The connection between the metal conduit and the distribution box must be grounded jumper, and each pipeline must be separately connected with the busbar or grounding trunk line, and shall not be connected in series.

Important equipment and equipment framework shall have two grounding downleads connected at different locations from the main grounding grid.

If the junction box is cancelled, the fixing parts of the tunnel cover shall be embedded on the tunnel wall The wall shall be troweled with cement mortar.

(11) Process description of grounding trunk line in power distribution room: installation requirements for exposed grounding trunk line in power transformation and distribution room: the grounding device is convenient for inspection, and the laying position does not hinder the disassembly and maintenance of equipment; when it is laid horizontally along the building wall, it is 250 ~ 300mm above the ground; the gap between it and the building wall is 10 ~ 15mm; when the grounding wire crosses the deformation joint of the building, a compensation device is set; the surface of the grounding wire is along the In the length direction, each section is 15 ~ 100mm, which is painted with yellow and green stripes respectively; at least two wiring posts or grounding bolts for temporary grounding shall be set on the grounding trunk line of transformer room and high-voltage distribution room.

The connecting line between the equipotential bonding trunk line or local equipotential box shall form a ring network, and the ring network shall be connected with the nearby equipotential bonding trunk line or local equipotential box.

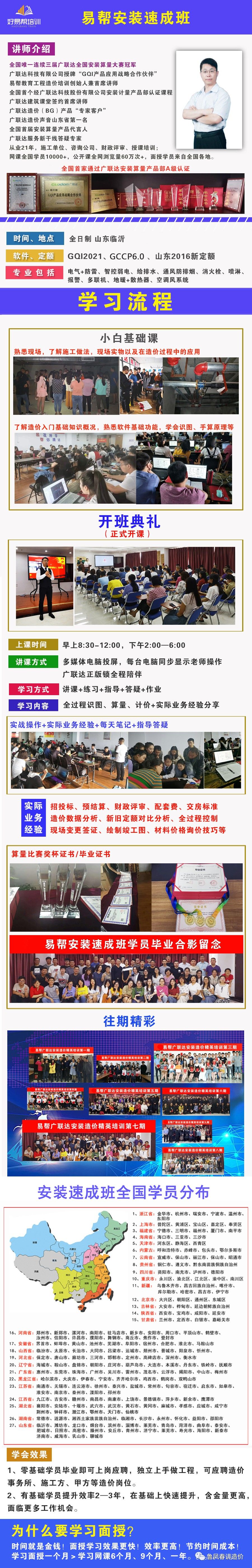

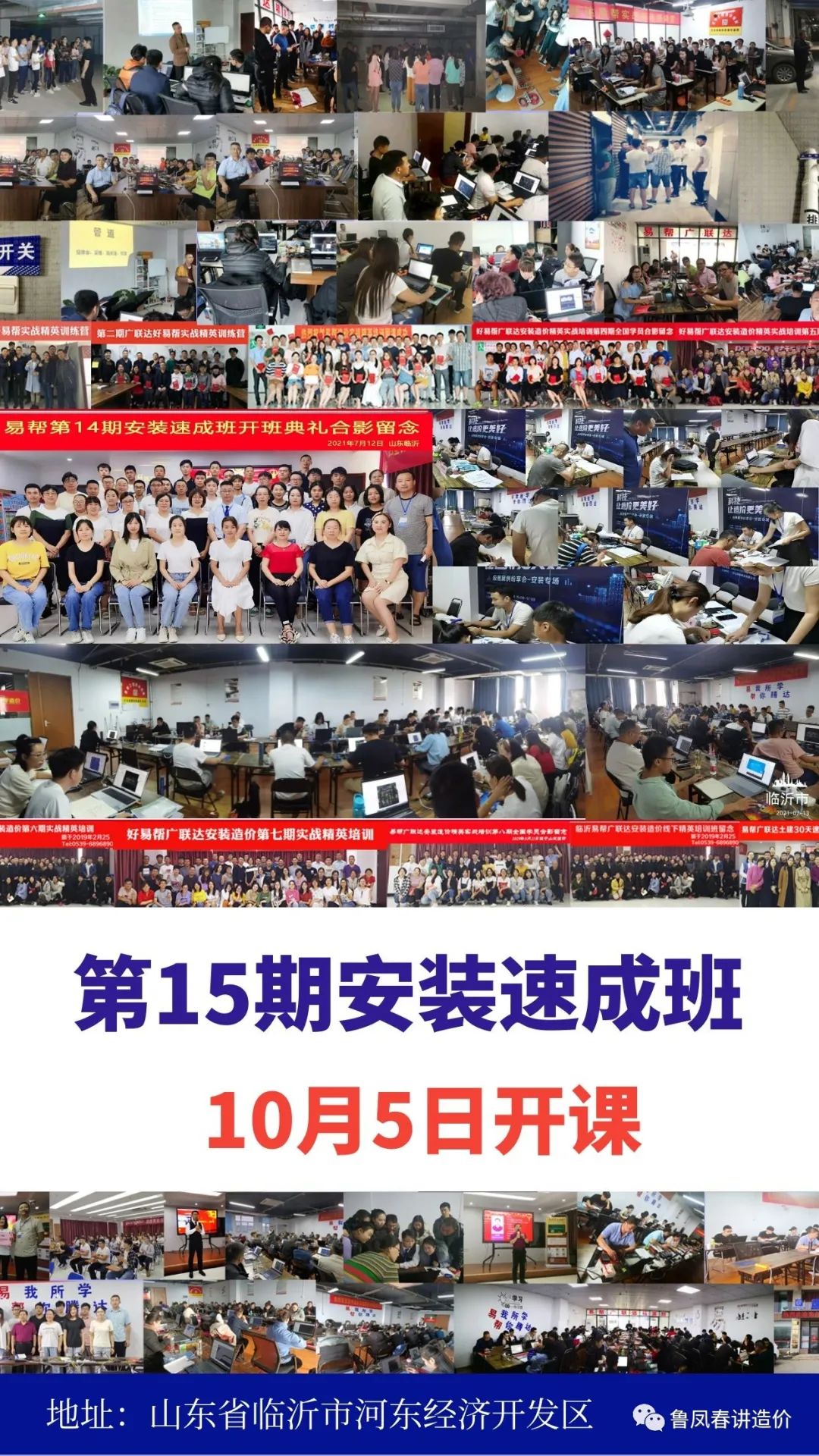

The 15th installation crash course countdown 8 days Lecturer: Lu Fengchun teacher major: Electrical + lightning protection, intelligent control of weak current, water supply and drainage, ventilation and smoke control, fire hydrant, sprinkler, alarm, multi online, floor heating + radiator, air conditioning and air system software and quota: gqi2021 latest version and new quota learning time: October 5, the class officially opened in Hedong Economic Development Zone, Linyi City, Shandong Province (1) Process description of lightning protection downlead: the grounding device shall be welded by lap welding, and the lap length shall comply with the following provisions: the lap between flat steel and flat steel shall be 2 times the width of flat steel, and shall not be less than three sides; the lap between round steel and round steel shall be 6 times the diameter of round steel, and shall be welded on both sides; the lap between round steel and flat steel shall be 6 times the diameter of round steel, and shall be welded on both sides; the lap between flat steel and steel pipe, and between flat steel and angle steel shall be welded closely The outer two sides of the angle steel, or close to the surface of 3 / 4 steel pipe, shall be welded on the upper and lower sides; in addition to the welded joints buried in the concrete, anti-corrosion measures shall be taken.

The lightning arrester in the power transformation and distribution room shall be connected with the grounding trunk line with the shortest grounding wire.

Junction box is generally used at the test points.

The branch lines shall not be connected in series.

(4) description of roof metal pipeline grounding process: the roof metal pipeline must be grounded reliably and shall not be welded directly.

When the building height of class III lightning protection building exceeds 60m, the handrails, doors and windows and other large metal objects on the outer wall of 60m and above shall be connected directly or through embedded parts Connect with lightning protection device.

It is strictly prohibited to connect several electrical devices requiring grounding in series in one grounding wire.

The test points shall form a disconnection card, which shall be fastened and connected with galvanized bolts at ordinary times for inspection and test.

