Buy materials from 9 a.m.

Now individuals can also trade carbon credits.

This is a 2-story villa roof photovoltaic power station with a total construction area of 400 square meters.

Many non professional teams use the hanging method, so that the strong wind is easy to lift the coiled material and reduce the waterproof time of the coiled material.

We will track industry trends in real time and help customers match cost-effective products to control power generation costs.

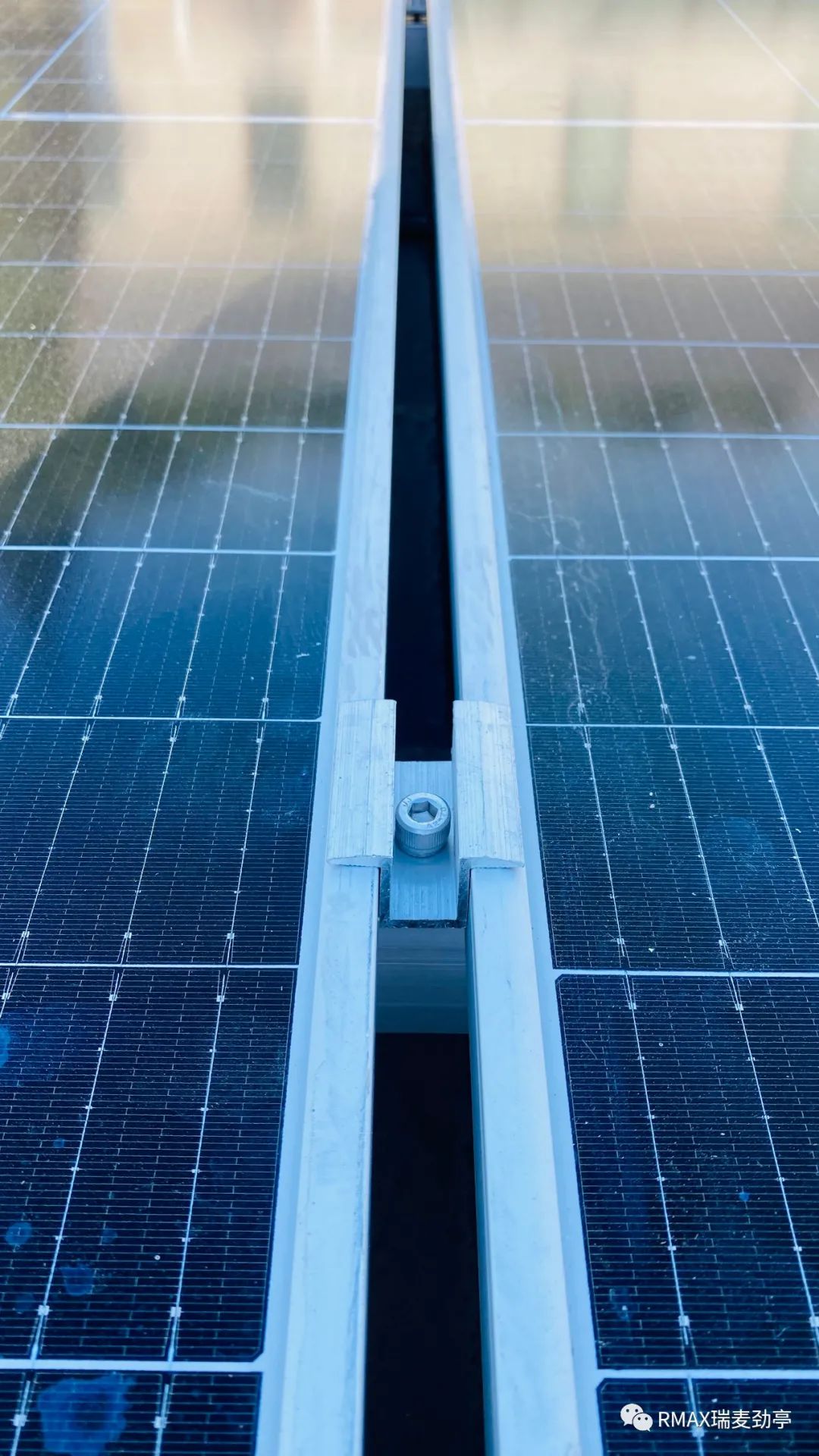

The progress of Guanting villa and the garden in the western suburbs is combined, which is a relatively complete installation process, so it can be perfectly spliced.

