Most of the space should be solved with 6 boards, and the height is basically the same.

In fact, the above three conjectures not only rely on the perception of designers, but also rely on the perception of on-site construction.

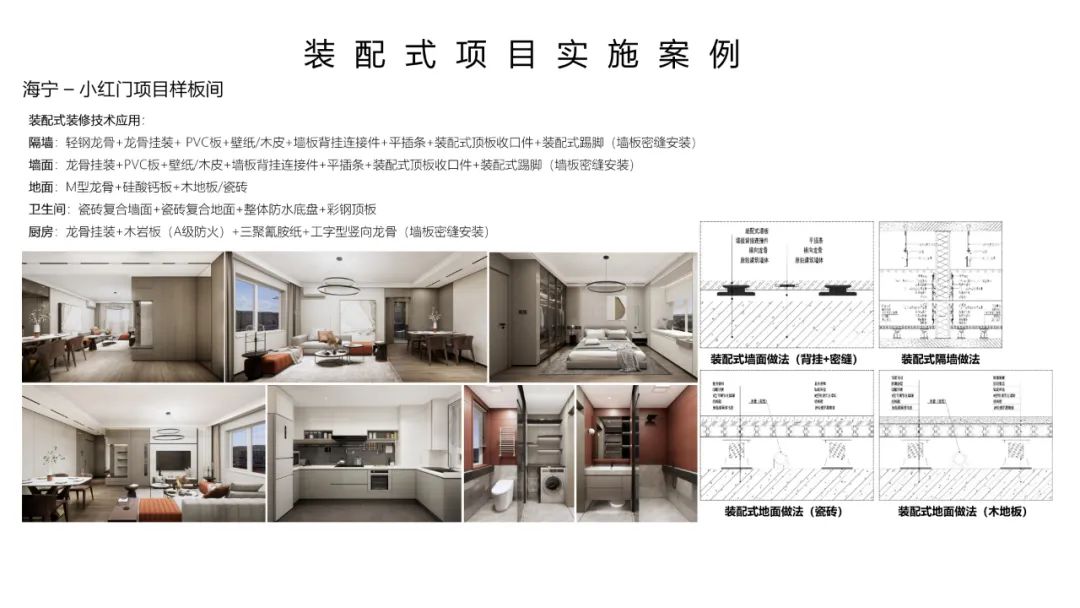

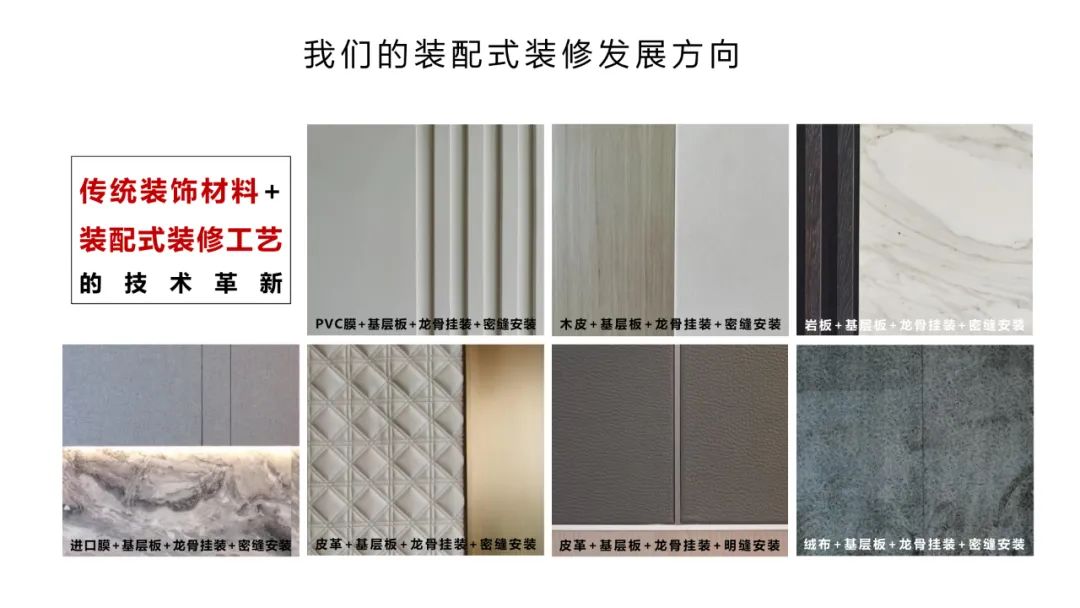

02 core of several common methods of assembly decoration: simple methods to solve complex matters ● This is the traditional assembly process, including light steel keel partition wall, modular partition wall, cross dragon bone glue, etc.

