For loose and collapsible strata or groundwater distribution and unstable hole wall, static mud wall protection drilling process must be adopted, and wall protection mud or stable fluid must be put into the hole for wall protection

.

The engine speed can be automatically controlled when the load is small or no load, automatically reduce the engine speed, reduce fuel consumption, noise and exhaust emission

.

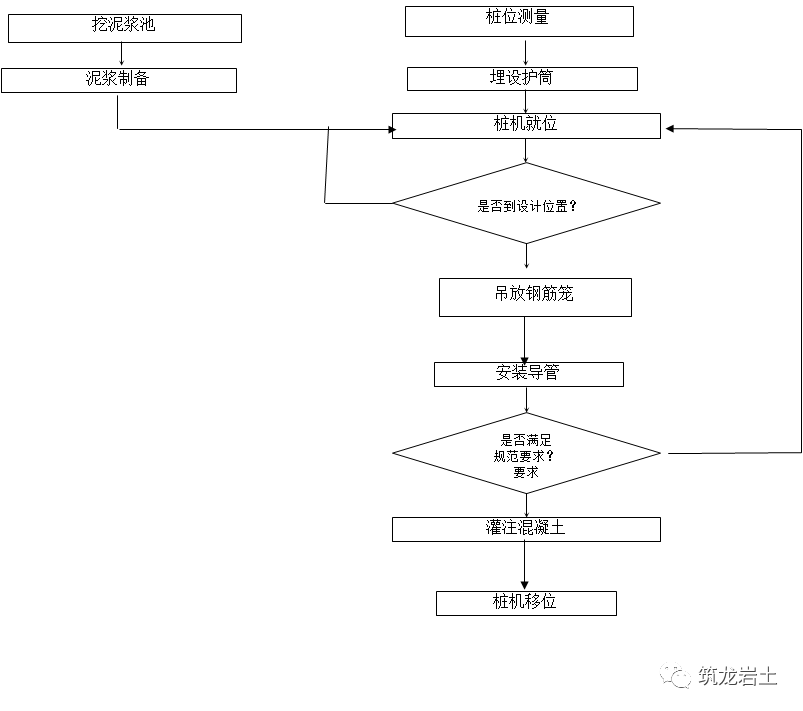

3) Pile driver in place: after the drilling rig is installed in place, the center of the drill bit shall be aligned with the center of the pile position to ensure that there is no hole position deviation during construction( Rotary drilling rigs generally have the locking function after positioning

.

The outer side of the foundation pit is overlapped with double rows of mixing piles to form a water stop curtain wall

.

The construction process is mainly divided into the following seven points: 1) pile foundation positioning: according to the benchmark and survey control network provided by the survey unit, make points on the extension line of the axis, check the on-site survey control points during pile construction, and make effective protection

.

Sd20 auger bit Ordinary dredger bit and borrow barrel When it is difficult to drill in, the rotary drill bit is used to drill in

.

2) Drill pipe and drilling tool drill pipe are key components, which are divided into internal friction external pressure telescopic drill pipe and automatic internal locking interlocking external pressure telescopic drill pipe

.

The motor drive generally adopts a special constant power two speed motor with large torque and strong overload capacity

.

The underground water in the site is mainly stored in muddy silty fine sand

.

The site is close to the Pearl River, and its groundwater confined head height is similar to that of the Pearl River

.

The pile driver has a high degree of automation control, can adjust the flatness of the base and the verticality of the drill pipe through the instrument display, and can display the drilling depth and drilling speed

.

The pile diameter of rotary excavation pile is 1000mm, the pile spacing is @ 150mm, and the pile body is made of C25 concrete

.

No matter what, it has the functions of low-speed drilling, reverse and high-speed soil throwing

.

The mud is made of sodium or calcium bentonite

.

At present, foreign rotary drilling rigs generally have the electronic control system of engine and pump, which can guide the best output of the main pump, match the hydraulic load with the engine speed, and make use of the maximum power of the engine

.

The two sections of the drill pipe are connected through the inner sleeve

.