The finished waterproof roof looks like this.

I hope today’s sharing can help you!!! If necessary, please contact us to buy, sell, lease, install photovoltaic, or deal with the waterproof / water leakage of the house separately…

Talk about the installation process and share it with you.

It is necessary to remove the cement that has fallen off the surface and strengthen the cement layer.

Last month, the author saw the 6000 flat roof of a factory, and the coiled materials that had been laid for less than two years had bubbles everywhere.

Please note: if the coiled material is to turn out the outer wall, please be sure to burn and bond the coiled material with the outer wall as shown in the figure.

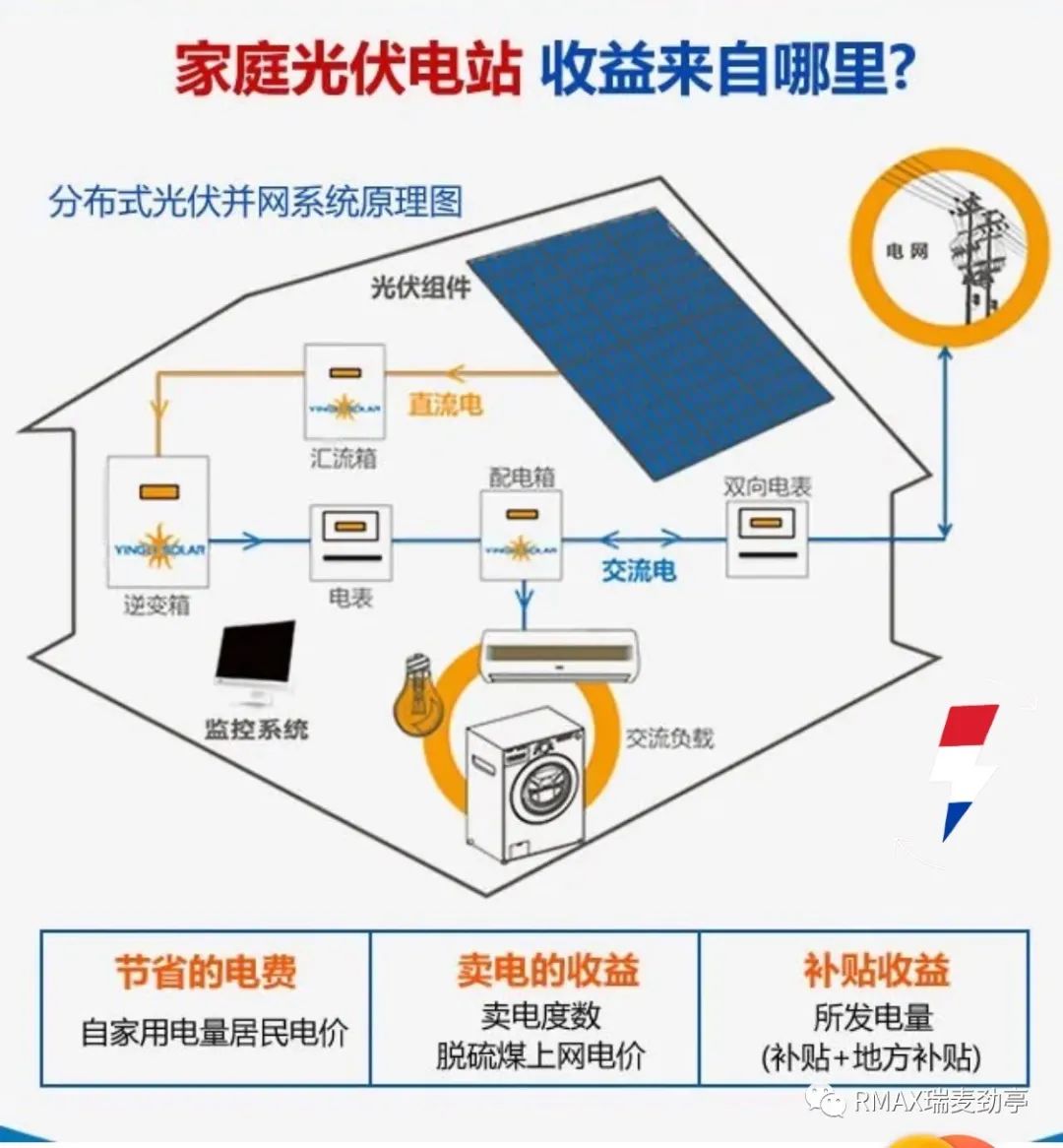

Let’s first take a look at the basic principle and structure of photovoltaic power generation.