It should be said that they are slowly sprouting and the future can be expected.

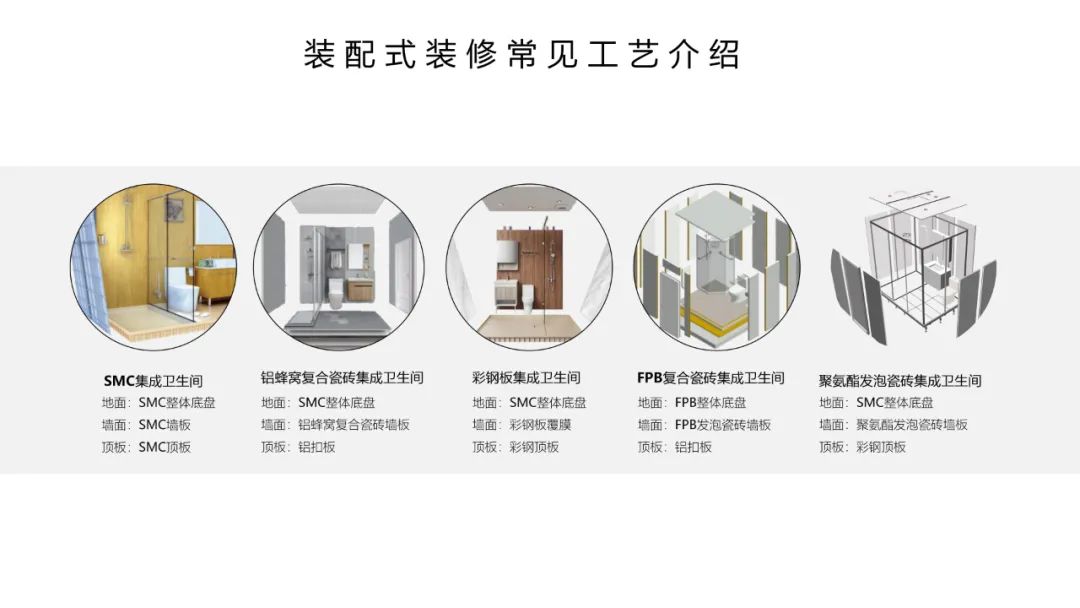

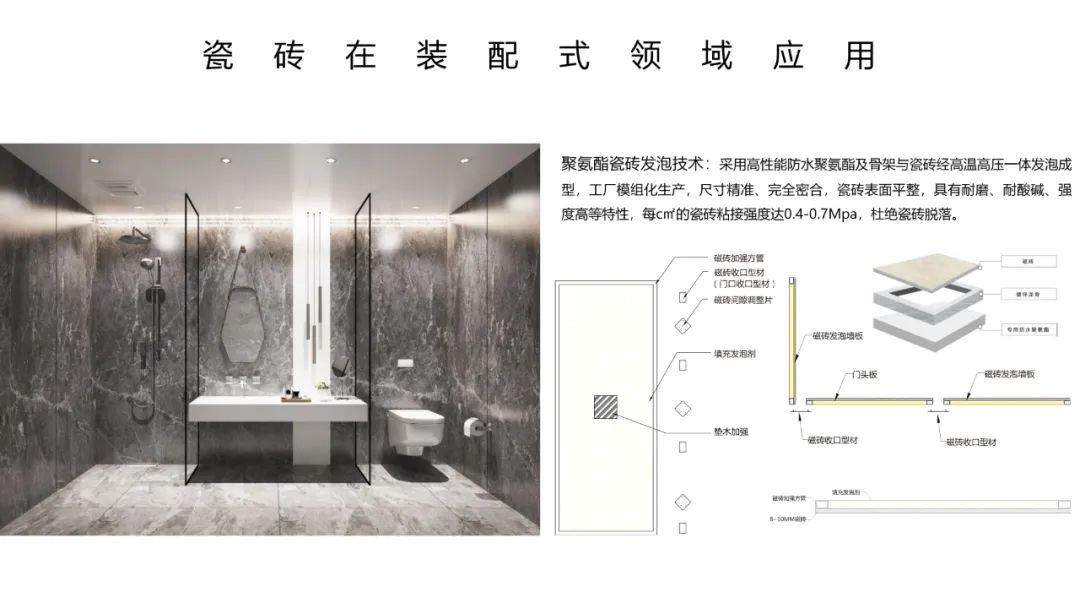

FPB is a self-supporting partition system, followed