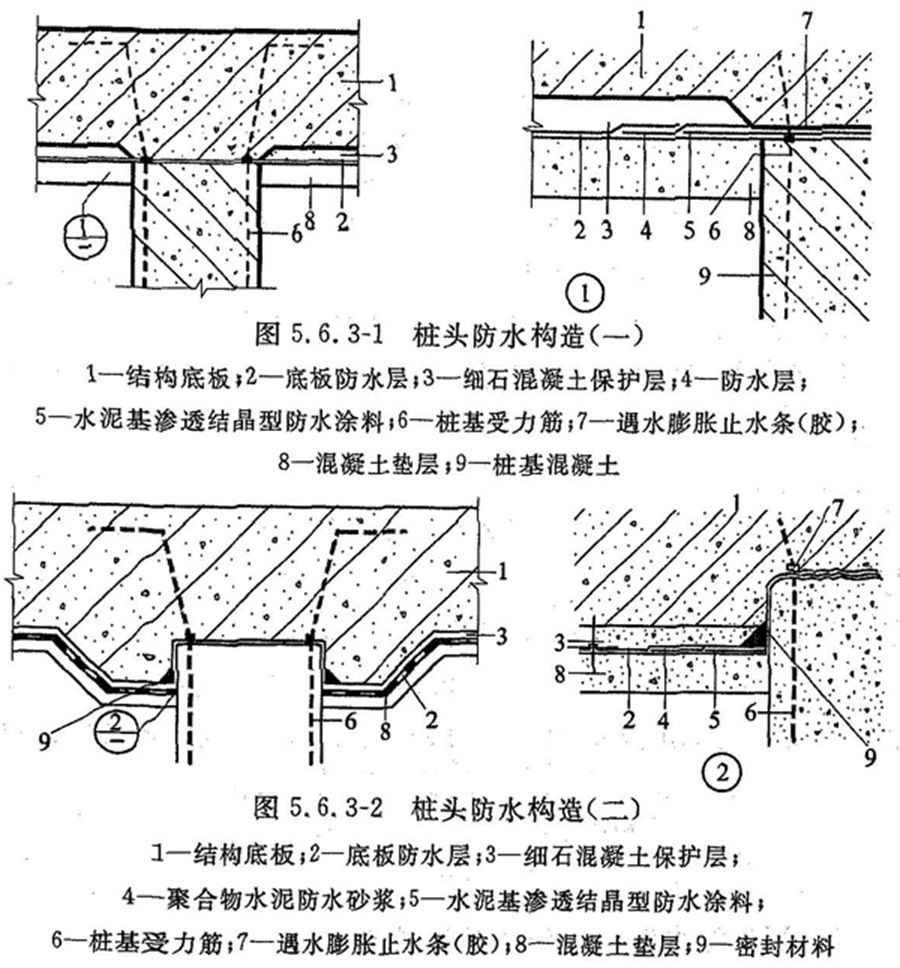

6 pile head waterproofing gb50208 code for quality acceptance of underground waterproofing works: the exposed parts of the top and side of the pile shall be painted with cement-based permeable crystalline waterproof coating, which shall extend to 150mm of the cushion of the structural bottom plate; Polymer cement waterproof mortar transition layer shall be provided within 300mm around the pile head

.

During coiled material construction, gasoline blowtorch or special flame spray gun shall be used to directly heat the junction between base course and coiled material

.

Hot melt method construction process hot melt standard: asphalt slurry leakage shall prevail

.

Article description: the thickness of the original specification shall not be less than 80% of the design thickness to 90%

.

