The sequence is correct, neat and the contact surface is seamless

.

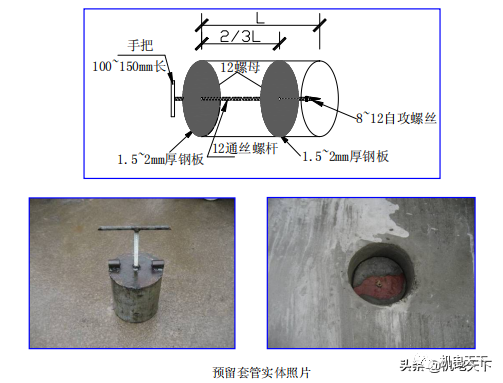

The operation is simple and recyclable, so as to ensure that the box is embedded at one time

.

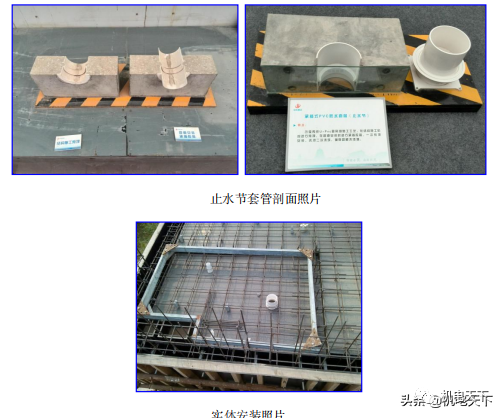

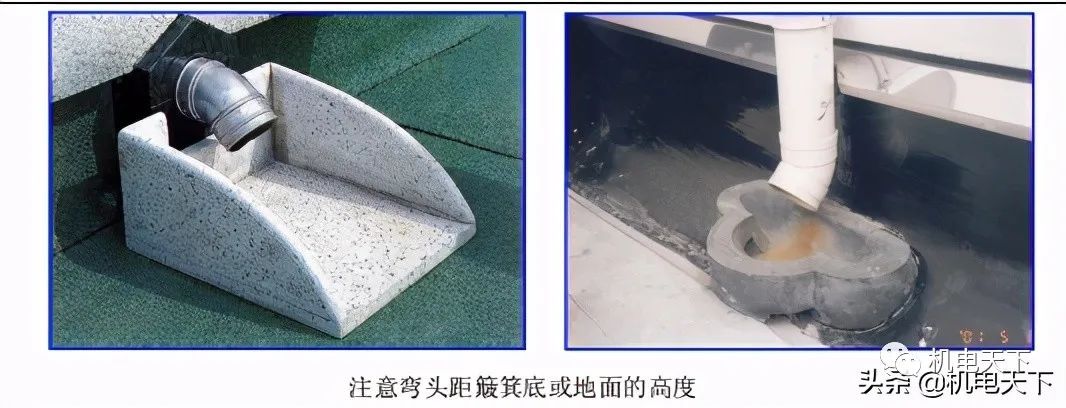

Determine the distance from the wall of the drainage pipe and the position of the reserved PVC water stop joint according to the drawings

.

3) Materials prohibited by national and industrial standards are strictly prohibited

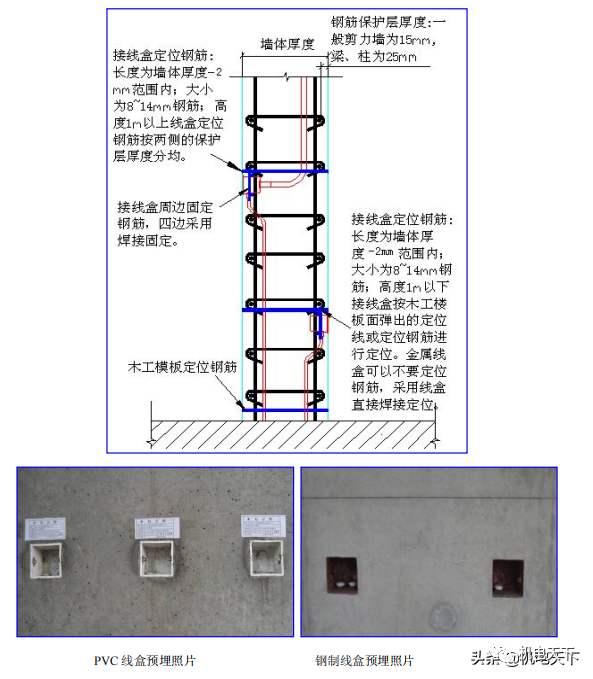

1.2 processing of semi-finished products 1) the steel wire box is counted through the physical engineering quantity, and the connector distributed by the manufacturer is used to block the pipe and plug the box mouth, which is classified as the upper shelf

.

