12 risk of breakage of hoisting instruments During combined hoisting of instruments, the single length shall not exceed 5m, and no more than 2 instruments shall be hoisted each time

.

14 the wellhead installation and disassembly workers shall wear labor protection and high-altitude operation safety belts and be fixed firmly to prevent falling

.

6

.

After the work is completed, they shall be collected and disposed in a centralized manner according to regulations

.

The ground inspection of the instrument is normal, and the data stored during logging is lost (1) before formal production, connect the instrument on the ground, use UPS power supply, and copy the sound amplitude variable density instrument in a water tank filled with water for more than ten hours to check whether the instrument works normally( 2) The instrument repair shall be equipped with storage module

.

Pay attention to your feet and don’t step empty during installation

.

At the same time, canvas shall be paved in wet places to prevent personnel from falling during construction

.

2

.

CPL lion park official account safety month special event – safety experience sharing for operation Engineers (due to tense time in June, replacement) MCET-1000 construction safety assessment Safety experience sharing person: Li Chengzhi’s work experience: rotation in Changqing, Qinghai and Tuha branches from 2018 to 2021; Served as operation engineer and team leader; The mcet-1000 cementing quality storage logging system manufactured by the 22nd Research Institute of China Electronics Technology Group has completed more than 100 well logging tasks in Zhejiang block of Tuha branch by July 2021, of which several wells have been compared and put into operation smoothly

.

When the well condition is bad, inform the oil company to conduct well wiper trip

.

The well site camera is at the height of the rear cabin

.

The work permit shall be handled in advance for hoisting and work at heights

The grounding devices of electrical equipment and facilities shall be checked regularly with a multimeter, and the problems shall be rectified in time

.

17 well pad wiring depth sensor line, wellhead video line, data reading line and other wiring shall be neat and hidden to prevent personnel from tripping

.

1173 the instrument is thin, the air bag is not tightly pressed during loading, and there is a risk that the instrument shakes and damages internal components during transportation

.

19

.

Bind the centralizer and center the instrument to prevent the instrument from hard grinding on the casing

.

Pay attention to the environment of the well pad

.

The wellhead worker and the oil company shall assign a special person to contact and prepare a walkie talkie

.

When reading the data stored in the instrument, if the drilling crew’s casing data is wrong, it will lead to column sequence error in time depth conversion or local curve tension and compression (1) if the column sequence is wrong, modify the imported casing data and ask the drilling crew to confirm it, and then import it again for time depth conversion( 2) If the length of a large section of casing is wrong, it will cause local logging curve stretching and compression

.

The risks in the construction process are summarized as follows

.

Many people carry it in cooperation, wear qualified labor protection articles correctly, and try to use the truck crane to carry heavy instruments and tools if possible

.

2

.

Risk of explosion when the battery is used

.

7 when lifting instruments and equipment, if there is oil stain, mud and other pollution on them, personnel are easy to slip, and there are risks of personal injury and equipment damage

.

16

.

During high-temperature construction in summer, water shall be added in time to prevent heatstroke

.

The details are shown in the table below: 1

.

473 the instrument has small outer diameter, thin wall and low mechanical strength, and there is a risk of enema caused by shell wear (1) formulate instrument flaw detection standards and specifications, and conduct flaw detection on the instrument regularly to prevent shell wear and cracks after repeated use of the instrument( 2) Add a flexible nipple at the top and connect the instrument with an adapter

.

3 when lifting the instrument, there is a risk of personal injury

.

The traffic safety of the round-trip road and terrorist attacks shall strictly comply with the traffic safety laws and regulations, and shall not exceed the speed limit, force to surpass the meeting and drive fatigue; Implement the emergency plan for terrorist accidents of the group company

.

10

.

The power of the battery short section is limited, and the instrument stops running after the power is exhausted (1) record the consumption time of the battery short section, and do not carry out deep well operation when the power is less than 10 hours, and replace the battery short section with sufficient power( 2) After the power of a single battery short section is exhausted, it is necessary to purchase a new battery short section from the manufacturer in time to supplement it, so as to ensure that two complete strings of instruments are ready for use.

.

Operation procedure risk assessment serial number risk analysis HSE control measures 1

.

9 if the instrument is blocked during oil connection and lowering, inform the oil connection team to control the speed Closely observe the change of tension and implement the relevant provisions of “four slows”

.

The sundries stacked by the drilling crew should be notified to clean up in time

.

15 during construction in rainy season, two persons shall cooperate in instrument connection, one person shall connect and the other shall protect the connector to prevent the instrument circuit board from moisture

.