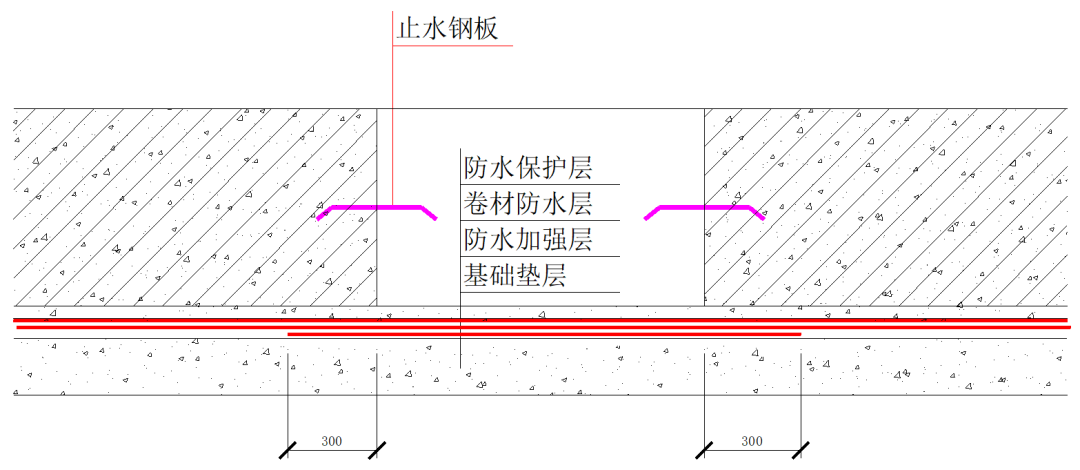

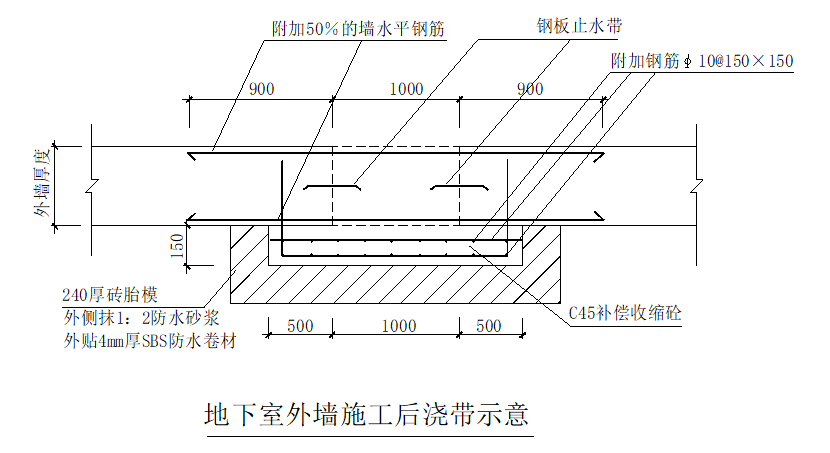

According to relevant experiments, the secondary vibration can increase the holding and wrapping force of reinforcement by 1 / 3, increase the 28d strength by 10% ~ 15%, and save about 15% of cement consumption on the premise of maintaining the same strength· Sediment ditches or grooves shall be reserved on the cushion at the waterproof joints of raft post cast strip, post cast strip and reinforcing strip

.

5

.

The waterproof layer of structural base plate shall be made on the transition layer of polymer cement waterproof mortar and extend to the side wall of pile head, and the joint between it and the side wall of pile head shall be filled with sealing material

.

2

.

Clean the base course before brushing the base course treatment agent

.

The waterproof quality of basement is directly related to the use function and service life of buildings, and its importance is self-evident

.

Field pull off test base course bonding standard gb50208 code for quality acceptance of underground waterproof Engineering: the average thickness of coating waterproof layer shall meet the design requirements, and the minimum thickness shall not be less than 90% of the design thickness

.

3

.

The reserved notch shall be made of plastic strips of corresponding specifications embedded and drawn; Special process inspection shall be carried out for reserved notch, rubber expansion waterstop of reinforcement out of pile head, grooved waterproof ointment, etc; The application range of waterproof coating applied by cement-based permeable crystallization shall be in accordance with the requirements of the drawing, and the thickness shall be ≥ 1.5mm

.

