The remaining live garbage will be transported away from the station to avoid damaging the fragile ecological environment nearby.

In order to open the “throat” channel of Wuwei expressway as soon as possible, the courageous Chinese diplomats of skilled people give up “conservative treatment” and use the combined technology of “TBM middle pilot tunnel + main tunnel drilling and blasting method” in the field of highway tunnel for the first time to realize “long tunnel short play” The construction period is shortened to 72 months.

TBM middle pilot tunnel + main tunnel drilling and blasting method ▲ schematic diagram of tunnel construction.

Previously, only poor road conditions and In the near future, the situation of national highway 216 with dangerous terrain will change with the completion of an expressway.

Active geological activities and groundwater create its fragile “glass core” constitution.

In addition, extreme low temperature will not only reduce the efficiency of workers’ construction machinery, but also greatly reduce the “glass heart” of the super tunnel.

Ordinary people may have altitude reaction above 3000 meters.

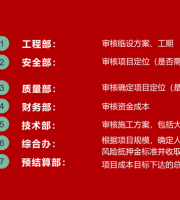

The smart site cloud platform creates the project “Super Brain” based on BIM, cloud computing, Internet of things, mobile applications and other technical means ——Smart site cloud platform realizes one screen overview of “human, machine, material, method and environment” Real time remote monitoring and real-time scheduling of key elements to improve cooperation efficiency and improve construction quality, safety, cost and progress.

The project operation platform uses steel plate pavement to replace the locally damaged turf during concrete pouring construction, and immediately carry out manual repair to protect the grassland and promote intelligent production waste water treatment to the greatest extent For water treatment, domestic sewage and production wastewater will be collected, precipitated and filtered.

The driving time from Urumqi to Yuli will also be shortened from 7 hours to 3 hours.

It has fragile texture and a wide variety of rock mass components.

In addition to TBM excavation in the middle pilot tunnel, the left and right main tunnels also adopted “three machines, one bridge and five vehicles” A series of tunnel construction procedures such as mechanized personnel reduction, drilling and wet spraying are realized, and the workers will be far away from the tunnel face, greatly avoiding safety risks.

The tunnel intelligent equipment management platform takes intelligent construction equipment as the center, integrates high-precision positioning and navigation and perception of three-dimensional laser scanning, Internet of things, Bim and other technologies to provide data support for tunnel digital construction and management, and opens a new intelligent construction mode of tunnel drilling and blasting method Wuwei project is located deep in the no man’s land of Tianshan Mountains.

With a 22 km longitudinal of Tianshan Shengli tunnel and more than 2500 km from east to west, Xinjiang, which is separated from north and south by Tianshan, will get a new connection construction: just talk about the obstacles of engineering construction!..

At the same time, this is the first time that TBM machine is applied in expressway tunnels in China.

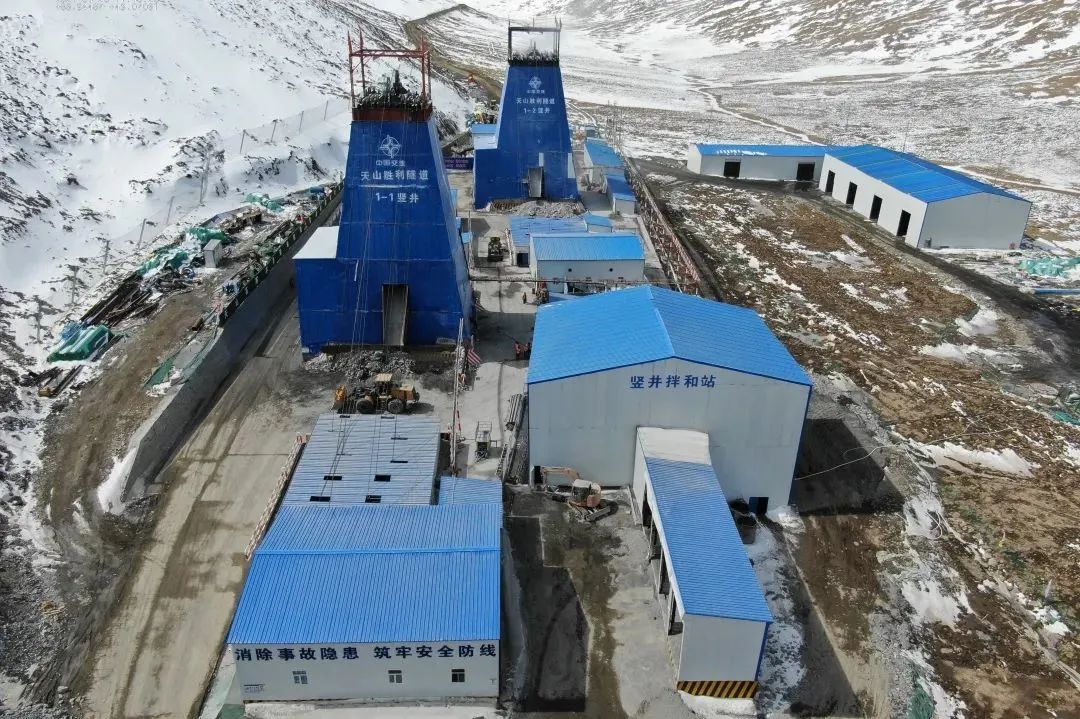

2 shaft of Tianshan Shengli tunnel with a depth of 702 meters is the deepest highway tunnel shaft in China.

At present, the TBM at the inlet has passed through F The biggest “roadblock” in the construction of the core section of 6 has been won by CCCC First Highway Bureau Group.