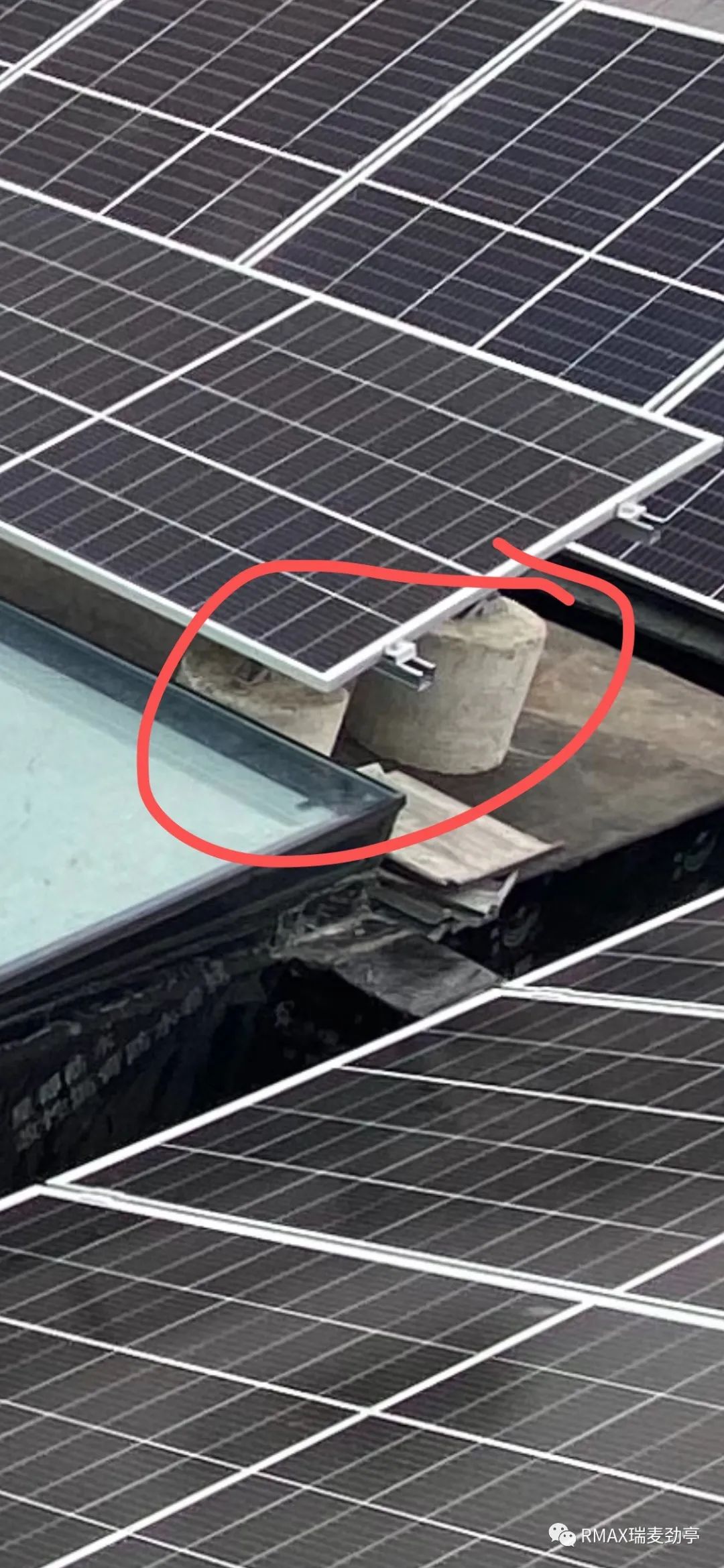

As shown in the figure below, the construction procedure for fixing 4 photovoltaic panels with 600kg stone pier is as follows: prepare materials and go to the power supply bureau to apply for power generation account opening; Laying the track according to the design scheme; Install and fix the photovoltaic panel; Link the transmission line and connect it to the inverter; When the power supply bureau installs two-way electricity meters (most of the time they distribute electricity meters, we install them) to connect the line and grid connected power generation.

According to the assistant general manager, it’s because the former assistant has a good unprofessional team.

Photovoltaic AC and grid AC supply household electricity in coordination.

You can pay attention to the information of carbon exchange.

in PV field, to understand the latest developments in PV industry.

Don’t worry about the author’s scribbling because of the inconsistent appearance of the villa At 8 a.m., when the community began to allow construction, I and the waterproof construction workers came to the site to check.

In order to avoid a water leak in the future, which will lead to a string of water under the coiled material.

So far, we have handled the leaking roof and can safely install the photovoltaic power generation device later.

Today, there are two villas.

Green coil represents reducing the carbon consumption of coal-fired power stations: you know, Tesla earns more than one billion dollars a year by relying on carbon points.

However, because the capacity of major photovoltaic manufacturers has reached the limit recently, the prices of companies may be adjusted after the expanded capacity is released.

A brief introduction is: photovoltaic modules (power generation panels) generate DC power under sunlight, which is collected into the inverter and then turned into AC.

At this time, we took out the coiled material we brought before and started the coiled material laying construction of the second tool.

The most professional construction scheme can be given; The person in charge of waterproofing, the key account manager of Dongfang Yuhong company, is responsible for docking services and supporting our PV.

That’s because of informal construction.

The Yellow coil represents the real-time power generation: when the grid is just connected to the power generation, the sun is large at noon and there is more power generation; It gets cloudy in the afternoon, so the power generation is much less.

