The stirrup shall be straightened before rounding

.

c

.

03 pile casing is embedded, the pile casing is rolled with 8mm thick steel plate, the butt joint is welded, and the weld is dense

.

The construction access road to the pouring ramp at each pile position has been built on site, and the height of the pouring ramp is confirmed according to the height of the pouring platform and tank car chute

.

The length of each section of the reinforcement cage can be divided into 9m or 12m sections according to the length of raw materials

.

09 pouring underwater concrete 4.9.1 check a before concrete pouring, detect the pile casing top elevation after hole completion, calculate the reinforcement cage top elevation, concrete pouring top elevation and determine the two control surfaces according to the pile casing top elevation, design hole bottom elevation, design pile top elevation, design reinforcement cage top elevation, reserved pile breaking head height and other data

.

Prevention measures shall be taken according to the causes

.

The length of double-sided welding shall not be less than 5D, and the length of single-sided welding shall not be less than 10d (D is the diameter of the main reinforcement)

.

Before pouring concrete, the performance index of slurry in the hole and the sedimentation thickness at the bottom of the hole shall be checked again

.

The protection blocks are made of high-strength mortar

.

d

.

Before using the conduit, the specification, quality and connection structure must be carefully inspected and accepted to ensure the sealing effect of rubber sealing ring is intact and the thread thread is in good condition

.

The conduit joint is connected by screw thread, with a diameter of 250mm, a wall thickness of 5mm, a section length of 2 ~ 4m and a section length of 4m at the lowest end

.

Firstly, the Surveying Engineer shall accurately set out and measure the pile position of the bearing platform, and set up protective piles outside the construction scope

.

Measure the mud ratio, weight and sand content 07 reinforcement fabrication and installation

.