2) Before the main body embedding construction, the wall (if the wall is built in the middle of the beam or on the left or right of the beam) and the opening position must be identified according to the architectural construction drawing

.

Fixing PVC water stop joint: fix the water stop joint on the formwork with hammer and steel nail

.

3、 Water and electricity installation and decoration stage 1

.

1.8 arrangement of junction boxes on the roof of common parts and installation of junction boxes on the roof of common parts of residential buildings

.

For the works in the public parts without ceiling, the lamps, smoke detectors and various crossing boxes shall be embedded in line, centered and symmetrical

.

2

.

According to the design requirements of plumbing, the reservation and embedding of plumbing main body shall ensure that it meets the construction specifications and standards, and optimize the layout of the reserved hole size and spacing for its actual function

.

The wiring pipe shall be fixed with direct head iron nails or direct head with ears

.

When there is no ceiling on the roof of common parts of residential buildings, detailed positioning dimensions must be made for the arrangement of junction boxes to ensure that they are arranged in rows

.

8) Galvanized iron wire shall be used to bind and tie the pipeline every LM, and a fixed binding point shall be added at the center point of the arc and 300 ~ 500mm at both ends of the junction box and the turning part

.

1.10 the wiring pipe in the beam body shall be laid through the beam bottom plate

.

1.3 the optimized design of the distribution room shall be comprehensively arranged

.

For the fabricated PVC pipe joint with nails, nail the nails on the PVC pipe into the beam bottom formwork with the help of short reinforcement

.

The construction dimension drawing, such as the position of the lower water inlet of the toilet seat, shall consider the thickness of the brick on the decorative wall to ensure the reserved spacing

.

For residential works, especially the position of the socket at the head of the bed in the bedroom and the socket near the TV, the conduit shall be reasonably arranged according to the relevant positions

.

4) When the lamp junction box is embedded in transformer, high and low voltage distribution cabinet, bridge, large pipe row and other parts, the reserved junction box position shall be optimized

.

1.2 the distribution box shall be installed with complete fittings, lock head assembly, crimping and tinning of wire head, standard wiring color, neat wiring in the box, complete circuit identification and purpose identification, and neat shell

.

1.3 in the early stage, the distribution box shell shall be expanded by 5cm according to the design, the mold shall be processed, the internal reinforcement shall be done, and the sealing shall be done to avoid mold expansion and slurry leakage

.

reservation and embedment works for hydropower installation 1

.

1.4 the secondary optimization design is required for the pipeline room, the accurate positioning of the pipeline casing is carried out, and the finished casing is made in place at one time to reduce the workload of subsequent hole plugging

.

1.5 conduit embedding 1) the design and construction drawings for the embedded layout of conduit and junction box generally have no position and size

.

It is required to determine the specific size according to various functions and specifications

.

7) The inner wall of welded steel pipe must be provided with anti-corrosion measures

.

4) Special personnel shall be assigned to take care of the concrete to ensure that the reserved and embedded holes shall be free of displacement, deviation and skew

.

1) the reserved hole position shall be correct, and the size of the hole shall meet the design and specification requirements

.

2.1 circular reserved holes shall be reserved in the floor slab, and shaped casing tools shall be used

.

2) Materials and equipment must be selected, identified, sealed, ordered, etc., and node schedules shall be formulated

.

2) the PVC wire box is counted through the physical engineering quantity, the upper box is connected to the processing box, the metal lug is painted with anti-corrosion paint to dry, the upper pipe is blocked, and the plug filler is used to block the box mouth, which is classified as the upper shelf

.

The process shall verify whether the goods enter the site in advance, formulate various goods entry checklist, and inspect the goods according to the schedule

.

When reserving, pay attention to the displacement of the wall, properly adjust the position of the water stop joint according to the displacement, and control the verticality of the upper and lower water stop joints

.

1.6 the method of connecting the embedded box in the shear wall

.

3) In the underground garage, attention shall be paid to avoiding the centralized corridor of large air ducts and pipelines

.

