The scaffold foundation is hard sandstone, and the bearing capacity of the foundation can meet the erection requirements of the external scaffold (see the scaffold calculation sheet).

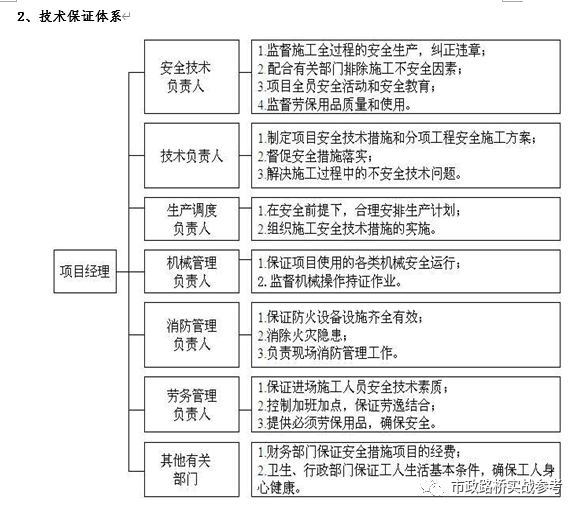

Contents section I, project overview section II, preparation basis section III, double row turnbuckle steel pipe scaffold I, steel pipe turnbuckle scaffold II, scaffold up and down ladder structure III, scaffold material requirements Section IV, construction technology I, technical parameters II, process flow III, construction methods IV, inspection and acceptance Section V, construction safety assurance measures I, organization guarantee II Technical measures III.

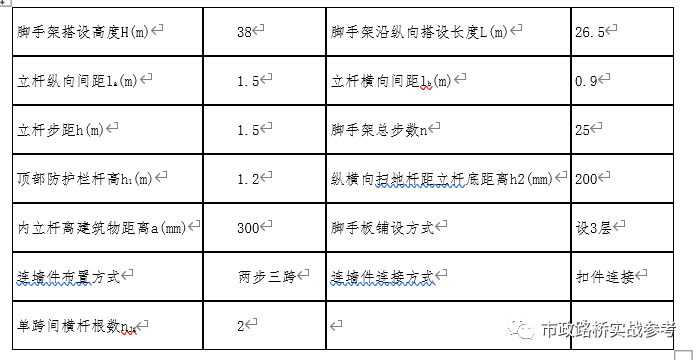

3 pier of XX River 2# bridge is selected as the technical parameters II.

The width of the ladder step and rest platform is 0.9m, the length of the stair is 1.8 and the height is 1.5m.

section VI of the emergency plan, labor plan I, full-time safety production management personnel II, special operation personnel Section VII, calculation sheet of turnbuckle scaffold [calculation sheet] [node diagram] section I, project overview, work area 6-7 of general contracting Division I of XX Expressway (Chongqing), stake number: (xx31 + 350 ~ xx40 + 053), with a total length of 9.7 km.

Fixed distance positioning: measure the distance between the inner and outer upright rods and the column with a ruler at the four corners of the pier column according to the structural size of the frame material, and make marks; Use a steel ruler to distinguish the position of the vertical pole and mark it with small bamboo pieces; 2.

