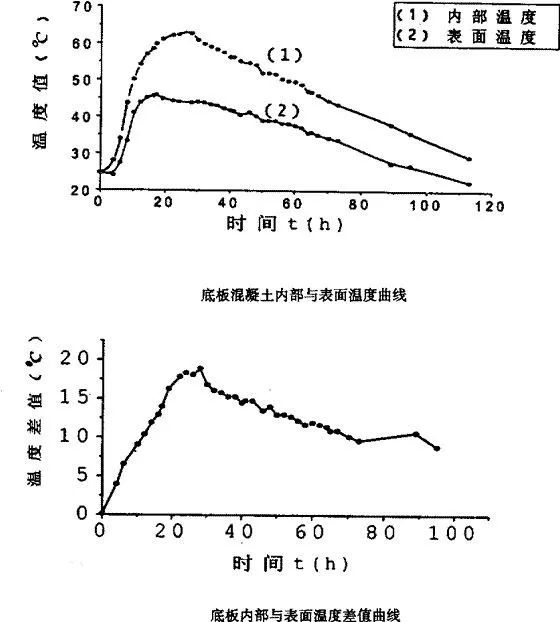

It is characterized by large volume, the minimum size of general entity is greater than or equal to 1m, its surface coefficient is relatively small, the release of cement hydration heat is relatively concentrated, and the internal temperature rise is relatively fast

.

2) The discharge port of each concrete pump is equipped with 4 vibrating rods and 3 working rods, which are arranged in three channels

.

6) When the concrete is transported to the construction site, it shall be poured into the formwork immediately

.

Firstly, scrape with a long ruler according to the structural surface elevation, and then pat and flatten with a wooden trowel; Secondly, use the slurry extractor to extract the slurry before initial setting; Finally, before final setting, polish, compact and level with a calender to close concrete shrinkage cracks

.

The mixer truck shall drain the accumulated water in the tank before loading

.

4) During concrete pouring and vibration, the vibrating rod shall not touch the reinforcement, formwork and embedded parts

.

The vibrating rods shall be arranged at the slope tip, slope and slope top respectively to ensure that the concrete is vibrated compactly without missing vibration

.

The following points should be paid attention to for the raw materials used for mass concrete: 1

.

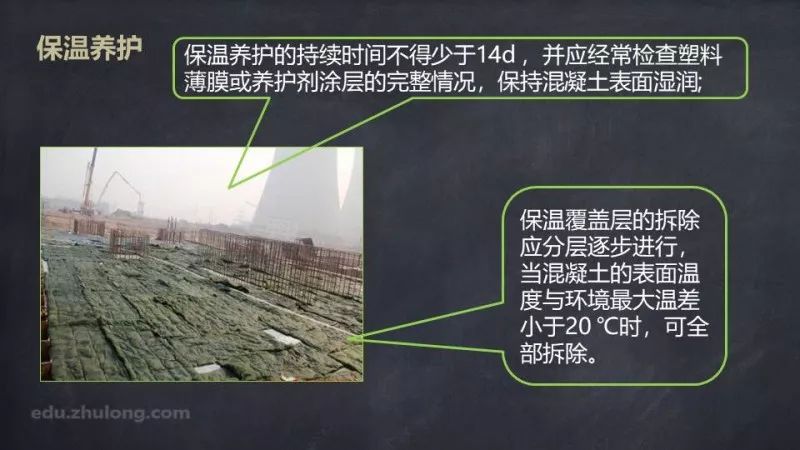

When the temperature difference inside and outside the concrete is large, the concrete will produce temperature cracks, affecting the safety and normal use of the structure

.

The layer thickness shall be controlled at about 300 ~ 500mm to minimize the heat of hydration; 6) The upper layer of concrete shall be poured before the initial setting of the next layer of concrete, step by step and in place at one time

.

On the premise of ensuring the concrete strength and slump requirements of mass concrete, the content of admixtures and aggregates shall be increased to reduce the cement consumption of cubic concrete

.

Retarder and water reducer should be used as admixtures; The admixture should be fly ash, slag powder, etc

.

In case of deformation and displacement, the pouring shall be stopped immediately for treatment

.

The senior chief engineer personally teaches many years of work experience and learns to work independently for 2 months!

.

The vibration time, moving distance and insertion depth at each point on the slope shall be strictly controlled

.

When it is necessary to supplement admixture or adjust the quality of mixture during mixing and transportation, the following provisions should be met: (1) when segregation occurs during transportation or admixture is used for adjustment, the mixing truck shall carry out rapid mixing, and the mixing time shall not be less than 120s( 2) It is forbidden to add water to the mixture during transportation

.

Pouring Scheme of mass concrete 1) the pouring of mass concrete shall be carried out when the temperature is low in a day

.

The formwork and fresh concrete shall be protected from direct sunlight, and the temperature of formwork and reinforcement before concrete pouring and the local temperature nearby shall not exceed 40 ℃

.

6) For surface bleeding, when the pouring of each layer of concrete is close to the end, the surface bleeding shall be artificially directed to the low-lying edge and reduced to a small pool, and then the water shall be pumped to the nearby drainage well with a small water pump

.

From construction preparation to completion acceptance, you can learn the whole process of one-stop learning

.

Therefore, it must be analyzed fundamentally to ensure the quality of construction

.

Transportation of mass concrete and concrete mixture shall be transported by concrete mixer truck, which shall be equipped with wind, sun, rain and cold protection facilities

.