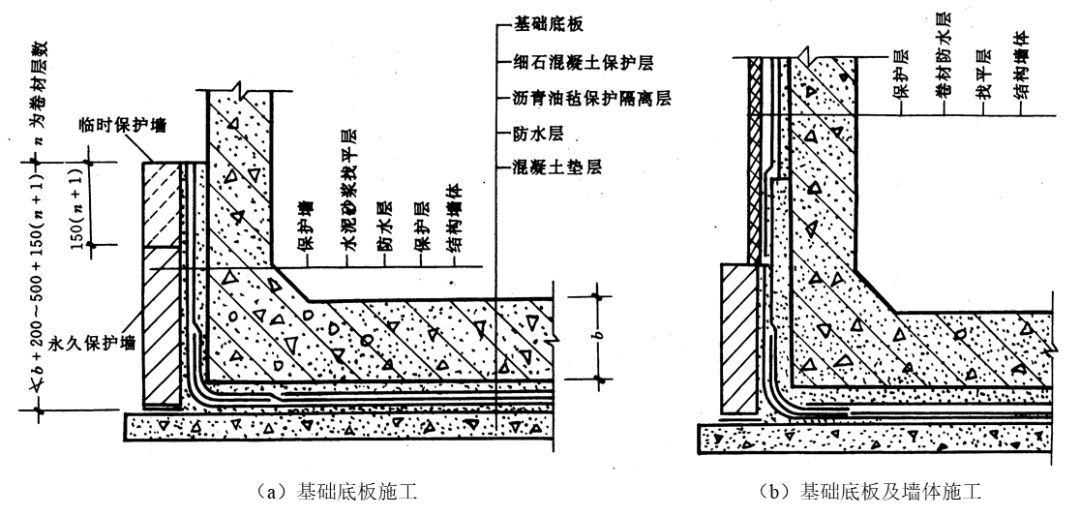

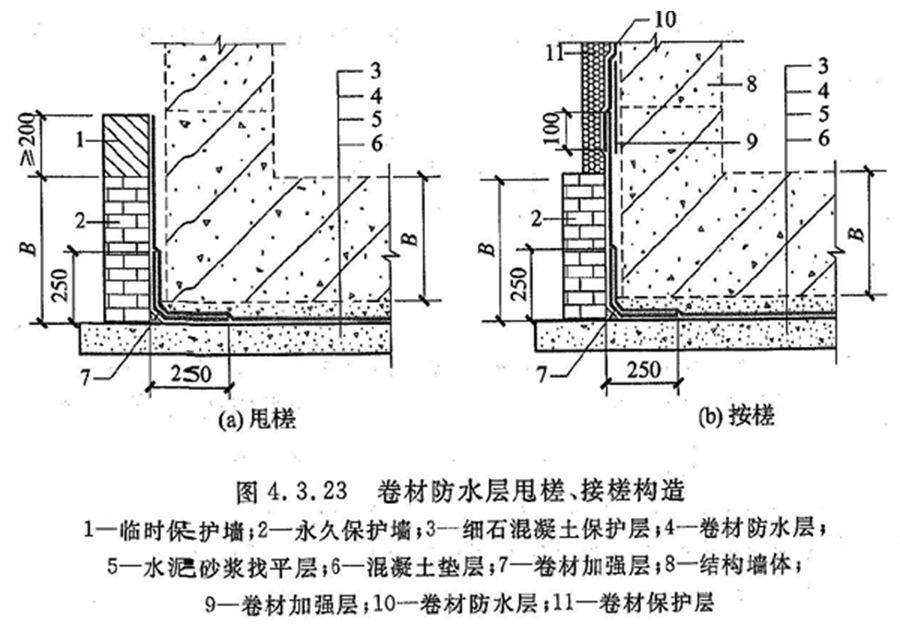

The contact part between the coiled material folded from the bottom plate to the facade and the permanent protective wall shall be constructed by empty paving method

.

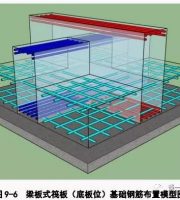

Basement waterproof construction mainly includes three parts: ① bottom plate, ② outer wall and ③ top plate

.

Secondary polishing, polishing by grinder

.

Rolling laying shall be carried out when the asphalt of coiled material has just melted, and the force shall be uniform without air

.

The exposed parts of the top and side of the pile shall be painted with cement-based permeable crystalline waterproof coating, which shall extend to 150mm of the cushion of the structural bottom plate

.