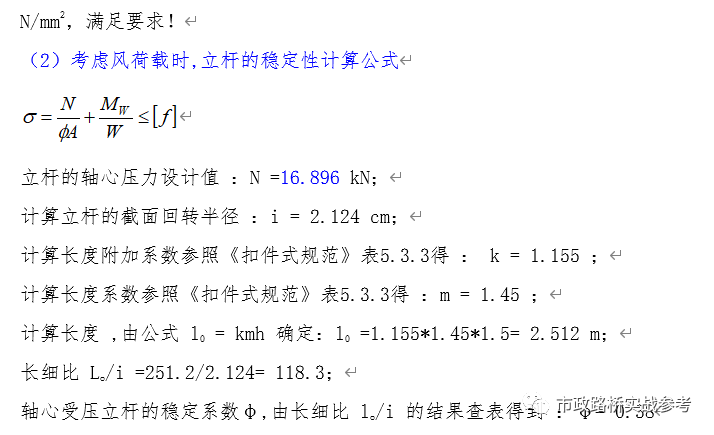

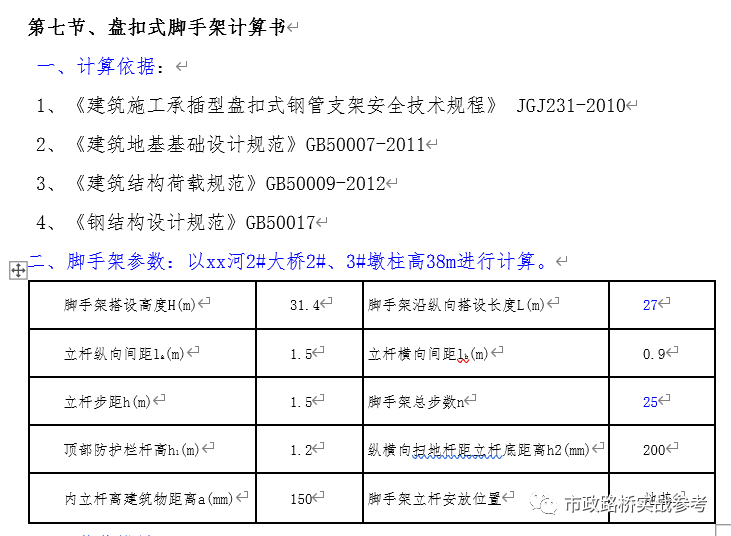

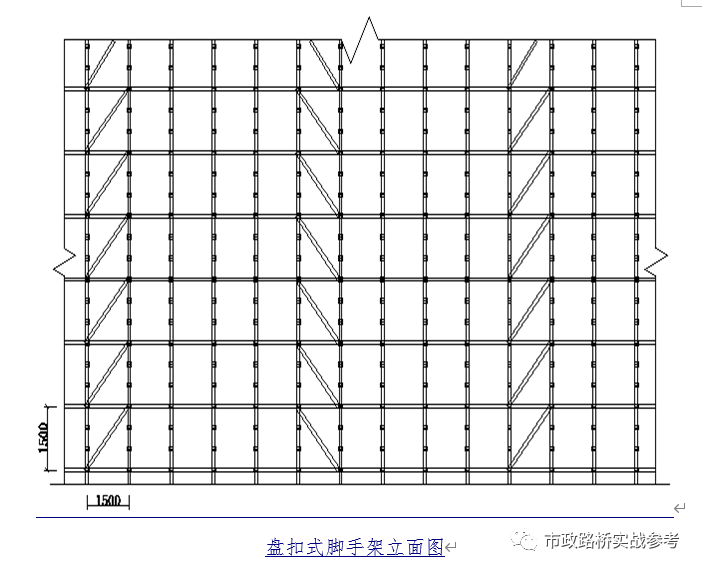

technical parameters of turnbuckle scaffold: the height of No.

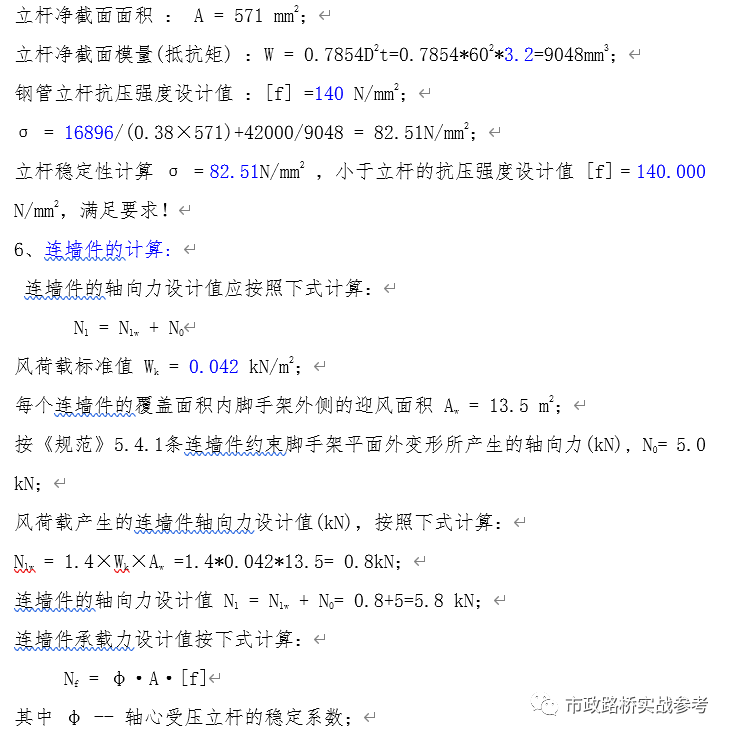

The wall connecting parts shall be made of steel pipe or section steel, and their materials shall comply with the provisions of grade Q235 steel in the current national standard carbon steel structure GB / T700 or grade Q345 steel in low alloy high strength structural steel GB / t1591.

Bridges, slab culverts, slab channels, retaining walls and other structures are included along the line.

