The thickness is adjusted by the manufacturer

.

1

.

After the putty is approved, the last time it is dried is polished

.

Important large noodles and light oriented large noodles can be slightly more strict

.

It is two completely different concepts

.

You can make a comparison ↓↓↓ 1 the most common putty is made of lithopone, cellulose (which can be replaced by rubber powder, cellulose is easy to fuzz), white latex and lithopone

.

If the grass-roots level is OK and there is no need to shovel, after rolling the interface agent or putty glue, some survived twice, while others with poor civil engineering survived three times

.

Waterproof putty is solidified after contacting with moisture in the air to form a solid and tough seamless integral waterproof film on the surface of the base course

.

You may think it’s necessary to smoke until you finish decorating your home? Not to mention this for the time being, I explored this matter with curiosity

.

Finished putty paste

.

Therefore, waterproof putty and waterproof putty are two different things

.

The water-resistant putty requires the product to be immersed in water for 48 hours after scraping, without peeling, cracking and bulging, and can reach the bonding strength of more than 0.30mpa (more than 0.50mpa before not soaking in water), while the general product will fall off after soaking in water, and the strength is zero

.

2

.

Compared with the finished putty powder and finished putty paste, the thickness of the finished putty powder can be controlled by workers themselves, which is easy to level

.

The following views only represent my personal identity

.

Grinding is the key

.

There are also better 6-11 yuan

.

The wet wall can also be constructed

.

For the matter of painting the wall, I started to find out what kind of configuration is the most economical and environmentally friendly after painting the wall

.

The quality of this lithopone is different from that of the first kind

.

The water-resistant putty can survive by directly adding water for two to three times

.

Now some masters use an electric grinder to operate the large surface

.

Most of this kind of putty is produced locally

.

The dust collection effect is good, and the leveling effect of the grinder is also very good

.

The use of this waterproof putty will cause the wall to be airtight and truly form a waterproof layer

.

Doing it several times is only a control means

.

This kind of quality is similar, that is, the difference in weight

.

Our home decoration wall is to maintain air permeability, so we choose water-resistant putty for both

.

If the base course is good, even if the surface course is medium-grade material, it is similar to high-grade coating; On the contrary, if the base course is very poor, even if the surface course is high-grade material, it can only make medium and low-grade coating

.

The internal and external corners are flat

.

2

.

In the later stage, it is necessary to timely add corner guards to prevent people from inadvertently or the collision of furniture entering the site

.

Although there is generally no special agreement in the contract, they can follow the crowd

.

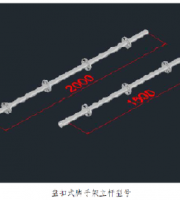

Now they are generally treated with internal and external corner strips

.

They carry a backpack machine on their back

.

And JSJ sells lithopone for about 14 yuan

.

Putty with good water resistance not only has good adhesion under moldy and damp conditions, but also is of great help to the film-forming of coating on its surface

.

If it is winter, considering the temperature difference, the interval will be increased by 2 days

.

The hardness is very good

.

The first method: remove the wall of the house with sandpaper, wipe it clean, and then dip your hand in water to apply it on the putty layer

.

The powder is finer

.

On this basis, the function of surface material is mainly “coloring”, that is, giving surface color and beautifying decoration

.

There is an old saying in the coating industry: “three sides, seven bottom.” It means that the surface material accounts for only 30% of the quality, while the base material accounts for 70%

.

Water resistance is often an important symbol to determine the quality of putty

.

It is mainly used for external walls, toilets, bathrooms, kitchens and other walls

.

Welcome to clap bricks

.

What kind of putty is high-quality putty? First: firmly bonded

.

It will not fall off and peel in case of water

.

I look forward to the help and explanation of relevant experts

.

In addition to coatings, what else plays a more important role than coatings? That is the base material for coating: “putty”

.

