This training is mainly for the high fill soil subgrade related to the project.

Compared with the general subgrade, the height of the high fill subgrade is larger, resulting in the increase of filling quantities and cross-sectional area, resulting in more filling defects of the subgrade.

After the thickness is measured, roll it when the water content meets the requirements (the best water content ± 2%)( 3) Vibratory roller shall be used for construction during rolling.

If it is repaired in time, it will need to invest a lot of repair cost, and it is difficult to achieve the ideal effect.

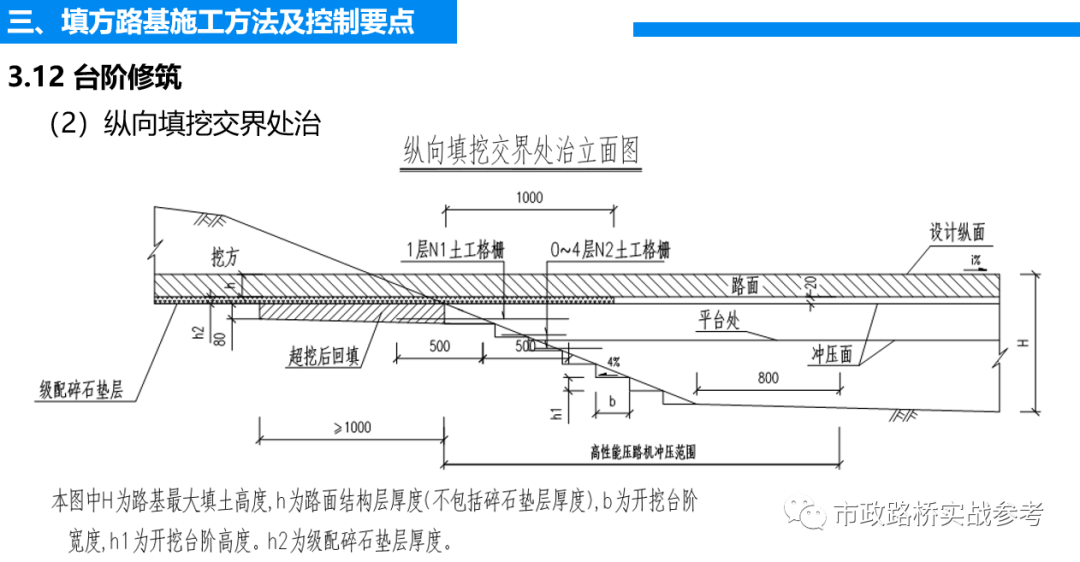

When the filling reaches the subgrade design elevation, cumulative settlement deformation will inevitably occur, and settlement will occur under the action of repeated load and filler self weight( 5) The subgrade filling fails to excavate steps and lay geogrid at the filling and excavation junction according to the specification requirements.

② The soil less affected by moisture and freeze-thaw shall be filled in the upper part of the subgrade.

if the quality is not well controlled during construction, the low filled subgrade will also have similar quality problems.

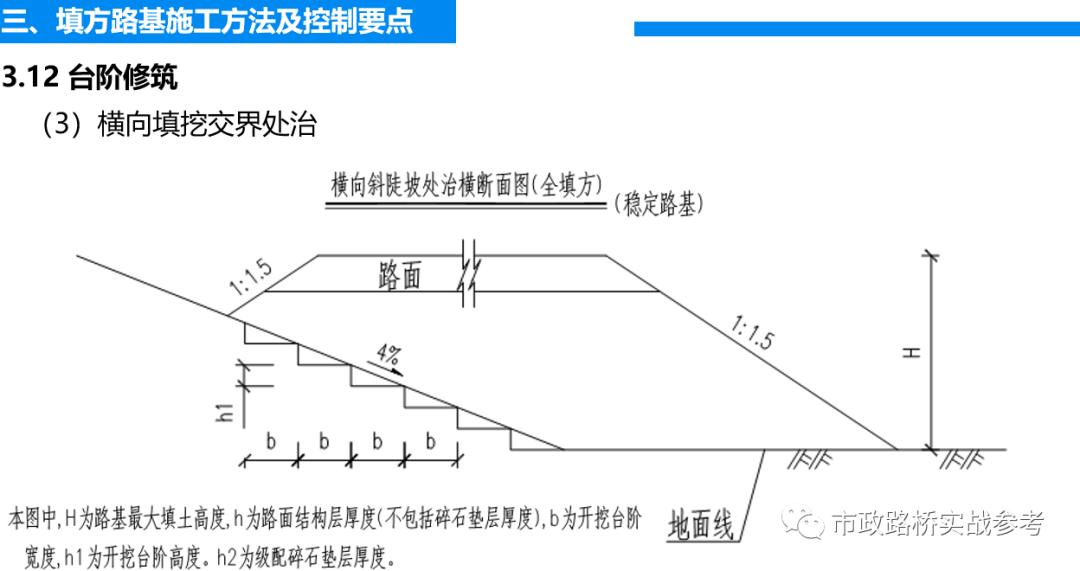

⑤ When the cross slope of the original ground is 1:10 ~ 1:5, the topsoil shall be scarified before filling; Steps may not be made in sandy soil sections, but the topsoil shall be scarified.

