It is made of self-adhesive rubber base material, strong and tough high-density polyethylene film or aluminum foil as the surface material, and peelable silicon coated isolation film and isolation paper as the surface anti-adhesive isolation material.

quality standard VII.

Pressure sensitive reaction self-adhesive waterproof coiled material is a kind of waterproof material made of SBS and other synthetic rubber, tackifier and high-quality road petroleum asphalt.

Technical code for waterproofing of underground works (gb50108-2008) 4.

According to the characteristics of the project, strong technical measures and strict management must be taken to ensure the quality of waterproof engineering.

Finished product protection VIII.

TPO waterproof construction II.

In order to ensure the quality of the project, ensure no leakage after putting into use, and ensure the safety of equipment and facilities, waterproof works must be done well.

order Record I.

construction preparation v.

It can be constructed at room temperature.

It is simple and fast to operate and protect the environment.

2021 municipal road and Bridge actual combat reference Baidu network disk member 2021 municipal road and Bridge actual combat reference Baidu network disk member..

safety and civilized construction assurance measures I Preparation basis 1.

Under the unified management of the underground comprehensive pipe gallery headquarters, each project department takes its own responsibilities, and selects the waterproof engineering construction team with excellent technology, qualification and many years of construction experience to be responsible for the waterproof construction of their respective sections.

See the section construction organization design for the allocation of main construction management personnel and technical personnel of the project management department.

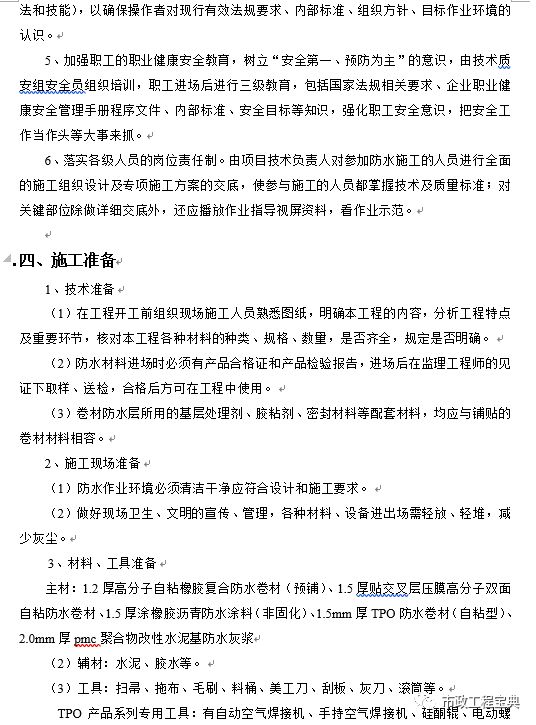

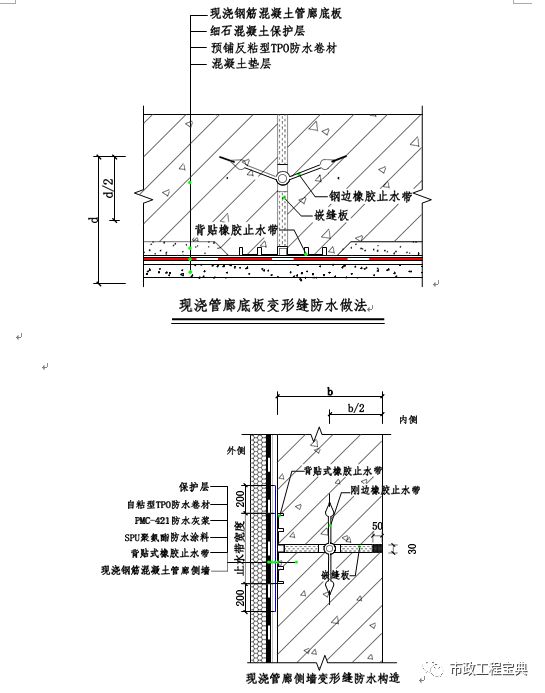

The waterproof design of the comprehensive pipe gallery of the project is wrapped with pressure-sensitive reaction self-adhesive polymer waterproof coiled materials around, and a waterproof coiled material protective layer is set outside the waterproof coiled materials on the side walls and roof on both sides of the comprehensive pipe gallery.

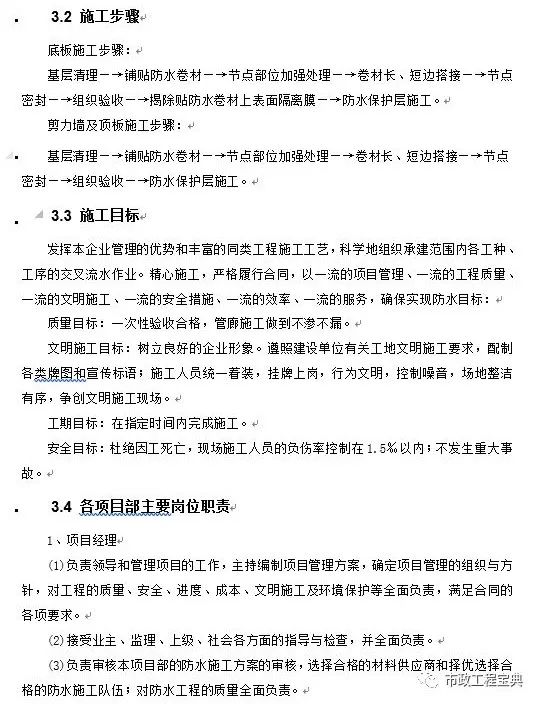

The design service life of the structures of the project is 100 years, and the underground waterproof design grade standard is grade II; The comprehensive pipe gallery shall be provided with a deformation joint every less than 20m.

3、 Construction arrangement 3.1 construction organization and management organization setting the design service life of the buildings of the project is 100 years.

It has the characteristics of low temperature flexibility, self-healing and good adhesion.

Construction drawing of East Ring Road of underground comprehensive pipe gallery in Baoshan central city 6.

This item is a four compartment structure.

Waterproof structure of underground buildings (10j301) 3.

Project overview III.

100mm thick C25 fine aggregate concrete protective layer is adopted for the bottom plate of the comprehensive pipe gallery, 50mm thick extruded polystyrene insulation board protective layer is adopted for the outer wall of the comprehensive pipe gallery, and 100mm thick C25 fine aggregate concrete protective layer is adopted for the top plate of the comprehensive pipe gallery.

construction method VI.

construction arrangement 3.1 construction organization and management organization setting 3.2 construction steps 3.3 construction objectives 3.4 main job responsibilities of each project department 3.5 construction section division 3.6 material organization 3.7 labor organization IV.

preparation basis II.

Quality assurance measures IX.

Project overview The project is a waterproof project within the contract scope of 2.53km East Ring Road (gl0 + 020 ~ gl2-510) of Baoding underground comprehensive pipe gallery.

Unified acceptance standard for construction quality of Building Engineering (GB 50300-2013) 2.

Therefore, waterproof engineering is listed as the key quality control sub item and special process of the project.

The pipe gallery works are buried underground, and the underground waterproof design level is high.

Code for quality acceptance of underground waterproofing works (50208-2011) 5.