Cantilever pile (row pile) wall + anchor cable, cantilever pile wall + internal support 3

.

Hoisting and pouring reinforcement hpb300 for pile reinforcement cage – ( Grade I steel) hot rolled plain round bar strength grade 300mpahrb335 – ( Grade II steel) hot rolled ribbed bar strength grade 335mpahrbf335 – (grade II steel) fine grain hot rolled ribbed bar strength grade 335mpahrb400 – ( Grade III steel) hot rolled ribbed steel bar strength grade 400mpahrbf400 – (grade III steel) fine grain hot rolled ribbed steel bar strength grade 400maarrb400 – (grade III steel) waste heat treatment ribbed steel bar strength grade 400mpahrb400e – (grade III steel) ordinary hot rolled ribbed steel bar with high seismic performance strength grade 400mpahrb500 – (grade IV steel) ordinary hot rolled ribbed steel bar strength grade 500mpahrbf500 – (grade IV steel) fine grained hot rolled ribbed steel bars with strength grades of 500mph, P, R, B, F and E are the English first letters of hot rolled, plain, ribbed, bars, fine and earthquake respectively

.

Independent foundation: when the superstructure of a building adopts frame structure, the foundation often adopts square or rectangular independent foundation, which is called independent foundation or column foundation

.

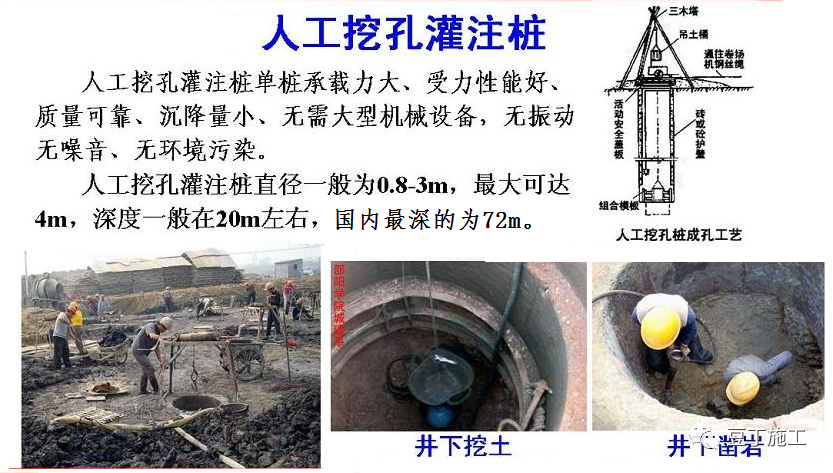

Bored cast-in-place pile refers to the pile formed by squeezing soil with machinery and steel pipe in the foundation soil at the project site, placing reinforcement cage and pouring concrete in it

.

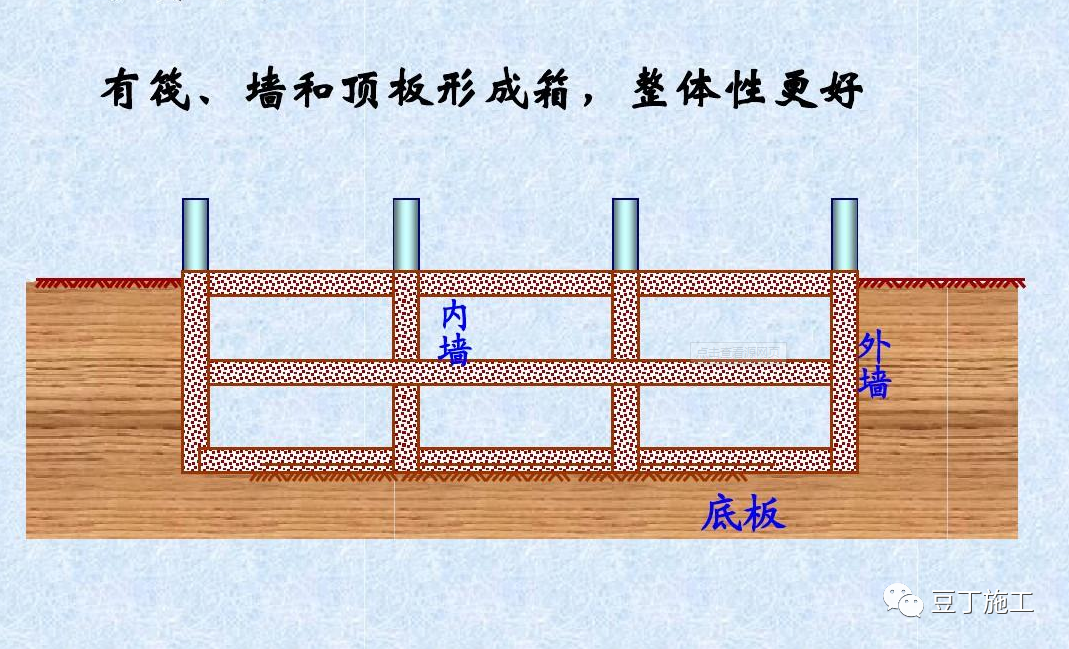

Box foundation is an integral structure composed of reinforced concrete bottom plate, top plate and several longitudinal and transverse partitions

.

