For top masonry construction, the top block shall be built with diagonal cutting supporting concrete blocks after not less than 14 days, and shall be filled with mortar during masonry.

If it is really difficult, it shall be poured with fine aggregate concrete not less than C20 as the secondary structure.

Fullness of binder: before the first skin masonry, the bottom and sides shall be fully coated with adhesive before masonry.

After masonry, the overflowing adhesive shall be removed and pointed in time.

The design of process flow quality control points shall be preceded by the detailed design of aluminum mold.

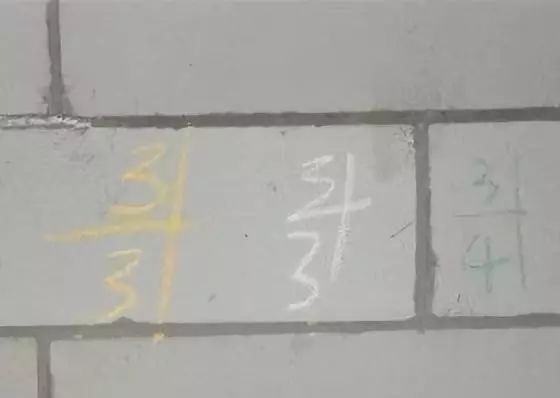

The data wall masonry team shall fill in the name of workers, masonry time and measured data on the wall; The quality inspector shall fill in the measured data and time, and the supervisor shall fill in the review time and data.

The reserved embedded trunking of water supply pipe must be filled with mortar or concrete.

If the copyright of the work is involved, please contact us and we will delete the content at the first time! Long press QR code of Henan Rongtai Engineering Management Co., Ltd | Latest policy expertise 。.

The masonry height shall be controlled within 1.4m every day (within 1.2m in spring).

The height of the anti sill roughened concrete retaining sill shall not be less than 200mm.

The subsequent mortar paving shall be paved on the surface of the lower skin block with a special serrated scraper, which is conducive to enhancing the fullness of mortar joints.

Before pouring the retaining sill, the ground and wall shall be cleaned and roughened.

The joint control corner and T-junction shall be built with centralized processing supporting blocks.

It is advisable to pour it at the same time with the structural floor slab.

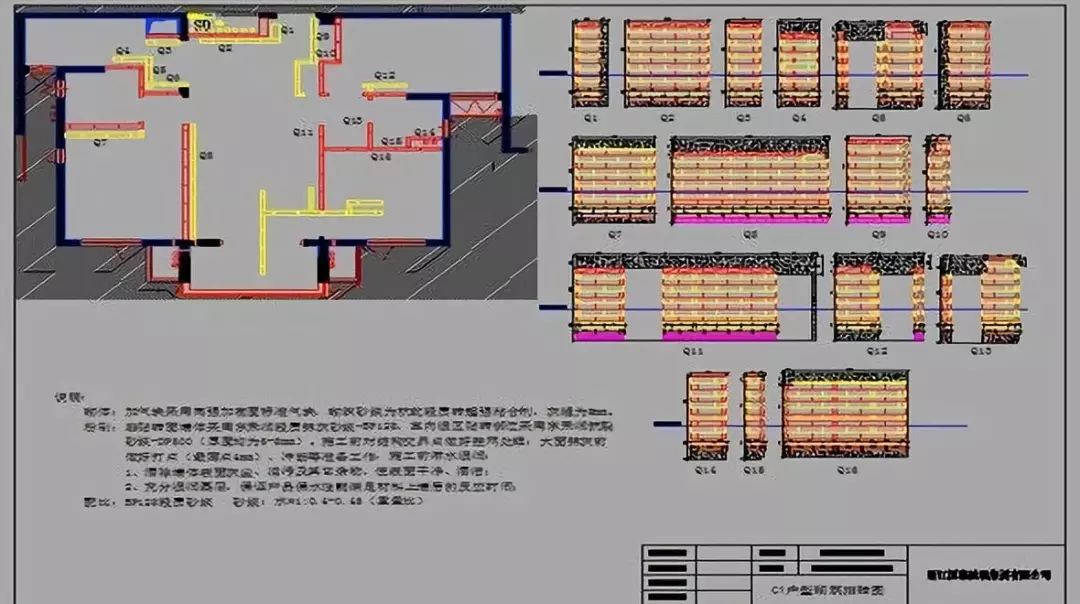

On the drawing, before each wall is built, the blocks of various specifications shall be arranged, placed and adjusted according to the pre drawn wall block arrangement drawing, and the parts to be repaired of each wall shall be recorded on the elevation arrangement drawing for practical construction.