At the same time, it is the decoration quality of the later pipe well, so as to ensure that the overall feeling after installation is good and meets the construction quality requirements

.

Operation standard instructions for hydropower installation and construction of Construction Engineering (rich in pictures and texts) I

.

3) Photos of prefabricated parts of distribution box and formal practices for later installation (directly pouring the box shell into fine aggregate concrete)

.

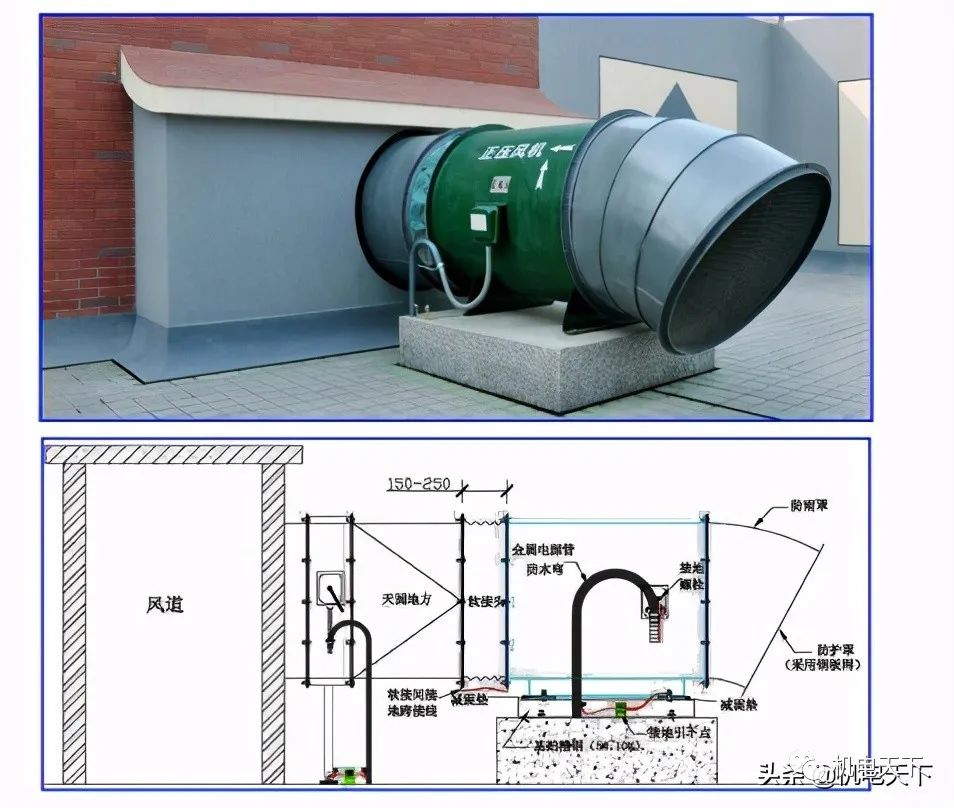

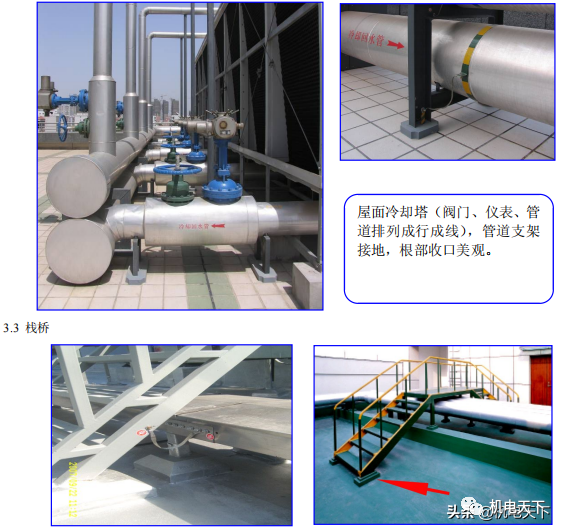

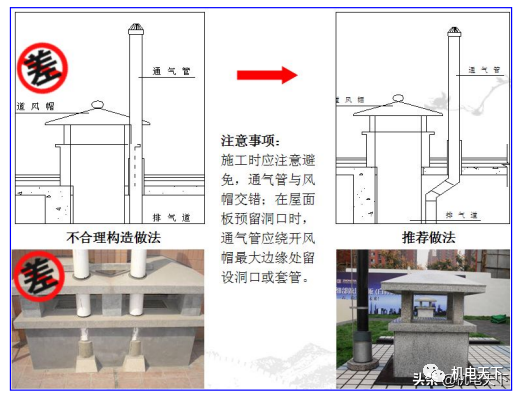

2.4 reserved hole for roof vent pipe 1) there is overlap between roof vent pipe and hood, so it is necessary to optimize the layout in advance, and reserve and install water stop joint steel sleeve

.