The most common is the foundation of rural houses

.

Grade I steel is generally used in column and beam stirrups, wall tie bars, floor distribution bars, etc

.

This kind of foundation is called strip foundation or strip foundation

.

Grade III steel is generally used to avoid mistakes by workers in on-site construction

.

With the progress of earth excavation, the foundation construction is supported with excavation Common foundation forms are: strip foundation: when the upper structure of the building adopts wall bearing, the foundation is set along the wall body, and more long strips are made

.

Several forms of foundation pit support: 1

.

in non civil air defense areas; Although the code allows the use of non seismic reinforcement in the foundation part, the grade III steel used in the project is all seismic reinforcement

.

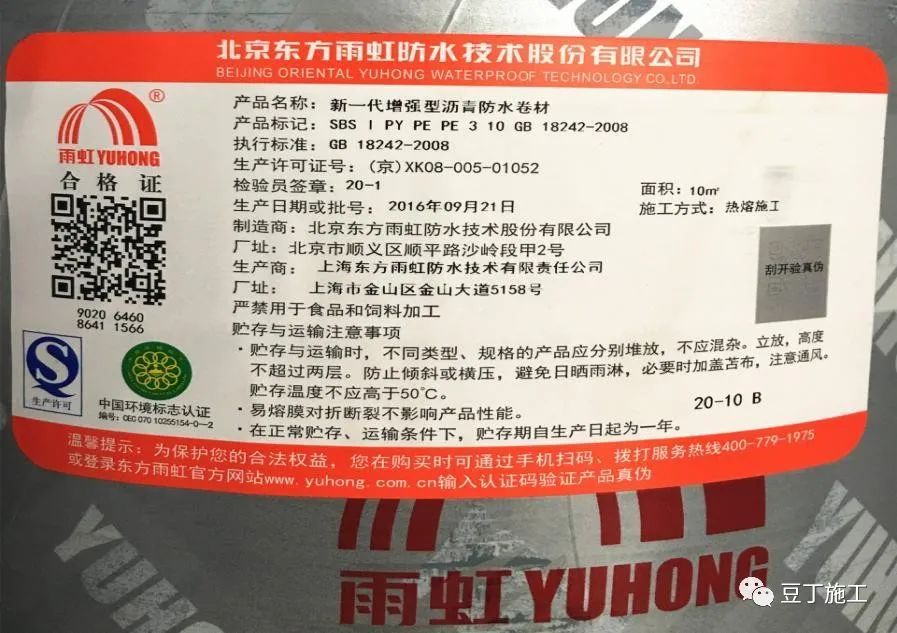

According to the isolation material on the upper surface, it is divided into polyethylene film (PE), fine sand (s) and mineral aggregate (m)

.

Punching pile: punching is to raise the heavy bit with drilling edge (also known as punching hammer) with an impact drill and form a hole by the impact force of free falling

.

Sometimes grade II steel appears in the design, but few parts are used

.

Raft foundation in the form of single foundation + coupling beam: when the load on the upper part of the building is large and the foundation is weak, the foundation under the wall or column is usually connected into one, so that the load of the building can be borne on a whole plate to become a raft foundation

.

The following numbers represent the yield strength of * * * MPa

.