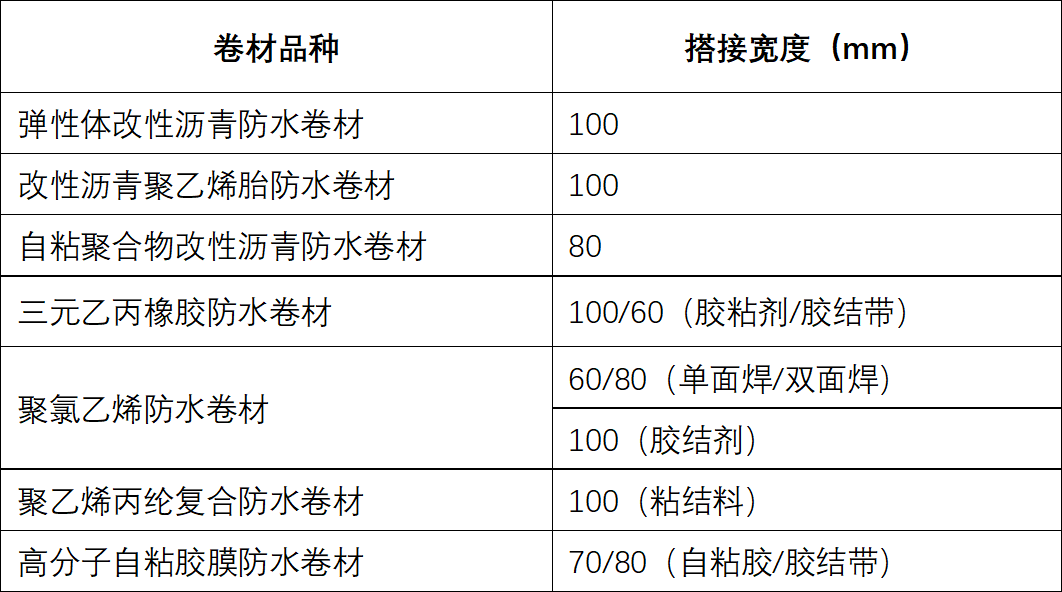

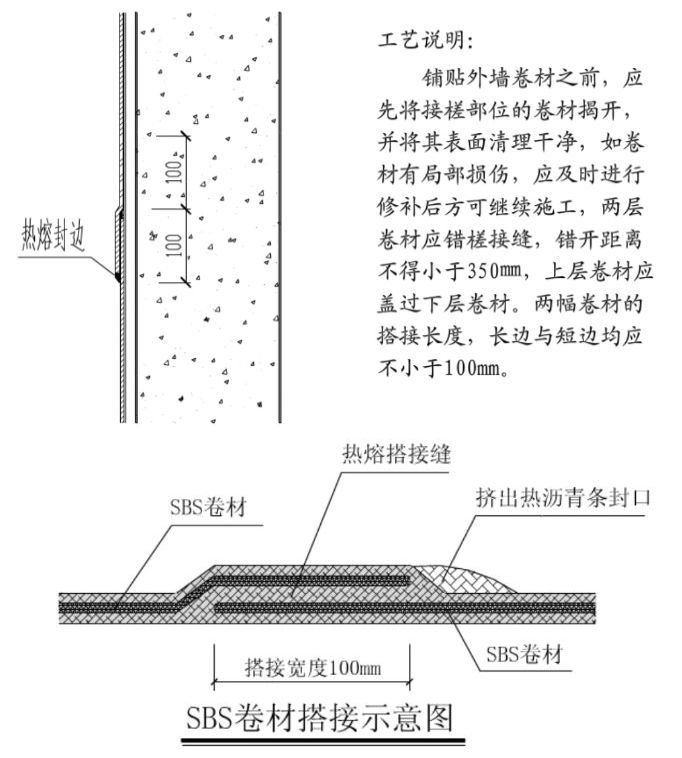

Large area paving of waterproof coiled material gb50208 code for acceptance of quality of underground waterproof Engineering: the overlapping width of waterproof coiled material shall meet the requirements in the table below

.

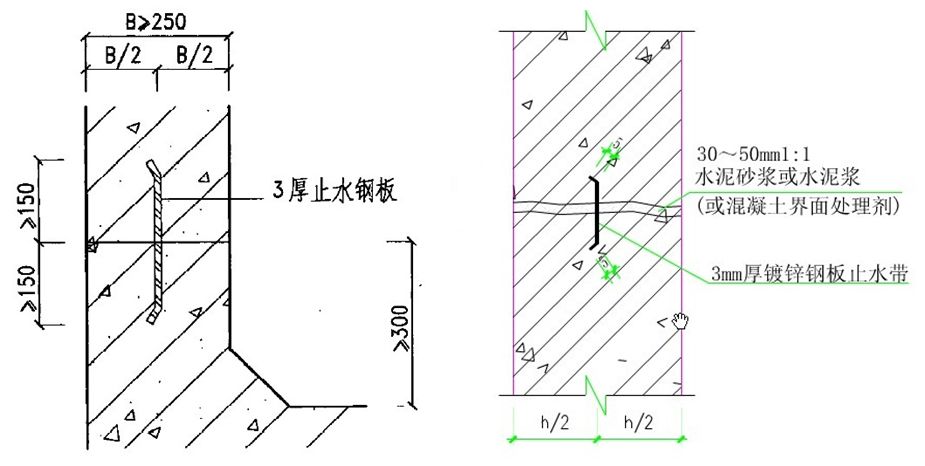

The post cast strip concrete shall be poured at one time without construction joints; The concrete shall be cured in time after pouring, and the curing time shall not be less than 28d

.