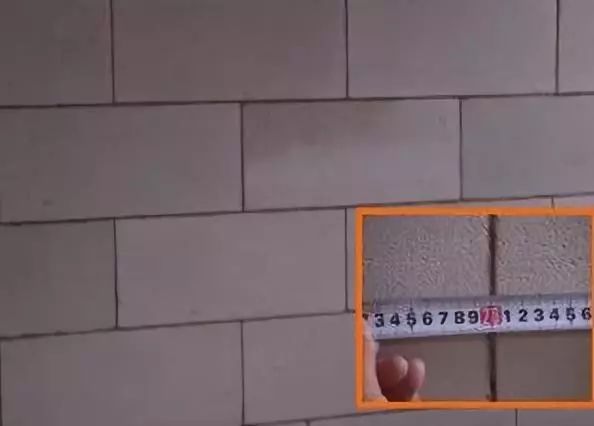

The masonry height shall be staggered up and down during masonry, and the overlapping length shall not be less than 1 / 3 of the block length, and shall not be less than 150mm.

Steel wire mesh with specification of 20 * 20 * 1.0mm is set in the surface plastering layer.

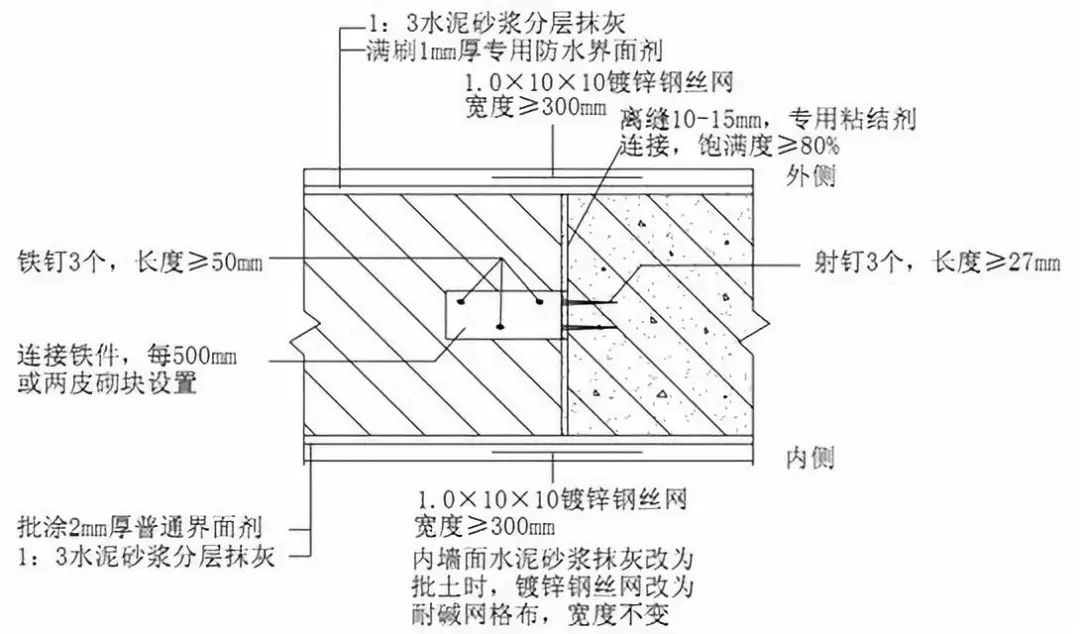

L-shaped wall connecting pieces shall be connected with L-shaped iron pieces every 500mm high or two skin blocks; L-shaped iron parts and block walls are fixed with three iron nails with a length of ≥ 50mm, and with walls and columns with three shooting nails with a length of ≥ 27mm.

Dry masonry is carried out in combination with special adhesives and tools, and the mortar joint is controlled by 3mm, which reflects the fine construction of masonry engineering.

High precision block generally refers to the dimension error of aerated brick, length ± 3mm, width ± 1mm and height ± 1mm.

Copyright statement of material performance index management measures: the copyright belongs to the original author.

When aluminum-plastic composite water supply pipe is adopted, steel wire mesh can not be hung.

The thickness of mortar joint is 2 ~ 4mm, the plumpness of horizontal mortar joint is required to be ≥ 90%, and the plumpness of vertical mortar joint is required to be ≥ 80%.

