The used formwork shall be corrected before installation; ② When installing the formwork, ensure that the splicing between the formwork is tight, the support is firm, and the overall stiffness is sufficient

.

Treatment method ① when the missing edges and corners are small, brush them with steel wire, wash them with clean water, fully wet them, and fill them with 1:2 or 1:2.5 cement mortar; ② In case of large missing edges and corners, chisel off the untrue concrete and prominent aggregate particles, wash them clean and wet with water, and then erect the formwork with pea stone concrete one level higher than the original concrete, and carefully maintain them

.

It shall be cured every 2 hours in the first 24 hours and every 4 hours after 24 hours

.

Treatment method ① for fine cracks, pour pure water slurry into the cracks, embed them, then cover them for maintenance, clean the cracks, apply Epoxy Mastic twice or stick epoxy glass cloth to seal the surface after drying; ② For deep or penetrating cracks, the surface shall be sealed with epoxy resin mastic after epoxy resin grouting.

.

The selected data shall be entered into I

.

2

.

2

.

The slope of the inclined plane is generally greater than 1:20-1:30, and the maximum should not be greater than 1:10

.

1

7、 Wrong platform (1) setting out error is too large( 2) The formwork is displaced and deformed, and no alignment measures are taken during formwork erection( 3) The top of the lower formwork is inclined or expanded, and the upper formwork is corrected and reset to form a staggered platform

.

2

.

1

.

1

.

Prevention and control measures ① the formwork shall have sufficient rigidity and flat edges

.

Prevention measures ① all vertical structure molds shall be paved with cement mortar with the same mix proportion as the concrete

.

The construction process is as follows: chiseling the old concrete → washing and saturating with clean water → pouring and coating the grouting slurry → curing

.

The treatment method is grouting repair, and the material is concrete grouting material

.

2

.

4、 Exposed reinforcement (1) is the same as “honeycomb” reason( 2) The reinforcement framework is not processed properly, and the formwork is pasted on the top( 3) Lack of protective layer cushion block( 4) The reinforcement is too dense( 5) No reinforcement positioning measures, reinforcement displacement and formwork sticking

.

2

.

Prevention and control measures ① the formwork shall be cleaned, the wood formwork shall be fully wetted before concrete pouring, and the steel formwork shall be evenly coated with isolating agent; ② The slab joint shall be blocked tightly, and the slurry leakage shall be handled at any time during pouring; ③ The vibration shall be fully compacted

.

1

.

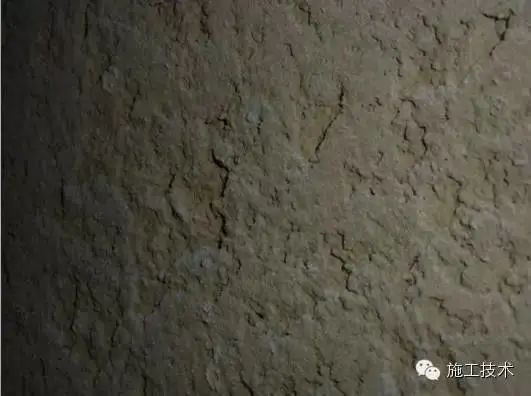

honeycomb by pressing the QR code below (1) the mix proportion measurement is inaccurate and the sand and gravel grading is not good( 2) Uneven mixing( 3) Formwork leakage( 4) Insufficient or missing vibration( 5) The once poured and vibrated concrete is too thick, the layering is not clear, the concrete handover is not clear, and the vibration quality cannot be mastered( 6) If the free fall height exceeds the specified value, concrete segregation and stone piling( 7) The vibrator is damaged or missing vibration is caused by temporary power failure( 8) The vibration time is insufficient and the bubbles are not eliminated

.

2、 Same reason as “honeycomb” (1)( 2) The formwork is not cleaned, or the formwork is removed too early, and the formwork is adhered( 3) Uneven or missing brushing of release agent( 4) The wooden formwork is not watered and wet, and the concrete surface is dehydrated and powdered( 5) The pouring time is too long, too much ash hanging on the formwork is not cleaned in time, resulting in the surface layer is not dense( 6) The vibration time is insufficient and the bubbles are not eliminated

.

The treatment method is to chisel out the loose concrete around the hole, wash it with high-pressure water, and carefully pour and tamp it with fine aggregate concrete of higher strength grade after formwork erection

.

1

.

5、 Rotten root (1) the gap at the root of the formwork is not tightly blocked and slurry leakage( 2) No stone free mortar with the same concrete mix proportion and composition before pouring( 3) The workability of concrete is poor, the water cement ratio is too large, and the stones sink to the bottom( 4) The pouring height is too high, the concrete is concentrated at one place, the concrete is separated or the stones are piled up( 5) The vibration is not solid( 6) Unclean cleaning and poor wetting in the mold

.