4

.

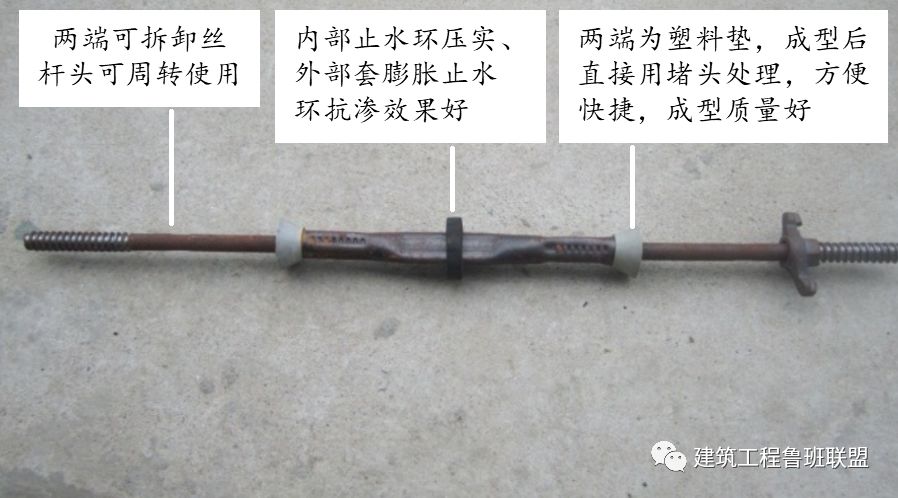

Water swelling waterstop or water stop glue shall be used at the root of the stressed reinforcement at the pile head, and protective measures shall be taken· Construction points of pile head waterproof node construction site: 1

.

5

.

Polymer cement waterproof mortar transition layer shall be provided within 300mm around the pile head

.

3

.

This paper is a comprehensive interpretation of basement waterproof construction technology based on project examples on the basis of code for quality acceptance of underground waterproof engineering, technical code for waterproofing of underground engineering and waterproof structure of underground buildings, It is worthy of your reference, study and practice to jointly improve the project quality

.

The overlapping length of the rolling part of the second layer of coiled material is 300mm and 500mm, and the top is temporarily fixed with four bricks made of lime mortar

.

When paving double-layer coiled materials, the joints of the upper and lower layers and two adjacent coiled materials shall be staggered by 1 / 3 ~ 1 / 2 of the width, and the two layers of coiled materials shall not be paved perpendicular to each other

.

It is strictly prohibited to add water directly

.

The waterproof layer of structural base plate shall be made on the transition layer of polymer cement waterproof mortar and extend to the side wall of pile head, and the joint between it and the side wall of pile head shall be filled with sealing material

.

