The lamp cap box of the project adopts customized finished lamp cap box, so as to save the lock head and effectively prevent the common problem of tube box falling off

.

Positioning of switch, socket and lamp position box Switches, sockets and light position boxes must be positioned in strict accordance with the actual drawings and specifications

.

Grading ring grading ring is a horizontal lightning strip around the building designed for side lightning protection of high-rise buildings

.

The ears shall be customized on both sides of the switch and socket bottom box, which is convenient for reinforcement when the bottom box is embedded.

.

Its purpose is to facilitate the connection of metal doors and windows on the upper and lower floors within 6m height with the grading ring

.

Lightning rod the setting law of lightning rod is generally: the highest point and protruding point, such as ridge, eaves corner, flat roof and wall corner

.

During concrete pouring, special personnel must be assigned to strengthen protection to prevent displacement or damage during vibration; The personnel on duty must watch until the concrete pouring and tamping is completed, and shall not leave the post halfway

.

The buried pipeline shall be laid along the shortest path to minimize the number of turns

.

The shear wall piping and roof electrical piping must use galvanized wire pipe, and PVC plastic pipe is prohibited

.

The incoming pipeline is connected with the trunking of the electric shaft

Downlead spacing: class I lightning protection building: ≤ 18m; Class II lightning protection building: ≤ 20m; Class III lightning protection building: ≤ 25m

.

The grounding resistance R is required to be less than 1 ohm

.

All upward pipe orifices and junction boxes buried in the concrete must be sealed tightly to prevent sundries from entering the pipe

.

Process grounding device Two diagonal main reinforcements in (around) the foundation ring beam of the building are welded into a ring network (4 main reinforcements shall be used if the main reinforcement is less than ø 12), and the downlead is welded into a whole with the ring network

.

The equipotential method of toilet adopts the welding of two main reinforcements in the ring beam around the toilet, The surface reinforcement of the toilet bottom plate is welded into a grid according to 600 * 600, and connected with the longitudinal and transverse ring beam reinforcement

.

The plane position of the junction box must be measured based on the axis and rechecked with the civil wall line

.

In design, the grading ring can be welded into a closed ring by using two main reinforcements in the ring beam, which must be connected with all down conductors

.

Lightning protection construction 1

.

The local wire pipe is too dense, the spacing of some wire pipes is less than 15mm, and the wire pipe overlaps more than three layers, affecting the floor structure

.

4

.

Lightning protection test point 4

.

The pipeline and the bottom reinforcement shall be bound firmly with iron wire to avoid the displacement and damage of the pipeline

.

Source: prepared by Baidu Library: if country garden has infringement, please contact to delete 1

.

2

.

The double-sided welding length of the weld shall be greater than 6D, and the lower end shall be welded with the two main reinforcements of the building pile foundation reinforcement and the foundation bottom beam reinforcement

.

The grounding body (wire) shall be connected by welding

.

When mixing and piping, the steel pipe or galvanized wire pipe is at the bottom and the PVC pipe is at the top

.

The connecting parts of the incoming pipeline and the bridge in the electrical shaft shall be arranged according to the professional order to prevent the intersection between the incoming line and the bridge in the later stage

.

The welds of the welding points shall be full without slag inclusion, undercut, false welding, air holes and other defects

.

If the embedded pipe box is damaged, the socket pipe bent from the ground to the slab surface shall be repaired in time, and the buttress shall be protected when pouring and tamping concrete

.

The positioning electric pipe and electric box of electrical and water supply and drainage shall not be embedded next to the drainage pipe, and the distance from the water pipe and reserved hole shall be greater than 300mm, so as to reduce the hidden danger of floor water leakage

.

The box must be positioned accurately, the box end face is closely attached to the template, and the box is filled with waste paper and foam board, and the red paint is used as a mark

.

The measurement and positioning of switch socket is divided into three aspects: plane position, height and concave convex distance from the wall

.

After welding, the coating shall be removed

.

II

.

Find out the position of all main reinforcement according to the design requirements, mark it with paint, weld the disconnection clip at 0.5m away from the outdoor surface, weld it to the top layer in series with the reinforcement layer by layer, and weld a certain length of down lead on the roof Ф 12mm galvanized round steel for connection with lightning strip

.