084。.

After the earthwork is paved, level it with a grader to form a road arch.

Manual compaction shall be less than 20cm.

③ Within the subgrade width, the virtual paving thickness of each layer shall be determined according to the function of compaction machines and tools.

During rolling, measure and record the compactness of Subgrade Earthwork at different stages and the thickness of soil layer after rolling until the specified compactness is reached( 4) After the completion of the test section, the construction of the test section shall be summarized to determine the appropriate construction process parameters.

Therefore, in the actual construction, the subgrade with high filling height but not meeting the requirements of the definition of high filling should also be constructed and strictly accepted with reference to the standards of high filling subgrade.

In the construction of high fill subgrade, the filling layer is too thick or the layered filling and rolling process is not strictly followed, and the subgrade compaction is insufficient, resulting in subgrade settlement and deformation; The whole section is not filled evenly in layers, but half of it is filled first and then the other half, resulting in uneven settlement( 8) When backfilling the abutment back of bridge and culvert structures and filling the transition section of roads and bridges (generally within 10 ~ 20m from the abutment back), due to inconvenient operation of large machinery, insufficient compaction of small machines and tools or excessive thickness of filling layer; The transition section of road and bridge is formed first and then filled.

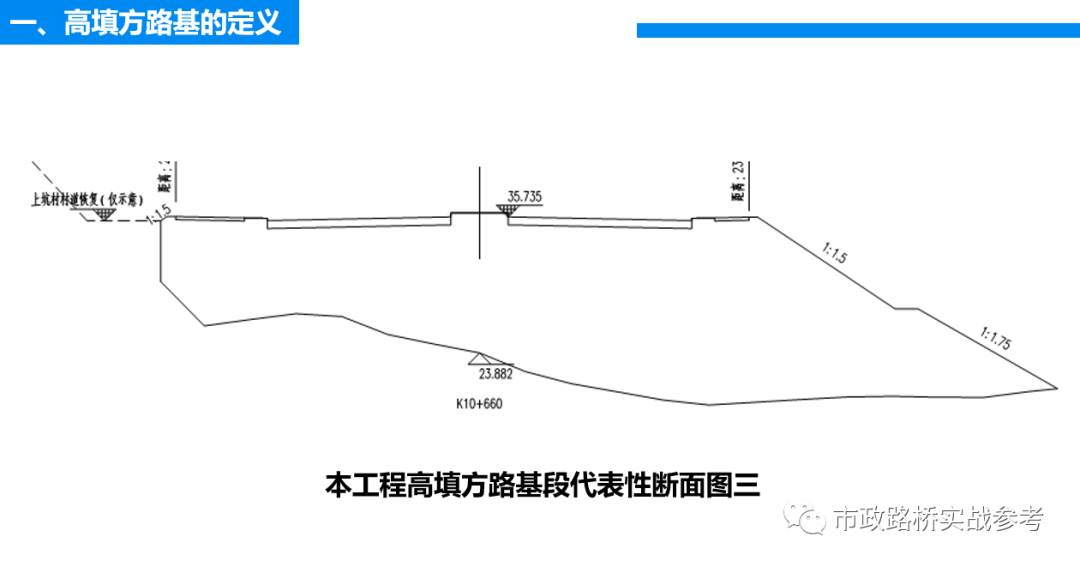

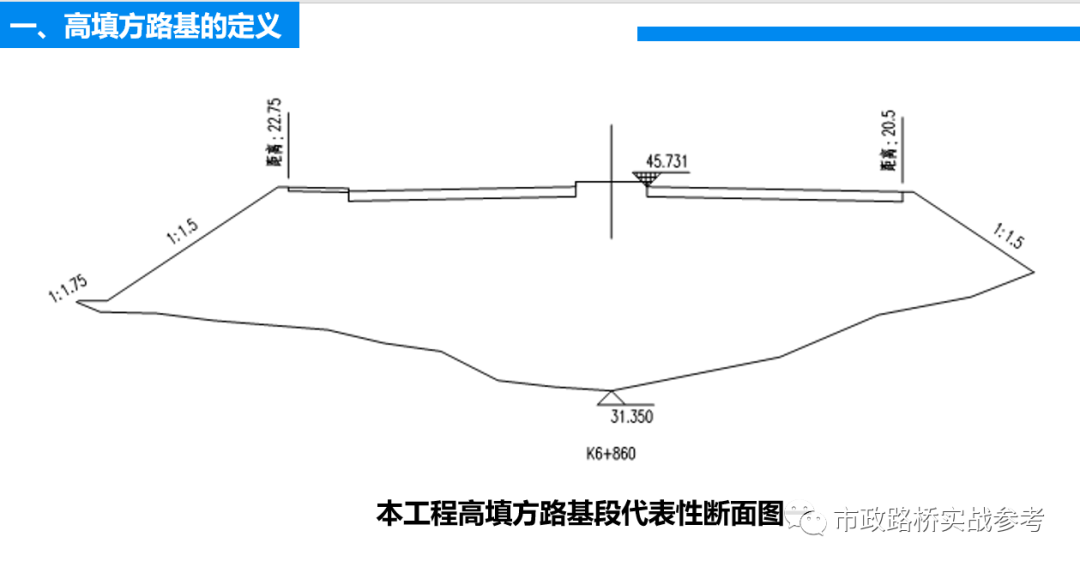

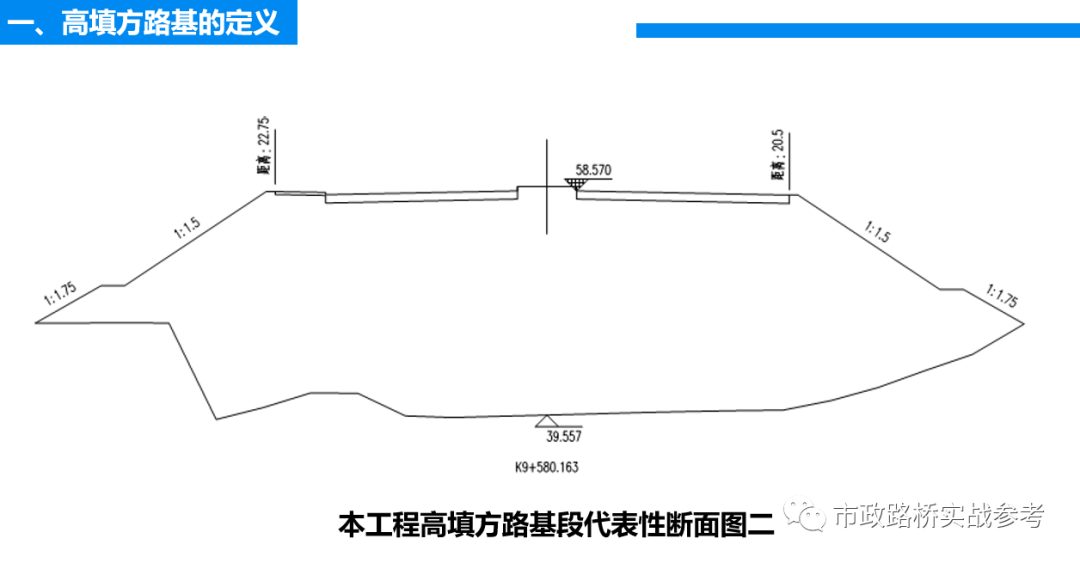