2) Embedding of pile casing: align the center line of pile casing with the measured pile position center, strictly protect the verticality of pile casing, and ensure that the center line coincides with the pile center; After the pile casing is fixed in the correct position, it shall be backfilled and compacted with clay to ensure its verticality

.

This layer is thick and continuously distributed, with medium permeable layer, which is the strong permeable layer in the site

.

Although the construction period lags behind, the overall construction progress is still faster than that of traditional punching pile and bored pile

.

As long as the drilling rig does not shift as a whole, the drill pipe can rotate freely

.

The change of groundwater level in the site is affected by tide, and the groundwater level fluctuates greatly

.

Generally, the rotary bucket is used to dig out the residue directly

.

BJ series rotary drilling rig made in Germany also has the function of automatic alignment of pile position, which is very beneficial to controlling the hole forming quality

.

There are many kinds of drilling tools

.

At present, it is adopted by a few domestic manufacturers

.

3) power heads

.

The drilling speed of the power head generally has multiple gears, which is suitable for operation under various working conditions

.

The hydraulic drilling system is used to dig out the muck directly through the rotary bucket and transport it out of the hole, which can be drilled to a depth of 40m, It is not necessary to load and unload the drill pipe frequently in the drilling process like an ordinary drill rig

.

The latch drill pipe improves the downward pressure applied by the power head to the drill pipe and transmitted to the drill tool

.

Therefore, the groundwater in the Quaternary strata within the site has a good hydraulic connection with the Pearl River water, and its main supply source is the Pearl River water

.

The mast verticality automatic leveling system can monitor the mast in real time, realize manual and automatic switching, and automatically adjust the angle within a certain range, so as to ensure the verticality requirements of pile holes during construction and improve the construction quality; It also has the functions of rotary soil dumping control, drilling depth measurement and display, body working state animation display and virtual instrument display, fault detection, alarm and information display, and pre automatic detection before starting the whole machine

.

The rotary drilling rig first breaks the rock and soil through the barrel bit with valve at the bottom, and directly loads it into the drilling bucket, and then the drilling bucket is lifted out of the hole and unloaded by the drilling rig lifting device and telescopic drill pipe

.

In order to improve operation efficiency, most of a drilling rig is equipped with two sets of drill pipes

.

The common drill bit of the ordinary baoe tooth bullet tooth rotary drilling rig is ¢ 600 ~ 1200mm

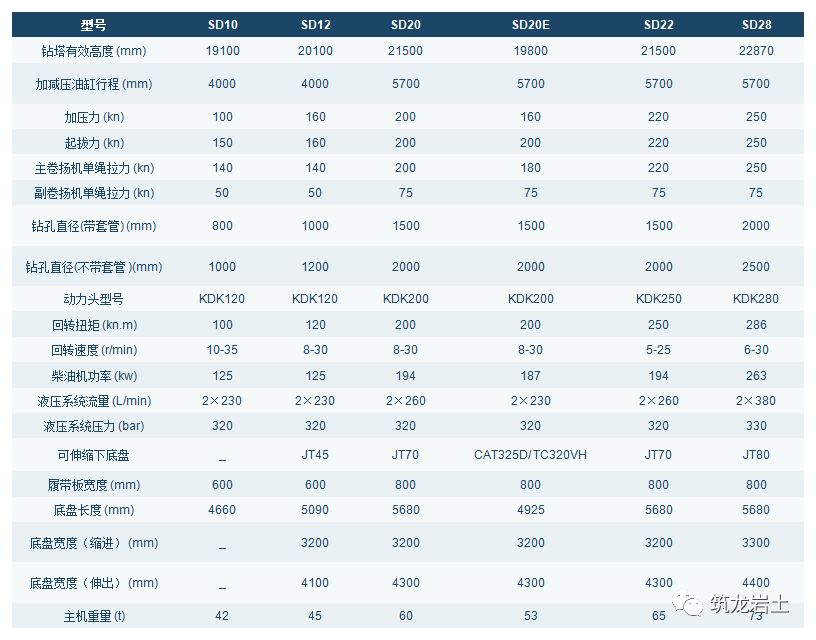

The detailed technical parameters of SD series rotary excavator are shown in the table below: the construction process flow of the second rotary excavator

.