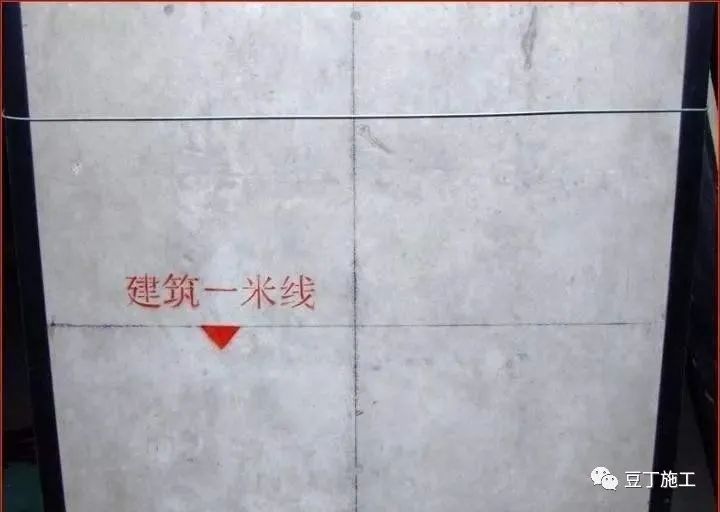

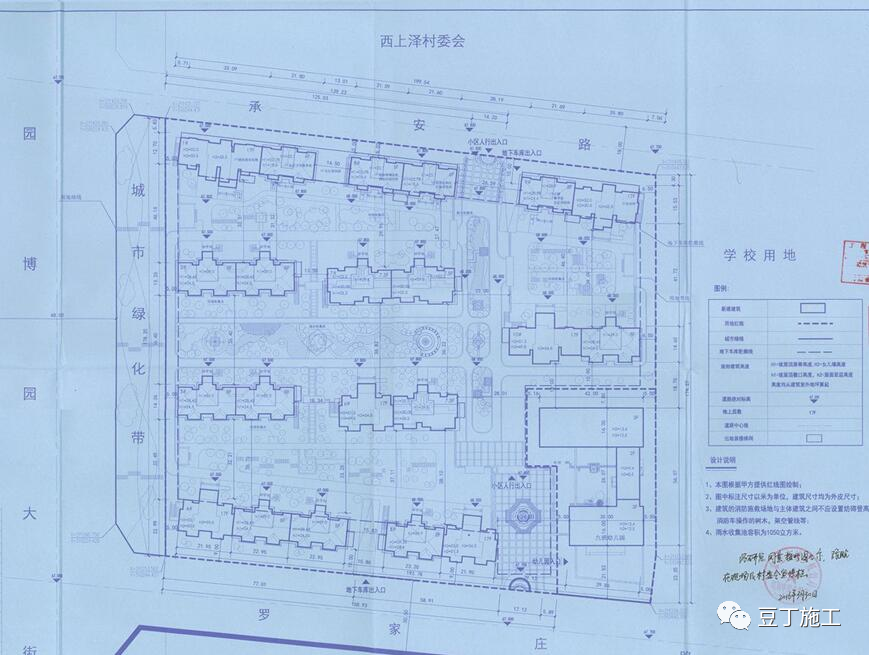

Construction procedure Cultural relics exploration → geological exploration → drawing design → foundation pit support design → earth excavation (slope support) → piling → leveling soil between piles → chiseling pile head → cushion → waterproof (waterproof protective layer) → foundation reinforcement Concrete → basement structure → aboveground structure → secondary structure → water and electricity installation → internal and external powder → door and window installation → public part decoration → external wall decoration → external network of the park → garden landscape and enclosure → acceptance, cultural relics exploration and geological exploration The main exploration contents of geological exploration include: geological structure or geological structure, landform, hydrogeological conditions, physical and mechanical properties of soil and rock

.

![]()