20

.

6

.

13 pay attention to your feet when walking during construction at night

.

Waste oil and sewage shall not be dumped at will, and waste garbage such as oil cotton yarn and waste gloves shall be discarded

.

4

.

Do not hand over the well directly, which will cause large depth error with completion

.

When the instrument storage module is damaged, it can be replaced in time to avoid being unable to go to the well due to missing parts( 3) After the instrument is out of the wellhead, the sound amplitude and density of the instrument shall be changed, and the sound of the instrument shall be normal( 4) Two strings of instruments are equipped to prevent secondary well entry due to data loss

.

73 When the instrument is loaded, install two rows on one layer as far as possible, so that the air bag can compress the instrument, lock it with a chain and do a good job of secondary fixation

.

3

.

There are risks of staff being trapped by disorderly placed objects at the logging site, such as crushing and falling

.

Instrument use risk assessment serial number risk analysis HSE control measures 1

.

2、 Construction risk assessment this time carries out risk identification from two categories of fields such as operation procedures and instruments, combs the existing risk points and formulates measures one by one

.

For long-distance transportation of the instrument, if the transportation personnel do not handle it with care, it is easy to cause gamma crystal damage and internal parts loosening

.

Once the evacuation instruction is received or the evacuation alarm is heard, evacuate the site to a safe area in time

.

8 there is a risk of personnel poisoning when measuring toxic gas wells

.

If the drilling crew does not recognize it, it is necessary to conduct wireline survey verification in the vertical section and crawler wireline survey verification in the horizontal section

.

In case of damage, claim compensation( 2) After the long-distance transportation of the instrument, the core shall be pulled out to check whether the gamma crystal is broken and whether the internal parts are loose and damaged( 3) The instrument repair shall be equipped with gamma crystal and necessary parts for replacement

.

Before lifting instruments and equipment, Clean the oil and mud on the instruments and equipment

.

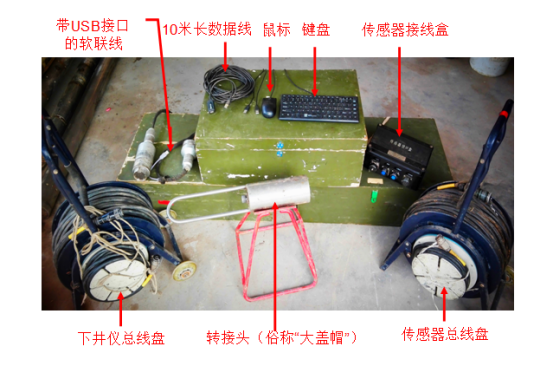

1、 Equipment supporting 1

.

During the operation of toxic gas wells, wear personal toxic gas monitor and pay timely attention to the toxic gas monitoring at the well pad

.

Before lifting and placing instruments, the path and place of lifting shall be cleaned

.

5 waste oil and sewage are at risk of environmental pollution

.

5

.

There should be enough space within the logging construction area

.

(1) before long-distance transportation of the instrument, inform the transportation company to handle it with care, and it is strictly prohibited to drop the instrument

.

When hoisting instruments at the wellhead, all qualified hoisting protective caps and plugs shall be used

.

There is a risk of electric shock in the use of electrical equipment and facilities

.

Operation feasibility analysis after receiving the construction task, formulate the single well construction design, carry out construction feasibility analysis and risk identification, and select the best instrument string

.

The supporting equipment of the instrument is in short supply, which is easy to be damaged when the work intensity is high, resulting in the situation that it cannot be replaced at the moment (1) during logging operation, pay attention to protect the centralizer with variable sound amplitude and density, and inform the oil company in advance to start slowly when the well condition is poor and slow down when the instrument comes out of the wellhead, Do not accidentally damage the centralizer or cause the centralizer to fall into the well( 2) When connecting the instrument, the silicone grease shall be applied in time, and the instrument repair shall be equipped with a special sealing ring to prevent the sealing ring from being replaced in time after aging

.

According to the battery inspection procedure, the positive and negative poles of the battery shall be reliably insulated and short circuit is strictly prohibited; The battery connector shall avoid direct contact with metal objects; Prevent fire or explosion caused by battery energy leakage

.

There are 2 sets of ground system, 1 set of portable box type and 1 set of independent box type; 2

.

18 install the well site camera

.

2

.

Downhole instruments, cementing measuring instruments, 2 sets and 4 strings in total, 2 strings with outer diameter of 89mm and 2 strings with outer diameter of 73mm

.