It is not allowed to pump directly with a pump; ② The pouring shall be carried out in strict layers, the formwork joint shall be tight, and the cushion blocks of the reinforcement protective layer shall be evenly arranged; ③ Clean the formwork before formwork closing, and strictly control the slump of concrete to prevent segregation; ④ Materials to be hoisted shall be dispersed; ⑤ The concrete shall be watered for curing in time, and the curing time shall not be less than two weeks

.

Treatment method ① for small honeycombs, after washing, use 1:2 cement mortar to trowel and compact; ② For large honeycomb, chisel away weak loose particles, set up formwork after cleaning, and carefully fill and tamp with fine aggregate concrete of higher strength grade; ③ For deep honeycomb, the grouting pipe and exhaust pipe can be buried inside, and the cement grouting treatment can be carried out after plastering mortar or pouring concrete on the surface

.

8、 Cracks (1) the water cement ratio is too large, resulting in pores and cracks on the surface( 2) Excessive amount of cement, shrinkage crack( 3) Poor or untimely maintenance, surface dehydration, dry shrinkage cracks( 4) The slump is too large, the pouring is too high and too thick, the plain slurry floats up, and the surface is cracked( 5) Early formwork removal and improper force pry the concrete( 6) The concrete surface is not plastered tightly( 7) The protective layer of reinforcement is too thin and cracks along the reinforcement( 8) Concrete cracking due to lack of stirrup and temperature reinforcement( 9) Mass concrete has no measures to reduce internal and external temperature difference( 10) There is no reinforcing bar at the application concentration such as opening corner

.

3、 Hole (1) is the same as “honeycomb” reason( 2) The reinforcement is too dense and the concrete aggregate is too coarse, so it is not easy to ash and vibrate( 3) There is no vent for the formwork at the hole and pit bottom, and there is an air bag in the concrete

.

In particular, it is necessary to strengthen the fastening between the formwork and the old concrete; ③ If the pouring height is high, it is better to keep the last formwork when removing the formwork of the previous warehouse and splice it with the formwork of the new pouring warehouse; ④ Pay attention to the follow-up work during the concrete pouring process, monitor the deformation of the formwork after stress in real time, and adjust the deformed formwork in time; ⑤ When the concrete is poured to 1 / 3 and 1 / 2 height, the formwork support shall be fastened once respectively, and then fastened again when the pouring is completed

.

The curing age is 7 days

.

2

.

Prevention and control measures ① before pouring concrete, check that the position of reinforcement and protective layer cushion block is correct, and the wooden formwork shall be fully wetted; ② When the reinforcement is dense, the coarse aggregate shall be gravel with appropriate particle size; ③ Ensure that the concrete mix proportion and workability meet the design requirements

.

The mortar shall be lifted to the site with a hopper and evenly unloaded with a shovel

.

Prevention measures ① before pouring concrete, the formwork shall be fully wetted or coated with isolating agent; ② Do a good job in concrete curing as required; ③ Remove the formwork according to the specified time and protect the finished products

.

Treatment method ① exposed reinforcement on the surface can be cleaned and then plastered with 1:2 cement mortar on the surface; ② The exposed reinforcement shall be filled and compacted with high-grade fine aggregate concrete after the interface is treated

.

Prevention and control measures ① fine aggregate concrete with high strength grade shall be used at the place with dense reinforcement, which shall be tamped carefully in layers or manually inserted; ② Where there are reserved holes, materials shall be cut from both sides at the same time and vibrated carefully; ③ Timely remove sundries falling into the concrete

.

The treatment method adopts the form of chiseling into an inclined plane to form a gradual transition

.

2

.

The top surface shall be covered with wet gunny bags to avoid exposure to the sun; ② Vibrate and compact without segregation, and conduct secondary plastering and pressing on the plate surface to reduce the shrinkage

.

Prevention and control measures ① strictly control the mix proportion, measure strictly and check frequently; ② Concrete mixing shall be sufficient and uniform; ③ If the blanking height exceeds 2m, a tumbling barrel or chute shall be used; ④ Blanking and tamping in layers to prevent vibration leakage; ⑤ The formwork gap shall be blocked, and the slurry leakage shall be checked and corrected at any time during pouring

.

1

.

1

.

1

.

Prevention and control measures ① the concrete shall be cured 6 hours after pouring

.

2

.

6、 Missing edges and corners (1) the factors preventing the removal of formwork from corners are not considered in the formwork design( 2) The wooden formwork is not wetted in advance, and the expansion of the wooden formwork after pouring causes the tensile crack of the concrete angle( 3) The formwork joint is not tight and mortar leakage( 4) The formwork is not painted with isolating agent or poorly painted, resulting in formwork removal adhesion( 5) Formwork removal is too early and too fierce, and the formwork removal method and procedure are improper( 6) Poor maintenance

.

Generally, flat chisel and hand grinding wheel are used as tools

.

Treatment method ① the surface painted may not be treated; ② If the surface is not painted, the pockmarked part shall be fully wetted and troweled with cement mortar

.