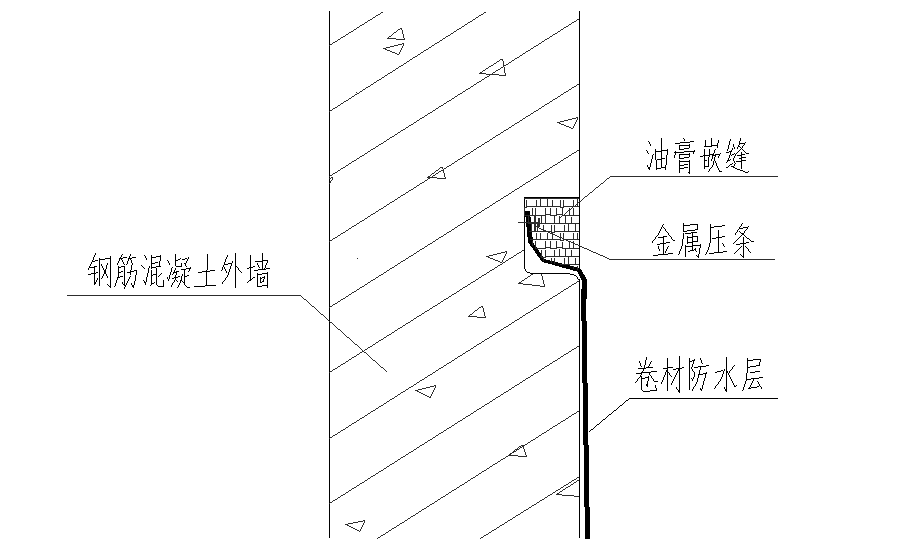

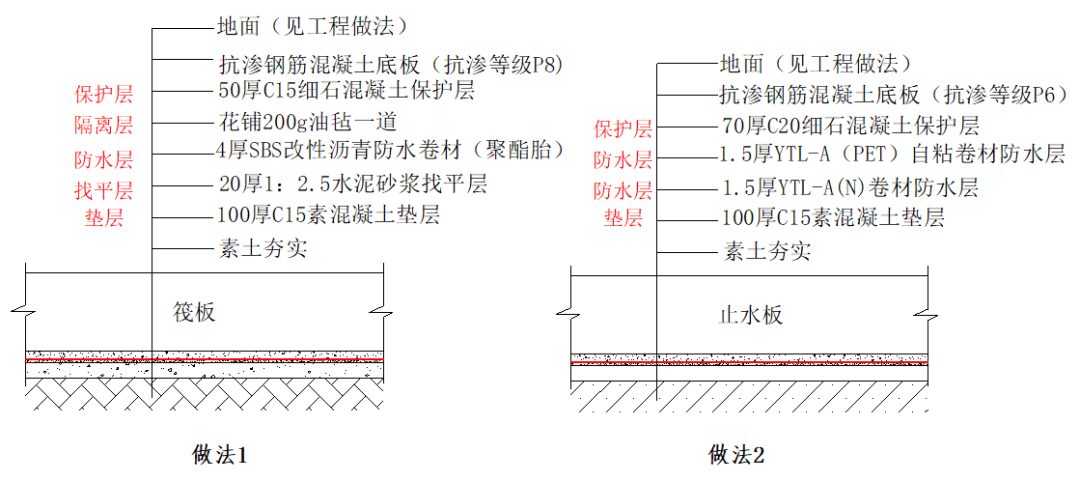

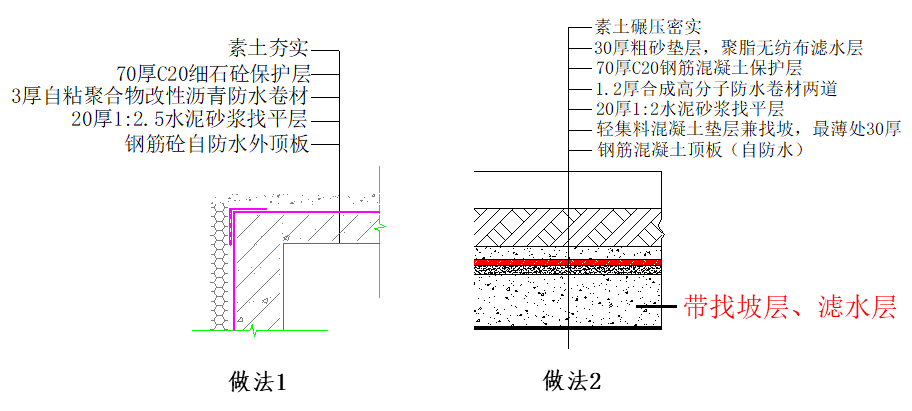

Conventional waterproof practices of basement (I) bottom plate waterproof practices (II) exterior wall waterproof practices (III) top plate waterproof practices (I) bottom plate waterproof process: base surface treatment → coating base course treatment agent → detail reinforcement → paving coiled material → joint treatment → protective layer 1 cushion construction is constructed in blocks to avoid long base exposure time

.

It is recommended to select 5 points according to 10 ㎡ of each place, and the distance between the two points shall not be less than 2.0m

.

Then, one person will wipe and press the coiled material from the middle to both sides with cotton yarn, discharge the air under the coiled material, scrape and press the overflowing hot melt adhesive to the edge seam with a scraper, and the other person will compact the coiled material with a pressing roller to make it firmly bonded, the surface flat and free of wrinkles

.

When paving the additional layer of coiled material, do not tighten it, but lay it loose naturally without wrinkles

.