to 16 p.m.

Therefore, we only use Dongfang Yuhong (a listed company) for waterproof coiled materials, which can protect customers; Photovoltaic modules that recently use Trina Solar Energy (listed company); The inverter uses goodway’s (listed company).

Previously, the author wrote the article “advantages and disadvantages of installing photovoltaic power generation on the roof”.

Fix the expansion screw on the roof, and cover the tiles after waterproof.

It is a reference for readers who are hesitant to install distributed photovoltaic power generation.

Today, the author continues to follow up the photovoltaic power generation installation project on the roof of two villas.

You can’t touch the luxury decorated villa yet.

For the coiled material waterproof roof without expansion screws, we will use a cement pier with a counterweight of 150 kg to fix a photovoltaic panel.

The owners who are away on business in the south are also very happy to send real-time monitoring power generation diagrams!!! The total installed capacity circled by the red line is 23KW, and the maximum power generation is 23 degrees per hour.

Photovoltaic panels (listed company Trina Solar) these photovoltaic panels weighing 20kg each need the cooperation of four workers and sent them to the roof by hand.

Finally, let’s introduce our construction team: I, a real estate agent who has traded villas for 19 years, know all kinds of houses; PV director, Ph.D.

Coupled with the hard working drawings of some masters, burning, sticking, handling and climbing are all high-altitude operations.

Cuplock Scaffolding Bottom Cup

It is found that in the pictures provided before, it can not be seen that the cement surface of the roof has weathered into the following figure, so the coiled material construction scheme originally prepared can not be directly implemented.

Interested readers can click in and have a look first.

Unused PV AC will be sold to the grid through a two-way meter..

After that, the roof and ground will look like this: you can see that the ground has no gravel and is very flat.

This is the track and buckle of splicing photovoltaic power generation board.

The laying of coiled materials must be burned to ensure that the coiled materials are 100% bonded to the cement surface, and the splicing shall also be handled carefully.

This is the buckle of series power generation board, which is waterproof and anti leakage.

So I went back to the building materials market and bought the following materials to start the construction of the first process.