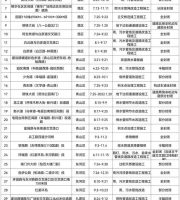

Embedded grounding flat steel 1) water supply and drainage, cable, wire and gas inlet (if the installation height of inlet pipe is relatively high, its grounding terminal can be reserved in the ceiling) 2) cable, information wire The telephone line enters the pipe (see equipotential bonding installation (02d501-2) P12) 3) high and low voltage distribution room (at least 2 points) 4) power distribution cabinet in pump room (it is recommended to surround the pump room and connect the conductor within the arm, see the provisions of Atlas) 5) temporary power distribution box 6) distribution box in basement and outdoor distribution box 7) basement machine room (ventilator room Civil air defense fan room) 8) outdoor distribution box (such as outdoor advertising distribution box and roof outdoor advertising distribution box) 9) the first distribution box introduced outdoors (such as civil air defense distribution box) 10) elevator shaft 11) temporary construction elevator 5

.

Prevent the root of the electric tube from being bent and broken Special lock head (cup comb) shall be used for pipe entering the box, and cushion block shall be plugged under the lock nut to prevent the lock nut from being stepped off or disconnected

.

At the same time, the elevation of each junction box shall be retested with a horizontal pipe to see whether it is consistent

.

Country garden requires a grading ring on the 10th floor, and then a grading ring on every two floors

.

3、 Electrical piping (I) structural piping 1

.

A – 25 * 4 galvanized flat steel is welded by the ring beam to connect the local equipotential box of the toilet (300mm from the ground)

.

The bending radius of the pipe and the number of turn boxes shall be in strict accordance with the national specifications

.

The junction box shall be installed according to the design height of various appliances

.

Electrical pipe embedding The prefabrication of buried pipes shall be completed in advance

.

The weld at the welding position shall be full and have sufficient mechanical strength, and there shall be no slag inclusion, undercut, crack, false welding, air hole and other defects

.

After the foundation grounding project is completed, the grounding resistance test shall be conducted at the outgoing line of each grounding electrode

.

After the coating at the welding position is knocked clean, anti-corrosion treatment shall be carried out

.

In architectural design, when the height exceeds the rolling ball radius (class I 30m, class II 45m and class III 60m), a grading ring shall be set every 6m

.

After the welding of each lead down point on each floor and before concealment, the on-site constructor and supervisor shall be invited to carry out concealed inspection, and the concealed inspection records shall be filled in at the same time

.

The spacing between the fixed points of PVC pipeline shall not be greater than 1m, and the distance from the end and bending midpoint shall not be greater than 500mm

.

2

.

Construction quality requirements of lightning protection grounding

.

3

.

2

.

The junction box on the shear wall shall be measured with the top of the red mark on the civil column reinforcement as 50cm

.

The switch beside the door shall generally be on the side of the door opening, and the clear distance between the switch box and the door opening shall be 150mm (200mm if the door frame is added)

.

If it fails to meet the requirements, an artificial grounding electrode shall be added until it meets the requirements

.

Except that the welding points buried in the concrete are not treated, the other welding points shall be taken with anti-corrosion measures: brush one layer of antirust paint and two layers of silver powder paint

.

The position of the air conditioning socket shall be consistent with the position of the air conditioning embedded hole and the air conditioning board in the architectural drawing (the air conditioning socket is generally 100mm higher than the air conditioning casing)

.

The socket of washing machine shall be consistent with the floor drain of washing machine

.

When the main reinforcement in the structural column is used as the down lead, each down lead shall not be less than two main reinforcements, and the diameter of each main reinforcement shall not be less than Ф 16mm, the lightning protection downlead position should be symmetrical

.

Foundation Grounding 1

.

The bending radius of concealed piping shall not be less than 10 times of the outer diameter of the pipe; There shall be no creases, depressions and cracks at the bend

.

3

.

The welding of lightning protection grounding adopts lap welding, and the lap length shall comply with the following provisions: the lap length of round steel and round steel shall not be less than 6 times the diameter of round steel, and welding shall be carried out on both sides (when the diameters are different, the lap length shall be subject to the larger diameter); When the round steel is overlapped with the flat steel, it shall not be less than 6 times the diameter of the round steel, and shall be welded on both sides; The overlap between flat steel and flat steel shall be that the flat steel shall not be less than 2 times of its width and shall be welded on no less than three sides (when the width of flat steel is different, the overlap length shall be subject to the width); When flat steel is welded with steel pipe or angle steel, it shall be close to the surface of 3 / 4 steel pipe or the two sides outside the angle steel, and the upper and lower sides shall be welded

.

The downlead in the column shall be reliably welded with the grading ring in the beam, which adopts double-sided welding

.