When the total number of piles is less than 5, it shall not be less than 2

.

Copyright belongs to the original author (the manual hole digging pile technology has begun to be restricted!) 1、 Preparation basis II

.

4

.

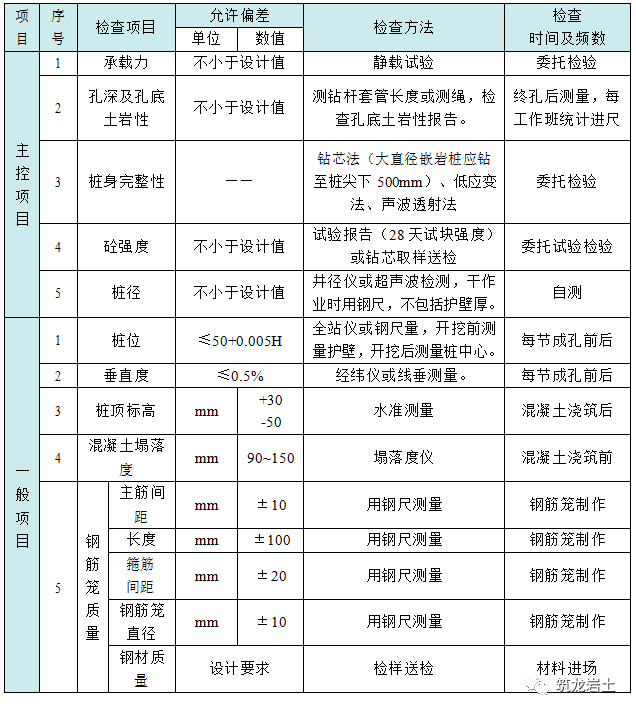

Inspection standard (1) allowable deviation of pile diameter, verticality and pile position of cast-in-place pile (2) quality inspection standard of bored cast-in-place pile in dry operation.

.

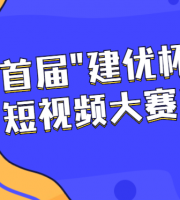

construction points v

.

Generally, the thickness of the retaining wall shall not be less than 100mm, the concrete strength grade shall not be lower than the concrete strength grade of the pile body, and shall be vibrated and compacted( 4) In case of poor soil quality, in order to prevent hole collapse, the on-site soil quality shall be mastered before excavation, the pile position shall be staggered for excavation, the height of each section shall be shortened, and the soil looseness shall be observed at any time

.

At least one group of test pieces shall be reserved for a single pile( 10) In case of conflict between the supporting column and the pile hole, the position of the pile hole shall be changed through consultation with the design, owner, survey and other units to ensure that the distance from the supporting column to the pile edge is controlled at more than 1.8m( 11) After construction, the bearing capacity of the pile, the integrity of the pile body and the strength of the concrete shall be inspected

.

The divisional and subdivisional works with greater risk exceeding a certain scale with excavation depth of 16m and above shall be demonstrated by experts

.

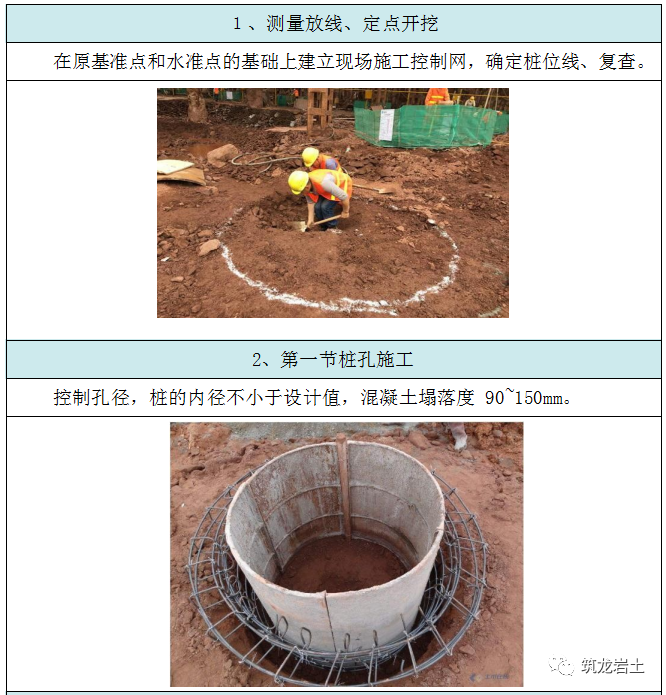

After the protective wall of each pile hole is completed, the axis and elevation of the pile position must be measured at the upper opening of the protective wall, then the cross line shall be used for alignment, and the plumb bob shall be set to the hole bottom

.

quality control points and inspection standards 1

.