The upper and lower ladders of the scaffold are shaped hanging buckle steel ladders.

construction technology of turnbuckle scaffold I.

Process flow of turnbuckle scaffold: site leveling, compaction and concrete paving → foundation bearing capacity test and material allocation → drawing the position line of vertical pole installation point, positioning and setting full-length base plate and adjustable base → vertical pole → vertical and horizontal bottom sweeping pole → vertical and horizontal bottom sweeping pole Horizontal cross bar → vertical bar → vertical and horizontal cross bar → external vertical syncline bar and horizontal inclined bar → wall connecting parts → hanging buckle steel scaffold board → binding protective railing → binding flame retardant dense mesh safety net III.

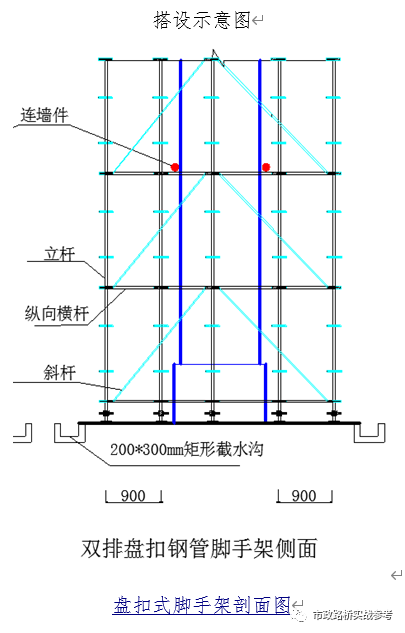

Intercepting ditch is set around the outside of the frame, with the size of 20 * 30cm, which is connected with the nearby drainage ditch.

The thickness of scaffold board shall not be less than 50mm, and two galvanized steel wire hoops with a diameter of not less than 4mm shall be set at both ends.

Except for special requirements, the materials of components and accessories of socket and turnbuckle steel pipe support shall comply with the provisions of current national standards low alloy high strength structural steel GB / t1591, carbon structural steel GB / T700 and cast carbon steel parts for general engineering GB / t11352.

The allowable deviation of width and thickness shall comply with the provisions of the current national standard code for acceptance of construction quality of wood structure engineering gb50206; Twisted, deformed, split and decayed scaffold boards shall not be used; 3.

The safety net used must have product production license, quality certificate and permit issued by relevant construction safety supervision and management department( 7) Conduct penetration resistance test without penetration, 1.6 × The weight of 1.8m single net is more than 3kg( 8) The color shall meet the requirements of environmental effect, and green shall be selected; 4.

The step height is a multiple of the pole disc (50cm) node, which shall be adjusted by using the pole node position difference with the adjustable base, and the width shall be the same as the erection size of the frame (including intercepting ditches on both sides).

construction method of turnbuckle scaffold 1.

Sandstone can be used as the bearing capacity of the scaffold foundation, and the wooden plate or channel steel can be directly laid under the upright base plate.

5.

Setting requirements for scaffold board of operation layer: (1) The hook of the steel scaffold board must be completely buckled on the horizontal bar, the hook must be locked, and the scaffold board on the operation layer shall be fully paved..