Therefore, we should understand the main problems in the construction of high fill subgrade in advance, do a good job in the quality control of subgrade construction and improve the quality of road construction! Definition: paddy field or perennial ponding area shall be filled with fine-grained soil, and the subgrade height shall be more than 6m; In other areas, soil subgrade with filling height greater than 18m or stone subgrade with filling height greater than 20m is called high fill subgrade.

Generally, in the scheme design, the subgrade with a filling height of more than 8m can be regarded as high fill subgrade (also known as high fill embankment).

According to the specifications, a section with a length of 200m is generally selected for Subgrade test( 2) After the base passes the inspection, calculate the soil stacking spacing according to the capacity of the dump truck, lay a grid on the construction section, unload the soil evenly, and pave the whole subgrade width with a bulldozer according to the design loose paving thickness.

Note: high fill subgrade and low fill subgrade are only a relative concept.

The full width of Subgrade in the same horizontal layer shall be filled with the same filler, and mixed filling is not allowed.

Both of them are easy to cause settlement due to insufficient compactness( 9) The filler used in the construction of high fill subgrade has too much water content and is not turned over, or mixed with inferior soil such as planting soil, humus soil or mire soil, or the soil contains large pieces of soil or frozen soil blocks that have not been broken; Due to the poor water resistance and low strength of inferior soil, the embankment will have plastic deformation or settlement failure; In frozen or seasonally frozen regions, due to the existence of low-quality soil or frozen soil blocks, the embankment is prone to freeze-thaw churning.