Concrete from the same mixing pile shall be poured every 50m ³ At least one group of test pieces must be retained; When the pouring amount of concrete is less than 50m ³ At least one group of test pieces must be reserved every 12h of continuous pouring

.

The hole depth shall be measured one by one based on the datum point to keep the arc of the hole wall vertical up and down( 3) The thickness, tie bar, reinforcement and concrete strength of the retaining wall shall meet the design requirements

.

2

.

process flow IV

.

The number of inspected piles shall not be less than 1% of the total number of piles, and shall not be less than 3

.

If there is a small amount of ponding, the pile end can be sealed with low water concrete in time when pouring concrete; When the water seepage is too large, effective measures such as site water interception, precipitation or underwater concrete pouring shall be taken

.

2

.

The number of sampling inspection for pile integrity shall not be less than 20% of the total number of piles, and shall not be less than 10

.

Control requirements (1) before opening, the pile position shall be accurately positioned and set out, and the positioning reference pile shall be set outside the pile position

.

The position of the formwork must be corrected with the pile center point when installing the retaining wall formwork, and a special person shall be responsible for it( 2) The verticality and center position of the pile hole shall be strictly controlled

.

Construction preparation (I) technical preparation 1

.

The special construction scheme shall be prepared

.

Check the coordinates in the drawings, the layout of axis and horizontal base points is reasonable, and the axis setting out and elevation measurement meet the construction requirements

.

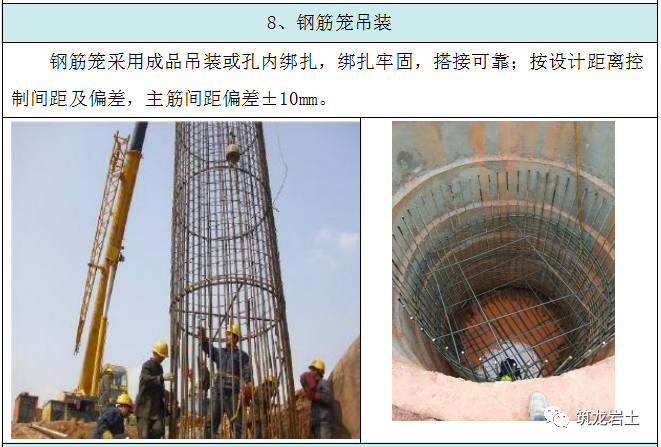

After the pile hole is excavated to the design depth, the soil condition must be checked, and the pile bottom must be supported on the bearing layer specified in the design( 6) Carefully check the hole bottom before and after placing the reinforcement cage, remove sundries, and seal the bottom with cement mortar or concrete if necessary( 7) During the excavation process, a water collecting well shall be dug at the bottom of the hole, and the pump shall be pumped in time

.

The vertical flatness of the hole wall shall be checked with a radius ruler rod

.

If necessary, the hole collapse can be blocked with brick, steel sheet pile and wood pile; The operation process shall be compact without space( 5) The final pile hole shall ensure the design pile length, rock depth and enlarged head size

.

Carefully study the geological survey report, advance drilling data of pile position, analyze the geological conditions, formulate targeted safety measures and allocate corresponding materials for possible quicksand, quickmud and harmful gas

.

The number of piles under the bearing platform of each column shall not be less than 1

When the design grade is class A or the address conditions are complex, the static load test method shall be used to inspect the pile bearing capacity

.

3

.

It is strictly prohibited to pump water while excavating and pouring in the pile hole( 8) Before pouring concrete, the operation technical disclosure must be done well, and the layered pouring, layered vibration and continuous operation shall be adhered to( 9) The test pieces for concrete strength inspection shall be randomly selected at the construction site

.

