Bonding: the suspended waterproof board and geotextile shall be bonded as a whole with the next waterproof board and geotextile.

When arc welding is used, it can be separated by iron sheet and other flame-retardant materials to prevent the waterproof board from burning out at high temperature.

During circumferential laying, the lower waterproof board and geotextile shall press the upper waterproof board and geotextile.

When welding multi-layer waterproof boards, the welds at the overlapping parts must be staggered, and there shall be no overlap of more than three layers.

The arch shall be drilled with an electric drill according to the longitudinal and transverse spacing of 1m, and the expansion bolt shall be driven in.

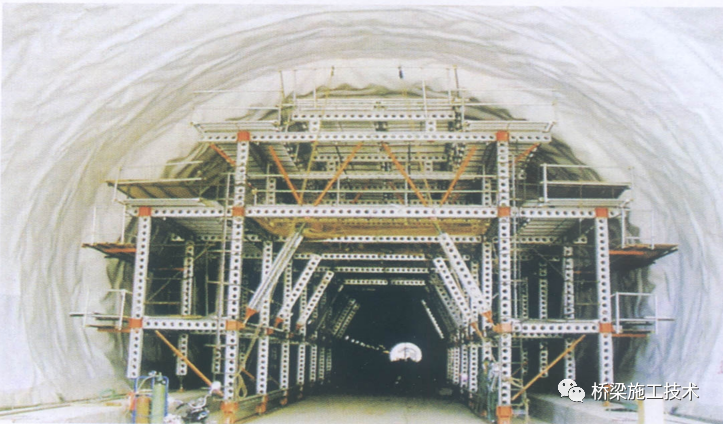

The surrounding rock with good geological conditions and the tunnel constructed according to the principle of NATM are basically stable after the initial support, but in the poor special geological section, the initial support is difficult to ensure the long-term stability of the surrounding rock structure, and the secondary lining of molded concrete is required to immediately strengthen the deformation support of the surrounding rock.

E.

The end formwork at the circumferential deformation joint shall be nailed with a joint filler plate to make the air hole center line of the water stop coincide with the center line of the deformation joint.

Installation of waterstop and waterstop (1) Installation of externally attached rubber waterstop the externally attached waterstop shall be fixed on the paved waterproof board by waterproof pasting or welding; when the back attached waterstop and the waterproof board cannot be welded, the butyl adhesive tape pasted on both sides can be used for pasting.

The circumferential waterstop joint shall be set at the higher position of the side wall and shall not be set at the corner of the structure Special welding shall be adopted for the head.

During construction, the temperature, speed and pressure shall be strictly controlled, generally the speed shall be controlled at 1.5 ~ 1.8m/min, the temperature shall be controlled at 500 ~ 550 ℃, there shall be uniform slurry dissolution and no welding slag, and the welding slag and other sundries on the welding nozzle shall be cleaned in time by common iron brush.

The role of primary and secondary lining is long-term.

Source: the copyright of bridge construction technology belongs to the original author.

Use fine aggregate concrete to level obvious potholes.

Otherwise, find the leakage point and repair it in time.

2.

Mark the center line of the arch crown and the section line perpendicular to the tunnel axis on the initial support surface.

(2) laying waterproof board and geotextile a.

The waterproof board is different before welding Operators and different welding machines shall carry out welding test, and formal welding can be carried out only after passing the test.

A layer of waterproof board shall be strengthened at the longitudinal overlap and circumferential overlap.

Use steel nails or special clips to fix the blind ditch (pipe) on the concrete surface along the line to ensure close to the surface.

Welding can be started only after meeting the requirements.

The waterproof board and geotextile shall be hung on the side wall of the tunnel.

The secondary lining ensures the permanent stability, safety and beauty of the tunnel in operation.

the connection between waterproof board and geotextile adopts double seam welding machine and hot wedge double weld technology.

In case of natural changes, such as earthquake, mountain bias pressure, excessive pressure water and other natural disasters with strong destructive force, the initial support of the tunnel can not fully ensure the stability of surrounding rock, so it is necessary to carry out secondary lining to strengthen the support and stability of mountain changes.

(3) weld detection tear damage detection: tear test and tensile test shall be carried out on the test weld sample.

The 3mm iron wire shall be tensioned and fixed on the bolt horizontally.

The layout and installation of the drainage blind ditch pipe behind the waterproof board shall be located and marked on the shotcrete surface.

The joint shall be leveled, pressurized and firmly bonded, and the overlapping width shall not be less than 10 (the railway now requires 15cm) cm.

the waterproof board and geotextile shall be laid by nailless laying process from top to bottom, with appropriate tightness and allowance (the ratio of actual laying length to arc length is 10:8).

The overlapping width of weld shall not be less than 10cm, and the width of each weld shall be 1.5cm.