⑥ When the old road is widened, the filling soil should be the same as the original subgrade soil or the soil with good water permeability.

The quality of subgrade construction directly affects the quality of pavement construction and the service life of road.

Introduction subgrade is the foundation of pavement.

Or due to the different density and bearing capacity of the original soil and filler, such as the soft soil and humus at the filling and excavation interface are not removed completely, or the filling method is incorrect and the compaction is insufficient, there will be poor connection of the joint, resulting in uneven settlement of the subgrade( 6) The construction organization is improper, and the construction of high fill subgrade is not arranged in advance.

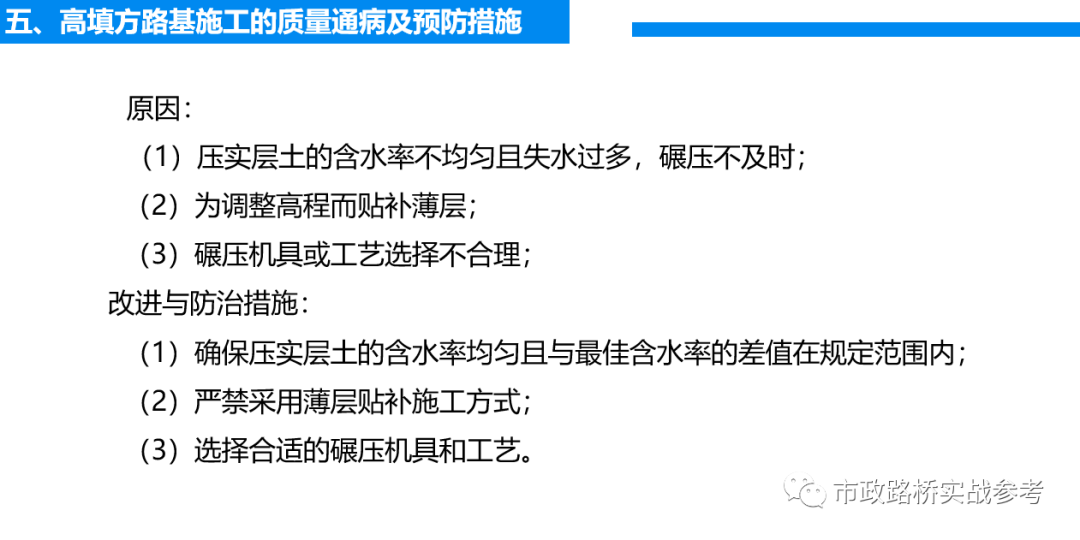

The original ground treatment is not complete, such as grass roots, tree roots, sludge and other bad soil, insufficient foundation compaction and other factors, resulting in subgrade settlement and deformation under the action of static and dynamic loads( 3) Subgrade settlement and deformation caused by untreated or improper treatment of unfavorable geological sections( 4) When the high fill subgrade is filled in layers, it is not paved according to the thickness required by relevant specifications or design, and the paving thickness is thickened at will; The compaction machines and tools are not compacted in real time according to the specified rolling times, and the compactness cannot meet the requirements specified in the specification.

The stability of the filled subgrade is not only related to the filling height, but also related to the subgrade filler and its properties, slope gradient, hydrogeological conditions of the foundation, subgrade compaction machines and tools, construction methods, etc.

3.6 subgrade test section (1) before the commencement of subgrade, the construction of subgrade test section shall be carried out.

① Length of working section for each earthwork, bulldozer leveling and roller rolling; ② Loose paving coefficient of soil layer that can meet the required compactness standard; ③ Compaction times and the best mechanical combination; ④ Compaction times compaction degree, water content compaction degree relation curve( 5) The large-scale construction of subgrade can be carried out only after the construction summary of the test section is submitted to the supervising engineer for approval.

④ When the subgrade filling is interrupted, the soil layer on the filled subgrade surface shall be compacted and maintained.

Moreover, due to the relatively large cumulative settlement of the subgrade, if the relevant quality control is not done well for the high fill subgrade, the high fill section may have problems such as collapse, cracking and pavement settlement within one or two years after it is put into use, which will seriously affect the normal use of the road.

The pavement is often paved not long after the construction of high fill subgrade is completed, and the subgrade does not have enough time to consolidate, so that the pavement is damaged due to the natural settlement of subgrade soon after use( 7) Improper filling sequence.

⑦ Soil with different properties shall be filled in layers and sections.

The cumulative total thickness of each filling layer shall not be less than 0.5m.

2021 municipal road and Bridge practical reference Baidu network member (10) other requirements for subgrade filling ① soil slope with high permeability should not be covered by soil with low permeability.