Take over when the secondary masonry is

.

The box is reinforced with angle steel and adjustable screw to prevent deformation

.

4) Products that do not meet the design requirements and specifications, and “three noes” products are prohibited from use

.

2.2 embedding of water stop joint sleeve in toilet in order to reduce the leakage of toilet in the later stage, toilet and floor drain shall be embedded with water stop joint sleeve

.

The direct head shall be nailed at the position in the beam to be led down, the pipe head shall be inserted into the direct head, and the connection shall be firm and tight

.

Purchase schedules shall be formulated according to the project progress nodes

.

Fill the water stop joint with yellow sand in plastic bags to prevent the inner wall of the water stop joint from being polluted during the pouring of cast-in-situ slab

.

When it is PVC and other non-metallic conduit, the protective opening shall be set at the place where the conduit enters the junction box

.

1) the conduits of strong and weak current entering the room in the distribution room shall be subject to secondary deepening design, arrangement and concealed laying in the electric well; Moreover, it shall be laid behind the corresponding bridge frame or distribution box and installed with crossing box or junction box to ensure that the pipeline installation will not be messy during the construction of weak current subcontractor in the later stage

.

2) The steel formwork box shall be cleaned and coated with release agent

.

2) One galvanized flat steel-40 is usually laid in the distribution room vertically × 4 as the grounding bus, another 1-25 is horizontally laid along the shaft wall × 4 flat steel shall be connected with it, and the thickness shall not be less than 4mm ² The copper braided belts are connected with each other, and the bridge, support and distribution box must be connected with the grounding bus.

.

3) The casing shall be fixed firmly and reliably, and the three-point fixing method shall be adopted

.

Reservation and embedment of main body of electrical junction box 1.1 material control 1) review the physical project according to the geographical environment, and whether there is any conflict between the selection of electromechanical professional designers and national, local, industrial, enterprise (development and construction) standards and construction specifications, If there is early adjustment

.

2.3 when the casing between pipes is embedded in the main construction, the secondary deepening arrangement of the pipeline shall be done first, and the one-time concrete pouring shall be used to reserve the casing construction, so as to ensure the pouring quality of the floor and save labor

.

1.11 practice of reserved hole box in shear wall 1.12 the cable tray of distribution room is embedded in the hole, and the strong and weak current conduits entering the indoor distribution room are subject to secondary deepening design, arrangement and concealed laying in the electric shaft; Moreover, it shall be laid behind the corresponding bridge frame or distribution box and installed with crossing box or junction box to ensure that the pipeline installation will not be messy during the construction of weak current subcontractor in the later stage

.

1.9 the lower drainage pipe of the embedded box on the floor and the single pipe are fixed and protected

.

The PVC line pipe is arranged by formwork opening and positioning, the pipe spacing is consistent, and the opening formwork is protected

.

6) The conduit extending upward or downward out of the structural surface shall be vertical, and the exposed length shall be 5cm (the welded connecting conduit can be extended appropriately), and the spacing of multiple extended conduits shall not be less than 15mm

.

Do not blindly measure the position with a ruler from the drawing

.

Electrical engineering 1.1 installation of switch and socket panel 1) before the installation of switch and socket panel, the panel must be installed after the closure of the junction box is completed

.

Secondary piping for electrical installation 1.1 installation of hollow brick wall piping and distribution box sleeve 1) ensure the flatness of the wall, avoid wall slotting in the later stage, lay a good foundation for the measured quantity and ensure the overall quality

.

5) Control the formwork drawing time (the formwork drawing time shall be subject to the civil engineering requirements), the cave in will occur too early, and the formwork will be given too late, which will cause difficulties and damage the integrity of the cave

.

2) When the hollow brick wall is built, the prefabricated parts of the distribution box are directly built into the wall to reduce the hollowing phenomenon

.

2、 Secondary piping for water and electricity installation 1

.

5) When the conduit enters the junction box, the connector distributed by the manufacturer shall be used as required, and the set screw shall be tightened

.