The rock has to bear the weight of 218kg, which is more than 50 times the general rock bearing capacity, which means that it is likely to encounter rock burst during construction.

Wuwei expressway is almost a straight line connecting the two cities.

In addition, a series of plans such as tunnel support, water gushing, pumping and drainage, clearing and transporting collapse stones, backfilling collapse cavity and so on have also been launched one after another, which has gone through 80 days On August 23, 2021, the “glass core” F6 fault zone was successfully crossed through the ▲ steel formwork reinforcement.

The annual average temperature is minus 5.4 ℃ and the lowest temperature is minus 41.5 ℃.

Korla and Urumqi are the two largest cities in southern and Northern Xinjiang.

It is very prone to water inrush, mud gushing and large-scale collapse during crossing! The tunnel site is located in the cold and high altitude area.

Tianshan, one of the seven mountain systems in the world, has rich mineral resources and broad tourism prospects.

Its completion will have a far-reaching impact on promoting the economic development of Xinjiang, a “natural moat into a thoroughfare” The total length of the super tunnel from Yuli to Urumqi is about 528 kilometers.

The so-called “TBM middle pilot tunnel + main tunnel drilling and blasting method” is to add a TBM (Hard Rock Roadheader) in the middle of the double main tunnels The middle pilot tunnel TBM can be excavated at the fastest speed of 1000 meters per month, which is 3-10 times faster than the traditional drilling and blasting method.

The No.

After the tunnel is completed, the traffic will bid farewell to the original dangerous four volt journey over mountains.

How difficult is it to get through a super tunnel? The tunnel crosses Tianshan Mountain with complex geological and natural environment.

The F6 borokonu aqikkuduk fault zone, the largest and most dangerous, is located 1900 meters from the north entrance of Shengli tunnel, with an influence width of 440 meters ▲ schematic diagram of F6 fault F6 borokonu aqikkuduk fault zone is the largest “roadblock” in tunnel construction at present.

The greater the buried depth, the higher the probability of rock burst, large deformation of soft rock, high temperature, high-pressure water gushing and other problems.

It is the longest tunnel under construction in Xinjiang and the longest expressway tunnel in the world – Xinjiang Urumqi Weili High speed Tianshan Shengli tunnel ▲ the towering Tianshan Mountains are a fast passage connecting the north and south of Xinjiang.

How to treat it? If the conventional drilling and blasting method is adopted, the connection of Tianshan Shengli tunnel will take about 12 years.

Even from June to August, it is still covered with snow and glaciers all year round.

Tianshan Shengli tunnel is the “throat” of Wuwei expressway The Tianshan Shengli tunnel of the project is 22 kilometers long.

The construction difficulties can be summarized as heavy, broken, cold, deep and high! The maximum in-situ stress in the tunnel construction section is 21.8 MPa, which is equivalent to 1 square centimeter.

The extreme environment increases safety risks, affects the construction quality control and restricts the construction progress! The maximum buried depth of the tunnel is 1112.66 meters.

Behind the convenient traffic is a large number of bridges and tunnels, replacing the original sharp turns and steep slopes.

It runs across the central part of Xinjiang and separates Xinjiang into North and south parts.

There is one TBM at both ends of the tunnel entrance and exit, named “Tianshan” and “Shengli” In order to overcome the most dangerous F6 fault zone in the whole line, the project team used horizontal directional drilling for long-distance coring detection in the survey and design of domestic highways for the first time, with a maximum drilling distance of 2271m, which provided accurate geological information for design, construction and construction, and also created the horizontal orientation of domestic highway industry Drilling one-way drilling record ▲ horizontal directional drilling sampling core excavation with TBM can effectively deal with complex geological environment, and also realize automatic initial support installation, reduce the investment of operators and further reduce safety risk ▲ excavation with TBM can effectively reduce safety risk.

This long “chimney” is 100 meters higher than the “small Manyao” of Guangzhou Tower! The highest elevation of the shaft is 3624 meters.

It is the longest expressway tunnel in the world.

When the rock burst is serious, the destructive force is equivalent to the earthquake of magnitude 4-5 ▲ the rock stratum distribution map of Tianshan Shengli tunnel is broken! The tunnel passes through 16 fracture zones with poor surrounding rock stability and high risk of collapse, water inrush and mud gushing.

It is also the longest super long tunnel with high cold, high altitude and high stress in the expressway under construction in China.

In addition, the project also sprinkles low salinity kitchen waste on the hillside on the right side of the station for birds and wild animals to peck.

Mechanized arch installation also reduces the arch installation personnel and installation time by half, but the installation quality is higher.

The construction speed of the middle pilot tunnel is much faster than that of the left and right main tunnels.

Although it is dominated by dry desert, it has rich biodiversity and is known as the “gene bank of endangered wild animals” ▲ after decades of grazing prohibition and maintenance, the North goat around the project has grown into a wasteland with a height of less than one foot.

The distance is only 60% of the current national highway.

A 22km long super tunnel is under construction between Tianshan Mountains, which is 3000 meters above sea level and 2500 kilometers long.

The treated domestic and production wastewater will meet the class II drinking water standard and be recycled for construction and production.

The Wuwei Expressway under construction by CCCC group, with a total length of about 318.5km, will become the fastest channel from Urumqi to Korla.

It is also very difficult to build a general ventilation shaft.

Once the grassland and ecological environment in the construction area are damaged, it is very difficult to repair.

After the middle pilot tunnel is connected, four auxiliary working faces are added to the main tunnel through the vehicle cross tunnel for vehicle turning.