

The construction site of template formwork erection is shown in Figure 7

.

4 reinforcement diagram of arch side structure Fig

.

The technical personnel’s disclosure to the operators also adopts the form of three-dimensional disclosure, which makes it easy to master the construction technical difficulties and quality control points

.

Figure 9 Detailed drawing of arch structure foundation and site construction drawing 3.3 positioning, setting out, positioning and setting out pull out the size according to the three-dimensional drawing, set out according to 1:1 in the floor, pop up the starting line of arch structure on the low wall foundation, and recheck the longitudinal and transverse width of arch structure after snapping

.

When the concealed column reinforcement passes through the structural beam at the second floor, the method of planting reinforcement is generally adopted

.

The woodworking formwork erection adopts the lump sum method, and the selected personnel shall have similar construction experience as far as possible

.

Preliminary preparation 2.1 technical preparation due to the complex shape of arch structure, it is relatively difficult to locate and set out during construction

.

If any error is found, it shall be corrected in time

.

2.3 template construction in order to prevent rework caused by operators’ failure to deeply understand the drawings, operators shall first make the template for template construction before construction

.

Source: in case of infringement by Nantong second construction, please contact to delete 1

.

Since the formwork has radian, the nails shall be densified to prevent warping

.

Fig

.

The lower opening of the large formwork shall be placed directly according to the popped line, and at the same time, it shall be limited and fixed with steel nails

.

Figure 12 Fine adjustment of arch side large formwork Fig

.

The radian of the horizontal bar at the arch bottom shall be cold bent according to the circular arc set out in the floor (see Fig

.

14)

.

Reinforcement binding, arch top formwork, reinforcement and concrete pouring are carried out in sections with the floor as the boundary

.

There are 2 floors underground parking garage, 1 to 3 floors underground are commercial, 4 floors are catering and entertainment, and the roof is sky garden

.

The formwork is directly nailed on the wooden ridge

.

Figure 17 After the reinforcement binding at the arch side is completed and the reinforcement is accepted, the formwork sealing and reinforcement construction shall be carried out

.

6 three dimensional model and effect of arch structure Fig

.

It shall be made in the open space of the sample area according to the planned designated position

.

15)

.

There are 18 arch doors of different sizes on the facade, together with curtain walls and antique brick strips

The formwork erection of the same type of arch shall be completed by the same woodworking team, and the woodworking formwork erection team shall be equipped according to the construction progress

.

The project has 2 floors underground and 4 floors above ground, with a total construction area of 184687 ㎡, including 85083 ㎡ above ground and 99604 ㎡ underground

.

Since the line on the upper opening cannot be snapped out, pull and hang the line according to the line of the floor, and fine tune it with the edge sealing steel pipe (see Fig

.

Since the entity setting out is not easy in the early stage, after the bent and bottom formwork are erected, it is necessary to recheck whether the elevation at the junction of the arch linear section and the arc section, the arch crown elevation and the outer angle are accurate

.

Figure 8 Construction flow chart of arch structure 3.2 foundation construction the project is a commercial complex, the basement is a connected basement, the height difference between high and low spans of the basement roof is 1.5m, and the arch gate foundation adopts 400mm wide concrete low wall foundation

.

13 In the upper arc section of the installation drawing of wood ridge at the arch bottom, a 60 steel pipe shall be vertically placed every 200mm on the sealing arc steel pipe × 90mm timber square, which is firmly bound with steel pipe with binding wire (see Figure 13)

.

There are 5 lines on the outside of the arch structure, and there is a small arch 3.6m high and 1.7m wide on the side of the structure

.

The inner side of the arch structure is vertical, and the outer angle is 820, which is flush with the outer wall

.

Because the size of the template rib is the same, it is processed uniformly to improve the efficiency

.

After getting the drawings, first establish a three-dimensional model to generate the effect drawing (as shown in Figure 6), and the construction personnel should have an intuitive understanding of the arch structure

.

The formwork erection personnel of each arch shall be controlled at 3 ~ 5

.

The four 200mm wide lines at the arch bottom of the arch structure are assembled on the ground first, and then nailed directly, so that the construction efficiency is high and the construction is convenient

.

Construction process 3.1 overall construction idea due to the high construction height of arch structure, some arches span two floors and some span three floors, and it is not easy to pour concrete at one time, so the construction is based on the floor as the dividing line

.

Bent and arch bottom formwork can be formed at one time

.

The size of the template is scaled by 1:2

.

Figure 7 Site drawing of arch structure formwork template 3

.

After the low wall foundation is bound, the arch joint reinforcement shall be embedded in place

.

Since the left and right sides of the arch structure are completely symmetrical, in order to save cost, only half of the template is made during construction, which can also achieve the expected effect

.

Because the reserved reinforcement at the beam bottom is not easy to operate and the position is difficult to control, the form of planting reinforcement is adopted

.

The overall effect of the project is quite artistic and the beauty of the building is reflected incisively and vividly

.

4 and Fig

.

The formwork shall be hoisted after being assembled on the ground

.

16)

.

The project is a characteristic art and commercial complex integrating commerce, leisure and entertainment, and along the subway station

.

One arch side and arch crown are selected as the schematic diagram, and the structural reinforcement is shown in Fig

.

11), but the radius of the circular arc shall deduct the height of the timber and the thickness of the formwork, and the butt fastener shall be used for the connection between the steel pipes

.

Technicians, constructors and operators of the project department cooperate to complete positioning and setting out

.

Figure 10 Construction drawing of bent erection site 11 Arch bottom horizontal bar 3.5 arch bottom formwork supports the straight-line section formwork on both sides of the arch structure

.