The fabrication of test points shall be combined with the external decoration of the building to be practical and beautiful.

(5) Grounding process description of roof metal components: other metal components exposed on the roof must be connected with the lightning strip as an integral electrical path.

(the article comes from the Internet and is deleted ~) read the full text directly to the crash course to learn more about the crash course.

(10) Description of electrical equipment grounding process: the grounding of each electrical device shall be connected with the grounding busbar or grounding trunk line with a separate grounding wire.

The grounding connection at the fence door of the isolation and static compensation device in the power distribution room and the metal door hinge of the power transformation and distribution room shall adopt braided copper wire.

And each grounding downlead shall meet the requirements of thermal stability and mechanical strength The connecting lead shall be convenient for regular inspection and test.

(12) General equipotential bonding process description: the building equipotential bonding trunk line shall be led out from the grounding trunk line or general equipotential box with no less than 2 direct connections with the grounding device.

(9) the door (frame) of the distribution room Grounding Process Description: the grounding jumper must be adopted between the door and door frame of the power transformation and distribution room, and connected with the indoor grounding trunk line to form a good electrical path.

The grounding snap ring must be adopted and connected with the grounding flat steel with copper core flexible wire, and the anti loose parts are complete.

When grounding metal doors and windows, the connecting conductor should be concealed, and should be carried out after the positioning of window frame and before the construction of wall decoration layer or plastering layer.

(7) grounding process description of lamp metal shell: when the height of lamp from the ground is less than 2.4m, the accessible bare conductor of lamp must be reliably grounded (PE) or neutral (pen), and there shall be special grounding bolts.

For details, please contact wechat: 1045166966..

(2) Process description of roof lightning strip: the lightning wire shall be laid horizontally or vertically, or parallel to the inclined structure of the building; the lightning wire shall be straight and firm, free of ups and downs and bending, and 100mm away from the building surface.

The distance between supports should be 0.5 ~ 1.5m in the horizontal straight part; 1.5 ~ 3m in the vertical part; 0.3 ~ 0.5m in the turning part.

The metal nameplate shall be used for permanent identification at the lightning down lead.

Rat baffle must be set at the door of transformer and distribution room, and the height of rat baffle shall not be less than 60cm.

(3) Process description of grounding resistance test point: manual grounding device or grounding device using building foundation reinforcement must set test points above the ground according to the design requirements.

Each component shall not be connected in series, but must be separately connected with the grounding trunk line.

(8) Process description of jumper connection between distribution box and metal conduit: the metal frame and foundation section steel of cabinet, panel, platform, box and panel must be grounded (PE) or neutral (pen) Reliable; openable doors equipped with electrical appliances shall be connected with bare braided copper wire and marked between the door and the grounding terminal of the frame.

(6) Description of indoor metal door and window grounding process: when the building height of class II lightning protection building exceeds 45m, the handrails, doors and windows and other large metal objects on the outer wall of 45m and above shall be connected with the lightning protection device directly or through embedded parts.

Hot dip galvanizing The hot-dip galvanizing will be damaged during steel welding, and the anti-corrosion treatment shall be carried out within 100mm within the weld mark.