by polyurethane foam ceramic tile wallboard.

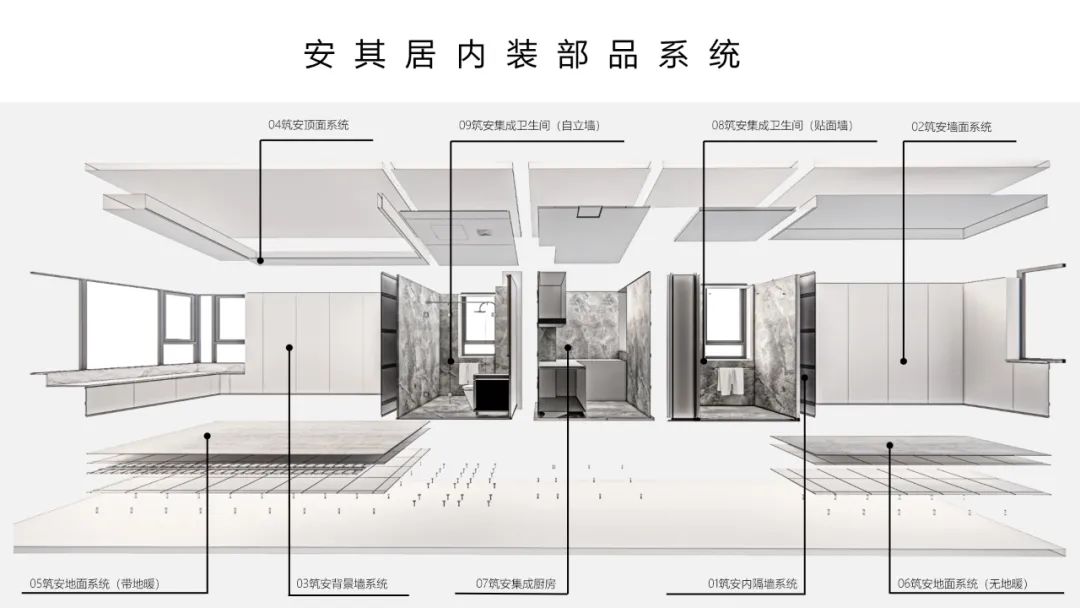

What can you do? A brief introduction later: ▲ this is the location analysis I made for Vanke poyu ▲ this is the wall layout.