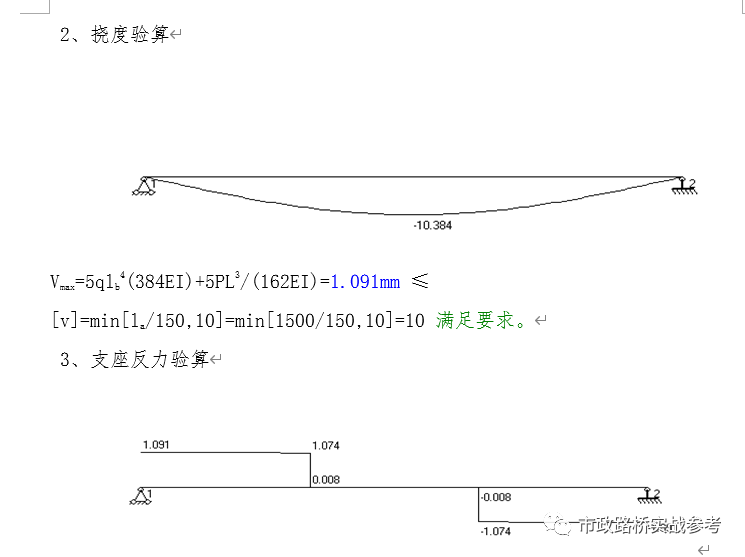

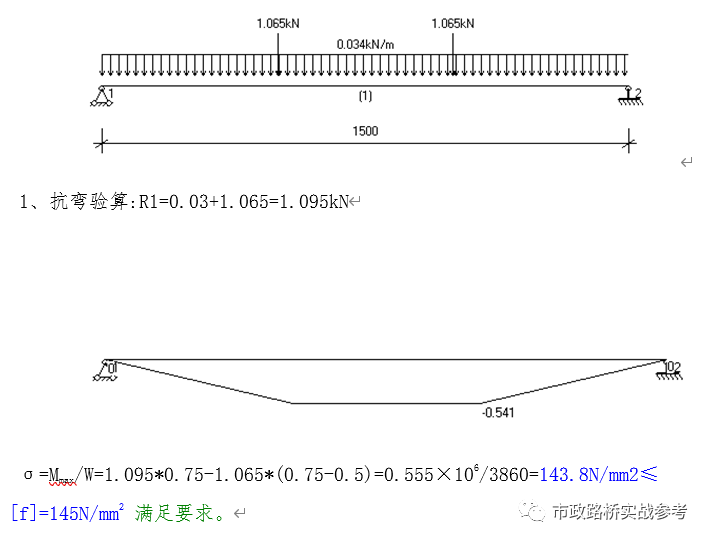

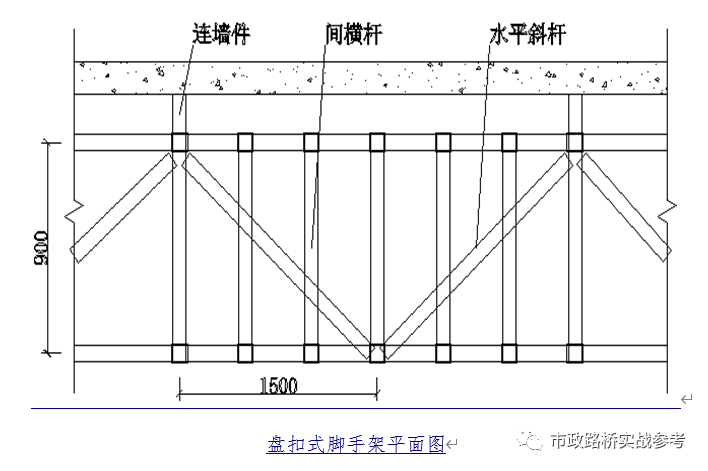

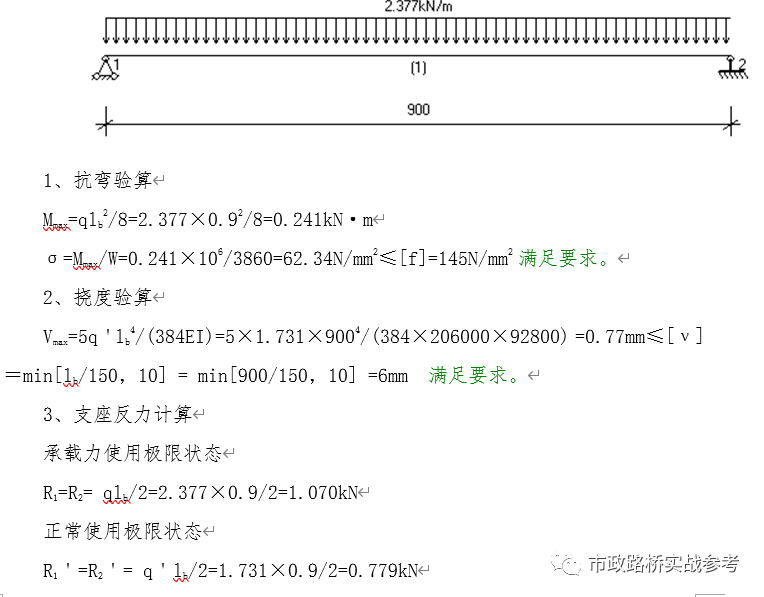

The vertical distance of the vertical pole erected by the double row socket and socket type steel pipe scaffold is 1.50M, the horizontal distance is 0.9m and the step distance is 1.50M.

The safety net adopts dense mesh safety vertical net, which shall meet the following requirements: (1) the mesh density shall not be less than 2000 mesh / 100C ㎡( 2) The eyelet buckle at each edge of the mesh body must be firm and reliable, and the aperture shall not be less than 1mm( 3) There shall be no needle skipping or exposed seam on the mesh suture, and the seam edge shall be uniform( 4) There shall be no more than one joint on a net, and the joint part shall be upright and firm( 5) There shall be no sand breaking, holes, deformation and weaving defects that hinder the use( 6) The continuous burning and flame retardant time of flame retardant safety net shall not be less than 4S.