It is required to pass through the soft soil layer and enter the strongly weathered soil for no less than 2m

.

3 Schematic diagram of plane distribution of rotary excavation pile construction 4 construction of rotary excavation pile a total of 170 rotary excavation piles in the project are expected to be completed in 24D, with an average of 8 piles completed every day

.

In this way, the soil is taken and unloaded continuously until it is drilled to the design depth

.

Now the sd20 rotary excavator used in the project is introduced

.

The chassis working device of crawler crane adopts attachment type, and the main boom is divided into retractable box structure and frame structure, which can be used as rotary drilling rig and crawler crane to save equipment investment

.

It is suitable for drilling hard rock layer and has high requirements for operation

.

For rock and soil layers with good adhesion, dry or clean water drilling technology can be adopted without mud wall protection

.

The walking chassis is generally a three fulcrum hydraulic walking support with good stability, but the mobile transportation is not convenient and the cost is low

.

Construction of sd20 rotary excavator sd20 rotary excavator video recording process flow and key points of construction process control – rotary excavator structure and technical parameters the rotary excavation pile of Qiaoxi commercial residential building project adopts Jintai SD series multi-functional drilling rig commonly used in China

.

Source: copyright of Baidu Library and Zhulong forum belongs to the original author

.

2 engineering geological conditions the project site mainly includes the following soil layers: (1) miscellaneous fill( 2) Silt soil( 3) Muddy silty fine sand( 4) Strongly weathered argillaceous siltstone( 5) Moderately weathered argillaceous siltstone( 6) Slightly weathered argillaceous silty

.

At present, there are long spiral and large-diameter short spiral bits, rotary drilling bucket, sand bailing bucket, cylindrical drilling bucket, bottom expanding bit, core bit, etc

.

4) Electronic control technology in the 1990s, the control technology of foreign rotary drilling rigs gradually realized intelligence

.

At present, hydraulic drive is mostly used, including double variable hydraulic motor, double speed reducer drive or low-speed high torque hydraulic motor drive

.

The mixing amount can be converted according to the requirements of mud specific gravity or controlled by mud specific gravity meter.

.

Power heads include hydraulic drive, motor drive and engine drive

.

The special chassis for crawler has the advantages of compact structure, convenient transportation, beautiful appearance and high cost

.

In the early stage of construction, 8 ~ 10 pieces are completed every day, but due to the later mechanical failure and the impact of the Spring Festival holiday, the average number of pieces completed per day is 4 ~ 5

.

The internal friction drill pipe has high drilling efficiency in soft soil layer

.

The excavation depth of the foundation pit is about 8.3m

.

The cover of the drill bit is opened

.

The structural characteristics of these parts are briefly introduced below

.

Project overview 1 foundation pit support structure scheme Qiaoxi commercial and residential building project is a high-rise building with 30 floors above the ground and 2 floors underground

.

Drill pipe: friction type and self-locking telescopic drill pipe are available Drill bit: it can be equipped with short spiral drill bit, ordinary drill bit, sand fishing drill bit and other chassis: it adopts a special expandable chassis, which has strong mobility and improves the stability of the whole machine

.

Power configuration: it adopts Cummins series turbocharged intercooled engine, and the electronic control part: it adopts the automatic and manual leveling system of paifen automatic control company Hydraulic system: the whole machine adopts full hydraulic transmission system to realize full power load timely control Structural part: segmental foldable mast is adopted to reduce the height of transportation state The structure of rotary excavator is mainly composed of chassis, drill pipe, drilling tool, power head and electric control system

.

1) The chassis of rotary drilling rig can be divided into special chassis, crawler hydraulic excavator chassis, crawler crane chassis and walking chassis

.

The foundation pit adopts the support form of support pile (rotary excavation pile) + support

.

After the operation of the operator, it will still align with the original pile position center.) 4) Pore forming: the mud tank and mud pit are used together, and the mud is mixed manually (using mud pump)

.