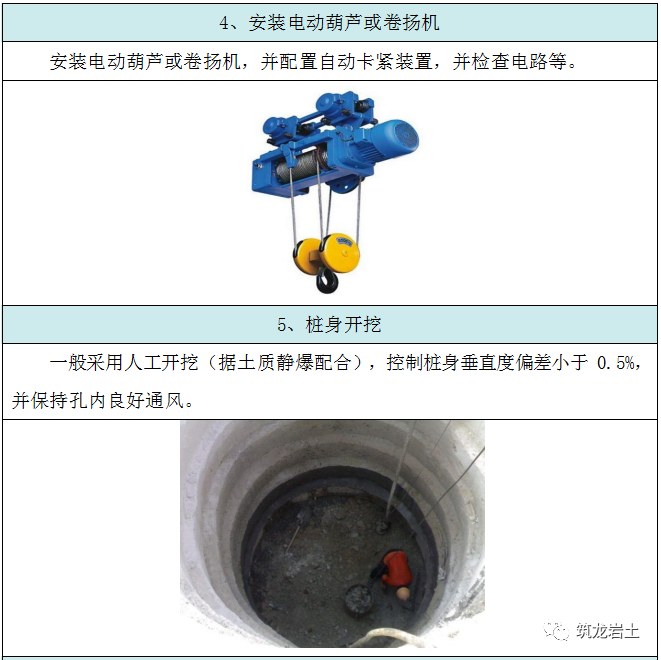

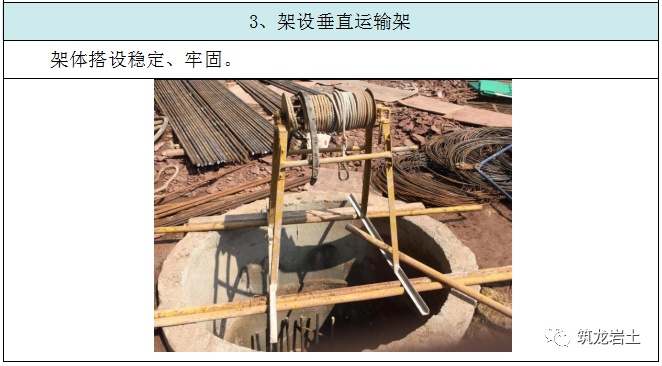

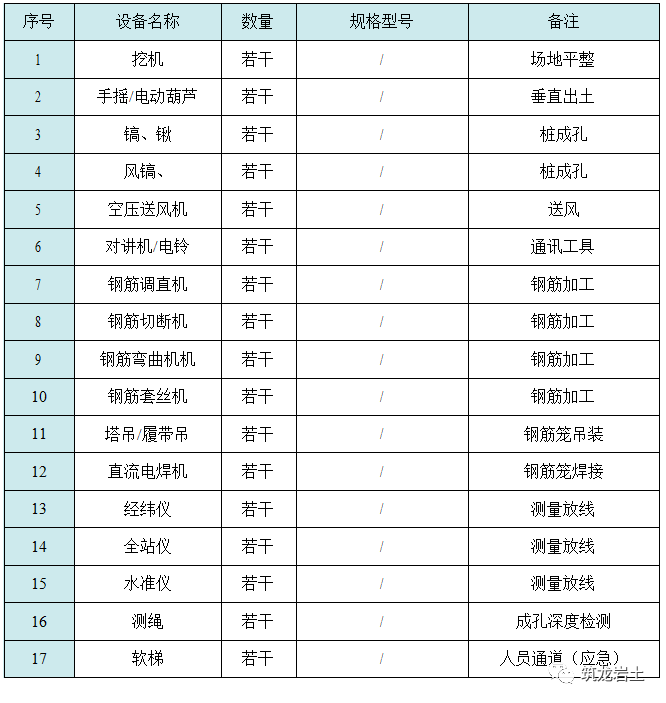

The scheme disclosure shall be carried out after review and approval( 2) Material preparation plan for reinforcement, formwork, wood brace, reinforcement, concrete and other materials, and enter the site according to the plan( 3) Site preparation (1) before construction, the “three supplies and one leveling” work shall be completed on the site, the underground pipelines and ground waste buildings shall be removed, and the temporary water and electricity have been connected in place and can meet the construction needs( 2) Considering the proposed equipment model parameters, temporary construction roads shall be built on the site to meet the traffic of large machinery, equipment and material transportation vehicles( 3) Do a good job in site handover( 4) Plan the stacking site and processing site of wall protection formwork, cement, sand, stone, reinforcement and other materials, and master the mix proportion of wall protection concrete( 4) Mechanical preparation common mechanical equipment table III

.