What do we need to pay attention to when painting the wall? How to choose putty and emulsion paint? In the online collection and dialogue with experts in the field of decoration, I sorted and summarized

.

It’s best to check it with a guiding ruler, because the strange image comes out as soon as the skirting line is installed

.

It is not suitable for the walls with poor base course

.

3 water resistant putty 1

.

Who knows that high-grade coating is one thing, and the decoration effect (or coating effect) is another

.

If your hand turns white, it means that the putty is not water-resistant.

.

Most of the waterproof putty is two-component, which is mixed with group A and group B

.

At present, most decoration companies still use the original method to prepare putty

.

There are many brands and prices vary from 10 to 27

.

The difference of finished putty paste is mainly the thickness of powder and the amount of glue

.

It is recommended to use brands of large manufacturers or second and third tier brands with relatively good products

.

This kind of putty can be scraped directly without adding anything

.

a

.

The price of water resistant putty ranges from 25-45

.

Special attention should be paid to: 1

.

The interval between primer and topcoat is more than 8 hours, and the interval between topcoats is 2 hours

.

Generally speaking, the role of base material is mainly firm, flat and smooth

.

But a little water-resistant putty is alkaline, and the color wall will be painted carelessly

.

This kind of putty can be scraped by adding water directly

.

The number of times depends on the specific situation

.

Key points: the most fundamental function of puttying is to level the wall

.

The error of 2 to 3mm within 2m is good

.

The effect of some masters twice is better than that of other masters four times

.

Generally speaking, the coating formed after coating film formation is only dozens of wires thick, so the smoothness of the putty layer directly determines the smoothness of the coating surface

.

I very much agree with this statement

.

In fact, high-grade coatings do not necessarily achieve high-grade coating, but for high-grade coating, high-grade coatings only play a small role

.

How to choose putty? When people decorate their homes, they often think of using high-grade coatings

.

The putty prepared by this method is prone to peeling and falling off due to improper proportion, inaccurate measurement and poor adhesion

.

2

.

At present, many house developers have scraped white

.

The large surface is flat, which can be seen with a guiding rule

.

The quality mainly depends on the thickness of the powder and the amount of glue

.

Second: smooth and delicate

.

Introduce several kinds of putty and several construction processes

.

The fineness and whiteness are OK

3

.

Therefore, when decorating the home, in addition to paying attention to the choice of finish paint, it is more important to choose high-quality putty

.

Conclusion: leveling and straightening is the purpose

.

Pay attention to the acceptance of large noodles

.

Waterproof putty is different from waterproof putty

.

Third: good water resistance

.

2 finished putty 1

.

If they are too strict, the labor price is very expensive

.

The quality difference lies in the thickness, whiteness and water resistance of powder

.

At the lower corner of the wall, remind me to be a little strict

.

Once and for all, there is no need to shovel the wall skin for the second renovation and decoration, no need to buy putty, and no need to find workers to approve the wall

.

Method for verifying whether water-resistant putty or ordinary putty

.

b

.

After brushing the wall, literacy shall be eliminated first, and the normal process of brushing the wall shall be as follows: shovel the wall (this link is not required if the room is delivered as a cement wall) → one time of interface agent → leveling gypsum leveling (the putty leveling is too thick and will fall off and crack, so it shall be roughly leveled with sand containing gypsum first) → two to three times of putty (the wall surface is flat, and the internal and external corners shall be vertical) → grinding → cleaning floating ash → one time of primer → finish paint on both sides

.

For some internal and external corners, 4 times and 5 times are not uncommon

.

The finished putty powder is 15-20

.

Lithopone generally sells 2.5-6 yuan a bag on the market

.

As for the time interval of each time, it is mainly determined according to the season: in summer, the interval between the first time and the second time is 3-4 days, the second time is 2-3 days, and the last time is 2-3 days

.

2

.

3

.

3

.

Don’t be too difficult for the master

.

In the process of painting, the primer is usually one time and the topcoat is two times

.