The secondary vibration of concrete has many advantages

.

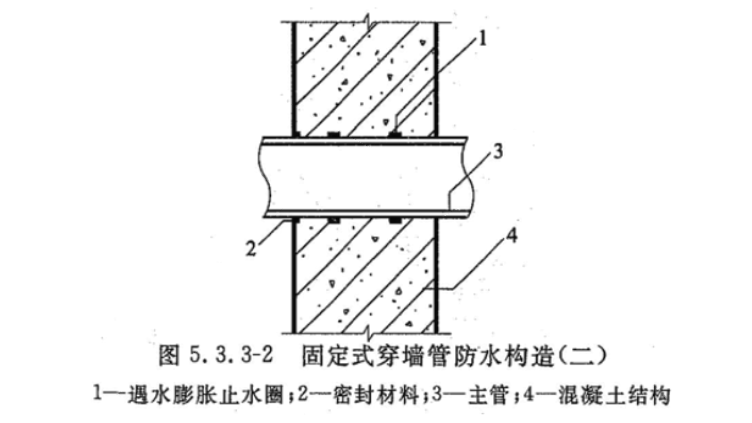

Additional layer gb50208 code for quality acceptance of underground waterproof Engineering: coiled material reinforcing layer shall be paved at corners, deformation joints, construction joints, post cast strips, through wall pipes and other parts, and the width of the reinforcing layer shall not be less than 500mm

.

The secondary vibration of concrete actually refers to the appropriate time after concrete pouring

.

It is recommended that the waterproof coiled material with sand particles be used for the inclined surface of elevator shaft and ponding pit, so as to facilitate the construction of waterproof protective layer

.

2

.

It can not only improve the strength of concrete, or save the amount of cement on the premise of ensuring the strength, but also increase the compactness of concrete, improve anti-seepage, and eliminate cracks and fine joints caused by concrete settlement

.

1

.

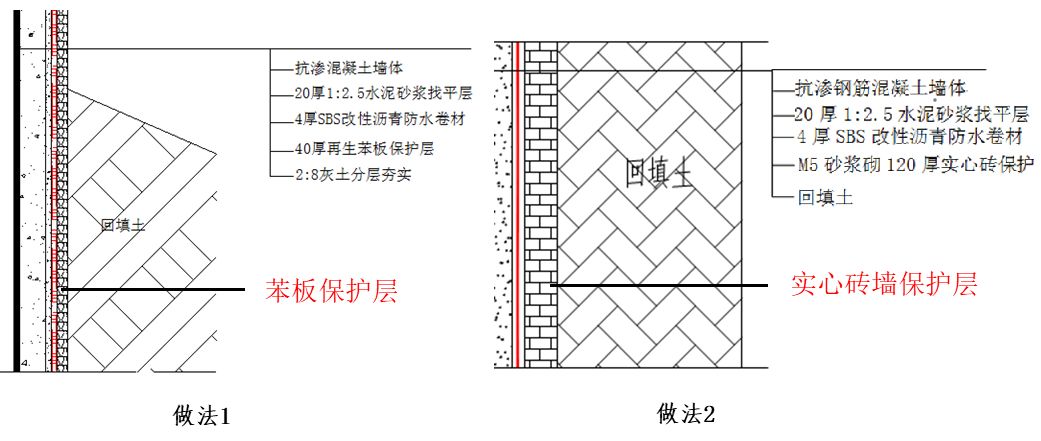

The side wall is constructed with full adhesion, which can achieve the best waterproof effect of rigid flexible seamless combination.

.

2

.

Calculate the average value of the 5 points and report the minimum value

.

7

.

The bottom plate of underground works is laid empty, and the moisture of the base course has no impact, which can greatly improve the construction speed and shorten the construction period

.

When the slump loss fails to meet the construction requirements, the cement slurry with raw water binder ratio or water reducing agent of the same variety shall be added for mixing

.

Chisel the pile top to the dense concrete and clean it

.