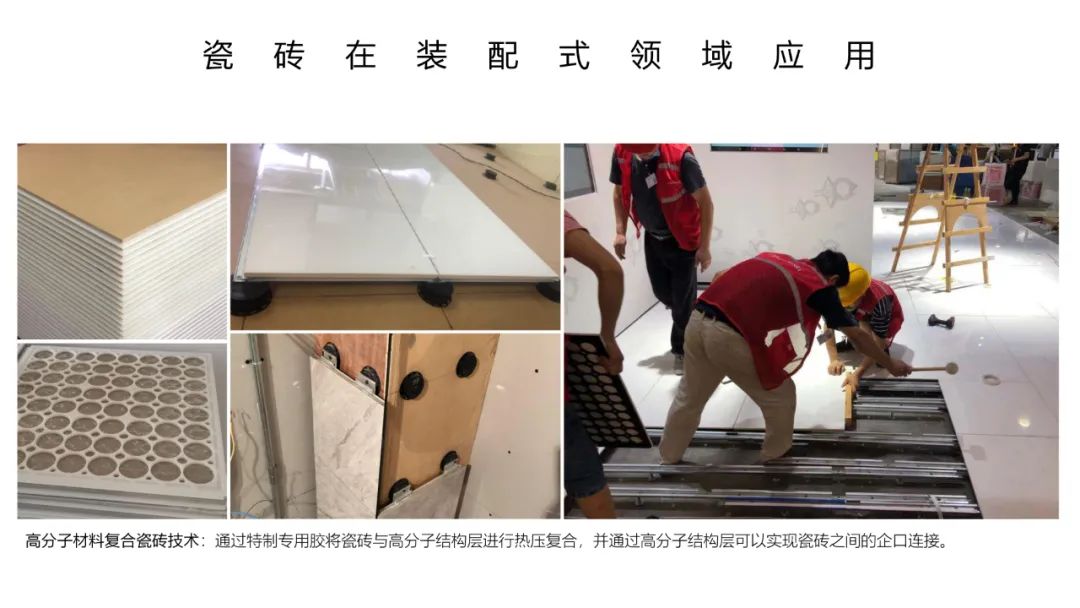

The pur “anti striking” technology of ceramic tiles is adopted: Although polymer materials can solve the problem of relatively light cost and material, if there is floor heating below, there will be a problem of poor thermal conductivity, because the middle is hollow.

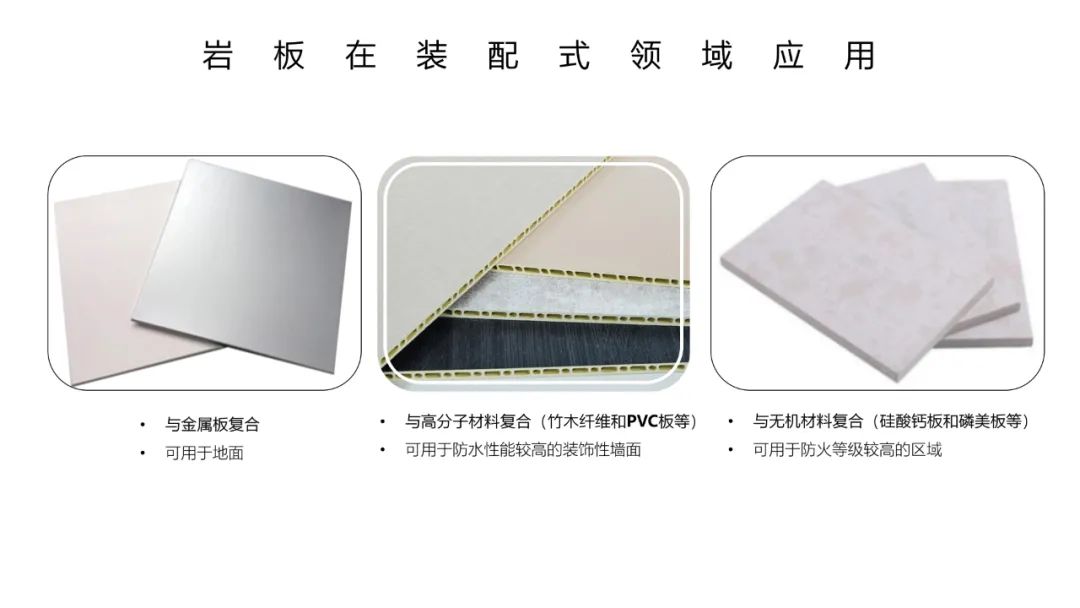

● inorganic material composite is said to have been achieved.

The wall here is rock plate, which is hung.