Cement with low hydration heat and long setting time shall be selected as far as possible, and medium heat Portland cement, low heat slag Portland cement, dam cement, slag Portland cement, fly ash Portland cement, pozzolanic Portland cement, etc

.

When pouring concrete, vibrating rod shall be used for vibration, and the uniformity and compactness of concrete shall be strictly controlled

.

Secondary plastering shall be carried out before final setting to eliminate the cracks

.

When ready mixed concrete is used, the one-way transportation time of mixer truck shall comply with the relevant provisions of the current national standard ready mixed concrete GB / t14902

.

2

.

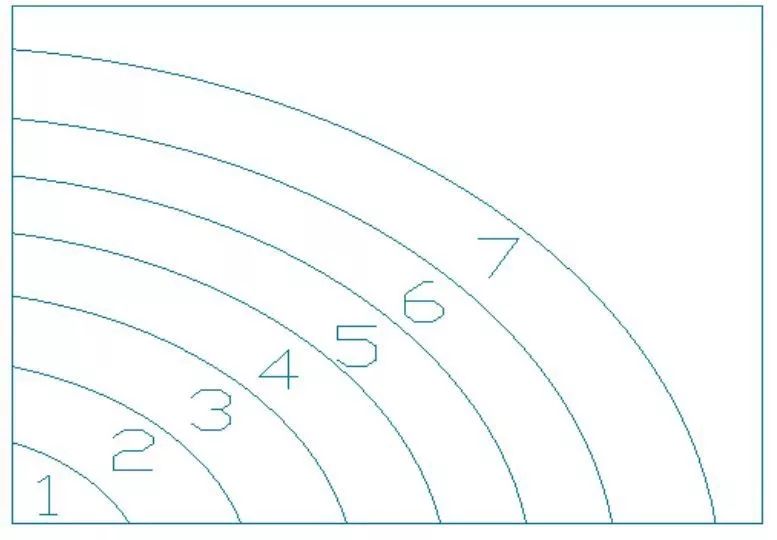

3) The mass concrete shall be poured in layers, and the thickness of each layer shall not be greater than 50cm

.

It can be appropriately extended in the concrete with retarder and controlled within 1.5 ~ 2.5h

.

Make the water on the concrete surface no longer sink significantly, no bubbles appear, and the surface is flooded with mortar

.

The first course is arranged at the discharge point to form a natural flow slope of the concrete, the second course is arranged at the foot of the slope to ensure the compactness of the lower part of the concrete, and the third course is arranged in the middle of the slope

.

3

.

The concrete shall be cut in layers from a large slope and vibrated by layers

.

When pouring concrete, special personnel shall be assigned to observe the formwork, reinforcement, support and reserved holes

.

Therefore, reasonable and effective vibration measures can partially ensure the effect of “solid inside and smooth outside” of mass concrete, During the construction, the following controls shall be made: 1) the concrete shall be vibrated with a vibrating rod, which shall be “inserted quickly and pulled out slowly”, pumped up and down and vibrated evenly

.

5) The concrete surface treatment shall be “three pressure and three leveling”

.

During the whole pouring process, the thickness of reinforcement protective layer and the position of embedded parts shall be checked at any time

.

7) Part of the laitance shall be removed within 4 ~ 8 hours after concrete pouring, scraped with a long scraper, and then rubbed and compacted with a wooden trowel

.

shall be preferred

.

The interval time of the second vibration is 40-60 minutes

.

4

.

You don’t need to piece together to learn the construction well

.

7) During the mass concrete pouring of foundation slab, in order to ensure the timely supply of concrete, two pumps shall be poured at the same time to avoid cold joints

.

4) During concrete pouring, the on-site dispatching management shall be strengthened to ensure that the poured concrete is covered by the upper concrete before initial setting without “cold joint”

.

Mass concrete with the minimum geometric size of concrete structure not less than 1m, or concrete that is expected to cause harmful cracks due to temperature change and shrinkage caused by hydration of cementitious materials in concrete, is called mass concrete

.

The coarse aggregate should be continuously graded and the fine aggregate should be medium sand

.

For more detailed construction methods, you can scan the QR code in the picture below to learn

.

5) The concrete shall be poured in sections and layers, and the concrete shall be poured in layers with natural flow

.

Pouring should be arranged in the evening as far as possible to avoid the hot day, and it should not be poured in the morning to avoid aggravating the internal temperature rise of concrete when the temperature rises to the highest

.

After initial setting, cracks will appear on the concrete surface

.

It can be moved in the order of “determinant” or “staggered”, but it can not be mixed

.

Click the blue words above to pay attention to our ~ author’s wechat a960047403

In case of serious slump loss or segregation during transportation, and the process performance of concrete mixture cannot be restored after supplement of admixture or rapid mixing, it shall not be poured into the formwork

.

2) Under the high temperature climate, the temperature of concrete entering the formwork shall not exceed 30 ℃

.

3) The second vibration shall be carried out before the initial setting of the concrete

.

Pouring shall be carried out from east to west and from the middle to both sides( Vibration of mass concrete (construction drawing of push type continuous pouring) the vibration of concrete can not only make the concrete dense, but also eliminate most of the bubbles in the concrete

.

The “section fixed point, one slope, thin-layer pouring The method of “advancing in sequence and reaching the top at one time” shall ensure to avoid construction cold joints

.