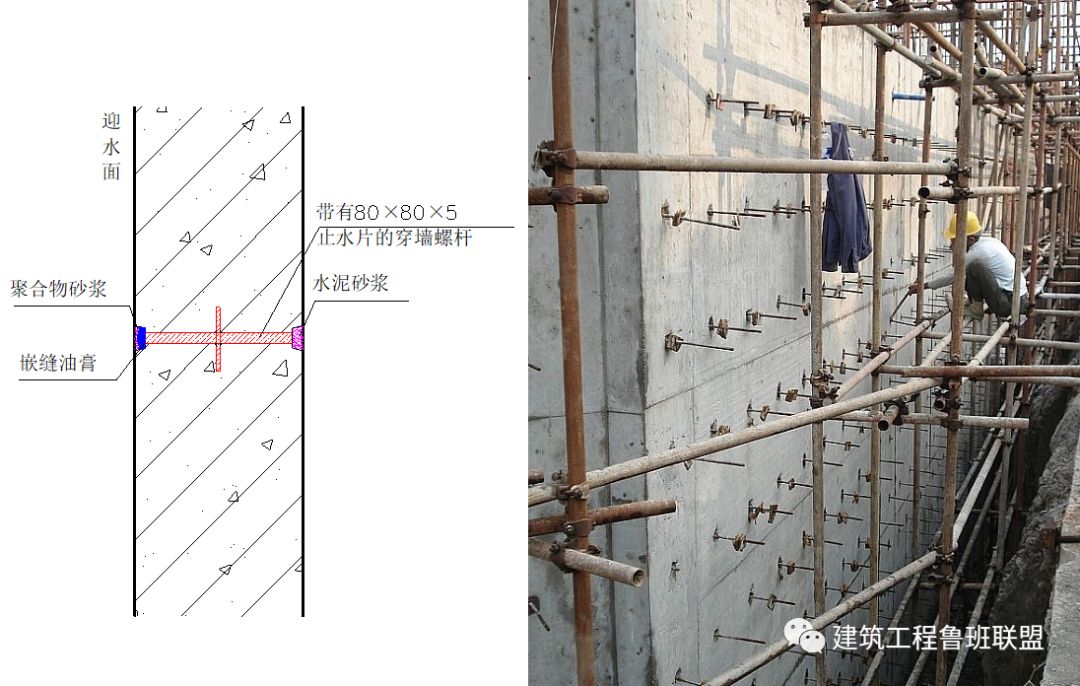

The basement floor shall be given reasonable maintenance time and reasonable maintenance measures (covering, watering, water maintenance and internal cooling) shall be taken( 2) Construction procedures and methods of exterior wall waterproof exterior wall: according to the sequence of wall structure and coiled material construction, it can be divided into external pasting method and internal pasting method( 1) External pasting method: Wall structure → waterproof → protection Features: the quality of structure and waterproof layer is easy to check and has strong reliability; The required fertilizer tank is wide and the construction period is long( 2) Internal pasting method: cushion, protective wall → waterproof layer → bottom plate and structural wall features: small groove width and formwork saving; The damage is undetected, the reliability is poor, and the inner formwork is not fixed well

.

The construction method is flexible: the construction and installation methods of SBS coiled material waterproof system include: full bonding method, strip bonding method, point bonding method, empty paving method, etc

.

JS composite coating (polymer cement waterproof coating) 8 waterproof protective layer 9 base plate impermeable concrete gb50108 technical code for waterproofing of underground engineering: if the waterproof concrete mixture is separated after transportation, it must be mixed again

.

Generally, the vibration effect is the best one hour before the initial setting of concrete

.

Process Description: 1

.

when the auxiliary mechanical fixation is adopted, the system performance is more superior

.

Water stop steel plate shall be installed in the middle of post cast strip

.

Pay attention to the flatness, straightness and overlapping width of the coiled material at any time

.

It is used when the site is small and the external pasting method cannot be used

.

The joint surfaces on both sides of the pouring belt shall be cleaned first, and then painted with concrete interface treatment agent or cement-based permeable crystalline waterproof coating

.

Construction points: 1

.

3 brush the base course treatment agent (cold primer oil)

.

Process Description: the additional layer coiled material of plane internal and external corners and three internal and external corners shall be cut and cut according to the shape shown in the above figure

.

5

.

2

The internal and external corners of base course treatment, fetal membrane plastering and chamfering shall be made into arc or 45 ° slope angle, and its size shall be determined according to the type of coiled material

.

4

.

When the waterproof roll is pasted on the outer wall, the joints shall be staggered in layers

.

The post cast strip shall be constructed after the concrete age on both sides reaches 42d

.

Water swelling waterstop or water stop glue shall be used at the root of the stressed reinforcement at the pile head

.

4

.

Test method: needle test

.

2

.

The brushing shall be uniform without bottom exposure

.