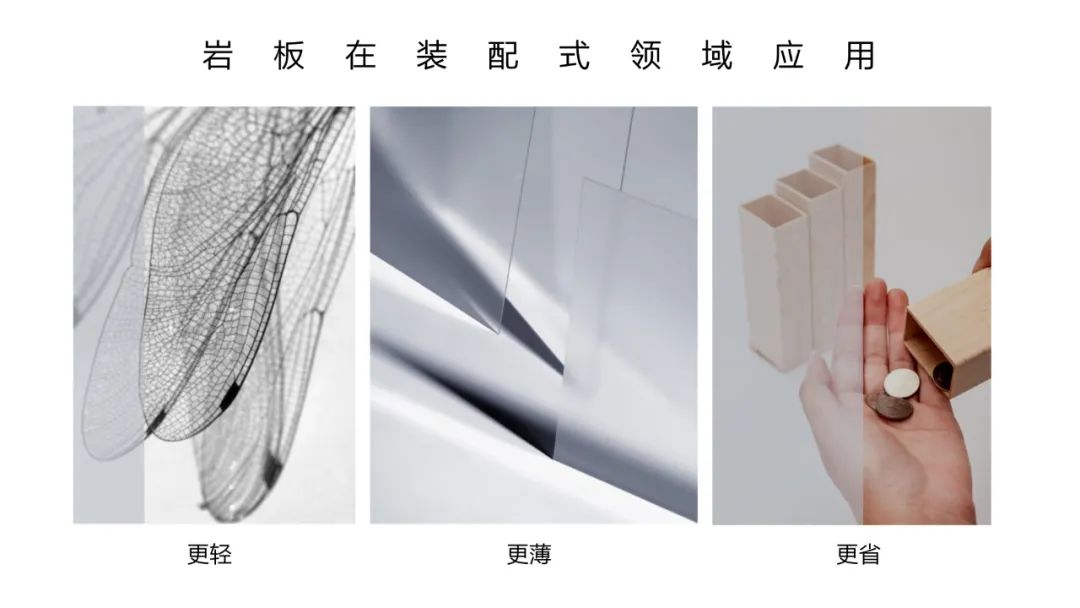

04 conjecture of composite innovative materials: when metal plates, polymer materials and inorganic materials return to the identity of designers, they will put forward some demands, that is, “lighter, thinner and more economical”.

● This is from Shidong International: ● This is the office building of “Beitou”:▲ the effect drawing is on the left and the photo is on the right.

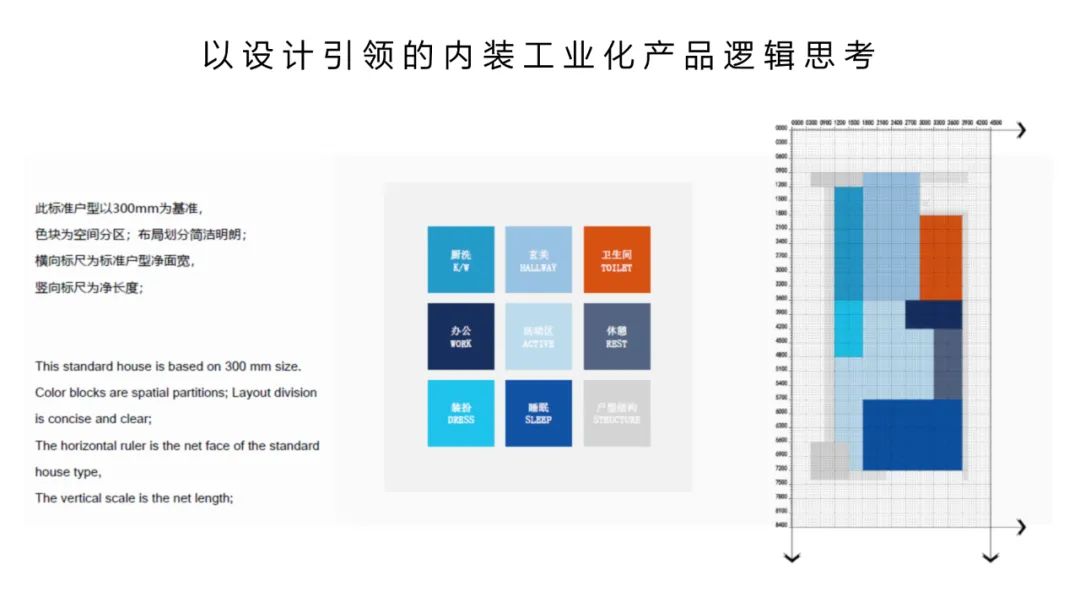

First, it formulates a so-called product logic.

▲ this is a conventional modular induction ▲ this is a simulated space.

Of course, ceramic tiles originally had 600, 300 and so on.