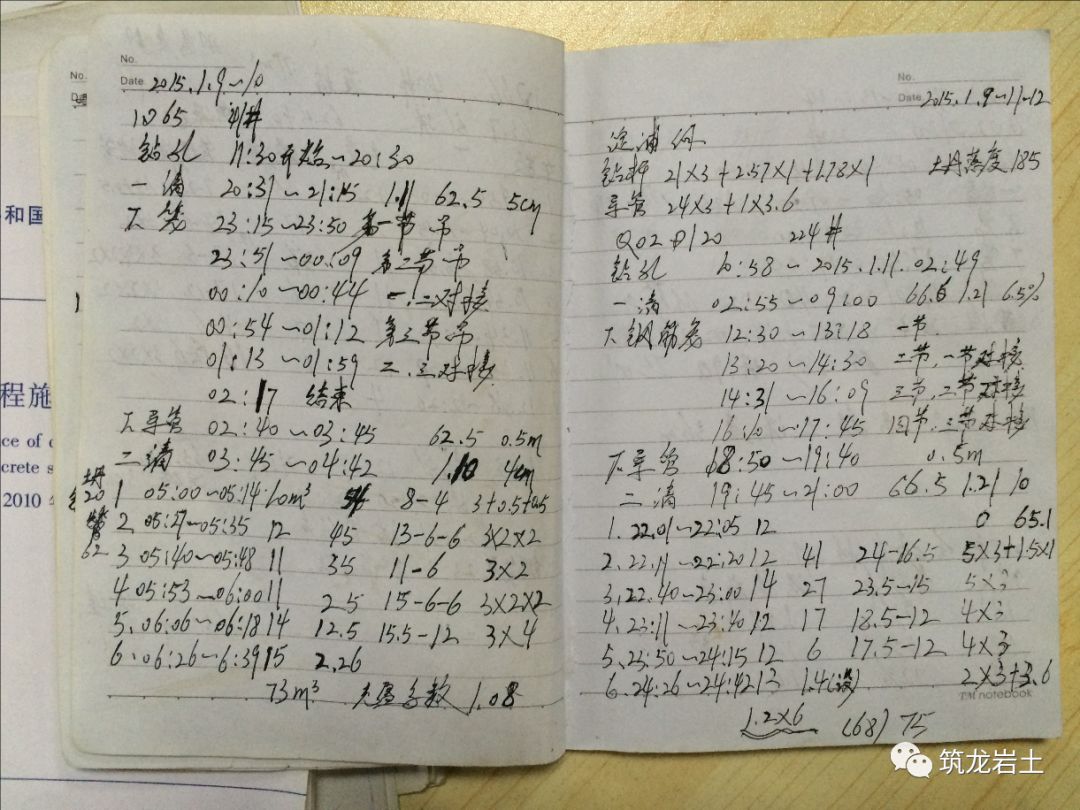

The relevant data must be recorded

.

Slow drilling shall be carried out during drilling, and the drilling can be accelerated only after all the guiding parts or bits enter the formation

.

b

.

The drilling operation shall be carried out continuously in shifts, the drilling construction records shall be filled in carefully, and the drilling conditions and matters needing attention in the next shift shall be explained during shift handover

.

e

.

The top of the conduit shall be firmly clamped with steel wire rope and special card to prevent pipe falling

.

If it cannot meet the design requirements, it shall be re drilled until it meets the design requirements

.

The circulating slurry exchange method is adopted for hole cleaning, that is, the drill bit continues to rotate 20 ~ 30cm away from the hole bottom, and is pressed in with (1.06 ~ 1.10) mud with low relative density to exchange the suspended drilling slag and mud with high relative density in the hole, so as to achieve the purpose of hole cleaning

.

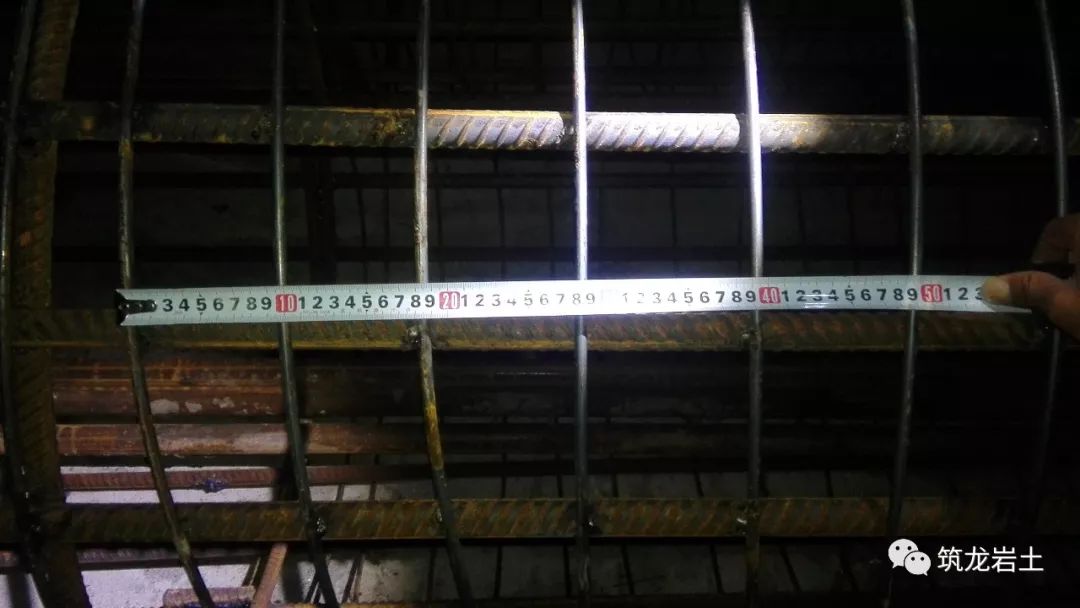

The reinforcement cage shall ensure the welding length, the reinforcement cage shall ensure the stirrup spacing 08

.

When the hole reaches the design depth and the specified rock stratum, the hole cleaning operation shall be started after being confirmed by the supervisor

.

Four retaining piles are set at each pile position, and the pile position shall be accurately measured before the drilling rig is in place

.

04 drilling mud drilling mud consists of water, clay (bentonite) and additives

.