During concrete pouring, the vibrating rod shall not collide with the waterproof board.

b.

the overlapping width of two waterproof boards and geotextile shall not be less than 10 (15cm) cm, the distance between the overlapping joint of waterproof board and geotextile and the lining construction joint shall be no less than 1 ~ 2m.

Hot wedge double-sided welding machine is adopted, and the welding machine is self-propelled welding machine, During welding, one person shall tidy up the waterproof board and geotextile, one person shall hold the welding machine and one person shall cooperate.

Check whether the fracture occurs outside the effective weld, and check the effective width of the weld.

Impermeable concrete shall be used for secondary lining, and water stop belt or water stop strip shall be set between each formwork concrete.

General tunnel design waterproof and drainage system: Circular blind drainage ditch (pipe) and waterproof layer (integral waterproof board) are set between the initial support and secondary lining of the tunnel, longitudinal drainage pipes are set at the arch feet on both sides of the tunnel, longitudinal cement pipe warm water ditch is set at the center of the tunnel inverted arch, and transverse drainage pipe is set between the longitudinal plastic drainage pipe at the arch foot and the cement pipe at the center of the inverted arch.

In principle, the line position shall be arranged according to the designed blind ditch pipe spacing, but it shall be adjusted according to the actual water seepage of the tunnel wall, and pass through the low recess of the shotcrete surface and the place with water outlet as far as possible.

Meanwhile, fill in the weld inspection report (4) precautions: when binding the reinforcement, the reinforcement shall not be in direct contact with the waterproof board.

Unfold the waterproof board and geotextile along the circumferential direction of the bench, manually lift the waterproof board and geotextile, close to the rock surface, and hang it on the fixed iron wire.

1.

During inspection, ensure that all areas of waterproof board and geotextile can reach the surrounding rock.

When fixing and removing the lining trolley plug, pay close attention to protection to prevent the waterproof board from being damaged.

Then adjust the temperature of the welding machine and test weld the samples.

At the same time, it is also an engineering measure as a safety reserve.

F.

If the pressure drop is less than 10%, it is qualified.

3.

The pressure shall be controlled at 600 ~ 650n, The maximum shall not exceed 1000N.

Waterproof and Drainage Construction II.

It shall be laid forward ring by ring according to the above methods.

The parts with severe unevenness on the excavation surface shall be chiseled and leveled.

During arch crown concrete pouring, prevent pressure If it is too large, it will force the waterproof board to tear.

Check the quality of the waterproof board for discoloration, aging, ripple, knife mark, tear, hole and other defects; Draw the welding line and the arch crown center line at the edge of the waterproof board; The waterproof layer shall be intercepted according to the actual contour length and rolled up symmetrically for standby.

The concrete at the construction joint shall be vibrated and cured in time..

(2) when the middle buried rubber waterstop is installed and the inverted arch or side wall concrete is constructed in advance, it shall be used longitudinally at a spacing of 40cm φ The rubber waterstop shall be accurately positioned on the small side wall (or fixed on the special positioning frame with waterstop) The dirt on the belt surface shall be cleaned.

Air pressure detection: clamp and seal both ends of the weld with a special iron clamp, insert the detection needle into the air groove between the two welds at one end of the weld, and press it to 0.25MPa with a manual air pump Observe for 15 minutes.

Firstly, the “grape” agglomeration on the shotcrete surface shall be chiseled, the initial support shall be cut off by electric welding or oxygen welding, the exposed anchor rod head, reinforcement head and other iron parts shall be cut off completely, and the cut part shall be troweled and covered with fine aggregate concrete to prevent puncturing the waterproof board.

D.

Once a leakage point is found, mark it and timely determine treatment measures for repair welding and detection.

The joint filler plate must be set vertically and firmly supported without formwork running.

The concentrated water outlet shall be drilled along the water source direction, and then a single water diversion blind pipe shall be inserted into it, and the surrounding shall be blocked with quick setting mortar, so that the groundwater can flow out of the pipe.

c.

The secondary lining also bears the creep pressure of weak surrounding rock, expansive ground pressure, or the additional load of shallow tunnel.

The thickness of the butyl adhesive tape shall not be greater than 1.5mm.

Assembly and laying of waterproof and drainage board (1) the tunnel section shall be measured during construction preparation, and the section shall be trimmed by operation trolley.

The initial support is also difficult to close the water system in the mountain, resulting in water leakage in the tunnel, which requires the waterproof and drainage system combined with the secondary lining to ensure the non leakage of the tunnel.

The water stop shall be clamped and fixed with additional reinforcement clips, iron wires and formwork.

Prevent fire caused by fireworks and high temperature.

firstly, wipe the welding place of waterproof board and geotextile, and keep it clean without dust, sundries and ponding.

The water behind the waterproof layer flows to the longitudinal drainage pipe at the arch foot on both sides of the tunnel through the blind ditch (pipe) and behind the waterproof layer, then flows to the thermal ditch of the inverted arch central cement pipe through the transverse drainage pipe, and finally flows to the outside of the tunnel through the central ditch.