Section III of Chongqing Expressway Construction Standardization guide, double row socket and turnbuckle steel pipe scaffold I The structure of double row socket and socket type steel pipe scaffold is floor type.

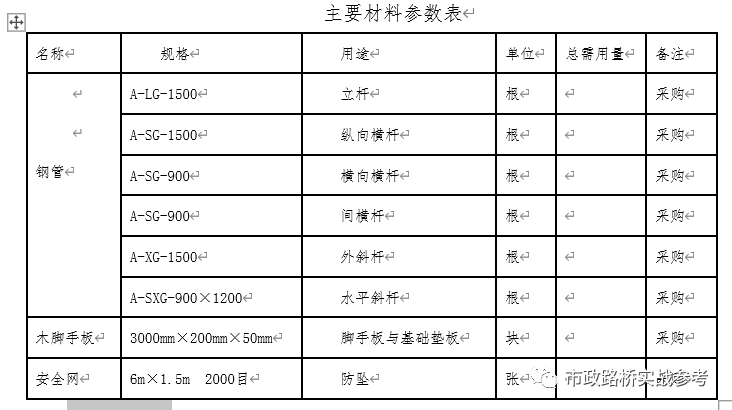

See table 2-1.

The vertical spacing of the wall connecting parts of the scaffold is 3.0m and the horizontal spacing is 4.50M.

Preparation basis 1.

3、 Scaffold material requirements 1.

Technical code for safety of socket and turnbuckle steel pipe scaffold in building construction jgj231-20102, code for design of steel structures gb50017-20173, safety management measures for dangerous divisional and subdivisional works 4.

Vertical pole setting: place the base at the four corners of the pier column, adjust the base wrench, measure the elevation with a level gauge so that the base wrench is at the same horizontal height, and then hang the line at the four corners to adjust the middle wrench so that the bottom end of the vertical pole is on the same horizontal line; The vertical poles of the first floor shall be staggered with different lengths, and the vertical distance of staggered poles shall not be less than 500mm; The vertical pole is connected with casing socket and fixed with bolt.

The materials of main components and accessories of various supports shall comply with the provisions in the following table( 1) The allowable deviation of the outer diameter of the steel pipe of the socket and disc type steel pipe support shall comply with the provisions in the following table, and the allowable deviation of the wall thickness of the steel pipe shall be ± 0.1mm( 2) When the connecting plate, buckle joint, bolt and adjusting handle of adjustable nut of socket and disc type steel pipe support are made of carbon steel, the material mechanical properties shall not be lower than the requirements of yield strength, tensile strength and elongation of zg230-450 in the current national standard cast carbon steel parts for general engineering (GB / t11352).

Scaffold board (1) scaffold board can be made of steel and wood materials, and the mass of a single scaffold board shall not be greater than 30kg( 2) The material of wooden scaffold board shall comply with the provisions of class IIa material in the current national standard code for design of wood structures (gb50005).

Section IV.

Foundation: the base of pier column scaffold is on backfill, which shall be mechanically compacted, and the soft foundation shall be replaced with rubble, The concrete with strength grade no less than C15 shall be used for hardening, with a thickness of 10cm.

The foundation is treated according to the requirements of the scaffold.

The length and width of the frame shall be set out according to the diameter and spacing of the pier column.

The platform is fully covered with steel scaffold plates.

The channel guard rail: the upper part is 1.2m high, the middle part is 0.6m high, and the lower part is provided with 0.18m high toe guard plate, and the height of the ladder guard is 0.9m, The ladder shall be erected synchronously with the frame.

In the process of erecting the first layer of scaffold, an inclined support shall be set in each frame grid around, and it shall be added in two directions at the corner.

According to the characteristics of structures, height and geographical conditions, floor type double row steel pipe fastener scaffold shall be selected for abutment, retaining wall and culvert; The socket type steel pipe scaffold with coiled buckle shall be selected for the pier column according to the height and steep and gentle terrain.

Section II.

When the foundation height difference is large, steps shall be chiseled.

The operating platform is fully paved with scaffold boards.

2.

The frame body is set in the middle of the left and right pier columns.

The base plate length shall not be less than 2 spans, the wooden plate thickness shall be 5cm and the width shall be 20cm.

2、 The structure of the upper and lower ladders of the scaffold.

It can be removed only after the scaffold at this part is reliably connected with the wall connecting parts of the main structure.