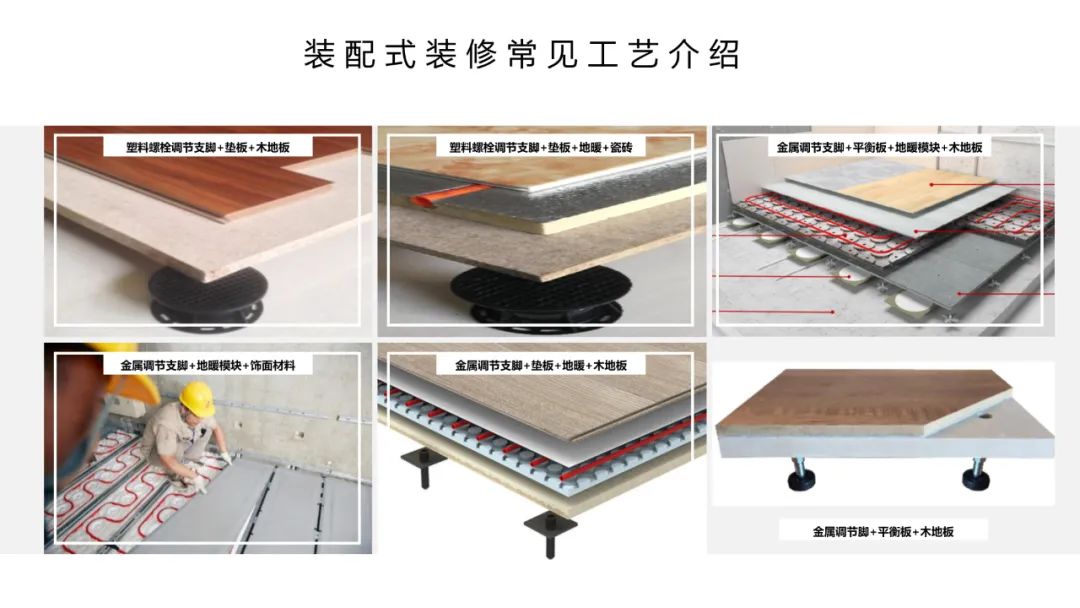

● At present, the overhead process on the ground is basically based on these methods: ● There are also many kinds of toilets: SMC, aluminum honeycomb composite ceramic tile, color steel plate and FPB.

▲ the above is partition wall, and the following is wall facing, cross keel or point keel.

The thermal conductivity is also very good, the ductility of the material is also very good, and it is not easy to crack.

Why? The material is quite good.

But I think there are more than one solution.