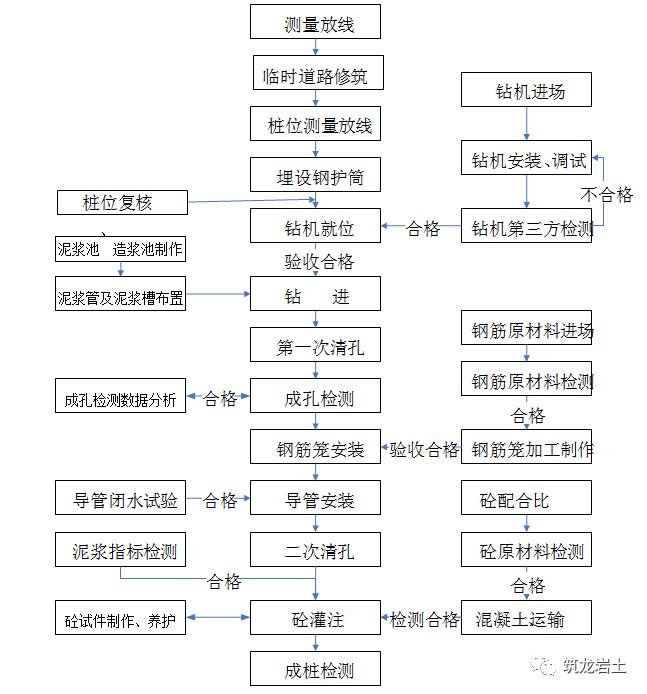

Construction process and construction method 01 pile position setting out

.

The positioning inner hoop reinforcement of the reinforcement cage shall be welded with the main reinforcement

.

The protective piles are embedded with steel bars at a depth of more than 1.0m underground, and the surface is consolidated with concrete so that the protective piles will not deviate

.

Calculate the amount of the first batch of poured concrete to ensure that the depth of the tremie embedded in the concrete is ≥ 1m and the quality of bottom sealing

.

Pay attention to the change of soil layer during drilling, measure the mud index, record it in the drilling record table and report to the supervising engineer

.

c

.

Before setting the stirrup, the control measures to ensure the stirrup spacing shall be taken

.

The reinforcement cage shall be transported by flat car or self-made extended truck from the reinforcement processing plant to the pile foundation construction position

.

The secondary hole cleaning time is about 20 ~ 30min, When the sediment thickness at the hole bottom is less than 50mm, the concrete pouring construction can be carried out

.

The former shall use high-quality mud with low water loss rate to protect the wall, and the latter shall weld and repair the drill cone in time

.

During the fabrication of reinforcement cage, an environmental protection protection block is set every 2m, and four protection blocks are set for each ring

.

Source: copyright of Zhulong forum belongs to the original author

.

The reinforcement cage is fabricated in sections in the reinforcement processing plant

.

After embedding, recheck with total station to ensure the accuracy of pile position

.

For the prepared drilling mud and circulating purified mud, the mud consistency shall be determined according to the drilling method and formation conditions

.

The drilling mud shall be inspected and tested frequently, and the unqualified ones shall be corrected at any time

.

The mud consistency shall be controlled flexibly according to the formation changes or operation requirements

. Loop Box

After the first hole cleaning, the mud meets the requirements (relative density ≤ 1.20); Viscosity: 18 ~ 22pa • s; Sand content ≤ 8%; After the colloid ratio > 98%), place the reinforcement framework and steel conduit

.

After meeting the requirements, the outer wall of the conduit shall be numbered section by section with obvious marks, and the length and size shall be marked

.

When the conduit is hoisted in the conduit sealing test, the conduit must be centered, the axis must be straight and stable, so as to prevent the reinforcement cage from being stuck and colliding with the hole wall

.

After the installation of the reinforcement cage, the secondary hole cleaning shall be carried out

.

b

.

The footage shall be properly controlled

.

After the drilling rig is installed in place, the base and top shall be kept stable to ensure that there is no displacement and settlement during drilling, otherwise it shall be handled in time

.