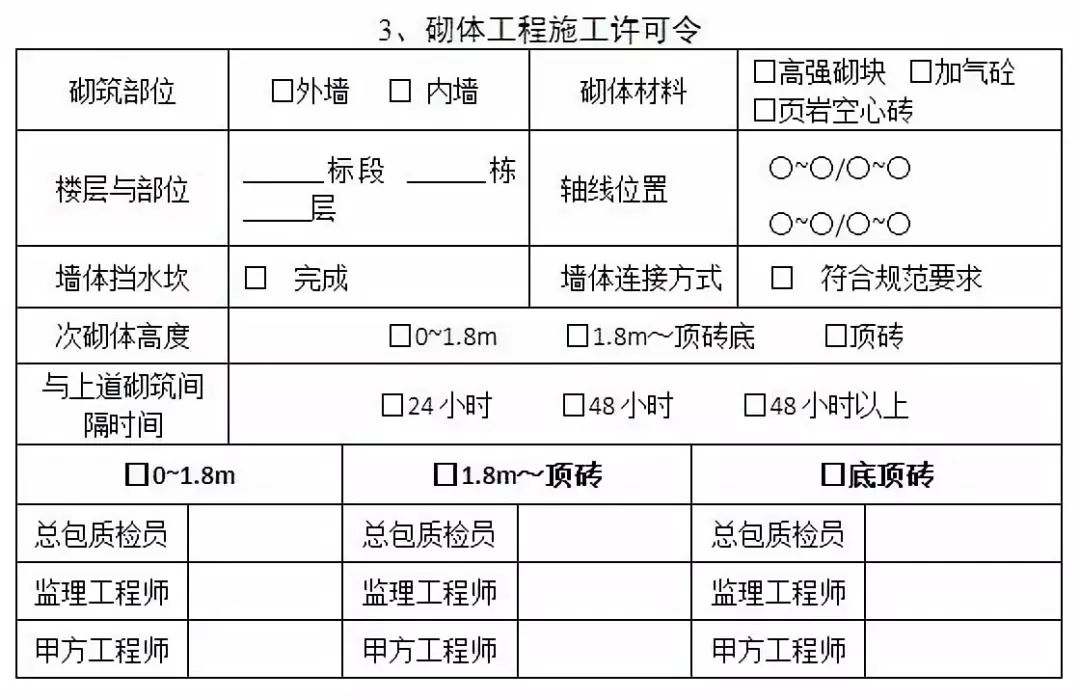

During the detailed design, the secondary structures such as structural column, door head plate, inverted sill and guide wall shall be optimized, and the embedding process of strong and weak current box and fire box shall be given priority.

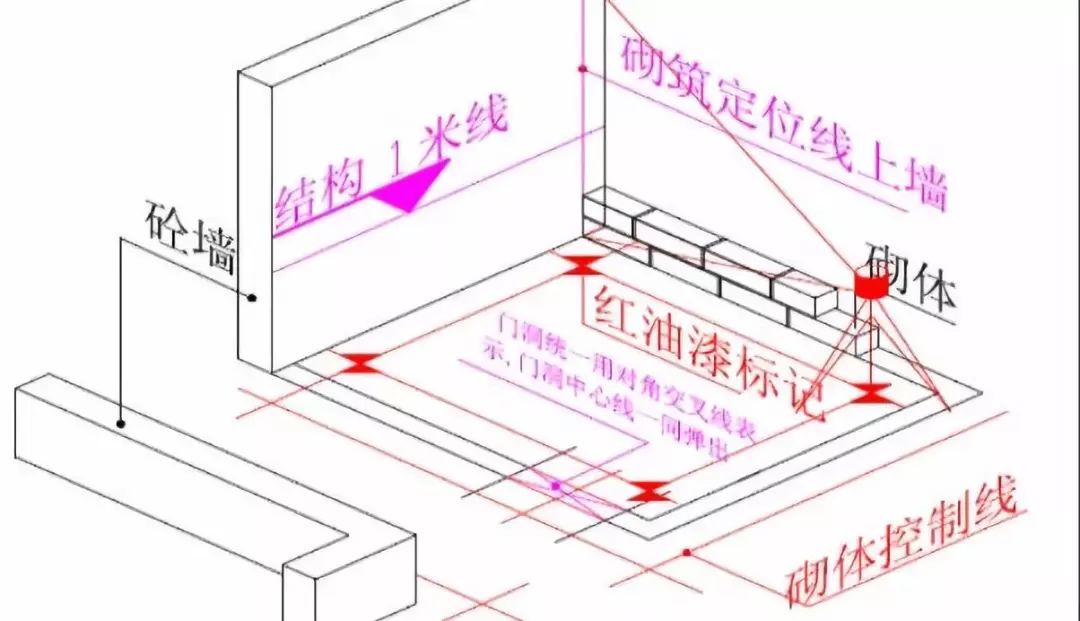

Accurate setting out, masonry positioning and setting out must adopt double control lines (positioning lines and control lines shall be popped up), and the structural 1m line shall be popped up in advance on the concrete wall after construction.