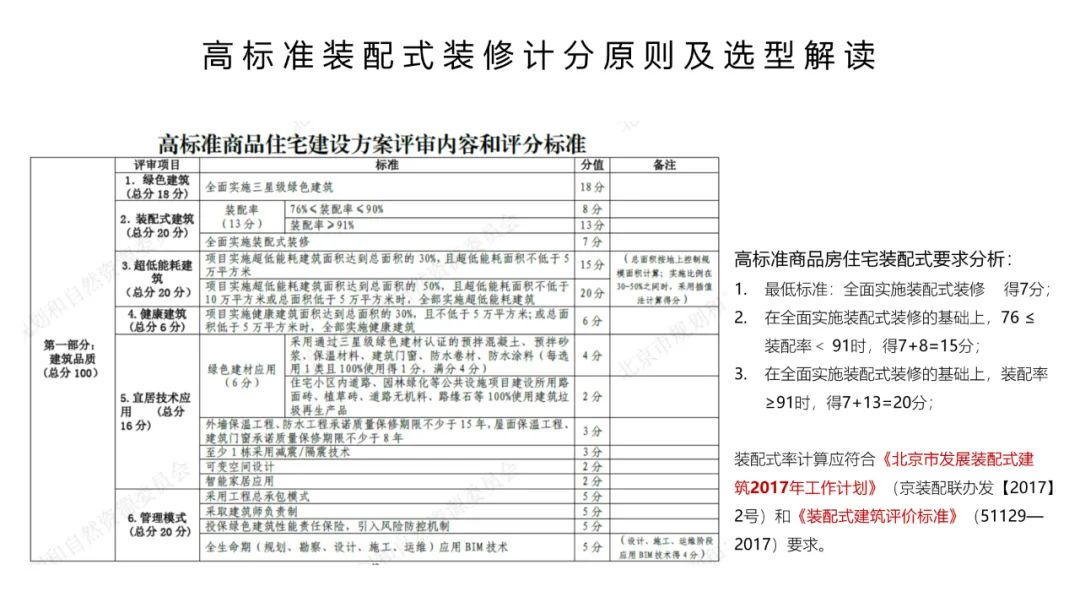

Previous theme “prefabricated decoration under high standard residential system – innovative application and thinking of traditional decoration materials” 01 “prefabricated decoration”, that is, interior decoration industrialization, aims to move on-site operations to factories What is assembly decoration? “Dry construction method” is actually a technique in assembly decoration; The word “prefabricated decoration” can be explained literally, but there is no specific unified standard in the industry.

The bathroom and kitchen are at least for everyone here, whether it’s the ceramic industry or the stone industry.

It can be lighter and the transportation link can be opened up, because the transportation cost is getting higher and higher.

● Including this, including the TV background wall, are also rock plates: how to solve complex problems in the simplest way.

03 interior decoration industrialization requires high installation accuracy.

Therefore, when the ceramic tile is deformed, it will increase its deformation or reduce its fault tolerance after paving.

If they deviate, there is no way to do these things and promote them.

Then design and R & D should not be on the same path, but these two thoughts cannot deviate.

What is product logic? For example, the cabinet body, whether it is the storage cabinet body or the cabinet body, must be 600 wide and 600 diameter deep, and then the size of the door panel is basically defined to a certain extent, and what is the general size of the cabinet; But if you want special customization, you can.

▲ this is the 06 intelligent manufacturing after completion.

There are still some in spring.

I think this is also the direction of ceramic tiles in the future.

No matter how to find the cement, there must be a 3mm error.

Author| You Suowei duty editor| Chief Editor Liu Rui| Old cow..

You may not notice that it is completed by the so-called assembly process, such as the bathroom.

If the proposed industry remains unchanged, the design group should have the strongest understanding of this in the whole industry, rather than giving everything to the back end and the manufacturer.

Ceramic tiles can no longer deal with this with the traditional national standard.

05 the product logic led by front-end design, from indoor to outdoor, the European School of high-standard architectural drawings has grasped two problems.

● This is a “land” residence with 100000 square meters: ▲ this is an application of industrialized materials for interior decoration of kitchen ● We have a large collective rental house in Xiaohongmen area of Beijing, with an area of 200000 square meters: This is a real photo: I won’t tell you.

In fact, there are not many things that can be done in the deepening stage.

Unlike cement mortar, it can be leveled by chiseling with a hammer and relying on the skills of workers.

What is the direction of rock plate research and development to realize “standard products + non-standard products” combined with “innovative process + composite processing”? R & D is to abandon all complex personalized needs and find a single path to solve the problem, so R & D is to solve the problem of commonality.

We also conducted experiments the year before last, and the drawing strength cannot be achieved unless primer penetration is done and the inorganic materials are treated well.

It should be regarded as a process method.

Thinking guided by design will first re recognize this industry.

▲ these are some practices in local areas.

There are several conjectures; This is the composite with metal plate, polymer material and inorganic material: let me talk about several application scenarios first: ● metal plate composite is the most suitable.

Can we reduce our consumption? In fact, reducing the consumption can not only improve the yield, but also be completed through secondary processing.

Yanban should return to its most basic logic: its innovation logic should have more unique characteristics of its own products.

Because of the idea of industrialization, Beitou’s project was completed soon.

As an assembly logic, it must be flat below.

Basically, these are the surface finishes, such as bamboo wood fiberboard, stone plastic board, calcium silicate board, or polymer or inorganic board.

For self leveling, the cement is uneven, and the rock plate is only 3mm.

Special customization costs more money, or you will do it in my system.

● polymer composite is now a composite with PVC version, which will cause two problems: it is easy to use in waterproof space, the composite property of composite materials in fireproof space can not be achieved, and the operation cost and composite cost are relatively high.