Reaming and shrinkage: reaming is mostly caused by small collapse of hole wall or excessive swing of drilling cone

.

The connection of each reinforcement cage shall be welded, the weld shall be full, and the length and width of the weld shall meet the requirements of the specifications and drawings

.

Firstly, the drilling rig is lifted to the approximate position of the pile position by the crane, and then the walking steel pipe is manually adjusted to be in place

.

Binding wires shall be used for binding between the main reinforcement and stirrup, and the binding points shall not be less than 4 per square meter, and shall be arranged in quincunx shape

.

The first hole cleaning shall be carried out after the hole completion test of 06 hole cleaning and drilling pile is qualified

.

When shrinkage has occurred, the drill cone can be used to sweep the hole up and down repeatedly to expand the hole diameter

.

The pile casing is placed into the pre excavated hole with a crane, aligned, and finally tamped and filled with clay around

.

It has the functions of floating and suspending drilling slag, cooling bit, lubricating drilling tool, increasing hydrostatic pressure, forming mud skin on the hole wall, isolating seepage inside and outside the hole and preventing hole collapse

.

The quantity of the first batch of concrete is calculated as follows: at the same time, a certain safety factor should be considered on the basis of calculating the quantity of the first batch of poured concrete according to the specifications.

.

After the pile foundation is in place and the pile casing is buried, check the drilling rig with the pile casing to ensure that the center point of the drilling rig is on a vertical line with the center point of the pile position

.

The height from the bottom of the conduit to the bottom of the hole shall be controlled at about 40cm

.

d

.

05 drilling a, the hole position must be accurate when drilling

.

After the drilling rig is in place, the base and top are stable without displacement or settlement

.

The water pressure for watertight test shall not be less than 1.3 times of the water depth in the hole, nor less than 1.3 times of the maximum internal pressure P that the conduit wall and weld may bear when pouring concrete

.

Check the level of the drilling rig platform with a level ruler to ensure that the drilling rig is level and stable

.

Drilling cone shrinkage is often caused by the formation containing soft plastic soil or silty sand that can expand when encountering water; If the drill cone is worn too much, it can also make the hole diameter slightly smaller

.

The length of the conduit is designed according to the drilling depth

.

The reinforcement cage can be made to make the fetal membrane, and the fetal membrane can be used to control the stirrup spacing

.

The main reinforcement of the reinforcement is connected by welding

.

The main reinforcement shall not be burned during welding, and the reinforcement cage shall be guaranteed to be firm

.

After the drilling depth reaches the design elevation, the hole diameter, hole depth and verticality shall be checked with a hole detector

.

If it does not meet the specification requirements, the second hole cleaning shall be carried out, and the underwater concrete can be poured only after it meets the requirements

.

The mud is too thin, the slag discharge capacity is small and the wall protection effect is poor; Too thick mud will weaken the impact function of the bit and reduce the drilling speed

.

The groove edge of the lifting pulley at the top of the drilling rig frame, the clamping hole for fixing the drill pipe and the center of the casing are on the same plumb line

.

Before using the conduit, the watertight pressure bearing test and joint tensile test shall be carried out

.

Before drilling, the mud in the hole shall be mixed first, and the footage shall not be started until the mud specific gravity reaches 1.05 ~ 1.2

.

02 drilling rig in place before the drilling rig in place, the site where the drilling rig is located shall be leveled and reinforced, and various drilling preparations such as the installation of main equipment, machines and tools, the placement of supporting equipment and the connection of water and electricity supply shall be inspected

.

The vertical line of the pile casing center coincides with the pile center line, the allowable plane error is 50mm, and the inclination of the vertical line is no more than 1%; The top of the retaining wall is 0.3m higher than the ground

.

The purpose of the secondary hole cleaning is to eliminate the damage of the mud retaining wall during the installation of the reinforcement cage and the excessive sediment thickness caused by the long hole rest time

.

The inner diameter of the pile casing is 200mm larger than the pile diameter

.