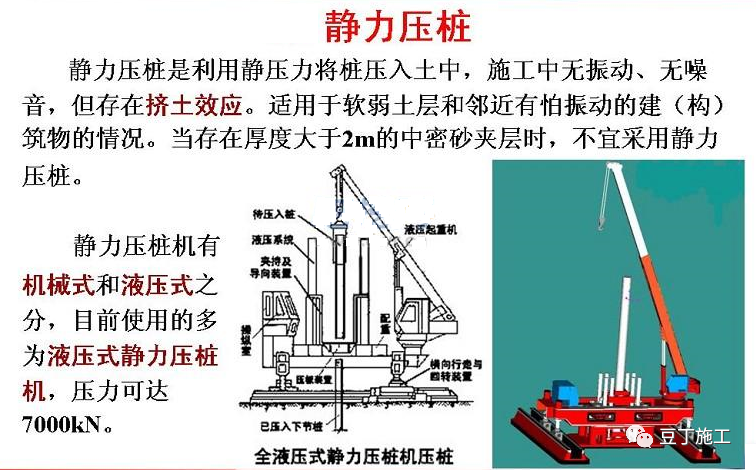

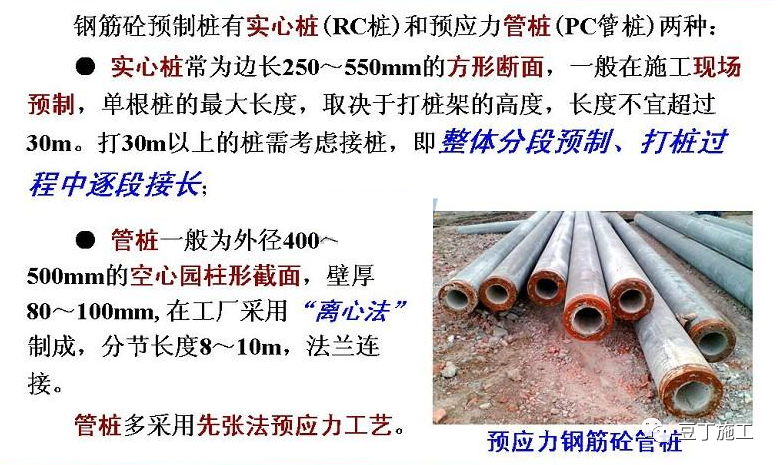

Pile foundation type hammering pile (small stones and loud noise) static pressure pile is allowed under the ground ( Silt soil, red clay, no noise) punching pile ( Bored cast-in-place pile with stone or through stone layer) ( No stone, good soil layer) rotary excavation pile ( Manual hole digging pile without large stone and various soil) ( Prestressed pipe pile hammering pile static pressure pile with diameter above 800 (good geological conditions and no groundwater): the pile sinking process of pressing the precast pile into the soil through the pile pressing mechanism of the static pile pressing machine to provide reaction force with the self weight of the pile pressing machine and the counterweight on the frame

.

Inverted arch wall soil nailing wall support cantilever pile (row pile) wall + anchor cable, cantilever pile wall + internal support Larsen steel sheet pile Larsen steel sheet pile + internal support diaphragm wall cement soil pile wall reverse arch wall earthwork excavation The project adopts soil nailing, shotcrete and anchor support

.

Box foundation: when the slab foundation is very deep, the foundation is often changed into box foundation

Precipitation measures will also be added in areas with abundant groundwater to ensure the normal progress of foundation construction

.

Rotary excavation pile generally refers to the pile type constructed by rotary drilling rig, which is fully called rotary excavation bored cast-in-place pile, and is referred to as rotary excavation pile in engineering

.

The isolation materials on the lower surface are fine sand (s) and polyethylene film (PE).

.

Pile foundation: pile foundation is composed of foundation pile and bearing platform connected to pile top

.

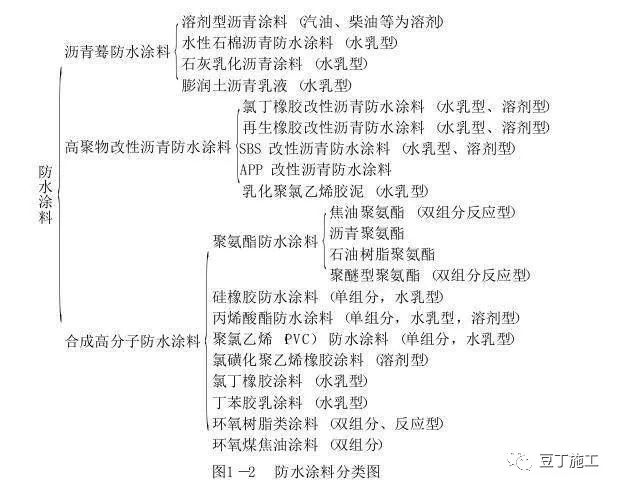

Top view of excavation pile construction site leveling inter pile soil cast-in-place pile cut-off head brick tire mold, cushion construction foundation coiled material waterproof construction waterproof material: SBS modified asphalt waterproof material used in the project is divided into polyester felt (py), glass fiber felt (g) and glass fiber reinforced polyester felt (pyg) according to tire base

.

The most commonly used are grade I steel and grade III steel

.

Soil nailing wall (shotcrete anchor support) 2

.

If the pile body is completely buried in the soil and the bottom surface of the bearing platform is in contact with the soil, it is called low bearing platform pile foundation; If the upper part of the pile body is exposed to the ground and the bottom of the bearing platform is above the ground, it is called high bearing platform pile foundation

.

Not all rolled up steel is grade I steel, and 6, 8 and 10 grade III steel are also delivered in this form

.

It is generally used in single storey or multi-storey buildings

.

According to different hole forming methods, cast-in-place pile can be divided into immersed cast-in-place pile, bored cast-in-place pile and dug cast-in-place pile

.

Larsen steel sheet pile, Larsen steel sheet pile + internal support 4, underground diaphragm wall 5, cement soil pile wall 6

.

Geological survey report and construction drawing Design blueprint: only when buildings, structures, water supply and drainage, electrical, HVAC and processes are stamped with “special seal for design drawing, name seal of person in charge of construction drawing, practice seal of registered * * engineer corresponding to the discipline and seal for drawing review” are qualified and complete drawings for construction, foundation pit support design It is mainly to ensure the safety of underground structure construction and buildings and underground pipelines around the foundation pit, and adopt retaining, reinforcement and protection measures for the side wall of the foundation pit and the surrounding environment

.